Abstract

A vertical tunneling field effect transistor composed of a doping-less tunneling heterojunction and an n+-drain is presented in this paper. Two highly-doped p+ silicon layers are devised to induce holes in an intrinsic source region. Due to employing a double gate configuration and Hafnium in the gate oxide, our proposed structure has an optimized electrostatic control over the channel. We have performed all the numerical simulations using Silvaco ATLAS, calibrated to the verified data of a device with the similar working principle. The impact of the wide range of non-idealities, such as trap-assisted tunneling, interface trap charges, and ambipolar conduction, is thoroughly investigated. We have also evaluated the impact of negative capacitance material to further improve our device switching characteristics. Introducing both n-channel and p-channel devices, and employing them into a 6T SRAM circuit, we have investigated its performance in terms of parameters like read and write SNM. The FOMs such as Ion = 34.4 µA/µm, Ion/Ioff = 7.17 × 107, and fT = 123 GHz show that our proposed device is a notable candidate for both DC and RF applications.

Similar content being viewed by others

Introduction

Although conventional transistors with over barrier conduction mechanism are still the primary choice of nanoelectronics industry giants, the search for novel electronic devices with a different conduction mechanism and superior performance is continuously ongoing1,2,3. Tunneling field effect transistors (TFETs) are among most promising and successful alternatives4,5. They filter the high (low) energy electrons (holes) from the flowing charge carriers and form a tunneling energy window, theoretically leading to a very low off-state current6. The other advantage of such a filtering is that the subthreshold swing of tunneling FETs can beat the physically-limited subthreshold swing of MOSFETs. However, TFETs suffer from weaknesses such as low on-state current (Ion)7 and trap-related problems8. The low on-current issue has been addressed in several studies and solutions have been suggested9,10,11,12,13,14,15,16,17,18,19,20,21. On the other hand, employing the charge plasma technique seems to be a viable solution for trap-related problems in TFETs. Kumar and Janardhanan proposed the first charge plasma based TFET in which to induce holes in the source region Platinum with the work function of 5.93 eV was used22. Doping-less TFETs (DL-TFETs) based on InGaN23 and heterojunction of GaAs0.5Sb0.5/In0.53Ga0.47As24 are the other proposed DL-TFETs, which benefited from the special features of III–V materials and achieved the on-state current of 80.2 µA/µm and 40.5 µA/µm, respectively. Sharma et al.25 suggested a DL-TFET with organic semiconductor, and obtained the Ion of 0.44 µA/µm and on/off current ratio (Ion/Ioff) of 1.85 × 1011. Using negative capacitance dielectric materials26, 2D materials27, L-shaped gate28 and cladding layer concept29,30 are the other proposed solutions for improving TFETs performance.

In the conventional doping-less TFETs, inductive metals have been employed to induce charge carriers in the source and drain regions. Such a technique increases the risk of silicide formation. In this article, we propose a TFET which benefits from a doping-less tunneling junction. Two highly-doped silicon layers are advised to induce holes in the intrinsic source region, while using n+-doped silicon as the drain region can reduce fabrication steps and challenges. Removing inductive metal over the drain region and employing a heavily doped drain can also lessen the gate-to-drain capacitance, leading to better AC performance. Here, using germanium in the source region is preferred over silicon due to its smaller band gap and higher electron mobility31,32. Considering the scalability, choosing a vertical structure is better than a horizontal one.

Device configuration, fabrication process, and simulation procedure

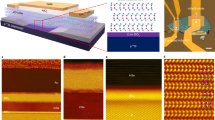

Figure 1 depicts our proposed vertical TFET. It includes two cladding layers to induce holes in an intrinsic Ge source region, while to reduce the fabrication process complexity an n+ Si drain region is deposited at the top of the structure. The material of the channel region is silicon, too. Because of employing the n+ drain and the cladding layer in our doping-less tunneling junction device, we name it NCDL-TFET. The electrostatic integrity of the gate is enhanced by using a 2 nm layer of Hafnium as the gate oxide. All other design parameters are tabulated in Table 1.

Despite the complexity of fabrication process of nanoscale transistors, we suggest a fabrication process flow for realizing NCDL-TFET that, according to the literature33,34, practically seems feasible. At the beginning a germanium layer is grown over a silicon substrate (see Fig. 2a,b). With the low-temperature in-situ doping technique, a p+ silicon layer, acting as a p-gate, is deposited over the germanium layer (see Fig. 2c). Then a thin isolator layer of SiO2 is deposited over the silicon layer, following which a U-shaped trench is carved in the cladding layer (see Fig. 2d,e). In the next step, an intrinsic germanium layer is grown in this trench to act as the source region (see Fig. 2f). The layers of intrinsic and n+-doped silicon are deposited to form channel and drain regions, respectively (see Fig. 2g,h). After selective etching of the two above mentioned layers, the high-k gate oxide is deposited (see Fig. 2i). The gate metal is deposited, followed by the deposition of the SiO2 as the spacer (see Fig. 2j,k). Finally, the source, gate, and drain contacts are connected (see Fig. 2l).

In Fig. 3, we have drawn the extracted ID–VG curve of Ref.22 alongside the reproduced result of our device simulator, and it can be inferred that a good matching is obtained. Silvaco ATLAS device simulator was employed to assess our device performance35. We have used Shockley–Read–Hall (SRH) recombination model, CVT, fermi, and dynamic non-local band-to-band-tunneling (BTBT) models for all the simulations. The charge transport model of drift–diffusion is also activated. Due to the large indirect band gap of silicon and channel thickness of 10 nm quantum confinement model is not incorporated in the simulations. During the calibration process, me = 0.22m0 and mh = 0.17m0 have been utilized.

Comparison between the measured transfer characteristic of the doping-less TFET22 and the reproduced curve by our calibrated simulation setup.

Simulation results

This section first evaluates the impact of cladding layers on the DC/RF performance of NCDL-TFET. Then, we assess our device performance in the presence of trap-assisted tunneling (TAT) and interface trap charges (ITC), temperature change, and ambipolar conduction. Then, we incorporate a negative capacitance in the design of NCDL-TFET, and its impact on our device performance is investigated. Finally, by designing a p-type doping-less TFET, a 6T SRAM cell is designed and its performance in terms of parameters such as reading and writing static noise margin (SNM) is evaluated.

Energy bands diagrams of NCDL-TFET along the A-B and C-D cutlines are depicted in Fig. 4a and b. As it can be inferred from Fig. 4a, no charge transport occurs between the cladding layers and the source region, mainly because of a large valence band offset between the mentioned regions. Figure 4b also depicts that no band-to-band tunneling happens in the parasitic tunneling path, which is from the valance band of the cladding layers to the conduction band of the channel. Thermionic emission is also suppressed due to the large band gap of SiO2 and p+ doping of silicon layers. Figure 4c shows the energy bands profile of NCDL-TFET along the \(\overline{\mathrm{EF} }\) segment (as displayed in Fig. 1) in the off-state (VGS = 0 V) for two different doping levels of the cladding layer. It can be seen that the higher doping of the cladding layers contributes to a smaller barrier width and a more-abrupt tunneling junction at the source-channel interface. This is mainly because increasing cladding layer doping levels induces more holes in the intrinsic source region. Figure 4d illustrates the energy bands diagram in the on-state (VGS = 0.7 V), indicating that a more-favorable tunneling junction is obtained by using higher level of doping concentration in the cladding layers.

According to Fig. 5a, the band-to-band tunneling rate has almost a horizontally uniform profile across the channel. Such a uniformity facilitates having a higher on-state current. The tunneling charge carriers move toward the drain side of NCDL-TFET, as represented in Fig. 5b.

As discussed earlier, the doping density of cladding layers plays a significant role in the modulation of the energy bands profile at the source-channel junction of NCDL-TFET. In Fig. 6a, we have plotted the transfer characteristics of our device for four different values of NClad. It can be seen that the device with NClad = 4 × 1019 cm−3 has a better performance compared with that of its counterparts. In Fig. 6b, the impact of cladding layers doping concentration on the Voff, Vth, and Ion is evaluated. We have defined Voff as the gate voltage in which BTBT is triggered. For the calculation of Vth, we have employed the constant current method, as mentioned in23. Obviously, when NClad = 4 × 1019 cm−3 the device shows the best performance with minimum Voff and Vth and maximum Ion of 34.4 µA/µm. Transconductance, given by gm = ∂ID/∂VGS, is another important parameter for evaluating FETs' performance. From Fig. 6c, it can be inferred that increasing NClad results in higher gm values, which are desirable for high-performance devices in low-noise, high-frequency applications. Another essential RF performance metric of a FET device is cut-off frequency (fT). It is a function of transconductance and parasitic capacitances of the device. Figure 6d illustrates the impact of NClad on the fT of NCDL-TFET. According to this figure, a significant frequency of 123 GHz can be achieved with NClad = 4 × 1019 illustrating that the role of higher gm is more critical than increased parasitic capacitance. In Fig. 6e, we can see how the amount of NClad affects the transit time of charge carriers in NCDL-TFET. Transit time, which represents the time it takes for charge carriers to move from the source to the drain side, is inversely proportional to fT, where τ = 1⁄(2π) × fT 36. The results show that when NClad is at 4 × 1019, the transit time values are the lowest, indicating that charge carriers require less time to move from the source to the drain side.

Figure 7a shows the impact of channel thickness on the transfer characteristics of NCDL-TFET. Increasing the channel thickness degrades the electrostatic control of the gate, contributing to higher off-state currents. We can see that tripling the channel thickness leads to an increment of Ioff from 4.94 × 10−10 to 7.11 × 10−9 µA/µm. A slight reduction of on-state current with the increment of the channel thickness is also attributed to the electrostatic control degradation. However, the abovementioned values ensure us quantum confinement has no considerable impact on the on-state current of NCDL-TFET when TC = 10 nm. In Fig. 7b, it is observable that with increasing TC from 10 to 30 nm, the on/off ratio decreases from 6.96 × 1010 to 2.93 × 109. Moreover, minimum subthreshold swing with ~ 153% increase reaches from 18.42 to 28.24 mV/dec.

Defect at the heterojunctions and multi-phonon excitation at the oxide–semiconductor interface can adversely impact the performance of TFETs8. In Fig. 8a, we compare the impact of both non-idealities on the performance of our suggested device. In case (a), we have defined the trap energy (Et) of 0.2 eV and the trap density (Dt) of 1 × 1012 cm−3 at the Ge-Si interface and the interface trap density (Dit) of 3 × 1012 cm−2 eV−1 at the HfO2-Si interface37, while in case (b), a hetero-oxide interface (comprising of 0.5 nm SiO2 and 1.5 nm HfO2) has been employed. So, the Dit = 3 × 1011 cm−2 eV−1 was used in the INTERFACE model of the device simulator. The change in the subthreshold swing of NCDL-TFET at the presence of these detrimental effects is shown in the inset of the figure. Figure 8b illustrates that by including both TAT and ITC models Ioff with almost three decades increment reaches to 4.88 × 10−7 µA/µm, leading to nearly three decades reduction of the on/off currents ratio from 6.96 × 1010 to 7.17 × 107. On the other hand, employing a hetero-oxide interface improves the off-state current and the on/off currents ratio. However, it leads to a more complicated fabrication process.

The impact of temperature variation on our NCDL-TFET performance is investigated in Fig. 9a, where we have used temperatures ranging from 300 to 400 K. Since thermal generation of charge carriers plays a significant role in subthreshold conductance, the temperature's impact on the off-state current is more significant than that on the on-state current. However, the Ioff = 3.65 × 10−7 µA/µm shows that NCDL-TFET has lower power dissipation than the short channel MOSFET even at temp = 400 K. In contrast, the on-state current remains almost unchanged, mainly because the transmission probability equation defined in Ref.4 has no direct dependency on the temperature. The inset of Fig. 9a shows that with an 100 K increment of temperature, the SSmin increases from 18.42 to 30.51 mV/dec which is still significantly lower than subthreshold swing of MOSFETs.

In order to suppress ambipolar conduction in the proposed device, the drain region of the device has not been heavily doped. As depicted in Fig. 9b, by choosing ND = 3 × 1018 cm−3, the ambipolar current (Iamb) is even lower than the off-state current. By one order of magnitude increase in ND the ambipolarity of NCDL-TFET rises about seven decades. As a result, the Ion/Iamb ratio reaches from 1.29 × 1013 to 1.25 × 106, exhibiting dramatic reduction of our device reliability.

Comparing the achieved performance of our proposed device with some of the recently published works on the same topic, listed in Table 2, indicates that NCDL-TFET is a notable candidate for CMOS applications.

Paraelectric Hafnium, a CMOS-compatible material, has a high potential to act as a negative capacitance material. Adding materials such as Si38, Al39, and ZrO240 into paraelectric HfO2 can be a viable solution to attain ferroelectricity. We have employed yttrium-doped HfO2 (Y: HfO2) in a Metal-ferroelectric-insulator-semiconductor (MFIS) configuration to enhance our device switching performance, as illustrated in Fig. 10. To evaluate the impact of Y: HfO2 material on the performance of NCDL-TFET, we first calibrated our device simulator with the extracted polarization curve of41 (see Fig. 11a). Then, the on-state current is calculated using the procedure explained in our previous work42. Figure 11b shows the impact of the thickness of (Y: HfO2) on the ID-VG curve of our proposed structure. It should be noted that although increasing Tfe improves the subthreshold swing, it can lead to more considerable hysteresis, which is not a desirable in CMOS applications. The inset shows the extracted values of Vth and SSavg, and it can be inferred that the higher values of Tfe lower Vth and improve SSavg.

(a) Calibration of the p–v curve using experimental data from Ref.41 and (b) the impact of thickness of ferroelectric material on the transfer characteristics of NCDL-TFET.

A more pragmatic assessment of a device's performance can be achieved by incorporating it into a familiar circuit configuration. In pursuit of this objective, our attention shifts to a hybrid six-transistor (6T) SRAM cell, depicted in Fig. 12. This configuration comprises four n-channel and two p-channel devices. The p-channel device chosen is a vertical PDL-TFET, designed along the same principles as the NCDL-TFET. According to the device structure exhibited in Fig. 13a, PDL-TFET has an intrinsic silicon source located at the bottom of the transistor, while germanium is employed in the channel and drain regions. All pertinent dimensions, parameter values, and activated models for simulations remain consistent with those utilized in NCDL-TFET simulations, with the exception of gate and source work functions which are assigned values of 4.65 eV and 3.9 eV, respectively. In Fig. 13b, our device simulator's accuracy is validated against simulation outcomes from the device highlighted in Ref.43. Additionally, we have plotted the transfer characteristics of PDL-TFET, which shows more-optimum performance for low-power applications.

(a) A schematic cross sectional view of vertical PDL-TFET and (b) comparison between the measured transfer characteristic of the doping-less P-TFET of43 and the reproduced curve by our calibrated simulation setup. The transfer characteristic of vertical PDL-TFET is also plotted in the figure.

By incorporating both n-channel and p-channel devices, we construct the 6T hybrid SRAM cell using four NCDL-TFET devices (Mn1, Mn2, Mn3, and Mn4) along with two PDL-TFET devices (Mp1 and Mp2). The stability performance of the 6T hybrid SRAM cell is explored through the examination of different static noise margins (SNMs) and their alterations in response to varying supply voltages (VDD). To ascertain the SRAM cell's SNM, the voltage transfer characteristics (VTC) of the two cross-coupled inverters are plotted. Various SNM values can be derived as the cell functions in the HOLD, READ, and WRITE modes. When the cell is in a HOLD or data retention state, the word line (WL) remains inactive, ensuring that the access transistors remain off. In this state, the cell retains its data using the cross-coupled inverters. Figure 14a visually presents the properties of the HOLD SNM and their shifts corresponding to different supply voltages (VDD). Notably, the HOLD SNM diminishes proportionally as the supply voltage decreases44.

During the READ operation, the SRAM cell is highly susceptible to noise45. Following a READ action, the cell must preserve its state without erasing the stored value. Bit lines (BL and BLB) are prepared for the READ operation prior to activating the word line (WL). The READ SNM of the SRAM cell, observed across various supply voltages, is illustrated in Fig. 14b. The minimal bit line voltage required to alter the cell's state is referred to as the WRITE margin. During the WRITE operation, data bits are transmitted on BL and BLB before enabling the word line. The WRITE action's properties in terms of SNM are portrayed in Fig. 14c. A summary of the HOLD, READ, and WRITE noise margins for different supply voltages is presented in Fig. 14d. Across all scenarios, the noise margin decreases with diminishing supply voltage, rendering the SRAM cell increasingly unstable.

Conclusion

We have suggested a TFET composed of a doping-less tunneling heterojunction and an n+-drain region in a vertical configuration. Due to using heterojunction of germanium/silicon in the tunneling interface, the on-state performance of our proposed device is more robust than Si-based doping-less TFETs. By employing a virtual fabrication process, we have shown that our structure can be realized in a feasible and convenient manner. Using Silvaco ATLAS, we have assessed the effect of non-idealities, such as defects at the tunneling interface and temperature, on our device performance. Our proposed device offers high scalability, sub-60 mV/dec performance even in the presence of defects, and higher AC performance than conventional doping-less TFETs. Although, using n+ doping in the drain region can increase the thermal budget but effectively reduce gate-to-drain parasitic capacitance and reduce fabrication steps. Moreover, silicide formation is no longer a challenge due to using highly doped cladding layers instead of inductive metal. We have also utilized yttrium-doped Hafnium as a negative capacitance material in an MFIS configuration, and a considerable improvement without any hysteresis was obtained. A CMOS-compatible p-TFET was also designed to meet all the requirements for developing a SRAM cell. The parameters such as Ion = 34.4 µA/µm, SSavg = 51.78 mV/dec, and fT = 123 GHz illustrate that NCDL-TFET is a notable candidate for high-performance applications such as designing SRAMs with lower power dissipation.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Gopalakrishnan, K., Griffin, P. B. & Plummer, J. D. Impact ionization MOS (I-MOS)-Part I: Device and circuit simulations. IEEE Trans. Electron Devices 52, 69–76. https://doi.org/10.1109/TED.2004.841344 (2004).

Salahuddin, S. & Datta, S. Use of negative capacitance to provide voltage amplification for low power nanoscale devices. Nano Lett. 8, 405–410. https://doi.org/10.1021/nl071804g (2008).

Niroui, F. et al. Tunneling nanoelectromechanical switches based on compressible molecular thin films. ACS Nano 9, 7886–7894. https://doi.org/10.1021/acsnano.5b02476 (2015).

Ionescu, A. M. & Riel, H. Tunnel field-effect transistors as energy-efficient electronic switches. Nature 479, 329–337. https://doi.org/10.1038/nature10679 (2011).

Seabaugh, A. C. & Zhang, Q. Low-voltage tunnel transistors for beyond CMOS logic. Proc. IEEE 98, 2095–2110. https://doi.org/10.1109/JPROC.2010.2070470 (2010).

Knoch, J., Mantl, S. & Appenzeller, J. Impact of the dimensionality on the performance of tunneling FETs: Bulk versus one-dimensional devices. Solid State Electron. 51, 572–578. https://doi.org/10.1016/j.sse.2007.02.001 (2007).

Avci, U. E., Morris, D. H. & Young, I. A. Tunnel field-effect transistors: Prospects and challenges. IEEE J. Electron Devices Soc. 3, 88–95. https://doi.org/10.1109/JEDS.2015.2390591 (2015).

Sant, S., Schenk, A., Moselund, K. & Riel, H. in 2016 74th Annual Device Research Conference (DRC) 1–2 (IEEE, 2016), https://doi.org/10.1109/DRC.2016.7548413.

Cherik, I. C. & Mohammadi, S. Cylindrical electron–hole bilayer TFET with a single surrounding gate and induced quantum confinement. J. Comput. Electron. 21, 235–242. https://doi.org/10.1007/s10825-021-01849-7 (2022).

Kato, K., Matsui, H., Tabata, H., Takenaka, M. & Takagi, S. Bilayer tunneling field effect transistor with oxide-semiconductor and group-IV semiconductor hetero junction: Simulation analysis of electrical characteristics. AIP Adv. 9, 055001. https://doi.org/10.1063/1.5088890 (2019).

Padilla, J. L., Medina-Bailon, C., Alper, C., Gamiz, F. & Ionescu, A. M. Confinement-induced InAs/GaSb heterojunction electron–hole bilayer tunneling field-effect transistor. Appl. Phys. Lett. 112, 182101. https://doi.org/10.1063/1.5012948 (2018).

Dewey, G. et al. in 2011 International Electron Devices Meeting 33–36 (IEEE, 2011), https://doi.org/10.1109/IEDM.2011.6131666.

Mohata, D. et al. Experimental staggered-source and N+ pocket-doped channel III–V tunnel field-effect transistors and their scalabilities. Appl. Phys. Express 4, 024105. https://doi.org/10.1143/APEX.4.024105 (2011).

Mookerjea, S. et al. in 2009 IEEE International Electron Devices Meeting (IEDM) 1–3 (IEEE, 2009), https://doi.org/10.1109/IEDM.2009.5424355.

Shih, P.-C., Hou, W.-C. & Li, J.-Y. A U-gate InGaAs/GaAsSb heterojunction TFET of tunneling normal to the gate with separate control over ON-and OFF-state current. IEEE Electron Device Lett. 38, 1751–1754. https://doi.org/10.1109/LED.2017.2759303 (2017).

Hanna, A. & Hussain, M. M. Si/Ge hetero-structure nanotube tunnel field effect transistor. J. Appl. Phys. 117, 014310. https://doi.org/10.1063/1.4905423 (2015).

Cherik, I. C. & Mohammadi, S. Double quantum-well nanotube tunneling field-effect transistor. Mater. Sci. Semicond. Process. 142, 106514. https://doi.org/10.1016/j.mssp.2022.106514 (2022).

Cherik, I. C., Mohammadi, S. & Orouji, A. A. Switching performance enhancement in nanotube double-gate tunneling field-effect transistor with Germanium source regions. IEEE Trans. Electron Devices https://doi.org/10.1109/TED.2021.3124984 (2021).

Musalgaonkar, G., Sahay, S., Saxena, R. S. & Kumar, M. J. Nanotube tunneling fet with a core source for ultrasteep subthreshold swing: A simulation study. IEEE Trans. Electron Devices 66, 4425–4432. https://doi.org/10.1109/TED.2019.2933756 (2019).

Tripathy, M. R. et al. Device and circuit-level assessment of GaSb/Si heterojunction vertical tunnel-FET for low-power applications. IEEE Trans. Electron Devices 67, 1285–1292. https://doi.org/10.1109/TED.2020.2964428 (2020).

Lee, H., Park, J.-D. & Shin, C. Performance booster for vertical tunnel field-effect transistor: Field-enhanced high-κ layer. IEEE Electron Device Lett. 37, 1383–1386. https://doi.org/10.1109/LED.2016.2606660 (2016).

Kumar, M. J. & Janardhanan, S. Doping-less tunnel field effect transistor: Design and investigation. IEEE Trans. Electron Devices 60, 3285–3290. https://doi.org/10.1109/TED.2013.2276888 (2013).

Duan, X. et al. A high-performance gate engineered InGaN dopingless tunnel FET. IEEE Trans. Electron Devices 65, 1223–1229. https://doi.org/10.1109/TED.2018.2796848 (2018).

Bhattacharyya, A., Chanda, M. & De, D. GaAs0.5Sb0.5/In0.53Ga0.47As heterojunction dopingless charge plasma-based tunnel FET for analog/digital performance improvement. Superlattices Microstruct. 142, 106522. https://doi.org/10.1016/j.spmi.2020.106522 (2020).

Sharma, P., Madan, J., Pandey, R. & Sharma, R. Numerical simulations of a novel CH3NH3PbI3 based double-gate dopingless tunnel FET. Semicond. Sci. Technol. 36, 055008. https://doi.org/10.1088/1361-6641/abec13 (2021).

Lahgere, A., Panchore, M. & Singh, J. Dopingless ferroelectric tunnel FET architecture for the improvement of performance of dopingless n-channel tunnel FETs. Superlattices Microstruct. 96, 16–25. https://doi.org/10.1016/j.spmi.2016.05.004 (2016).

Dubey, P. K. & Kaushik, B. K. A charge plasma-based monolayer transition metal dichalcogenide tunnel FET. IEEE Trans. Electron Devices 66, 2837–2843. https://doi.org/10.1109/TED.2019.2909182 (2019).

Li, C. et al. A novel gate engineered L-shaped dopingless tunnel field-effect transistor. Appl. Phys. A Mater. Sci. Process. 126, 412. https://doi.org/10.1007/s00339-020-03554-x (2020).

Cherik, I. C. & Mohammadi, S. Vertical cladding layer-based doping-less tunneling field effect transistor: A novel low-power high-performance device. IEEE Trans. Electron Devices https://doi.org/10.1109/TED.2021.3138669 (2022).

Cherik, I. C. & Mohammadi, S. Design insights into switching performance of germanium source L-shaped gate dopingless TFET based on cladding layer concept. IEEE Trans. Electron Devices https://doi.org/10.1109/TED.2022.3229257 (2022).

Kim, S. H. et al. Tunnel field effect transistor with raised germanium source. IEEE Electron Device Lett. 31, 1107–1109. https://doi.org/10.1109/LED.2010.2061214 (2010).

Toh, E.-H., Wang, G. H., Samudra, G. & Yeo, Y.-C. Device physics and design of germanium tunneling field-effect transistor with source and drain engineering for low power and high performance applications. J. Appl. Phys. 103, 104504. https://doi.org/10.1063/1.2924413 (2008).

Chen, S. et al. Symmetric U-shaped gate tunnel field-effect transistor. IEEE Trans. Electron Devices 64, 1343–1349. https://doi.org/10.1109/TED.2017.2647809 (2017).

Bagga, N., Kumar, A. & Dasgupta, S. Demonstration of a novel two source region tunnel FET. IEEE Trans. Electron Devices 64, 5256–5262. https://doi.org/10.1109/TED.2017.2759898 (2017).

Silvaco, ATLAS Device Simulation Software User’s Manual, No. Version 3.2. 2015.

Imenabadi, R. M., Saremi, M. & Vandenberghe, W. G. A novel PNPN-like Z-shaped tunnel field-effect transistor with improved ambipolar behavior and RF performance. IEEE Trans. Electron Devices 64, 4752–4758. https://doi.org/10.1109/TED.2017.2755507 (2017).

Kim, S. W., Kim, J. H., Liu, T.-J.K., Choi, W. Y. & Park, B.-G. Demonstration of L-shaped tunnel field-effect transistors. IEEE Trans. Electron Devices 63, 1774–1778. https://doi.org/10.1109/TED.2015.2472496 (2015).

Lomenzo, P. D. et al. Ferroelectric phenomena in Si-doped HfO2 thin films with TiN and Ir electrodes. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 32, 03D123. https://doi.org/10.1116/1.4873323 (2014).

Mueller, S. et al. Incipient ferroelectricity in Al-doped HfO2 thin films. Adv. Funct. Mater. 22, 2412–2417. https://doi.org/10.1002/adfm.201103119 (2012).

Lee, M. et al. in 2015 IEEE International Electron Devices Meeting (IEDM). 22–25 (IEEE, 2015), https://doi.org/10.1109/IEDM.2015.7409759.

Müller, J. et al. Ferroelectricity in yttrium-doped hafnium oxide. J. Appl. Phys. 110, 114113. https://doi.org/10.1063/1.3667205 (2011).

Cherik, I. C., Abbasi, A., Maity, S. K. & Mohammadi, S. Junctionless tunnel field-effect transistor with a modified auxiliary gate, a novel candidate for high-frequency applications. Micro Nanostruct 174, 207477. https://doi.org/10.1016/j.micrna.2022.207477 (2022).

Bashir, F. & Loan, S.A. in 2014 IEEE 2nd International Conference on Emerging Electronics (ICEE) 1–4 (IEEE, 2014), https://doi.org/10.1109/ICEmElec.2014.7151160.

Seevinck, E., List, F. J. & Lohstroh, J. Static-noise margin analysis of MOS SRAM cells. IEEE J. Solid-State Circuits 22, 748–754. https://doi.org/10.1109/JSSC.1987.1052809 (1987).

Grossar, E., Stucchi, M., Maex, K. & Dehaene, W. Read stability and write-ability analysis of SRAM cells for nanometer technologies. IEEE J. Solid-State Circuits 41, 2577–2588. https://doi.org/10.1109/JSSC.2006.883344 (2006).

Author information

Authors and Affiliations

Contributions

I.C.Cherik.: Conceptualization, Methodology, Software, Formal analysis, Investigation, Visualization, Data Curation, Writing—Original Draft. S.Mohammadi: Conceptualization, Validation, Supervision, Project administration, Resources, Data Curation, Writing—Review & Editing. S. K. Maity: Conceptualization, Methodology, Software, Formal analysis, Investigation, Visualization, Data Curation, Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cherik, I.C., Mohammadi, S. & Maity, S.K. Vertical tunneling FET with Ge/Si doping-less heterojunction, a high-performance switch for digital applications. Sci Rep 13, 16757 (2023). https://doi.org/10.1038/s41598-023-44096-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-44096-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.