Abstract

Monolayer molybdenum disulfide (MoS2) possesses a desirable direct bandgap with moderate carrier mobility, whereas graphene (Gr) exhibits a zero bandgap and excellent carrier mobility. Numerous approaches have been suggested for concomitantly realizing high on/off current ratio and high carrier mobility in field-effect transistors, but little is known to date about the effect of two-dimensional layered materials. Herein, we propose a Gr/MoS2 heterojunction platform, i.e., junction field-effect transistor (JFET), that enhances the carrier mobility by a factor of ~ 10 (~ 100 cm2 V−1 s−1) compared to that of monolayer MoS2, while retaining a high on/off current ratio of ~ 108 at room temperature. The Fermi level of Gr can be tuned by the wide back-gate bias (VBG) to modulate the effective Schottky barrier height (SBH) at the Gr/MoS2 heterointerface from 528 meV (n-MoS2/p-Gr) to 116 meV (n-MoS2/n-Gr), consequently enhancing the carrier mobility. The double humps in the transconductance derivative profile clearly reveal the carrier transport mechanism of Gr/MoS2, where the barrier height is controlled by electrostatic doping.

Similar content being viewed by others

Introduction

Graphene (Gr), which consists of carbon atoms in a planar two-dimensional (2D) array, provides a platform for a new era of 2D electronics to replace mainstream silicon-driven semiconductors owing to its excellent mobility of up to 200,000 cm2 V−1 s−1 at room temperature1,2. Yet, the poor switching due to the zero bandgap of Gr remains a critical issue hindering practical applications, despite extensive efforts such as functionalization3,4,5, chemical doping6, graphene nanoribbon formation7,8,9,10, and the development of bilayer graphene with a dual-gate structure11,12,13. Hexagonal molybdenum disulfide (MoS2) comprising one molybdenum atom with two surrounding sulfur atoms exhibits n-type semiconducting behavior with a high on/off current ratio exceeding 108 [ref. 14,16]. Nevertheless, the moderate carrier mobility (0.1 to 10 cm2 V−1 s−1)14,17,18,19, is several orders of magnitude lower than that of Gr, thereby limiting the potential of MoS2 for high-speed switching device applications.

Thus far, numerous approaches have been introduced to enhance electrical performance of MoS2 based device, for example, gate dielectric and contact resistance engineering have been suggested for enhancing the carrier mobility of MoS2 to achieve high switching performance. High-κ (e.g., Al2O3, HfO2) dielectrics suppress the surface reaction and enhance the dielectric screening effect20,21,22, thereby enhancing the carrier mobility of MoS2 (reaching 81 cm2 V−1 s−1)23. Sub-stoichiometric high-κ dielectrics generate more carriers in the thin MoS2 layer, effectively screening out various Coulomb scattering sources derived from polymer residues, charged impurities, and interface states15,24. Encapsulating h-BN is a prospectively ideal approach25, but mechanical exfoliation is impractical because of the scalability of the cleaved film. Contact resistance engineering by utilizing a low work-function metal such as titanium26 or scandium27 is one alternative approach for achieving high carrier mobility. Despite lowering the Schottky barrier height and improving the carrier injection of multilayer MoS2 significantly, the choice of contact metals for the monolayer in this approach is very limited due to Fermi level pinning depending on the surface states or defect sites of the metal/MoS2 interface. Recently, it has been successfully demonstrated that monolayer Gr enables to suppress the Schottky barrier height sufficiently at Gr/MoS2 heterointerface as an ideal contact material for 2D electronic materials28, which facilitates diverse 2D heterostructures29. Nevertheless, the limited carrier mobility of 2D materials still constrains their practical electronic applications, requiring different approaches.

We propose an ideal device platform based on a junction field-effect transistor (JFET) architecture featuring a Gr/MoS2 heterointerface, where the carrier mobility of MoS2 is enhanced by a factor of 10, while maintaining a high on/off current ratio of up to 108 at room temperature. The Schottky barrier height (SBH) governs the carrier injection and carrier mobility in the Gr/MoS2 heterojunction device. The low SBH regime at n-Gr/n-MoS2 provides an additional Gr conduction path for MoS2, leading to μFE ~ 100 cm2 V−1 s−1, whereas the high SBH regime at p-Gr/n-MoS2 blocks the contribution of Gr to MoS2, leading to μFE ~ 10 cm2 V−1 s−1, similar to that of the pure MoS2-based device.

Results and discussions

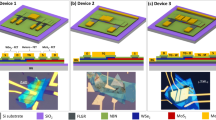

To simultaneously achieve high carrier mobility and on/off current ratio, chemical vapor deposited (CVD) monolayer MoS2 was intentionally stacked on top of a monolayer Gr strip that was also grown by CVD. Properly chosen mechanically exfoliated graphite flakes were employed as the source and drain contacts to protect the MoS2 channel during metal deposition, thereby circumventing the Fermi level pinning effect30. Fig. 1 presents a schematic of the conceptual Gr/MoS2 heterostructure device with the graphite contact (Fig. 1a), the corresponding optical image (Fig. 1b), and the simplified band diagram (Fig. 1c) in the lateral direction with graphite contacts (E3 and E4), respectively. The detailed device fabrication procedure is described in the Methods section.

Device structure and Raman characterization of the Gr/MoS2 heterostructure. (a) Schematic of a two-terminal device with the Gr/MoS2 heterostructure with graphite as the electrical contact. (b) Optical microscopic image of the heterostructure device. Electrode E1 and E2 are the source/drain contacts for the bottom Gr (green rectangular) layer, and E3 and E4 are electrically connected to the upper MoS2 layer via the graphite electrode. (c) Simplified band diagram of the Gr/MoS2 heterostructure in the lateral direction with graphite contacts (E3 and E4). (d) Optical Raman spectra of MoS2 and the Gr/MoS2 heterostructure. Blue-shift of A1g peak indicates charge transfer from MoS2 to Gr. (e) Band diagram of charge transfer direction at the Gr/MoS2 heterointerface under different gate bias conditions. \({E}_{vac}\), \({q\Phi }_{{MoS}_{2}}\), \({E}_{{C}_{{MoS}_{2}}}\), \({E}_{{F}_{{MoS}_{2}}}\), \({E}_{{V}_{{MoS}_{2}}}\), \({E}_{g}\), and \({E}_{{F}_{Gr}}\) indicate the vacuum level, work function of MoS2, conduction band of MoS2, Fermi level of MoS2, valence band of MoS2, band-gap, and Fermi level of Gr, respectively.

The optical Raman spectrum of the Gr/MoS2 heterostructure (Fig. 1d) was acquired under argon atmosphere to prevent unintended oxidation or degradation. The \({E}_{2g}^{1}\) peaks (~ 389.4 cm−1) of bare MoS2 and the Gr/MoS2 heterostructure are similarly positioned, implying negligible strain in the developed device. The blue-shift of the \({A}_{1g}\) peak for the heterostructure with respect to that of MoS2 indicates electron charge transfer from MoS2 to Gr, as reported previously31,32. The relevant band diagram depending on the carrier type of Gr (Fig. 1e) illustrates the vertical charge transfer direction based on the gate bias. In the n-Gr/n-MoS2 regime, the electron population in n-Gr is transferred to n-MoS2, leading to a negligible vertical SBH, whereas in the p-Gr/n-MoS2 regime, electrons in n-MoS2 are transferred to p-Gr, resulting in a large vertical SBH, as discussed later. This charge transfer model explains the key carrier transport mechanism in the developed heterostructure device associated with the vertical SBH at the Gr/MoS2 heterojunction.

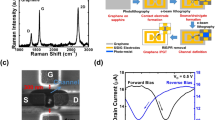

We first examined the back-gate bias (VBG)-dependent drain current (IDS) of graphene (Device #1: Gr-Gr/MoS2-Gr using metal electrodes E1 and E2) in the Gr/MoS2 heterostructure as displayed in Fig. 2a. The transfer curves based on the drain-source voltage (VDS) (Fig. 2b) demonstrate the ambipolar characteristics of the Gr in Device #1. The charge neutrality point (VCNP) is found at VBG = 12 V regardless of VDS. This positive VCNP indicates dominant electron transfer from Gr to the positive fixed oxide traps in the SiO2/Si substrate31,33,34. The field-effect mobility is described as μFE = gm (L/W) COX−1 VDS−1, where gm, L/W, and COX denote the transconductance (= ∂IDS/∂VBG), channel length-to-width ratio, and oxide capacitance per unit area, respectively. The maximum μFE is ~ 2,500 cm2 V−1 s−1 for n-Gr and ~ 3,500 cm2 V−1 s−1 for p-Gr (Fig. 2c). The μFE range is similar to that of the bare Gr device on SiO235. The collapse of the VDS-dependent μFE clearly mirrors the negligible SBH effect. Further, super-linear IDS‒VDS output characteristic curves were obtained because of the high tunability of the Fermi-level of Gr (Fig. 2d), confirming the low SBH or nearly ohmic contact.

Electrical characteristics of Gr/MoS2 heterostructure device. (a‒d) Gr/MoS2 heterostructure device employing Gr contact with E1 (source) and E2 (drain) (Device #1: Gr-Gr/MoS2-Gr, L/W = 28 μm/10 μm). (a) Optical device image, VDS-dependent (b) IDS‒VBG transfer curves (VCNP = 12 V) and (c) μFE, respectively. (d) VBG-dependent IDS‒VDS output characteristic curves. (e‒g) Gr/MoS2 heterostructure device employing MoS2 contact with E3 and E4 (Device #2: graphite-MoS2-Gr/MoS2-MoS2-graphite, L/W = 15 μm/5 μm). (e) Optical device image, VDS-dependent (f) transfer curves and (g) corresponding derivative of gm (= ∂gm/∂VBG) curves. The 1st and 2nd peak positions of VBG indicate the VFB of MoS2 and VCNP of Gr. (h) Comparison of transfer curves of the three devices (Gr, MoS2, Device #2) (right y-axis) and the μFE (left y-axis) of MoS2 and Device #2 at VDS = 0.1 V. An enhancement of μFE (~ 100 cm2 V−1 s−1) is clearly observed in the n-MoS2/n-Gr regime.

Investigation of the Gr/MoS2 heterostructure device with the MoS2 contact in the two graphite electrodes (Device #2: graphite-MoS2-Gr/MoS2-MoS2-graphite using metal electrodes E3 and E4) (see Fig. 2e), shows a distinct current path difference comparing to Device #1. Because the conductivity of MoS2 is much lower than that of Gr or the Gr/MoS2 heterojunction in this case, the bare MoS2 dominates the carrier transport of Device #2, in contrast with Device #1. The IDS‒VBG transfer curves (Fig. 2f) show clear switching behavior in the negative VBG regime, originating primarily from the bare MoS2 component in Device #2. Notably, in the positive VBG regime, a hump associated with a rapid enhancement of IDS appears, independent of VDS. This strongly implies the presence of two different conduction mechanisms or conducting paths, similar to double-gate Si and junctionless Si transistors36,37.

To gain insight into the carrier transport mechanism of Device #2 in detail, the flat-band voltage (VFB) was determined from the second-derivative of the current (Fig. 2g)38. The first peak at VBG = − 28.5 V is attributed to the turn-on voltage of MoS2. The second peak at VBG = 12 V is ascribed to the underlying Gr in Device #2, as confirmed by the identical VCNP of Gr (Fig. 2c). The coincident position of the second hump for VFB and VCNP further rationalizes the presence of second conducting path Device #2. Since it has theoretically and experimentally been suggested that the vertical SBH of Gr/MoS2 can be modulated by electrostatic doping39,40,41,42, the bare MoS2 consequently governs the carrier transport of the device exclusively when VBG ≤ VCNP (i.e., p-Gr/n-MoS2) at high vertical SBH. Another current path involving Gr in addition to MoS2 is provided at VBG ≥ VCNP (i.e., n-Gr/n-MoS2) with low vertical SBH, leading to μFE for Device #2.

To have a better picture, μFE of heterostructure (Device #2) and bare MoS2 (Device #5 with metal electrodes E9 and E10, see Supplementary Note 1 and Fig. S1) at VDS = 0.1 V is compared together in Fig. 2h. In principle, the current onset voltage for Device #2 and Device #5 should be identical because the bare MoS2 in both of them limits the carrier transport in the subthreshold regime. We ascribed this mismatched current onset voltage in Fig. 2h between the Gr/MoS2 (Device #2) and MoS2 (Device #5) to the different effective SBHs. While the MoS2 (Device #5) has a Cr/Au contact to MoS2, the MoS2/Gr (Device #2) possesses a graphite contact to MoS2, respectively. The maximum μFE of Device #5 ranges from 8 to 10 cm2 V−1 s−1 at VBG = 50 V, which reaches to 16–20 cm2 V−1 s−1 after contact resistance correction (see Supplementary Fig. S2). Meanwhile, the μFE of Device #2 is slowly developed after the turn-on voltage of MoS2 at VBG = − 28.5 V which is very similar to μFE of Device #5. This μFE behavior reflects clearly that the bare MoS2 part in Device #2 limits the overall carrier transport in this VBG regime. But, μFE rapidly increases after VFB or VCNP, reaching μFE saturation (~ 100 cm2 V−1 s−1) at VBG = 50 V. This mobility enhancement is mainly ascribed to Gr with low SBH in the central n-Gr/n-MoS2 heterojunction regime in Device #2. The high on/off current ratio of the device is further attributed to the bare MoS2 region in the device. As a consequence, provided that the portion of bare MoS2 in Device #2 shrinks as short as possible without losing the on/off current ratio, a further μFE improvement would expect via a device layout optimization. All devices were annealed at T = 150 °C for 2 h in high vacuum chamber before the electrical measurement to eliminate effect of adsorbates and interface trap sites between 2D materials and dielectrics (See Supplementary Fig. S3). Hysteresis at Gr/MoS2 interface was negligible from that of MoS2 device.

To systematically identify the transport mechanism in the Gr/MoS2 heterostructure, we constructed a device (Device #3: graphite-Gr/MoS2-graphite using metal electrodes E5 and E6) with the two graphite electrodes overlapping the lower graphene layer, intentionally excluding the bare MoS2 region (see Fig. 3a). It is worthy to underline that device structure of Device #3 is in contrast with that of Device #2 in particular for a spatial distance between graphite and underlying Gr (see Fig. 2e and Fig. 3d). The VDS-dependent transfer curves (Fig. 3b) were obtained from the two graphite electrodes (E5 and E6). The lack of a high on/off current ratio is ascribed to the direct tunneling (DT) current across the atomically thin monolayer MoS2 to the underlying graphene. The screening effect of the underlying graphene is another plausible underlying factor, resulting in weak gate modulation in the MoS2 channel. From the transfer curves of individual Gr, MoS2, and the Gr/MoS2 heterostructure (Fig. 3c), the charge neutrality point of Gr was found at VBG = 27 V. General μFE behavior of Device #3 is very similar to that of Device #1 as shown in Fig. 2h. The high μFE (~ 800 cm2 V−1 s−1) of Device #3 in the VBG ≥ VCNP confirms clearly that the origin of high μFE is the underlying Gr. Further relevant electrical characteristics of Gr in Device #3 is discussed in Supplementary Fig. S4. In such a structure, even if the SBH at the Gr/MoS2 interface is modulated by VBG, the Schottky barrier effect is largely suppressed by direct tunneling at the interlayer distance, while a small portion of the total current flows along the MoS2 channel based on the conductivity ratio between Gr and MoS2 (Fig. 3d).

Vertical Gr/MoS2 heterointerface device (the bottom Gr, MoS2, and top graphite layers all overlapped). (a) Optical image of the vertical Gr/MoS2 heterointerface device employing graphite contact with E5 (source) and E6 (drain) (Device #3: graphite-Gr/MoS2-graphite, L/W = 30 μm/5 μm). (b) VDS-dependent transfer curve shows low on/off current ratio. (c) Comparison of transfer curves of the three devices (right y-axis) and VBG-dependent μFE (left y-axis) of Device #3 at VDS = 0.1 V. (d) Current path marked by arrows for this device structure. Direct tunneling (DT) from graphite to graphene through monolayer MoS2 is suggested, as indicated by the red arrow. A small portion of the current flow along the MoS2 layer is represented by the blue arrow.

Now, we turn to evaluate the VBG-dependent vertical SBH in the Gr/MoS2 heterojunction at a given VBG using Richardson’s equation43:

where \({I}_{0}=A{A}^{*}{T}^{3/2}\mathrm{exp}(-\frac{q{\Phi }_{\mathrm{B}}}{{k}_{B}T})\), A is the junction area, A* (= 54 A K−2 cm−2) is the Richardson constant44, n is the ideality factor, kB is the Boltzmann constant, q is the electrical unit charge, ΦB is the effective SBH, and T is the absolute temperature. Rearranging Eq. 1 gives:

where n and ΦB can be respectively determined from the slope and y-intercept of the \(\mathrm{ln}[{I}_{\mathrm{DS}}\times \mathrm{exp}(q{V}_{\mathrm{DS}}/{k}_{\mathrm{B}}T)/(\mathrm{exp}(q{V}_{\mathrm{DS}}/{k}_{\mathrm{B}}T)-1)]\) versus the negative VDS plot, (see Supplementary Note 2 and Fig. S5–S6 for the detailed procedures for SBH estimation).

The VBG-dependent IDS‒VDS curves obtained from Device #4 (Gr-Gr/MoS2-graphite using metal electrodes E1 and E4) are plotted in Fig. 4a. The asymmetric IDS‒VDS curve is mainly derived from the asymmetric contact barrier (graphene contact vs. graphite contact). The band alignment is illustrated, along with the two dominating Schottky barriers that contribute to the total SBH (Fig. 4b). One barrier is the SB at the Gr/MoS2 heterojunction (\({\Phi }_{\mathrm{Gr}/{\mathrm{MoS}}_{2}})\) and the other is the SB at the graphite/Cr contact junction (\({\Phi }_{\mathrm{contact}})\). At the source terminal, the contact resistance at the Gr/Cr junction is negligible due to the low SB or nearly ohmic contact42, which is consistent with the linear output characteristics illustrated in Fig. 2d. The SB was clearly formed at the Gr/MoS2 junction due to the difference in the work function of the two materials. Thereafter, electrons flow naturally from MoS2 to graphite because the energy state of the conduction band of MoS2 is higher (~ 4.3 eV) than that of graphite (~ 4.8 eV)30. This implies that the SB at the MoS2/graphite interface can be excluded from the total SBH estimation. Electrons are then thermally emitted to Cr by overcoming the SB at the graphite/Cr interface, where the contact barrier is formed. Therefore, the total SBH (\({\Phi }_{\mathrm{total}}\)) obtained from this structure is attributed to the SB at the Gr/MoS2 (\({\Phi }_{\mathrm{Gr}/{\mathrm{MoS}}_{2}}\)) heterojunction and graphite/Cr contact (\({\Phi }_{\mathrm{contact}})\), where the total SBH can be expressed as\(: {\Phi }_{\mathrm{total}}={{\Phi }_{\mathrm{Gr}/{\mathrm{MoS}}_{2}}+ \Phi }_{\mathrm{contact}}.\) The IDS‒VDS curves of Device #3 present non-linear behavior in the VBG regimes below VCNP (‒50 V ≤ VBG ≤ 20 V) (see Fig. 4c). The low on/off current ratio of this device (see Fig. 3b) provides clear evidence of DT, where the electrons flow through the atomically thin monolayer MoS2 to the underlying Gr, leading to a negligible contribution of Gr/MoS2 SB to the total SBH. Accordingly, \({\Phi }_{\mathrm{contact}}\) at the graphite/Cr interface could be regarded as \({\Phi }_{\mathrm{total}}\) for this device structure, where \({\Phi }_{\mathrm{total}}\simeq {\Phi }_{\mathrm{contact}}\) (see Fig. 4d). Consequently, \({\Phi }_{\mathrm{Gr}/{\mathrm{MoS}}_{2}}\) can be deduced by subtracting \({\Phi }_{\mathrm{contact}}\) from \({\Phi }_{\mathrm{total}}\). The VBG-dependent \({\Phi }_{\mathrm{total}}\), \({\Phi }_{\mathrm{contact}}\), and effective \({\Phi }_{\mathrm{Gr}/{\mathrm{MoS}}_{2}}\) at T = 300 K are directly compared in Fig. 4e. Increasing VBG reduced \({\Phi }_{\mathrm{Gr}/{\mathrm{MoS}}_{2}}\) when the value of VBG was positive in the range of 528‒116 meV, clearly indicating the large Fermi-level tunability of Gr via electrostatic gating.

Determination of Schottky barrier height at Gr/MoS2 heterointerface and band diagram. (a) VBG-dependent output characteristic curves of Gr/MoS2 heterostructure device contact with E1 and E4 (Device #4: Gr-Gr/MoS2-graphite) and (b) corresponding band diagram. (c) VBG-dependent output characteristic curves of Device #3 and (d) corresponding band diagram. (e) Effective SBH for Gr/MoS2 heterointerface (ΦGr/MoS2) as a function of VBG − VCNP.

Conclusion

In conclusion, we propose that the Gr/MoS2 heterointerface can be employed as a high-performance electronic device. The high carrier mobility of 100 cm2 V−1 s−1 of Gr/MoS2 heterojunction device over 8–10 cm2 V−1 s−1 of MoS2 device is ascribed to the underlying Gr, which is activated when the low SBH is formed in the n-Gr/n-MoS2 regime. On the other hand, the high on/off current ratio of ~ 108 is attributed to the bare MoS2 region in the heterostructure device. Furthermore, we demonstrate that the high tunability of the Fermi level of Gr allows to control the SBH at the Gr/MoS2 interface, resulting in distinctive carrier conduction features of the Gr/MoS2 heterojunction device, and confirming consequently two different conduction mechanisms.

Methods

Material synthesis

Monolayer Gr flakes were first synthesized on a 100 μm thick Cu foil (111) in a chemical vapor deposition (CVD) chamber under hydrogen with a low concentration of methane (0.1%, balance Ar gas) as a carbon source. The synthesized graphene with the polymer supporting layer was softly detached by bubble interception in sodium hydroxide solution and rinsed thrice with distilled water to eliminate contaminants during the chemical wet etching process. The graphene layer was then transferred onto a 300 nm-thick SiO2 substrate. Reactive ion etching (RIE, AFS-4RT; O2 plasma power of 30 mW; flow rate of 20 sccm at 10‒3 torr) was used to define the channel area of Gr. Monolayer MoS2 flakes were grown in a separate CVD chamber and transferred onto graphene strips by a water-assisted transfer method45. Thereafter, the exfoliated graphite flakes (~ 5 nm) were placed on the Gr/MoS2 heterostructure by the aligned transfer technique, in a glove box. Finally, the source/drain metal electrodes were patterned on the polymer resist via electron beam lithography, followed by metal deposition. All processes were completed within 24 h to maintain consistency in terms of the device reliability and reproducibility.

Device fabrication

The devices were fabricated by a series of wet- and dry-cooperative transfer methods. The channel materials (single-crystal graphene and MoS2) were both prepared by CVD35,46. The graphene synthesized on copper was firstly delaminated by electrochemical bubbling and then transferred onto the target 300 nm SiO2/Si substrates47. Thereafter, the MoS2 grown on the SiO2/Si substrate was detached by chemical etching48. After rinsing copiously with deionized water, the MoS2 flakes carried by the polymethyl methacrylate (PMMA) transfer film were assembled on the dry transfer holder. The two channels were aligned in the desired positions, and MoS2 was brought into contact with the graphene and held at 140 ℃ for 5 min, thus isolating the PMMA film from the transfer holder. The electrical contact of MoS2 was improved by using graphite, which was mechanically exfoliated onto the PMMA coated 300 nm SiO2/Si substrates and then deposited on the designed positions inside or outside the overlapped graphene/MoS2 by the conventional PMMA supporting layer method49. Subsequently, the source and drain for the graphene channel and the contact to the graphite electrodes were patterned by e-beam lithography, followed by vapor deposition of 5/50 nm Cr/Au. For the strip graphene channel, an additional patterning step was performed by photolithography prior to O2-plasma dry etching.

Optical and electrical characterization

The optical Raman spectrum of the developed Gr/MoS2 heterointerface device was acquired under 532 nm laser excitation with a power of 12 μW (Witec Alpha 300) in an argon-filled glove box system, where the oxygen and moisture levels were kept below 1 ppm to prevent undesired oxidation and aging of the samples. Electrical measurements were carried out using a commercial source measurement unit (Keithley 4200-SCS) under low-vacuum conditions (~ 10−3 torr) in a vacuum probe station, at room temperature.

References

Schwierz, F. Graphene transistors. Nat. Nanotechnol. 5, 487–496. https://doi.org/10.1038/nnano.2010.89 (2010).

Novoselov, K. S. et al. Electric field effect in atomically thin carbon films. Science 5, 1–12. https://doi.org/10.1126/science.1102896 (2004).

Eda, G., Mattevi, C., Yamaguchi, H., Kim, H. & Chhowalla, M. Insulator to semimetal transition in graphene oxide. J. Phys. Chem. C 113, 15768–15771. https://doi.org/10.1021/jp9051402 (2009).

Hall, E. O. et al. Control of graphene’s properties by reversible hydrogenation: evidence for graphane. Science 323, 610–614. https://doi.org/10.1126/science.1167130 (2009).

Boukhvalov, D. W. & Katsnelson, M. I. Chemical functionalization of graphene. J. Phys. Condens. Matter 21, 344205. https://doi.org/10.1039/C7CS00229G (2009).

Zhou, S. Y., Siegel, D. A., Fedorov, A. V. & Lanzara, A. Metal to insulator transition in epitaxial graphene induced by molecular doping. Phys. Rev. Lett. 101, 086402. https://doi.org/10.1103/PhysRevLett.101.086402 (2008).

Han, M. Y., Özyilmaz, B., Zhang, Y. & Kim, P. Energy band-gap engineering of graphene nanoribbons. Phys. Rev. Lett. 98, 206805. https://doi.org/10.1103/PhysRevLett.98.206805 (2007).

Evaldsson, M., Zozoulenko, I. V., Xu, H. & Heinzel, T. Edge-disorder-induced Anderson localization and conduction gap in graphene nanoribbons. Phys. Rev. B Condens. Matter Mater. Phys. 78, 161407. https://doi.org/10.1103/PhysRevB.78.161407 (2008).

Kim, P., Han, M. Y., Young, A. F., Meric, I. & Shepard, K. L. Graphene nanoribbon devices and quantum heterojunction devices. in Technical Digest - International Electron Devices Meeting, IEDM 1–4 IEEE, https://doi.org/10.1109/IEDM.2009.5424379 (2009).

Li, X., Wang, X., Zhang, L., Lee, S. & Dai, H. Chemically derived, ultrasmooth graphene nanoribbon semiconductors. Science 319, 1229–1232. https://doi.org/10.1126/science.1150878 (2008).

Lin, Y. M. et al. Dual-gate graphene FETs with fT of 50 GHz. IEEE Electron Device Lett. 31, 68–70. https://doi.org/10.1109/LED.2009.2034876 (2010).

Fiori, G. & Iannaccone, G. Ultralow-voltage bilayer graphene tunnel FET. IEEE Electron Device Lett. 30, 1096–1098. https://doi.org/10.1109/LED.2009.2028248 (2009).

Banerjee, S. K., Register, L. F., Tutuc, E., Reddy, D. & MacDonald, A. H. Bilayer pseudospin field-effect transistor (BiSFET): a proposed new logic device. IEEE Electron Device Lett. 30, 158–160. https://doi.org/10.1109/LED.2008.2009362 (2009).

Liu, H., Neal, A. T. & Ye, P. D. Channel length scaling of MoS2 MOSFETs. ACS Nano 6, 8563–8569. https://doi.org/10.1021/nn303513c (2012).

Wen, M., Xu, J., Liu, L., Lai, P. T. & Tang, W. M. Improved electrical performance of multilayer MoS2 transistor with NH3-Annealed ALD HfTiO gate dielectric. IEEE Trans. Electron Devices 64, 1020–1025. https://doi.org/10.1109/TED.2017.2650920 (2017).

Liu, Y. et al. Pushing the performance limit of sub-100 nm molybdenum disulfide transistors. Nano Lett. 16, 6337–6342. https://doi.org/10.1021/acs.nanolett.6b02713 (2016).

Bergeron, H. et al. Chemical vapor deposition of monolayer MoS2 directly on ultrathin Al2O3 for low-power electronics. Appl. Phys. Lett. 110, 099901. https://doi.org/10.1063/1.4975064 (2017).

He, G. et al. Conduction mechanisms in CVD-Grown monolayer MoS2 transistors: from variable-range hopping to velocity saturation. Nano Lett. 15, 5052–5058. https://doi.org/10.1021/acs.nanolett.5b01159 (2015).

Zhang, W. et al. High-gain phototransistors based on a CVD MoS2 monolayer. Adv. Mater. 25, 3456–3461. https://doi.org/10.1002/adma.201301244 (2013).

Rai, A. et al. Air stable doping and intrinsic mobility enhancement in monolayer molybdenum disulfide by amorphous titanium suboxide encapsulation. Nano Lett. 15, 4329–4336. https://doi.org/10.1021/acs.nanolett.5b00314 (2015).

Rai, A. et al. Interfacial-oxygen-vacancy mediated doping of MoS2 by high-κ dielectrics. Device Res. Conf. - Conf. Dig. DRC 2015-August, 189–190, https://doi.org/10.1109/DRC.2015.7175626 (2015).

Valsaraj, A., Chang, J., Rai, A., Register, L. F. & Banerjee, S. K. Theoretical and experimental investigation of vacancy-based doping of monolayer MoS2 on oxide. 2D Mater 2, 045009. https://doi.org/10.1088/2053-1583/2/4/045009 (2015).

Li, X. et al. Effect of dielectric interface on the performance of MoS2 transistors. ACS Appl. Mater. Interfaces 9, 44602–44608. https://doi.org/10.1021/acsami.7b14031 (2017).

Yu, Z. et al. Realization of room-temperature phonon-limited carrier transport in monolayer MoS2 by dielectric and carrier screening. Adv. Mater. 28, 547–552. https://doi.org/10.1002/adma.201503033 (2016).

Chai, Y. et al. Making one-dimensional electrical contacts to molybdenum disulfide-based heterostructures through plasma etching. Phys. Status Solidi Appl. Mater. Sci. 213, 1358–1364. https://doi.org/10.1002/pssa.201532799 (2016).

Liu, W. et al. High-performance few-layer-MoS2 field-effect-transistor with record low contact-resistance. Tech. Dig. - Int. Electron Devices Meet. IEDM 19.4.1-19.4.4, https://doi.org/10.1109/IEDM.2013.6724660 (2013)

Das, S., Chen, H. Y., Penumatcha, A. V. & Appenzeller, J. High performance multilayer MoS2 transistors with scandium contacts. Nano Lett. 13, 100–105. https://doi.org/10.1021/nl303583v (2013).

Cui, X. et al. Multi-terminal transport measurements of MoS2 using a van der Waals heterostructure device platform. Nat. Nanotechnol. 10, 534–540. https://doi.org/10.1038/nnano.2015.70 (2015).

Chee, S. S. et al. Lowering the Schottky barrier height by graphene/Ag electrodes for high-mobility MoS2 field-effect transistors. Adv. Mater. 31, 1–7. https://doi.org/10.1002/adma.201804422 (2019).

Jeong, T. Y. et al. Spectroscopic studies of atomic defects and bandgap renormalization in semiconducting monolayer transition metal dichalcogenides. Nat. Commun. 10, 3825. https://doi.org/10.1038/s41467-019-11751-3 (2019).

Zhang, W. et al. Ultrahigh-gain photodetectors based on atomically thin graphene-MoS2 heterostructures. Sci. Rep. 4, 1–8. https://doi.org/10.1038/srep03826 (2015).

Perera, M. M. et al. Improved carrier mobility in few-layer MoS2 field-effect transistors with ionic-liquid gating. ACS Nano 7, 4449–4458. https://doi.org/10.1021/nn401053g (2013).

Ryu, S. et al. Atmospheric oxygen binding and hole doping in deformed graphene on a SiO2 substrate. Nano Lett. 10, 4944–4951. https://doi.org/10.1021/nl1029607 (2010).

Zhang, W. et al. Opening an electrical band gap of bilayer graphene with molecular doping. ACS Nano 5, 7517–7524. https://doi.org/10.1021/nn202463g (2011).

Nguyen, V. L. et al. Seamless stitching of graphene domains on polished copper (111) foil. Adv. Mater. 27, 1376–1382. https://doi.org/10.1002/adma.201404541 (2015).

Colinge, J. P. et al. Nanowire transistors without junctions. Nat. Nanotechnol. 5, 225–229. https://doi.org/10.1038/nnano.2010.15 (2010).

Cristoloveanu, S., Bawedin, M. & Ionica, I. A review of electrical characterization techniques for ultrathin FDSOI materials and devices. Solid-State Electron. 117, 10–36. https://doi.org/10.1016/j.sse.2015.11.007 (2016).

Amara, A. & Rozeau, O. Planar Double-Gate Transistor vol. 49, https://doi.org/10.1007/978-1-4020-9341-8 (2009).

Geim, A. K. & Novoselov, K. S. The rise of graphene. Nat. Mater. 6, 183–191. https://doi.org/10.1038/nmat1849 (2007).

Choi, W., Lahiri, I., Seelaboyina, R. & Kang, Y. S. Synthesis of graphene and its applications: a review. Crit. Rev. Solid State Mater. Sci. 35, 52–71. https://doi.org/10.1080/10408430903505036 (2010).

Yu, L. et al. Graphene/MoS2 hybrid technology for large-scale two-dimensional electronics. Nano Lett. 14, 3055–3063. https://doi.org/10.1021/nl404795z (2014).

Castro Neto, A. H., Guinea, F., Peres, N. M. R., Novoselov, K. S. & Geim, A. K. The electronic properties of graphene. Rev. Mod. Phys. 81, 109–162. https://doi.org/10.1103/RevModPhys.81.109 (2009).

Moon, B. H. et al. Junction-structure-dependent Schottky barrier inhomogeneity and device ideality of monolayer MoS2 field-effect transistors. ACS Appl. Mater. Interfaces 9, 11240–11246. https://doi.org/10.1021/acsami.6b16692 (2017).

Lin, Y. F. et al. Barrier inhomogeneities at vertically stacked graphene-based heterostructures. Nanoscale 6, 795–799. https://doi.org/10.1039/C3NR03677D (2014).

Kim, H. et al. Role of alkali metal promoter in enhancing lateral growth of monolayer transition metal dichalcogenides. Nanotechnology https://doi.org/10.1088/1361-6528/aa7e5e (2017).

Han, G. H. et al. Seeded growth of highly crystalline molybdenum disulphide monolayers at controlled locations. Nat. Commun. 6, 1–6. https://doi.org/10.1038/ncomms7128 (2015).

Wang, Y. et al. Electrochemical delamination of CVD-grown graphene film: toward the recyclable use of copper catalyst. ACS Nano 5, 9927–9933. https://doi.org/10.1021/nn203700w (2011).

Yun, S. J. et al. Synthesis of centimeter-scale monolayer tungsten disulfide film on gold foils. ACS Nano 9, 5510–5519. https://doi.org/10.1021/acsnano.5b01529 (2015).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726. https://doi.org/10.1038/nnano.2010.172 (2010).

Acknowledgments

This work was supported by the Institute for Basic Science (IBS-R011-D1) and Basic Science Research Program through the National Research Foundation of Korea (NRF) grant, funded by the Korean Government (MSIP) (NRF-2019R1C1C1003467 & NRF-2019K2A9A1A06083674) and Sookmyung Women’s University Research Grants (project number: 1-1903-2002).

Author information

Authors and Affiliations

Contributions

T.K., S.F., Y.H.L., and M.-K.J. conceived the research and designed the experiment. T.K. and S.F. performed most of the experiments including device fabrication, characterization and data analysis. S.L. prepared the CVD graphene and MoS2 samples. T.K., S.F., and M.-K.J. illustrated all the images and plots in main figures and supplementary information. T.K., S.F., M.-K.J., and Y.H.L. analyzed the results and wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kim, T., Fan, S., Lee, S. et al. High-mobility junction field-effect transistor via graphene/MoS2 heterointerface. Sci Rep 10, 13101 (2020). https://doi.org/10.1038/s41598-020-70038-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-70038-6

This article is cited by

-

Direct growth and properties of few-layer MoS2 on multilayer graphene prepared by chemical vapor deposition

Journal of Materials Science (2022)

-

High-performance MoS2/p+-Si heterojunction field-effect transistors by interface modulation

Nano Research (2022)

-

Effect of the strain on spin-valley transport properties in MoS2 superlattice

Scientific Reports (2021)

-

Molecular dynamics simulations of ion beam irradiation on graphene/MoS2 heterostructure

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.