Abstract

Carbon (C) and nitrogen (N) allocation and assimilation are coupled processes, likely influencing C accumulation, N use efficiency and plant productivity in agro-ecosystems. However, dynamics and responses of these processes to management practices in semi-arid agro-ecosystems are poorly understood. A field-based 13CO2 and urea-15N pulse labelling experiment was conducted to track how C and N allocation and assimilation during canola growth from flowering to maturity were affected by short-term (2-year) tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (T-0, T-100, NT-0, NT-100) on a Luvisol in an Australian semi-arid region. The T-100 caused greater (P < 0.05) belowground C allocation and higher (P < 0.05) translocation of soil N to shoots and seeds, compared to other treatments. Microbial N uptake was rapid and greatest in the fertilized (cf. non-fertilized) treatments, followed by a rapid release of microbial immobilized N, thus increasing N availability for plant uptake. In contrast, management practices had insignificant impact on soil C and N stocks, aggregate stability, microbial biomass, and 13C retention in aggregate-size fractions. In conclusion, tillage and N fertilization increased belowground C allocation and crop N uptake and yield, possibly via enhancing root–microbial interactions, with minimal impact on soil properties.

Similar content being viewed by others

Introduction

Plants allocate recently photo-assimilated carbon (C) to aboveground and belowground organs to support their structural and non-structural components and metabolic processes1, 2, influencing the C source sink balance3 and nutrient cycling in terrestrial ecosystems4. Of the total belowground C allocation, a significant amount can be translocated from roots to soil (e.g. as exudates) and subsequently respired as CO2 5,6,7. Root exudates are energy-rich substrates which influence the growth and activity of microbes, mineralisation of soil organic matter (SOM), and uptake of soil-released nitrogen (N) by plants4. Thus, belowground C allocation is a key process in influencing the coupled source–sink activities between shoots, roots and soil microorganisms with implications for C and N cycling, N use efficiency and biomass productivity in agro-ecosystems2, 8, 9. However, the responses of these agro-ecosystem dynamics to management practices, including the relationship between belowground C allocation and crop N uptake, are not well understood4, 7, 10. A better understanding is needed of the potential of management practices to enhance plant C input and N use efficiency in crop–soil systems7. Furthermore, research on the impact of agricultural management on soil C and N dynamics is critical for the sustainability of agro-ecosystems and the quality of the environment11,12,13,14.

There are studies that have examined allocation dynamics of newly assimilated C and N and their retention in aboveground and belowground pools under field and controlled conditions7, 10, 15. For example, in a recent field study, An et al.10 reported 12–15% allocation of the newly assimilated 13C to belowground pools (such as soil, roots and microbial biomass) 15 days after pulse labelling in differently managed maize–soil systems. Ge et al.15 reported 8–19% allocation of newly assimilated 14C to belowground pools 36 days after continuous labelling in differently managed rice–soil systems under controlled conditions. Further, in another recent field study under a dryland condition, Fang et al.7 reported 1–2% allocation of the newly assimilated 13C to belowground pools and 0.5–0.7% translocation of the new soil-released 15N to aboveground pools 50 days after pulse labelling in differently managed wheat–soil systems. Yet, less attention has been given to the understanding of how different management practices influence whole-plant C and N allocation, assimilation and interactions under field conditions7, particularly in semi-arid dryland agro-ecosystems, where 50% or more of plant available N is derived from SOM mineralisation16. Furthermore, dryland regions impart severe constraints to crop productivity, due to low moisture availability, low soil C and climatic variability7, 17, 18. It is thus important to identify how management practices could enhance key ecosystem processes and functions, such as mutualistic relationships between shoots, roots and microorganisms in relation to belowground C allocation, plant N use efficiency, crop yield, and retention of belowground allocated C in soil aggregates. In situ monitoring techniques using dual stable isotopic (13C and 15N) pulse labelling can allow to quantify such ecosystem processes and functions in contrastingly managed crop–soil systems4, 7, 19, 20. Many studies have reported that a tracing period of more than one to several weeks after 13C pulse labelling is appropriate to achieve an equilibrium partitioning of the newly assimilated C in plant–soil pools7, 10, 21,22,23. Further, a recent study has shown that a tracing period of several weeks can be useful to achieve an equilibrium partitioning of new C and N in plant–soil pools, and thus to provide a realistic assessment of the impact of management practices on the coupling between C allocation and N use efficiency in crop–soil systems7.

It has been proposed that soil aggregates can stabilize root- and microbial-derived C and N through physical and chemical mechanisms and may increase their stocks in soil24, 25. Studies reported that the allocation, fate and retention of newly added C and N can vary among different aggregate-size classes7, 26. For example, Fang et al.7 reported that after 50 days of pulse labelling, the new C and N retention was higher in micro-structures relative to larger-sized aggregates, likely due to less accessibility of SOM to microbes. Additionally, the processes of C and N accumulation in soil aggregates may also be related to the extent of belowground C allocation, which may concurrently enhance microbial activity, N cycling and soil aggregate stability7, 26, 27. As these soil processes may be impacted by tillage and N fertilization15, 28, a better understanding of the allocation, fate and retention of C and N in soil aggregates of different size classes is needed to acquire insights into pathways of SOM accumulation under contrastingly managed cropping systems.

Canola is the Australia’s third-largest broadacre crop after wheat and barley29. Canola is grown as a key rotation crop across the wheat belt areas of different countries29,30,31. Canola generally has a high N requirement to maintain adequate seed yield and quality32, 33. Further, studies have reported that, at the reproductive stage, C allocation to belowground pools may decrease due to increasing demand for the plant-assimilated C by the reproductive pools such as flowers, pods and seeds21, 34. However, some of the assimilated C may still be allocated belowground at the critical (reproductive) growth stage to meet the plant’s nutrient and water demand35, 36. This study therefore aimed to assess the impact of tillage intensity and N fertilization on the coupling between aboveground and belowground pools in relation to assimilation and allocation of new C and N, in a canola crop–soil system. In situ plant 13C and soil 15N labelling was performed at flowering to examine the flow of newly assimilated C and N in the crop−soil system until grain maturity, and to quantify their distribution in plant pools, microbial biomass and aggregate-size fractions in a Chromic Luvisol.

No-till is a widely adopted practice in Australian dryland cropping systems, providing benefits such as improvement in soil structure, water retention and SOC14, 37. Conversely, no-till farming may cause soil compaction and increase weed infestation38. It is also being recognised that relatively low-intensity tillage operations (e.g. scarifier, harrowing, discing), as performed in our study, may create a soil environment favourable for germination, root proliferation, soil microbial activity and plant growth, with minimal impact on soil structure and SOC39,40,41. Additionally, N fertilization can support crop growth and yield14 and may influence belowground C allocation and soil microbial activity42, 43. Thus, we hypothesized that (i) tillage with N fertilization could increase belowground C allocation through enhancement of root growth, stimulating microbial activity and interactions, compared to tillage without N fertilization and no-till with and without N, leading to the greatest plant N uptake from soil; (ii) uptake of soil-released N by microbes could be more prominent under tillage and N fertilization than under no-till (with and without N) and tillage without N; and (iii) tillage (vs. no-till) would have minimal impact on aggregate stability and C and N storage in stable aggregates.

Results

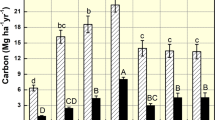

Allocation of newly assimilated 13C and 15N in canola–soil system

Pulse labelling with 13CO2 and 15N produced isotopically traceable assimilates that were allocated among aboveground and belowground pools immediately after pulse labelling (Figs 1, 2 and 3). Time had a significant impact on the allocation of newly assimilated C and N in all aboveground and belowground pools, except in the tap roots (Table 1).

Relative proportion (%) of the pulse-added 13CO2-C recovered in the aboveground (a,b,c) and belowground pools (d,e,f)) in a canola crop–soil system from flowering to harvesting as affected by tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (i.e. T–0, T–100, NT–0, NT–100). Error bars are ± standard errors (n = 3). Vertical black bars show least significant differences (at 5% level, LSD0.05) at different time points.

Relative proportion (%) of the pulse-added urea-15N recovered in the aboveground (a,b,c) and belowground pools (d,e,f)) in a canola crop–soil system from flowering to harvesting as affected by tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (i.e. T–0, T–100, NT–0, NT–100). Error bars are ± standard errors (n = 3). Vertical black bars show least significant differences (at 5% level, LSD0.05) at different time points.

Partial budget (g m−2) of the pulse-applied 13C and15N allocation across the aboveground (i.e. leaf, stem, flower/seed) and belowground pools (i.e. tap root and soil plus fine roots to 1 m depth) under different management practices at flowering stage (day two) (a,c), pod filling stage (day thirty) (b,d), and harvesting stage (day forty five) (c,f). Error bars are ± standard errors (n = 3).

Two days after labelling, most of the added 13C remained in the aboveground pools, while a small proportion of the assimilated 13C was allocated belowground across all management practices (Fig. 1). Of the total added 13CO2 (0.89 g m−2), 6–11%, 14–16% and 33–45% were recovered within two days in the leaf, stem, and flower + pod pools, respectively, across the management practices (Figs 1a–c and 3a). The relative proportion of 13C decreased in the leaf (P < 0.001) and flower + pod pools (P < 0.001), while 13C allocation increased in the stem (P < 0.01) with time. At harvest, 2–6%, 18–29% and 11–13% were recovered in the leaf, stem, and shell + seed pools, respectively, across the management practices (Figs 1a–c and 3c). Over the chasing period, fertilization (P < 0.001) and its interaction with tillage and time had significant effects on new C allocation in the leaf (Table 1). Overall, the leaf 13C recovery was higher in the T–100 than the other treatments.

Among the belowground pools 1.1–1.5%, 0.3–0.4% and 3.4–5.5% of the 13C was allocated to tap roots, fine roots (0–0.3 m depth) and soil (0–0.3 m depth), respectively, two days after labelling, across the management practices (Figs 1d–f and 3a). There were highly significant (P < 0.001) interactions between tillage, fertilizer and time in allocation to fine roots, but not in tap roots (Table 1). The 13C allocation to fine roots increased with time (P < 0.001), recovering 0.4–1.1% at harvest across the treatments (Fig. 1e). In the soil pool, fertilizer (P < 0.01), time (P < 0.01) and the interaction of fertilizer with tillage (P < 0.05), and time with tillage had significant (P < 0.01) effects on the 13C recovery (Table 1). After two days, the new C allocation in the soil either increased over the chasing period or stabilised among the management practices. At harvest, 3.0–7.0% of the added 13C was recovered in soil to 0.3 m depth. Overall, the new C allocation in fine roots and soil was highest in the T–100, relative to the other treatments. Further, at harvest, the aboveground biomass and seed yield was higher (P < 0.01) in the T–100 than the other treatments (Fig. S1). Although, there was a no clear relationship between the belowground C allocation and aboveground biomass, the belowground C allocation had a significant positive correlation with seed yield (Fig. 4).

Relationships between (1) canola seed yield (t ha−1) and relative proportion (%) of belowground carbon (13C) allocation to soil plus roots to 0.1 m depth (a), fine roots to 0.1 m depth (b) and tap roots (c); and (2) canola seed yield and relative proportion of aboveground nitrogen (15N) translocation to biomass plus seed (d) and seed (e), as affected by tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (i.e. T-0, T-100, NT-0, NT-100). *Significant correlation (P < 0.05); **highly significant correlation (P < 0.01).

Of the total added amount (0.89 g 13C m−2), the net 13C recovery in the aboveground pools varied between 0.50 and 0.64 g m−2 (56–71%) across the management practices on day two. The T–100 showed higher 13C recovery than the other practices (Fig. 3a). The net 13C recovery in the aboveground pools then decreased rapidly over time, and at the pod filling stage (day 30), 0.30–0.40 g 13C m−2 (32–45%) was retained, which was similar to that recovered at harvest (0.32–0.40 g m−2) (Fig. 3b,c). The net 13C recovery in the belowground pools to 0.3 m depth varied between 0.03 and 0.05 g m−2 (4–6%) on day two, which increased to 0.04–0.09 g m−2 (4–10%) at pod filling, and remained similar (0.04–0.08 g m−2) at harvest across the treatments (Fig. 3). The results to 1.0 m depth at harvest showed additional 13C recovery of 0.002–0.003 g m−2 (0.2–0.3%) in the fine roots and 0.03–0.05 g m−2 (4–5%) in the soil + fine roots to 0.3–1.0 m depth across the treatments (Figs 3c and 5b).

Root biomass (tap and fine roots) distribution (t ha−1) (a) and new 13C distribution (g m−2) in tap and fine roots (b), at 0–0.1 m, 0.1–0.2 m, 0.2–0.3 m, 0.3–0.7 m and 0.7–1 m soil depth at harvesting stage as affected by tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (i.e. T-0, T-100, NT-0, NT-100). Error bars are ± standard errors (n = 3).

The allocation of 15N in the aboveground and belowground pools showed the opposite pattern to that of 13C. On day two, the majority of soil-applied 15N (0.2 g urea-15N m−2) remained in the belowground pools, while a small proportion was translocated to the aboveground biomass in all management practices (Fig. 2). Of the total soil 15N, 2.0–6.5%, 1.5–2.0% and 1.5–6.0% was translocated to the leaf, stem, and flower + pod pools, respectively, within two days (Fig. 2a–c). However, with time, the allocation of soil 15N increased in the aboveground pools (Table 1; Fig. 3d–f). At harvest, 5–8%, 4–10% and 17–32% of the 15N was recovered in the leaf, stem, and shell + seed pools, respectively, across the treatments (Figs 2a–c and 3f). In the stem, 15N allocation was significantly impacted by the interactive effect of tillage × fertilizer × time (P < 0.05) (Table 1). In the leaf and flower + pod pools, tillage, fertilizer and time each had significant effects (P < 0.05) (Table 1). In contrast, 15N allocation in pod shell + seed was significantly impacted by the interacting effect of tillage × fertilizer (P < 0.05) (Table 1). The T–100 showed the highest allocation of 15N in flowers + pods throughout (Fig. 2c) and there was a significant positive correlation between aboveground N translocation and seed yield (Fig. 4). Two days after labelling, 0.3–1.0% and 0.4–1.6% of the soil-applied 15N was translocated to tap and fine roots (0–0.3 m), respectively, and 58–81% was recovered in soil (0–0.3 m), which decreased over time (Figs 2d–f and 3d–f). Tillage, fertilizer, time and their interactions had a significant (P < 0.001) effect on the 15N recovery in fine roots, whereas, only tillage, fertilizer or time had a significant effect (P < 0.05) on the soil 15N recovery (Table 1). Overall, the T–100 resulted in higher soil 15N recovery than the other treatments. The 15N recovery in the soil decreased rapidly from the flowering to pod filling and then stabilised. At harvest, 27–43% of the 15N remained in the soil to 0.3 m depth (Fig. 2).

Across the practices, the net recovery of the added 15N (0.2 g urea-15N m−2) in the aboveground pools varied between 0.01 and 0.03 g m−2 (5–15%) (Fig. 3d) on day two, and increased to 0.07–0.10 g m−2 (34–49%) at pod filling (Fig. 3e) and remained similar (0.06–0.10 g m−2) at harvest (Fig. 3f). On day two, the net recovery of 15N in the belowground pools to 0.3 m depth was 0.12–0.16 g m−2 (60–82%) (Fig. 3d). This recovery decreased to 0.06–0.09 g m−2 (29–44%) at harvest, while only 5–6% of the added 15N was recovered in the 0.3–1.0 m depth (Fig. 3f). The T–100 (cf. the other treatments) showed the highest 15N recovery in both the aboveground and belowground pools (Fig. 3d–f).

13C and 15N recovery in microbial biomass

Tillage and fertilizer, and their interactions with time had no significant (P > 0.05) effects on the recovery of 13C in MBC and DOC (Table 1; Fig. S2a). At two days, 0.13–0.18% of the added 13C was recovered in MBC, which increased with time (P < 0.001) to 0.36–0.42% at harvest across the treatments (Fig. 6a; Table 1). In contrast, the recovery of added 15N in microbial biomass was 26–61% on day two, which decreased (P < 0.001) rapidly to 3–14% with time (Fig. 6b, Table 1). The recovery of 15N in dissolved N (DN) also decreased rapidly over time (P < 0.001) (Fig. S2b). Over the study period, fertilization (P < 0.001) and its interaction with tillage (P < 0.05), and time (P < 0.01) had a significant impact on 15N recovery in microbial biomass (Fig. 6b; Table 1). Fertilization with or without tillage had higher 15N recovery in microbial biomass.

Relative proportion (%) of the pulse-added 13CO2-C in microbial biomass carbon (MBC) (a) and urea-15N in microbial biomass nitrogen (MBN) (b) in the 0–0.1 m soil from canola flowering to harvesting stage as affected by tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (i.e. T-0, T-100, NT-0, NT-100). Error bars are ± standard errors (n = 3). Vertical black bars show least significant differences (at 5% level, LSD0.05) at different time points.

13C and 15N recovery in aggregate–size fractions

The 13C recovery in whole soil and aggregate-size fractions at 0.1 m depth increased (P < 0.05) over time, while the 15N recovery in these soil fractions decreased (P < 0.001) over time (Fig. 7; Table 1). Two days after labelling, the recovery of 13C was the highest in macro-aggregates (0.7–1.5%), followed by micro-aggregates (0.4–0.5%) and mega-aggregates (0.15–0.21%). Similarly, the recovery of soil 15N in macro-aggregates was the highest (23–35%) on day two, while 16–19% and 14–19% of the 15N was recovered in the micro-aggregates and mega-aggregates, respectively (Fig. 7). At harvest, the recovery of 13C was in the order of macro-aggregates (1.4–3.0%) > micro-aggregates (0.6–1.0%) > mega-aggregates (0.3–0.45) (Fig. 7). Similarly, the soil 15N recovery was 11–18% in macro-aggregates, 10–11% in micro-aggregates, and 3–6% in mega-aggregates. Both tillage (P < 0.05) and N fertilization (P < 0.05) increased the 13C recovery in macro-aggregates. However, tillage and fertilization, and their interaction with time had no effects on the 13C recovery in mega- and micro-aggregates (Table 1). Both tillage (P < 0.05) and fertilization (P < 0.05), and their interaction with time (P < 0.05) had significant effects on 15N recovery in mega- and macro–aggregates, while only tillage (P < 0.05) or fertilization (P < 0.01) had significant effects on 15N recovery in micro-aggregates. Overall, T–100 had the highest 15N recovery in all the aggregate-size fractions over time.

Relative proportion (%) of the pulse-added 13CO2-C and urea-15N recovered in composite soil (a,e) and in different dry aggregate-size fractions (b,c,d and f,g,h) at 0–0.1 m soil depth from canola flowering to harvesting stage as affected by tillage (T) and no-till (NT) with or without 100 kg urea-N ha−1 (i.e. T-0, T-100, NT-0, NT-100). Error bars are ± standard errors (n = 3). Vertical black bars show least significant differences (at 5% level, LSD0.05) at different time points.

Discussion

Relationships between C and N allocation and assimilation in canola–soil system

This is one of the first field-based studies to provide insights into the impact of tillage intensity and N fertilization on the relationships between belowground C allocation and plant N uptake in a dryland canola crop–soil system. A simultaneous 13C– 15N isotopic approach was employed to trace the short-term dynamics of new C and N allocation and assimilation at the critical growth stages of canola, i.e. from flowering to harvest. We found that tillage intensity and N fertilization influenced belowground C allocation, root-microbial interactions and plant N uptake, possibly driven by changes in C source–sink relations among the aboveground and belowground pools3. For example, the T–100 resulted in significantly greater new C allocation to the belowground pools and significantly greater new N translocation to the aboveground pools over time, relative to the other treatments (Figs 1, 2 and 3), thereby confirming our first hypothesis. One of the mechanisms for the greatest belowground C allocation and plant N uptake is that the T–100 increased tap root biomass and net 13C recovery in both tap and fine roots, relative to any other treatments (Fig. 5), thus suggesting exploration of a greater soil volume, which is likely to enhance N uptake. Root activity and growth can also be associated with simultaneous release of energy rich root exudates, such as carbohydrates, amino acids and organic acids in soil44, 45. It is known that these energy rich root exudates are an important source of C for soil microorganisms46 stimulating microbial activity and growth, particularly in the root zone, and also in the surface soil layers (Fig. S3) that received a higher proportion of plant C inputs than deeper layers (Fig. 5).

There was a rapid and significant belowground C allocation, as indicated by 4–6% recovery of the 13C to 0.3 m depth within two days after pulse labelling (Fig. 3). These results agreed with previous studies that reported immediate allocation of new C to belowground pools, reaching a maximum within one to two days7, 22, 23. Our C recovery data in the whole plant–soil system indicate that 21–39% of the added 13C was lost from the system within two days (Fig. 3). This could be attributed to a loss of some 13CO2 during brief opening of the chamber four hours after pulse-labelling, and via plant and soil respiration.

Literature suggests that stimulation of microbial activity can facilitate greater microbial uptake of soil-released N4, 47. Consistently, our data on the dynamics of microbial 15N showed that on day two, the simulated soil-released N was rapidly taken up by microbial biomass (26–61%) across different treatments. Similarly, Grogan and Jonasson48 and Nordin et al.49 reported a significant uptake, 24–47% of soil-applied 15N, by soil microbial biomass. We also observed the greatest uptake of 15N in microbial biomass in the fertilized vs. non-fertilized treatments (P < 0.001), which is consistent with our second hypothesis that fertilization will increase soil mineral N uptake by microbes. Overall, tillage (cf. NT), and also T–100 (cf. NT–100) on day two, enhanced microbial uptake of soil 15N in our study, but only at 10% level of significance (Fig. 6; Table 1). As microbial activity will be constrained by N availability in drylands, tillage and tillage–N fertilization may enhance microbial activity and acquisition of SOM-released N for their cell synthesis50. After the initial uptake, the decreased recovery of 15N in microbial biomass with time (Fig. 6) was most likely due to its rapid turnover and consequent release of microbial-immobilized 15N for uptake by plant roots. Greater uptake of soil-released N by plant roots is likely possible when a mutualistic relationship between microbes and roots is enhanced, for example, through implementing management practices that cause greater belowground C allocation, with implications for enhanced N use efficiency, alleviation of N limitation for plant growth, and mitigation of soil N losses4, 51. Our study showed significant uptake of soil 15N by the plants over time (i.e. from 5 to 56%), which was greater in the T–100 cf. other treatments (Fig. 3). Furthermore, 15N retention in the soil at harvest was also greater in the T–100 cf. other treatments (Fig. 3). Thus, these results suggest that the T–100 that enhanced microbial activity, including through greater belowground C allocation, possibly facilitated rapid soil N utilisation by microorganisms to meet their N requirements, while enhancing plant N uptake, with potential to minimize N losses via leaching and emissions4, 52.

In our study, the allocation of new C was the highest in the flower + pod on day two, as also indicated by the 13Catom% excess (Fig. S4), which decreased rapidly over time, possibly due to translocation to the other aboveground and belowground pools (Figs 1 and S4), and loss via respiration7, 53, 54. As belowground C allocation would support plants to take up soil-released N, which is important for the development of aboveground organs, we observed greater translocation of 15N to flowers and pods (cf. shoots), as indicated by the 15Natom% excess across all of the treatments (Fig. S5). Clearly, the T–100 resulted in the highest recovery of soil 15N in the seeds at harvest (Fig. 3). Although the fertilized system, whether T or NT, had higher mineral N in the top (Fig. S6b) and deeper soil layers (data not presented), belowground C allocation and plant N uptake were the greatest in T–100 vs. NT–100 (Fig. 3). This highlights the importance of tillage (vs. soil N availability) in enhancing belowground C allocation, microbial activity, and plant N uptake43, while supporting structural and reproductive organs. In this study, we also observed a significant positive correlation (P < 0.05) between seed yield and belowground C allocation, or seed yield and crop N uptake (Fig. 4), and the T–100 resulted in the highest seed yield (Fig. S1). Tillage and N fertilization may also improve canola seed quality through increasing oil and crude protein in seed14.

Our study found relatively low belowground C allocation (i.e. only 4–10% of the 13C was allocated belowground to 0.3 m depth at the reproductive stages, i.e. from flowering to pod filling and maturity; Fig. 3). These results are consistent with other studies that also reported low belowground C allocation at reproductive stages, while allocating a maximum amount of assimilates to aboveground reproductive organs21, 34, 55, 56. Additionally, low root-to-shoot C ratio (0.11–0.15) (Table S2) may have caused a net decrease in belowground allocation of 13C in our study. In contrast, other studies reported a relatively high allocation of newly assimilated C into belowground pools. For example, depending on plant species, root-to-shoot C ratio (low or high), and plant growth stages (vegetative vs. reproductive), up to 10–40% of photo-assimilated C was recovered in soil up to 0.20 m depth10, 15, 44, 57, 58.

In the current study, C and N allocation values in the crop–soil were, however, higher than the values reported by another field study in a semi-arid dryland environment, which showed 1.3−1.8% of the new 13C allocated belowground to 0.3 m depth and 0.5–0.7% of soil-applied 15N translocated aboveground from the flowering to grain harvesting of wheat7. The differences could be due to an even distribution of rainfall that resulted in higher gravimetric soil moisture in our study site (8–16% vs. 4–8%) than examined by Fang et al.7 during the C–N chasing period. This might have alleviated the influence of aridity constraints on root activity, belowground C allocation, microbial activity and plant N uptake7, 18, 59. Furthermore, canola tends to have a more extensive root system in the top soil layers than wheat in a semi-arid dryland environment60.

To our knowledge, there is no field-based study that has examined allocation of newly assimilated C to 1 m soil depth. We found that of the total fine root biomass recovered at harvest, 87–91% was distributed in the top (0–0.3 m) and 9–13% in the deeper (0.3–1 m) soil layers (Fig. 5). Of the total recovered 13C in the soil profile in fine roots (i.e. 9–13% of added 13C to 1 m depth), a significant proportion (46%) was recovered in the 0.3–1 m layer (Fig. 3c), despite fine roots biomass in the deeper soil layers was low (Fig. 5). Interestingly, both tap root biomass and 13C allocation in tap root and fine root (to 1 m) were higher in the T–100 than the other treatments (Fig. 5). Thus, our study suggests that tillage with N fertilization in the semi-arid region may facilitate more root growth and new belowground C allocation to top and deeper soil layers over time61. These plant processes may then assist in better acquisition of nutrients (such as N) and deep soil water to support grain production, while increasing retention of plant-derived C, likely due to lower microbial activity, in deeper soil layers35, 36.

Carbon and nitrogen allocation and stabilization in aggregate-size fractions

Several studies have examined allocation and stabilization of added isotopically-labelled organic C substances in different aggregate-size fractions26, 62 that vary in their stability and stabilization of C, for example, micro-aggregates > macro- or mega aggregates24, 63. To our knowledge, only Fang et al.7 reported the impact of management practices on the stabilisation dynamics of belowground 13C allocation and soil-released 15N in aggregate-size fractions over time under field conditions. Consistent with the study of Fang et al.7, there were no significant interactive effects of the contrasting tillage and N fertilization practices on the allocation and stabilization of new 13C and 15N in the aggregate-size fractions (Fig. 7). Meanwhile, we observed rapid (within two days) allocation and distribution of the belowground 13C and 15N among all aggregate-size fractions, which was higher in macro-aggregates than micro- and mega-aggregates (Fig. 7). This pattern of 13C recovery in the aggregate-size fractions could be due greater association of belowground allocated 13C, and the fate of most of the fine roots during dry sieving, in macro-aggregates (vs. the other aggregate-size fractions), as confirmed by the highest 13Catom% excess (Fig. S7). Although 15N recovery was highest in macro-aggregates, the relatively high 15Natom% excess in mega-aggregates (cf. macro- and micro-aggregates) could be due rapid distribution of water-soluble 15N in pore spaces of mega-aggregates after soil 15N application (Fig. S7). The increased 13C recovery among all aggregate-size fractions over time could be related to the pattern of belowground C allocation. Additionally, there could be some retention of new root- and microbial-derived C in all aggregate-size fractions over time7, 64, 65. Although the T–100 resulted in higher belowground 13C allocation and recovery of the tracer 15N in whole soil (Fig. 3) and macro-aggregates (Fig. 7) over time, and also higher total C and N contents in macro-aggregates (Fig. S8), there was no difference in the total C and N stocks in the soil profile to 1 m depth across the management practices at the harvesting stage (Tables S3 and S4). This could be due to rapid decomposition of relatively labile (new inputs) root-derived organic matter by soil microbes with limited stabilization in soil micro-aggregates. Our results showed limited impact of the short-term tillage and N fertilization practices on soil C, soil N and soil aggregate stability (Tables S3 and S4; Fig. S6a). These results agreed with the findings of some other studies that also showed no or limited impact of long-term tillage intensity and/or N fertilization, or other improved management practices (such as reduced tillage and inclusion of pasture in crop rotations) on soil structural stability and/or the accumulation of C and N in soils under semi-arid or subtropical regions in Australia7, 66, 67.

In conclusion, our field-based study employed a novel simultaneous stable C and N pulse labelling approach to investigate the influence of contrasting tillage intensity and N fertilization on important coupled plant and soil processes, with implication for N use efficiency and crop yield. We found that during the reproductive stage of canola, management practices that allocated greater C belowground also enhanced plant N uptake. Specifically, tillage along with N fertilization enhanced the activity of belowground pools (i.e. roots and microbes) to facilitate the linkages between C and N allocation and assimilation, with implication for crop N use efficiency and seed production. In this two-year crop rotation experiment, although macro-aggregates retained more new 13C and 15N than micro- and mega-aggregates, soil structure stability and SOC stocks were not impacted by tillage intensity and N fertilization. Our research findings suggest that in Australian dryland conditions, tillage (e.g. when operated to shallow depths) combined with N fertilization can have minimal negative impact on soil structure or other soil properties, while creating a favourable environment for plant and microbial growth/activity, and may enhance belowground C allocation, crop N uptake and seed production of canola. Further research is needed over longer periods, and under different cropping systems, soil types and environments, to determine implications of changes in C–N allocation for soil C accumulation, N use efficiency and crop yield from low-intensity tillage operations.

Methods

Site description and experimental design

The field site is located in Wagga Wagga, New South Wales, Australia (35°01′45″S and 147°20′36″E; 210 m a.s.l), with the long-term average rainfall of 541 mm. The soil is a Chromic Luvisol (FAO classification), with a sandy clay loam texture, 5.8 pH, 1.5% total C, and 0.14% total N in the top 0–0.1 m soil layer (see further details in Table S1). Before commencing the tillage–N fertilization experiment in 2012, the site was cropped using no-till or minimal tillage for ~5 years. Canola (Brassica napus ‘Hyola 555’) was sown on 20 May 2013 after wheat in the second year of the experiment. The experimental design was a randomised split-plot design with the tillage treatments as the main plot and N application rates as the subplot (5.0 m width × 9.0 m length), replicated three times. Stubble was slashed after the previous crop harvest in both tillage and no-till plots. The tillage plots were cultivated to 0.1 m depth with a scarifier in both directions and then harrowed twice to mix stubble with soil before sowing of canola. At sowing, all plots received 5 kg N ha−1 as urea. The remaining amount of urea (95 kg N ha−1) was top dressed before stem elongation, 74 days after sowing14 (See Supplementary Information, SI).

In situ 15N and 13C pulse labelling

In this study, we selected 12 subplots (5.0 m width × 3.0 m length) across four treatments [0 or 100 kg N ha−1 under tillage (T-0 or T-100) or no-till (NT-0 or NT-100)]. Each of the selected subplots was divided into two equal microplots (2.5 m width × 3.0 m length; 10 canola rows each). One microplot was labelled with urea-15N at the flowering stage and the other was kept as a control, which did not receive any N or C supplement. For the 15N labelling, the soil surface of each microplot was uniformly sprayed with 12.0 l of urea solution at 0.2 g urea-N m−2 (99.0 atom% 15N, Sercon Ltd, Crewe, UK). Within each of the 15N-labelled microplots, a smaller microplot (1.5 m width × 2.0 m length; 6 canola rows) was pulse labelled with 13CO2 (equivalent to 0.89 g CO2-C m−2) within 20 h after the application of urea-15N.

For the 13C pulse labelling, the smaller microplot was sealed with a portable polyvinyl chloride (PVC) chamber (1.5 m width × 2 m length × 1.3 m height), comprising 25 mm thick PVC tube frame covered with 200 µm clear high density polyethylene sheet (Gro-tuff HDPE, 89% light transmission, Cheltenham, Australia). The excess sheet was buried inside soil ditches (10 cm deep) to seal the chamber. The canola plants within each of the sealed chambers were pulse labelled with 5 l 13CO2 (99.0 atom%, Cambridge Isotope Laboratories, USA). Six microplots across the tillage treatments were labelled on the 9th (15N) and 10th (13C) September 2013 and the remaining six microplots across the no-till were pulse labelled on the 10th (15N) and 11th (13C) September. On these two days, the weather was similar (partly cloudy), with the air temperature of 26–27 °C and the minimum and maximum photosynthetic active radiation of ca. 400 to 5000 μmol photons m−2 s−1 during the 4 h 13CO2 pulse labelling period. Between 11:00 h and 12:00 h, the 13CO2 was injected at ~500 cm3 min−1 in each of the chambers through a flow meter (S325-15-170-F/M CO2, Influx Duff and Macintosh, Gascon Systems, Sydney). Chamber air was circulated by a battery-operated mini-fan. The total CO2 concentration inside the chamber was monitored using a CO2 probe (Vaisala GMP 343, Finland), which dropped to ~250 μl l−1 before the injection of 13CO2 and then temporarily increased to ~500 μl l−1 within 10 min after pulse labelling. Between 15:30 and 16:00 h, when the total CO2 inside the chamber had dropped to near the compensation point (ca. 100–120 μl l−1) and the air temperature increased to 38 °C, a portion of the chamber was opened for 30 min to bring the temperature below 30 °C, while increasing the CO2 to ~300 μl l−1. The chambers were then resealed to capture 13CO2 respired overnight by canola. The chambers were removed the following morning when the night-accumulated CO2 decreased to ~100 μl l−1.

Plant and soil sampling, processing and analysis

Plant and soil samples, representing aboveground and/or belowground pools, were collected before labelling (day zero) and then at 2, 9, 15, 30 and 45 days after labelling. These pools were also collected from the non-labelled plots at seed harvest. At each sampling time, three canola plants were separated into tap roots, leaves, stems, and flowers/pods. At harvest, the pod was separated into pod shell and seed. Seed yield was calculated in t ha−1 (see SI Fig. S1). The plant parts were oven-dried at 70 °C soon after sampling, ground using a MM 400 Mixer Mill grinder (Retsch GmbH, Germany) and stored. Biomass yield (g m−2) for leaves, stems, flowers/pods (shell and seed at harvest), tap and fine roots was estimated (see SI).

Soil samples were collected on day zero, and then on 2, 9, 15, and 30 days after 13C 15N labelling using a soil core sampler (cutting head diameter of 6.35 cm), four cores per plot, at 0–0.1, 0.1–0.2, and 0.2–0.3 m depths. At harvest, soil samples were collected from the labelled and control plots to 1 m depth using a hydraulic corer (cutting head diameter of 4.4 cm), six cores per plot, sectioned and composited for each layer (0-0.1, 0.1–0.2, 0.2–0.3, 0.3–0.7 and 0.7–1.0 m). The soil samples were then divided into two portions which were either stored at 4 °C or −18 °C. Fine roots from each soil depth (sampled at day zero, 2, 9, 15, 30 and 45) were separated from the frozen soil by wet sieving and hand picking using tweezers. Soil bulk density was measured at 45 days (Fig. S9).

A subsample of the refrigerated soil was air-dried to ca. 20% of water holding capacity within a week, and gently passed through a 6.5 mm sieve. All visible shoot debris, coarse roots and gravels (>2 mm) were removed. Aggregates were separated into five size classes: 2–6.5 mm, 1–2 mm, 0.25–1 mm, 0.25–0.053 mm and <0.053 mm using a Vibratory Sieve-Shaker “Analysette 3”. Mean weight diameter (MWD) of the dry aggregate-size fractions was calculated by multiplying the soil proportion in each aggregate-size class by the mid-point of the size class68. Subsamples of macro-aggregates (0.25−2 mm) and micro-aggregates (<0.25 mm) were obtained by mixing the relevant fractions. Subsamples from mega-aggregates ( > 2 mm), macro-aggregates, micro-aggregates and whole soil were further dried at 60 °C for 16 h and ground (<125 μm).

After sieving (<4.75 mm) and removing plant debris, roots and gravels from the refrigerated soil microbial biomass C (MBC) and N (MBN) were measured by the chloroform fumigation-extraction procedure69, 70 (see SI). To track the fate of new C and N in microbial biomass, a 20 ml subsample of the 0.125 M K2SO4 extract (fumigated and non-fumigated) from day 0, 2, 15 and 45 sampling was oven dried at 60 °C and ground. The δ13C and δ15N of soil microbial biomass were calculated as per An et al.10 (see SI).

The ground, well-dried, plant (all the aboveground and belowground biomass), soil, (including aggregate) and K2SO4 samples were analyzed for C%, N%, δ 13C and/or δ 15N at the University of California’s Stable Isotope Facility, Davis, CA, USA. Standard deviations are 0.02–0.08‰ for δ 13C and 0.15–0.30‰ for δ 15N using a PDZ Europa 20-20 isotope ratio mass spectrometer (Sercon Ltd., Cheshire, UK). Mineral NH4 + and NO3 − were analyzed in the 0.125 M K2SO4 extracts from the non-fumigated soil samples by a SEAL AQ2 Analyzer (SEAL Analytical, Maquon, WI, USA). The δ 13C and δ 15N values of the control plant and soil samples (non-labelled; NL) collected at different sampling days (i.e. day zero and 45 days) were similar when comparing across each of the plant or the soil pools (see SI).

Recovery of added 13C and 15N in crop–soil system

After calculating the atom% of 13C and 15N in various measured pools (SI), the following Equations 1–3 were used to estimate 13C and 15N recovery in the crop–soil system. As calculations are the same for 13C and 15N, only the 13C calculations are presented below.

The enrichment of 13C in a sample after pulse labelling at a specific time (13Catom% excess, t) was calculated:

where 13CL,t is the 13Catom% of a sample from the labelled micro-plots at time t (t = two, nine, 15, 30, or 45) and 13CNL is the 13Catom% of the corresponding sample from the non-labelled (natural abundance) micro-plots.

The amount of 13C (g m−2) incorporated into each of the aboveground and belowground C pools at time t after pulse labelling (13Ci, t) was calculated:

where C i,t is the amount of C (g m−2) in each of the measured pools (i = leaf, stem, pods, pod shell, seed, tap root, fine root, soil, soil microbial biomass) at time t.

The weighted 13C recovery (13Crec i, t %) in each of the measured C pools at time t after pulse labelling was calculated as the percentage of total mass of added 13C (g C m−2) via pulse labelling.

The total 13C recovery (%) in the crop–soil system at a specific time was calculated by summing 13Crec i,t across all pools and/or soil depths except for the 13Crec i,t in the microbial biomass C (MBC) and dissolved organic C (DOC) pools, which is part of the soil 13C.

The calculations for the amount (g N m−2) of C and N in plant biomass, microbial biomass, and soil pools, including in aggregate-size fractions, are presented in SI.

Statistical analysis

Repeated measures analysis was performed for 13C and 15N partitioning in aboveground and belowground pools and soil properties over time using a linear mixed model. Each analysis consisted of fixed effects of tillage, fertilizer, time, and all interactions, and random effects of replicate, main plot (defined as tillage by replicate) and their interactions with time, and either plot effects or autoregressively correlated residual errors within plots, and with heterogeneous residual variances varying with time. For C and N stocks in pools, a linear mixed model was fitted with fixed effects of tillage, fertilizer and their interactions, and random effects of replicate and main plot. The degree of relationships between seed yield and belowground C allocation, or crop N uptake (i.e. aboveground N allocation), was examined using scatter plots with associated (Pearson) correlations. All models were fitted in the ASReml statistical package71 within the R statistical software environment72. Wald-type F statistics were calculated for all fixed terms (tillage, fertilizer, time and all associated interactions); predicted means for fertilizer by tillage by time are shown with 5% LSD at each time point.

References

Larcher, W. Physiological plant ecology, 4th edn. Berlin, Germany: Springer (2003).

Bahn, M. et al. Responses of belowground carbon allocation dynamics to extended shading in mountain grassland. New Phytol. 198, 116–126 (2013).

Andersen, C. P. Source–sink balance and carbon allocation below ground in plants exposed to ozone. New Phytol. 157, 213–228 (2003).

Kuzyakov, Y. & Xu, X. Competition between roots and microorganisms for nitrogen: mechanisms and ecological relevance. New Phytol. 198, 656–669 (2013).

Bahn, M., Schmitt, M., Siegwolf, R., Richter, A. & Bruggemann, N. Does photosynthesis affect grassland soil-respired CO2 and its carbon isotope composition on a diurnal timescale? New Phytol. 182, 451–460 (2009).

Sanaullah, M., Chabbi, A., Rumpel, C. & Kuzyakov, Y. Carbon allocation in grassland communities under drought stress followed by 14C pulse labeling. Soil Biol. Biochem. 55, 132–139 (2012).

Fang, Y., Singh, B. P., Badgery, W. & He, X. In situ assessment of new carbon and nitrogen assimilation and allocation in contrastingly managed dryland wheat crop–soil systems. Agric. Ecosys. Environ. 235, 80–90 (2016).

Kuzyakov, Y. & Gavrichkova, O. Time lag between photosynthesis and carbon dioxide efflux from soil: a review of mechanisms and controls. Glob. Chang. Biol. 16, 3386–3406 (2010).

Epron, D. et al. Pulse-labelling trees to study carbon allocation dynamics: a review of methods, current knowledge and future prospects. Tree Physiol. 32, 776–798 (2012).

An, T. T. et al. Carbon fluxes from plants to soil and dynamics of microbial immobilization under plastic film mulching and fertilizer application using 13C pulse-labeling. Soil Biol. Biochem. 80, 53–61 (2015).

Cassman, K. G., Dobermann, A. R. & Walters, D. T. Agroecosystems, Nitrogen-use Efficiency, and Nitrogen Management. Agronomy & Horticulture, Faculty Publications. Paper 356. http://digitalcommons.unl.edu/agronomyfacpub/356 (2002).

Pimentel, D., Hepperly, P., Hanson, J., Douds, D. & Seidel, R. Environmental, energetic, and economic comparisons of organic and conventional farming systems. BioScience 55, 573–582 (2005).

Powlson, D. S. et al. The potential to increase soil carbon stocks through reduced tillage or organic material additions in England and Wales: a case study. Agric. Ecosys. Environ. 146, 23–33 (2012).

Li, G. D. et al. Tillage does not increase nitrous oxide emissions under dryland canola (Brassica napus L.) in a semiarid environment of south-eastern Australia. Soil Res. 54, 512–522 (2016).

Ge, T. et al. Tracking the photosynthesized carbon input into soil organic carbon pools in a rice soil fertilized with nitrogen. Plant Soil. doi:10.1007/s11104-014-2265-8 (2014).

Smith, J. & Elliott, L. Tillage and residue management effects on soil organic matter dynamics in semiarid regions. Adv. Soil Sci. 13, 69–88 (1990).

Maestre, F. T. et al. Increasing aridity reduces soil microbial diversity and abundance in global drylands. Proc. Natl. Acad. Sci. 112, 15684–15689 (2015).

Hasibeder, R., Fuchslueger, L., Richter, A. & Bahn, M. Summer drought alters carbon allocation to roots and root respiration in mountain grassland. New Phytol. 205, 1117–1127 (2015).

Yasmin, K., Cadisch, G. & Baggs, E. M. The significance of below-ground fractions when considering N and C partitioning within chickpea (Cicer arietinum L.). Plant Soil 327, 247–259 (2010).

Putz, B. et al. A simple method for in situ-labelling with 15N and 13C of grassland plant species by foliar brushing. Methods Ecol. Evol. 2, 326–332 (2011).

Hafner, S. et al. Effect of grazing on carbon stocks and assimilate partitioning in a Tibetan montane pasture revealed by 13CO2 pulse labelling. Glob. Chang. Biol. 18, 528–538 (2012).

Leake, J. R., Ostle, N. J., Rangel-Castro, J. I. & Johnson, D. Carbon fluxes from plants through soil organisms determined by field 13CO2 pulse-labelling in an upland grassland. Appl. Soil Ecol. 33, 152–175 (2006).

Studer, M., Siegwolf, R. & Abiven, S. Carbon transfer, partitioning and residence time in the plant-soil system: a comparison of two 13CO2 labelling techniques. Biogeosciences 11, 1637–1648 (2014).

Six, J., Bossuyt, H., Degryze, S. & Denef, K. A history of research on the link between (micro) aggregates, soil biota, and soil organic matter dynamics. Soil Tillage Res. 79, 7–31 (2004).

Six, J., Conant, T., Paul, A. & Paustian, K. Stabilization mechanisms of soil organic matter: implications for C-saturation of soils. Plant Soil 241, 155–176 (2002).

Zhang, H., Ding, W., Luo, J., Bolan, N. & Yu, H. The dynamics of glucose-derived 13C incorporation into aggregates of a sandy loam soil following two-decade compost or inorganic fertilizer amendments. Soil Tillage Res. 148, 14–19 (2015).

Kong, A. Y. Y., Six, J., Bryant, D. C., Denison, R. F. & van Kessel, C. The relationship between carbon input, aggregation, and soil organic carbon stabilization in sustainable cropping systems. Soil Sci. Soc. Am. J. 69, 1078–1085 (2005).

Kihara, J., Bationo, A., Mugendi, D. N., Martius, C. & Vlek, P. L. G. Conservation tillage, local organic resources and nitrogen fertilizer combinations affect maize productivity, soil structure and nutrient balances in semi-arid Kenya. Nutri. Cycl. Agroecosyst. 90, 213–225 (2011).

ABS, 7121.0—Agricultural Commodities, Australia, 2014–15. Australian Bureau of Statistics (2016).

Statistics Canada, 2011 census of agriculture. http://www.statcan.gc.ca/ca-ra2011. Accessed 7 November 2012 (2011).

Barton, L., Murphy, D. V., Kiese, R. & Butterbach-Bahl, K. Soil nitrous oxide and methane fluxes are low from a bioenergy crop (canola) grown in a semi-arid climate. Glob. Chang. Biol. Bioenergy 2, 1–15 (2010).

Grant, C. A. & Bailey, L. D. Fertility management in canola production. Can. J. Plant Sci. 73, 651–670 (1993).

Singh, B. P., Rengel, Z. & Bowden, J. W. Carbon, nitrogen and sulphur cycling following incorporation of canola residue of different sizes into a nutrient-poor sandy soil. Soil Biol. Biochem. 38, 32–42 (2006).

Meng, F. et al. Investigation of photosynthate-C allocation 27 days after 13C-pulse labeling of Zea mays L. at different growth stages. Plant Soil 373, 755–764 (2013).

Lynch, P. J. & Wojciechowski, T. Opportunities and challenges in the subsoil: pathways to deeper rooted crops. J. Expt. Bot. 66, 2199–2210 (2015).

Lopes, M. S. & Reynolds, M. P. Partitioning of assimilates to deeper roots is associated with cooler canopies and increased yield under drought in wheat. Funct. Plant Biol. 37, 147–156 (2010).

Hobbs, P. R. Conservation agriculture: what is it and why is it important for future sustainable food production? J. Agric. Sci. 145, 127–137 (2007).

Chauhan, B. S., Gill, G. S. & Preston, C. Tillage system effects on weed ecology, herbicide activity and persistence: a review. Aust. J. Expt. Agric. 46, 1557–1570 (2006).

Busari, M. A., Kukal, S. S., Kaur, A., Bhatt, R. & Dulazi, A. A. Conservation tillage impacts on soil, crop and the environment. Int. Soil Water Conserv. Res. 3, 119–129 (2015).

Zhang, S., Li, Q., Lü, Y., Zhang, X. & Liang, W. Contributions of soil biota to C sequestration varied with aggregate fractions under different tillage systems. Soil Biol. Biochem. 62, 147–156 (2013).

Lal, R. Sequestering carbon and increasing productivity by conservation agriculture. J. Soil Water Conserv. 70, 55A–62A (2015).

Kuzyakov, Y., Siniakina, S. V., Ruehlmann, J., Domanski, G. & Stahr, K. Effect of nitrogen fertilisation on below-ground carbon allocation in lettuce. J. Sci. Food Agric. 82, 1432–1441 (2002).

Zhu, B., Panke-Buisse, K. & Kao-Kniffin, J. Nitrogen fertilization has minimal influence on rhizosphere effects of smooth crabgrass (Digitaria ischaemum) and bermudagrass (Cynodon dactylon). J. Plant Ecol. doi:10.1093/jpe/rtu034 (2014).

Hütsch, B. W., Augustin, J. & Merbach, W. Plant rhizodeposition – an important source for carbon turnover in soils. J. Plant Nutr. Soil Sci. 165, 397–407 (2002).

Jones, D. L., Nguyen, C. & Finlay, R. D. Carbon flow in the rhizosphere: carbon trading at the soil–root interface. Plant Soil 321, 5–33 (2009).

Koranda, M. et al. Microbial processes and community composition in the rhizosphere of European beech – The influence of plant C exudates. Soil Biol. Biochem. 43, 551–558 (2011).

Song, M. H. et al. Interactions of plant species mediated plant competition for inorganic nitrogen with soil microorganisms in an alpine meadow. Plant Soil 297, 127–137 (2007).

Grogan, P. & Jonasson, S. Controls on annual nitrogen cycling in the understory of a subarctic birch forest. Ecology 84, 202–218 (2003).

Nordin, A., Schmidt, I. K. & Shaver, G. R. Nitrogen uptake by arctic soil microbes and plants in relation to soil nitrogen supply. Ecology 85, 955–962 (2004).

Chen, R. et al. Soil C and N availability determine the priming effect: microbial N mining and stoichiometric decomposition theories. Glob. Chang. Biol. 20, 2356–2367 (2014).

Reynolds, H. L., Packer, A., Bever, J. D. & Clay, K. Grass roots ecology: plant–microbe–soil interactions as drivers of plant community structure and dynamics. Ecology 84, 2281–2291 (2003).

Louise, C., Andresen, Jonasson, S., Ström, L. & Michelsen, A. Uptake of pulse injected nitrogen by soil microbes and mycorrhizal and non-mycorrhizal plants in a species-diverse subarctic heath ecosystem. Plant Soil 313, 283–295 (2008).

Hill, P. W. et al. The fate of photosynthetically-fixed carbon in Lolium perenne grassland as modified by elevated CO2 and sward management. New Phytol. 173, 766–777 (2007).

Wang, Y. et al. Carbon budget of a winter-wheat and summer-maize rotation cropland in the North China Plain. Agric. Ecosys. Environ. 206, 33–45 (2015).

Kuzyakov, Y., Kretschmar, A. & Stahr, K. Contribution of Lolium perenne rhizodeposition to carbon turnover of pasture soil. Plant Soil 213, 127–136 (1999).

Jin, J. et al. Seasonal allocation of photosynthetically fixed carbon to the soybean-grown Mollisols in Northeast China. Crop Pasture Sci. 62, 563–570 (2011).

Zagal, E. Carbon distribution and nitrogen partitioning in a soil-plant system with barley (Hordeum vulgare L.), ryegrass (Lolium perenne) and rape (Brassica napus L.) grown in a 14CO2-atmosphere. Plant Soil 166, 63–74 (1994).

Atwell, B., Fillery, I., McInnes, K. & Smucker, A. The fate of carbon and fertiliser nitrogen when dryland wheat is grown in monoliths of duplex soil. Plant Soil 241, 259–269 (2002).

Ruehr, N. K. et al. Drought effects on allocation of recent carbon: from beech leaves to soil CO2 efflux. New Phytol. 184, 950–961 (2009).

Eberbach, P. L., Hoffmann, J., Moroni, S. J., Wade, L. J. & Weston, L. A. Rhizo-lysimetry: facilities for the simultaneous study of root behaviour and resource use by agricultural crop and pasture systems. Plant Methods 9, 3 (2013).

Guan, D. et al. Tillage practices effect on root distribution and water use efficiency of winter wheat under rain-fed condition in the North China Plain. Soil Tillage Res. 146, 286–295 (2015).

Angers, D. A., Recous, S. & Aita, C. Fate of carbon and nitrogen in water-stable aggregates during decomposition of 13C, 15N-labelled wheat straw in situ. Eur. J. Soil Sci. 48, 295–300 (1997).

Besnard, E., Chenu, C., Balesdent, J., Puget, P. & Arrouays, D. Fate of particulate organic matter in soil aggregates during cultivation. Eur. J. Soil Sci. 47, 495–503 (1996).

Sanaullah, M. et al. Decomposition and stabilisation of root litter in top– and subsoil horizons: what is the difference? Plant Soil 338, 127–141 (2011).

Cotrufo, M. F., Wallenstein, M. D., Boot, C. M., Denef, K. & Paul, E. The Microbial Efficiency‐Matrix Stabilization (MEMS) framework integrates plant litter decomposition with soil organic matter stabilization: do labile plant inputs form stable soil organic matter? Glob. Chang. Biol. 19, 988–995 (2013).

Crawford, M. H. et al. Changes in the soil quality attributes of continuous no-till farming systems following a strategic tillage. Soil Res. 53, 263–273 (2015).

Dalal, R. C., Allen, D. E., Wang, W. J., Reeves, S. & Gibson, I. Organic carbon and total nitrogen stocks in a Vertisol following 40 years of no-tillage, crop residue retention and nitrogen fertilisation. Soil Tillage Res. 112, 133–139 (2011).

Devine, S., Markewitz, D., Hendrix, P. & Coleman, D. Soil aggregates and associated organic matter under conventional tillage, no-tillage, and forest succession after three decades. PLoS One 9(1), e84988 (2014).

Gregoricha, E. G., Liang, B. C., Drury, C. F., Mackenzie, A. F. & McGill, W. B. Elucidation of the source and turnover of water soluble and microbial biomass carbon in agricultural soils. Soil Boil. Biochem. 32, 581–587 (2000).

Brookes, P. C., Landman, A., Pruden, G. & Jenkinson, D. S. Chloroform fumigation and the release of soil nitrogen: a rapid direct extraction method to measure microbial biomass nitrogen in soil. Soil Biol. Biochem. 17, 837–842 (1985).

Butler, J. L., Bottomley, P. J., Griffith, S. M. & Myrold, D. D. Distribution and turnover of recently fixed photosynthate in ryegrass rhizospheres. Soil Biol. Biochem. 36, 371–382 (2004).

R Team. R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. 2013. ISBN 3-900051-07-0, http://www.R-project.org (2014).

Acknowledgements

This research is supported by a GRDC project (DAN00169). We thank Adam Lowrie, Richard Lowrie, Khushbu Gandhi, Rebecca Coburn, and Michael McLean for technical assistance in the field and/or laboratory. The site is supported by funding from the Federal Department of Agriculture, Australia.

Author information

Authors and Affiliations

Contributions

J.R.S., B.P.S., X.H., Y.F., and G.D.L. planned and designed the research, performed experiments, and conducted fieldwork. J.R.S., B.P.S., Y.F., X.H., and D.C. analysed data. J.R.S., B.P.S., Y.F., A.L.C., X.H., D.C., G.D.L. wrote the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sarker, J.R., Singh, B.P., He, X. et al. Tillage and nitrogen fertilization enhanced belowground carbon allocation and plant nitrogen uptake in a semi-arid canola crop–soil system. Sci Rep 7, 10726 (2017). https://doi.org/10.1038/s41598-017-11190-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-11190-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.