Abstract

Seven novel types of acetylene monomers, 4-oxo-4-(prop-2-ynyloxy)butanoic acid ester derivatives (PSRs), having ester groups of 4′-substituted phenyl (PSPRs: –H=PSP; –CN=PSPCN; –OCH3=PSPOC1) or 4′-substituted biphenyl (PSBPRs: –H=PSBP; –CN=PSBPCN; –OCH3=PSBPOC1; –O(CH2)5CH3=PSBPOC6) as a pendant group were synthesized from 4-oxo-4-(prop-2-ynyloxy)butanoic acid (PS) with phenol derivatives and polymerized with a rhodium-catalyzed system. The structures and properties of the polymers were characterized and evaluated by nuclear magnetic resonance, infrared spectroscopy and gel permeation chromatography analyses. The polymerizations of the PSRs were carried out under nitrogen with Rh catalysts in tetrahydrofuran or toluene at 30 °C, producing a good yield of polymers. The resulting polymer showed a thermotropic mesophase as observed through polarized optical microscopy and differential scanning calorimetry.

Similar content being viewed by others

Introduction

Liquid crystalline (LC) materials have large anisotropies in their optical, electrical, magnetic and physical properties because of their molecular structure and molecular alignment.1 These materials can show a variety of characteristic behaviors on the application of electric and magnetic fields.2

In side-chain LC polymers in which the mesogenic groups are linked through flexible alkyl or poly(alkylene oxide) chains to the polymer backbone, the flexible spacer enables a partial decoupling of the motions of the polymer backbone and the mesogens; thus, mesogens have the potential to adopt flexible behavior similar to that of low-molecular-weight LC compounds.

Polyacetylene is a π-conjugated polymer with at least four possible conformations (cis–transoid, cis–cisoid, trans–transoid and trans–cisoid). Yashima and co-workers reported the synthesis of cis–transoidal poly((4-carboxyphenyl)acetylene) by the polymerization of (4-carboxyphenyl)acetylene using a rhodium catalyst. The synthesized polymer folded into a preferred-handed helical conformation on complexation with non-racemic primary amines and amino alcohols.3, 4 Unfortunately, 1-alkynes, which have flexible methylene spacers, show a low polymerization ability and give low sterically controlled polyacetylenes. However, Noyori and co-workers reported that (nbd)Rh+[η6-(C6H5)-B−(C6H5)3], a zwitterionic Rh(I) complex, functions as an excellent initiator of the polymerization of alkylated and aromatic monosubstituted acetylenes without trialkylsilanes.5

The propargyl group is one of the least expensive compounds and facilitates the synthesis of acetylene derivatives. Despite this, most polyacetylenes are prepared from 1-alkyne derivatives in studies on LC polyacetylenes, and there has been little investigation of LC polymers derived from 2-propyn-1-ol. Koltzenburg et al.6 reported LC polymers that connected 2-propyn-1-ol and biphenyl groups through alkyl chains by ether bonding. However, no LC polymers connecting 2-propyn-1-ol and biphenyl groups through alkyl chains by ester bonding have been reported.

Bonding groups can influence the molecular properties of liquid crystals because of their geometric and electronic asymmetry. The difference in bonding groups cannot influence the thermal behavior of nematic-phase liquid crystals because the thermal behavior is affected by long-range interactions, such as van der Waals attraction. In contrast, the thermal behavior of smectic-phase liquid crystals is strongly influenced by the orientation of bonding groups. The thermal behavior of smectic-phase liquid crystals is affected by relatively short-range interactions, such as dipole–dipole or dipole-induced-dipole interactions, in addition to van der Waals attraction. Ester groups, especially, can influence the geometric structure or electrostatic properties because of their geometric and electronic asymmetry.7

In this study, we focus on the syntheses and characterization of side-chain LC polyacetylenes with succinic acid as a spacer. The polymerizabilities of the 4-oxo-4-(prop-2-ynyloxy)butanoic acid derivatives (PSRs) using (nbd)Rh+[η6-(C6H5)-B−(C6H5)3] and the liquid crystallinity of the polymers were investigated.

Experimental procedure

Materials

Unless stated otherwise, reagents were purchased from commercial suppliers and used without purification. Tetrahydrofuran (THF), toluene and the other solvents used for polymerization were distilled using the standard procedure8 used before, and (nbd)Rh+[η6-(C6H5)-B−(C6H5)3] was prepared from [Rh(nbd)Cl]2 according to the literature.9

Monomer synthesis

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid (PS)10

Propargyl alcohol (2-propyn-1-ol, 12.0 g, 0.214 mol) and succinic acid anhydride (21.4 g, 0.214 mol) were refluxed at 120 °C for 10 h in an acetic acid (150 ml) solution, after which the acetic acid was evaporated. The reaction mixture was extracted by chloroform and by ethyl acetate, and the organic layer was evaporated. PS was obtained as a pale yellow solid at a yield of 70% with an m.p. of 54 °C.

1H nuclear magnetic resonance (NMR) (270 MHz, CDCl3): δ (p.p.m.)=4.71 (d, 2H, CH2–COO), 2.71–2.68 (m, 4H, –CH2–CH2–), 2.50 (t, 1H, ≡CH).

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid phenyl ester (PSP)

PS (5.00 g, 32.0 mmol), phenol (3.61 g, 38.4 mmol) and 4-dimethylaminopyridine (0.782 g, 6.40 mmol) were dissolved in 200 ml CH2Cl2, and the solution was cooled to 0 °C. To this solution, N,N′-dicyclohexylcarbodiimide (9.90 g, 48.0 mmol) in 50 ml CH2Cl2 was added, while stirring, using a dropping funnel. The reaction mixture was stirred at 0 °C for 1 h and then stirred at room temperature overnight. Afterward, the formed urea solid was filtered out, and the solution was concentrated. The product was purified by silica gel column chromatography with CH2Cl2 as the eluent. PSP was obtained as a pale yellow oil at a yield of 48%.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.40–7.34 (m, 2H, phenyl), 7.26–7.20 (m, 1H, phenyl), 7.11–7.08 (m, 2H, phenyl), 4.73 (d, 2H, CH2–COO), 2.94–2.89 (m, 2H, –CH2–), 2.82–2.77 (m, 2H, –CH2–), 2.48 (t, 1H, ≡CH).

13C NMR (125.7 MHz, CDCl3): δ (p.p.m.)=171.17, 170.56 (2C, –COO–), 150.44, 129.25, 125.74, 121.33 (6C, phenyl), 77.32 (1C, –C≡CH), 75.04 (1C, –C≡CH), 52.15 (1C, ≡C–CH2–), 28.97, 28.71 (2C, –CH2-CH2–).

High-resolution time-on-flight mass spectrometry [HRMS (TOF)] m/z [M-H]− (C13H11O4): calcd, 231.0675; found, 231.0678.

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid 4′-cyanophenyl ester (PSPCN)

The title compound was synthesized in a manner similar to the synthesis of PSP. PSPCN was obtained as a white solid at a yield of 37% with an m.p. of 50 °C.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.71–7.67 (m, 2H, phenyl), 7.27–7.24 (m, 2H, phenyl), 4.74 (d, 2H, CH2–COO), 2.96–2.90 (m, 2H, –CH2–), 2.83–2.78 (m, 2H, –CH2–), 2.49 (t, 1H, ≡CH).

13C NMR (125.7 MHz, CDCl3): δ (p.p.m.)=171.02, 169.85 (2C, –COO–), 153.67, 133.52, 122.56, 109.65 (6C, phenyl), 118.05 (1C, –C≡N), 77.21 (1C, –C≡CH), 75.13 (1C, –C≡CH), 52.27 (1C, ≡C–CH2–), 28.97, 28.57 (2C, –CH2–CH2–).

HRMS (TOF) m/z [M-H]− (C14H10NO4) calcd, 256.0610; found, 256.0615.

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid 4′-methoxyphenyl ester (PSPOC1)

The title compound was synthesized in a manner similar to the synthesis of PSP. PSPOC1 was obtained as a yellow oil at a yield of 51%.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.03–6.99 (m, 2H, phenyl), 6.89–6.86 (m, 2H, phenyl), 4.73 (d, 2H, CH2–COO), 3.79 (s, 3H, O–CH3), 2.92–2.86 (m, 2H, –CH2–), 2.81–2.76 (m, 2H, –CH2–), 2.48 (t, 1H, ≡CH).

13C NMR (125.7 MHz, CDCl3): δ (p.p.m.)=171.82, 170.90 (2C, –COO–), 157.14, 143.95, 122.06, 114.26 (6C, phenyl), 77.31 (1C, –C≡CH), 75.00 (1C, –C≡CH), 55.38 (1C, –OCH3), 52.13 (1C, ≡C–CH2–), 28.92, 28.75 (2C, –CH2–CH2–).

HRMS (TOF) m/z [M-H]− (C14H13O5): calcd, 261.0763; found, 261.0782.

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid 4′-biphenyl ester (PSBP)

PS (5.00 g, 32.0 mmol) of SOCl2 solution (10 ml) was stirred at room temperature for 5 h, and unreacted SOCl2 was removed under reduced pressure. The residual product was dissolved in 50 ml of dry THF. This solution was added dropwise to a dry THF solution (150 ml) of 4-phenylphenol (6.54 g, 38.4 mmol) and Et3N (5.40 ml, 38.4 mol). The reaction mixture was stirred at 0 °C for 1 h and then refluxed for 10 h. After the reaction, THF was evaporated, and the residual product was dissolved in ethyl acetate. The solution was washed with 0.1 M HCl aq. (100 ml), distilled water (100 ml × 3) and saturated NaHCO3 aq. (100 ml), and the combined ethyl acetate was dried over Na2SO4. The solution was concentrated and purified by column chromatography (silica gel, n-hexane/EtOAc=2:1) to obtain PSBP as a pale yellow powder at a yield of 24% with an m.p. of 46 °C.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.59–7.53 (d, 2H, phenyl), 7.47–7.31 (d, 2H, phenyl), 7.20–7.14 (d, 3H, phenyl), 4.74 (s, 2H, CH2–COO), 2.96–2.78 (q, 4H, –CH2–CH2–), 2.49 (s, 1H, ≡CH).

13C NMR (67.8 MHz, CDCl3): δ (p.p.m.)=171.27, 170.73 (2C, –COO–), 140.27, 139.01, 128.73, 128.09, 127.30, 127.04, 121.69 (12C, biphenyl), 77.38 (1C, –C≡CH), 75.10 (1C, –C≡CH), 52.29 (1C, ≡C–CH2–), 29.27, 29.11 (2C, -CH2–CH2–).

HRMS (TOF) m/z [M-H]− (C19H15O4): calcd, 307.0970; found, 307.0959.

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid 4′-cyano-4-biphenyl ester (PSBPCN)

The title compound was synthesized in a manner similar to the synthesis of PSBP. PSBPCN was obtained as a white solid at a yield of 29% with an m.p. of 97 °C.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.75–7.57 (d, 4H, phenyl), 7.26–7.20 (d, 4H, phenyl), 4.74 (s, 2H, CH2–COO), 2.97–2.80 (q, 4H, –CH2–CH2–), 2.49 (s, 1H, ≡CH).

13C NMR (67.8 MHz, CDCl3): δ (p.p.m.)=171.21, 170.58 (2C, –COO–), 150.93, 144.58, 136.82, 132.54, 128.23, 127.57, 122.16, 110.93 (12C, biphenyl), 118.74 (1C, –C≡N), 77.31 (1C, –C≡CH), 75.11 (1C, –C≡CH), 52.29 (1C, ≡C–CH2–), 28.75, 29.06 (2C, –CH2–CH2–).

HRMS (TOF) m/z [M-H]− (C20H14NO4): calcd, 332.0923; found, 332.0946.

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid 4′-methoxy-4-biphenyl ester (PSBPOC1)

To an ethanol solution of NaOH (2.15 g, 53.7 mmol) and 4,4′-biphenol (10.0 g, 53.7 mmol), methyl iodide (3.34 g, 53.7 mmol) was added dropwise, and the solution was refluxed for 3 h. After the solution was cooled to room temperature, the precipitate was filtered and washed by ethanol and methanol. The filtrate was concentrated to obtain 4′-methoxybipheny-4-ol (BPOC1). The title compound was synthesized in a manner similar to the synthesis of PSBP using BPOC1. PSBPOC1 was obtained as a white solid at a yield of 44% with an m.p. of 58 °C.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.58–7.45 (m, 4H, phenyl), 7.19–7.07 (m, 2H, phenyl), 7.03–6.86 (m, 2H, phenyl), 4.74 (s, 2H, CH2–COO), 3.84 (s, 3H, O–CH3), 2.97–2.75 (m, 4H, –CH2–CH2–), 2.49 (t, 1H, ≡CH).

13C NMR (67.8 MHz, CDCl3): δ (p.p.m.)=171.25, 170.76 (2C, –COO–), 159.07, 149.38, 138.53, 132.69, 127.98, 127.53, 121.58, 114.11 (12C, in biphenyl), 77.47 (1C, –C≡CH), 75.08 (1C, –C≡CH), 55.19 (1C, –OCH3), 52.22 (1C, ≡C–CH2-), 28.77, 28.57 (2C, –CH2–CH2–).

HRMS (TOF) m/z [M-H]− (C20H17O5): calcd, 337.1076; found, 337.1077.

Synthesis of 4-oxo-4-(prop-2-ynyloxy)butanoic acid 4′-hexyloxy-4-biphenyl ester (PSBPOC6)

The title compound was synthesized in a manner similar to the synthesis of PSBPOC1 using 1-bromohexane. PSBPOC6 was obtained as a white solid at a yield of 2.3% with an m.p. of 97 °C.

1H NMR (270 MHz, CDCl3): δ (p.p.m.)=7.58–7.45 (m, 4H, phenyl), 7.17–7.10 (m, 2H, phenyl), 6.97–6.91 (m, 2H, phenyl), 4.70 (s, 2H, CH2–COO), 3.98 (t, 2H, O–CH2), 2.94–2.79 (m, 4H, –CH2–CH2–), 2.48 (t, 1H, ≡CH), 1.98–0.62 (m, 11H, alkyl chain).

13C NMR (67.8 MHz, CDCl3): δ (p.p.m.)=171.28, 170.78 (2C, –COO–), 158.74, 149.42, 138.72, 132.58, 128.01, 127.60, 121.62, 114.74 (12C, biphenyl), 77.38 (1C, –C≡CH), 75.08 (1C, –C≡CH), 68.03 (1C, hexyl), 52.29 (1C, ≡C–CH2–), 31.54, 29.20 (2C, hexyl), 29.13, 28.86 (2C, –CH2–COO), 25.68, 22.55, 14.00 (3C, hexyl).

HRMS (TOF) m/z [M-H]− (C25H27O5): calcd, 407.1859; found, 407.1911.

Polymerizations

Polymerization with (nbd)Rh+[η6-(C6H5)-B−(C6H5)3]

PSR (0.300 g) was added to a Schlenk flask, placed under a N2 atmosphere and dissolved in a polymerization solvent. (nbd)Rh+[η6-(C6H5)-B−(C6H5)3] (0.01 equiv.) was added to a pear-shaped flask, placed under N2 atmosphere and dissolved in a polymerization solvent. The (nbd)Rh+[η6-(C6H5)-B−(C6H5)3] solution was added to a monomer solution, and the mixture was stirred vigorously at 30 °C for 24 h.

On complete polymerization, methanol was added to quench the polymerization. The solutions were concentrated and purified three times by reprecipitation from THF in methanol. The polymers were dried in a vacuum oven at room temperature for 3 days.

Polymerization with [Rh(nbd)Cl]2

PSBPCN (0.30 g, 0.90 mmol) was added to a Schlenk flask and placed under a N2 atmosphere. Thereafter, a volume of 0.12 ml of Et3N and polymerization solvent was added. [Rh(nbd)Cl]2 (4.7 mg, 9.0 μmol) was added to a pear-shaped flask, placed under a N2 atmosphere and dissolved in a polymerization solvent. The [Rh(nbd)Cl]2 solution was added to a monomer solution, and the mixture was vigorously stirred at 30 °C for 24 h.

On complete polymerization, methanol was added to quench the polymerization. The solutions were concentrated and purified three times by reprecipitation from THF in methanol. The polymers were dried in a vacuum oven at room temperature for 3 days.

Measurements

1H- and 13C-NMR spectra were recorded on a JEOL EX-270 and a JEOL GSX-500 spectrometer (JEOL, Tokyo, Japan) in CDCl3 using tetramethylsilane as an internal standard. The number- and weight-average molecular weights (Mn and Mw) of the polymers were determined by gel permeation chromatography on a CROMATOPAC C-R7A plus (SHIMADZU, Kyoto, Japan) (LC-10AS, CTO-2A, SPD-10A, JASCO OR-990) equipped with polystyrene gel columns (SHIMADZU) (HSG-40G, HSG-20H, HSG-15H and HSG-10H) using THF as an eluent at a flow rate of 1.0 ml min−1 and calibrated by polystyrene standards at 50 °C. Phase transition temperatures were determined with a DSC 3100 (BRUKER AXS, Madison, WI, USA) equipped with a liquid nitrogen cooling system at a constant heating/cooling rate of 10 °C min−1. The textures of the synthesized polymers were observed using an OLYMPUS BHSP polarizing optical microscope (OLYMPUS, Tokyo, Japan) equipped with a METTLER FP82 HT hot stage (METTLER-TOLEDO, Greifensee, Switzerland). Mass spectra were recorded on an LCP Premier XE (WATERS, Milford, MA, USA).

Results and Discussion

Syntheses and polymerizations of acetylene-based monomers

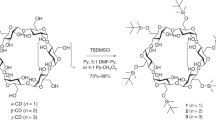

Acetylene monomers with phenyl or biphenyl moieties as a pendant group (PSPRs, PSBPRs) were synthesized from 4-oxo-4-(prop-2-ynyloxy)butanoic acid (PS) with phenol derivatives (Scheme 1). Polymerization of the monomers was carried out in THF or toluene using the rhodium catalyst (nbd)Rh+[η6-(C6H5)B−(C6H5)3] (Scheme 2). The progress of polymerization was monitored by 1H NMR spectroscopy. The results of the polymerization of PSPRs and PSBPRs are summarized in Table 1.

Polymers were obtained in higher yields by polymerizing PSRs using THF as a solvent than those polymerized using toluene. Poly(PSPR)s (PSP, PSPCN and PSPOC1) were obtained in lower yield and with higher number-average molecular weights than were poly(PSBPR)s (PSBP, PSBPCN, PSBPOC1 and PSBPOC6). It is interesting to note that PSBPOC1 was difficult to dissolve, and the corresponding polymer was obtained in low yield (2.4–6.5%), whereas poly(PSBPOC6) was obtained in very high yield (90.5–97.7%) because the chain length of the end groups affected the stability and solubility. These results suggest that solubility is very important to the polymerizability of PSRs.

The cis contents of polymers were calculated by 1H NMR integration ratios of the cis vinyl proton at 6.6–6.2 p.p.m. and the quarter of –CH2–CH2– protons at 3.0–2.4 p.p.m. (for example, Figure 1);11 the calculated results are summarized in Table 1. Higher cis contents were obtained for polymerizations of LC PSBPRs than those of non-liquid crystalline PSPRs. This result suggests that the LC state affected the alignment of acetylene monomers and that the cis content of the main chains was increased.

1H nuclear magnetic resonance spectrum of poly(PSBP) (Table 1, run 8) in CDCl3.

For comparison, the results of the polymerization of PSBPCN using the rhodium catalyst [Rh(nbd)Cl]2 are summarized in Table 2. Using [Rh(nbd)Cl]2 as a catalyst, the polymer yields were relatively low compared with the yields of polymerizations catalyzed by (nbd)Rh+[η6-(C6H5)B−(C6H5)3]. Moreover, the cis content dramatically decreased by changing the rhodium catalyst to [Rh(nbd)Cl]2 from (nbd)Rh+[η6-(C6H5)B−(C6H5)3]. These results also show that (nbd)Rh+[η6-(C6H5)B−(C6H5)3] was a better catalyst in polymerizing 1-alkynes and effectively controlled the configuration of the polymer obtained.

LC properties

The mesomorphic phase behaviors of monomers and polymers were characterized by differential scanning calorimetry and polarized optical microscopy. All polymers were measured at a heating rate of 10 °C min−1. It is notable that the isomerization temperature for the cis to trans transformation in polyacetylenes is in the range of 150–200 °C.12, 13

The mesomorphic phase behavior during the first cooling scan is summarized in Table 3. LC textures are shown in Figure 2, and differential scanning calorimetry curves of poly(PSBPCN) are shown in Figure 3. PSBPRs exhibited nematic and smectic phases, whereas PSPRs exhibited only a melting point. This difference was probably due to the strength of the intermolecular interactions, such as π–π stacking. In addition, poly(PSBPCN) and poly(PSBPOC6) exhibited the nematic phase. These polymers had relatively high cis contents, 47 and 71%, respectively. The LC properties of polymers are determined by the stereochemistry of the polymer, especially the double bond configuration. High contents of cis double bonds might favor the formation of the more stable and higher-ordered LC phase.

Differential scanning calorimetry curves of poly(PSBPCN) (Table 1, run 9).

Conclusion

In this study, we demonstrated syntheses and polymerizations of PSRs. The polymerizations of PSRs were carried out in THF or toluene using (nbd)Rh+[η6-(C6H5)-B−(C6H5)3]. Poly(PSPR)s were obtained in lower yields but with higher molecular weights than poly(PSBPR)s. PSBPOC6 exhibited high solubility, and the corresponding polymer using THF as the polymerization solvent was obtained in good yield (97.7%) and high cis content (77%). For the polymerization of PSRs, the solubility of the acetylene monomer was related to the polymer yield. All PSBPRs exhibited the nematic or smectic phase, and poly(PSBPCN) and poly(PSBPOC6) exhibited the nematic phase.

Syntheses of PSRs.

Polymerizations of PSRs.

References

Ho, M.- S. & Hsu, C.- S. Synthesis and hierarchical superstructures of side-chain liquid crystal polyacetylenes containing galactopyranoside end-groups. J. Polym. Sci. Part A Polym. Chem. 47, 6596–6611 (2009).

Hsu, C.- S. The application of side-chain liquid-crystalline polymers. Prog. Polym. Sci. 22, 829–871 (1997).

Yashima, E., Matsushima, T. & Okamoto, Y. Poly((4-carboxyphenyl)acetylene) as a probe for chirality assignment of amines by circular dichroism. J. Am. Chem. Soc. 117, 11596–11597 (1995).

Yashima, E. & Maeda, K. Chirality-responsive helical polymers. Macromolecules 41, 3–12 (2008).

Kishimoto, Y., Itou, M., Miyatake, T., Ikariya, T. & Noyori, R. Polymerization of monosubstituted acetylenes with a zwitterionic rhodium(I) complex, Rh+(2,5-norbornene)[(η6-C6H5)B−(C6H5)3]. Macromolecules 28, 6662–6666 (1995).

Koltzenburg, S., Wolff, D., Stelzer, F., Springer, J. & Nuyken, O. Investigation of the thermal and morphological behavior of liquid-crystalline acetylene homo- and copolymers. Macromolecules 31, 9166–9173 (1998).

Kusabayashi, S. in EKISHOU ZAIRYO 67–94 (Kodansha, Tokyo, 1991).

Goto, T., Shiba, T. & Matsuura, T. in YUUKIJIKKEN NO TEBIKI 1, (Kagakudoujin, Kyoto, 1988).

Schrock, R. R. & Osborn, J. A. π-Bonded complexes of the tetraphenylborate ion with rhodium(I) and iridium(I). Inorg. Chem. 9, 2339–2343 (1970).

Altintas, O., Hizal, G. & Tunca, U. ABC-type hetero-arm star terpolymers through ‘click’ chemistry. J. Polym. Sci. Part A Polym. Chem. 44, 5699–5707 (2006).

Abdul Karim, S. M., Nomura, R. & Masuda, T. Degradation behavior of stereoregular Cis-transoidal poly(phenylacetylene)s. J. Polym. Sci. Part A Polym. Chem. 39, 3130–3136 (2001).

Akagi, K., Piao, G., Kaneko, S., Sakamaki, K., Shirakawa, H. & Kyotani, M. Helical polyacetylene synthesized with a chiral nematic reaction field. Science 282, 1683–1686 (1998).

Goto, H., Nimori, S. & Akagi, K. Synthesis and properties of mono-substituted liquid crystalline polyacetylene derivatives-doping, magnetic orientation, and photo-isomerization. Synth. Met. 155, 576–587 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mizuta, K., Hiraga, N., Koga, T. et al. Synthesis of side-chain liquid crystalline polyacetylenes bearing succinic acid spacer. Polym J 43, 141–146 (2011). https://doi.org/10.1038/pj.2010.120

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2010.120

Keywords

This article is cited by

-

Synthesis of chiral side-chain liquid crystalline polyacetylenes bearing succinic acid spacer

Polymer Bulletin (2012)