Abstract

Random copolymers of l-lactic acid (LLA) and glycolic acid (GA) [P(LLA-GA)] with 0–100 mol% LLA units in the polymers were synthesized and their crystallization behavior was investigated by two representative crystallization methods of precipitation or melt-crystallization. P(LLA-GA) copolymers with LLA unit contents in the ranges of 0–20 and 73–100 mol% were crystallizable during precipitation or melt-crystallization. Surprisingly, these crystallizable ranges are similar to those reported for P(LLA-GA) copolymers synthesized by ring-opening polymerization of cyclic dimers (l-lactide and glycolide), which should have monomer sequence lengths twice those of the P(LLA-GA) copolymers synthesized by polycondensation of the monomers (LLA and GA) in the present study and are expected to have wider crystallizable ranges. The GA units of the LLA-rich P(LLA-GA) copolymers were incorporated in a lattice of LLA unit segments, whereas the LLA units of the GA-rich P(LLA-GA) copolymers were incorporated in a lattice of GA unit segments. Even the incorporation of relatively small-sized GA units in relatively large-sized LLA unit segments strongly induced structural disorder in the crystalline lattice. The crystalline size and melting temperature of the P(LLA-GA) copolymers decreased dramatically as the LLA unit content deviated from 0 to 100 mol%.

Similar content being viewed by others

Introduction

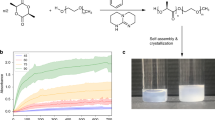

Biodegradable aliphatic copolymers synthesized by polycondensation of monomers [l-lactic acid (LLA) and glycolic acid (GA)] [P(LLA-GA)] and by ring-opening polymerization (ROP) of cyclic dimers (l-lactide and glycolide) (Fig. 1) have been extensively investigated in terms of biomedical and pharmaceutical applications because of their biocompatibility and appropriate degradation rates during implantation or drug release [1,2,3,4]. The crystallization behavior of these biodegradable copolymers has attracted significant attention because their initial crystallinity and crystalline size before degradation affects their biodegradation rate and behavior and their crystallizability in the presence of water during implantation also alters their biodegradation rate and behavior [5].

Gilding and Reed synthesized poly(l-lactide-co-glycolide) copolymers with l-lactide unit content of 0–100 mol% in the polymers by ring-opening polymerization (ROP) of cyclic dimers (l-lactide and glycolide) (Fig. 1) and reported that melt-quenched copolymers were crystallizable during heating for l-lactide unit contents of 0–20 mol% and 80–100 mol% in the polymers [6]. Grijpma et al. synthesized l-lactide-rich poly(l-lactide-co-glycolide) copolymers by ROP and found the as-polymerized copolymers crystallized for l-lactide unit contents from 73 to 100 mol% [7]. In our previous study, we synthesized l-lactide-rich poly(l-lactide-co-glycolide) copolymers with an l-lactide unit content of 68–100 mol% in the polymers by ROP and d-lactide-rich poly(d-lactide-co-glycolide) copolymers with a d-lactide unit content of 64–100 mol% in the polymers by ROP and reported that l-lactide-rich copolymers and d-lactide-rich copolymers were crystallizable during casting or solution-crystallization for an l-lactide unit content of 77–100 mol% and a d-lactide unit content of 84–100 mol% in the polymers, respectively [8]. Wang et al. [9] synthesized glycolide-rich poly(l-lactide-co-glycolide) copolymers with glycolide contents of 90–100 mol% (in the feeds or in the polymers, not specified) by ROP and investigated the morphological development of the copolymers during isothermal crystallization from the melt. They reported that the overall crystallization rate of GA-rich poly(l-lactide-co-glycolide) copolymers decreased with an increase in the l-lactide unit content [9]. In our previous study, we investigated the spherulite growth behavior of l-lactide-rich poly(l-lactide-co-glycolide) copolymers with l-lactide unit contents of 84–100 mol% in the polymers and found that the maximum radial growth rate of the spherulites of the copolymers decreased with the decreasing l-lactide unit content [10]. Li et al. [11] synthesized poly(l-lactide-co-glycolide) (75/25) by ROP and observed the crystallization of the l-lactide unit segments of poly(l-lactide-co-glycolide) (75/25) during hydrolytic degradation due to selective removal of the glycolide units.

Chatani et al. [12] compared the lattice parameters of poly(glycolide) and poly(lactide-co-glycolide) with 8 mol% lactide content in the feed (the enantiomeric form was not specified) and found that incorporation of relatively large-sized lactide units in the lattice of relatively small-sized glycolide unit segments increased the lattice parameters of a and b but did not alter the lattice parameter of c. Marubayashi et al. [13] synthesized LLA-rich copolymers with various 2-hydroxyalkanoic acids (comonomer unit content below 11 mol% in the copolymers) including LLA-rich P(LLA-GA) copolymers by polycondensation of monomers (LLA and hydroxyalkanoic acid comonomers including GA) and investigated the crystallization behavior of LLA-rich P(LLA-GA) copolymers by melt-quenching and annealing samples at a fixed degree of supercooling. They reported that LLA units and some relatively small-sized 2-hydroxyalkanoic acid comonomer units of LLA-rich copolymers including GA units were cocrystallizable, and the interplanar distance (d) values for the (110) and (200) planes of the PLLA homopolymer (d110,PLLA and d200,PLLA, respectively), which are identical to those of the poly(l-lactic acid) (PLLA) homopolymer, were split into d110,PLLA and d200,PLLA, respectively, for the LLA-rich P(LLA-GA) copolymers [13]. In addition, Wang et al. [14] synthesized P(LLA-GA) copolymers with varying LLA contents of 0–100 mol% in the feed by melt-condensation and investigated the crystallization behavior by WAXD using as-purified samples. They found the 2θ of the (110) plane of poly(glycolic acid) (PGA) at 22.2° did not change or changed very slightly in GA-rich P(LLA-GA) copolymers with 10 and 30 mol% LLA units in the feeds, whereas a P(LLA-GA) copolymer with 50 mol% LLA in the feed and 42 mol% LLA units in the polymer became amorphous [14]. Here, the LLA unit contents in the former GA-rich copolymers were not specified.

As far as we are aware, a comprehensive study on the crystallization of polycondensed P(LLA-GA) random copoolymers over a well-defined, wide range of LLA unit contents has not been reported. To investigate the crystallizability and crystallization behavior of P(LLA-GA) copolymers with a well-defined, wide range of LLA unit contents (0–100 mol%) in the polymers, we synthesized P(LLA-GA) random copolymers by polycondensation of monomers (LLA and GA). The crystallizability and crystallization behavior of P(LLA-GA) copolymers with a well-defined, wide range of LLA unit contents of 0–100 mol% in the polymers were investigated using WAXD and DSC. In the present study, we utilized a monomer polycondensation method instead of a dimer ROP method because the monomer distribution should be more random in the P(LLA-GA) copolymers synthesized by the former method and a higher probability for cocrystallization of the two monomer units was expected for the polycondensed P(LLA-GA) copolymers with shorter minor monomer unit sequences.

Experimental section

Materials

PLLA, P(LLA-GA) copolymers with different LLA unit contents, and PGA were synthesized by polycondensation of LLA and GA (hydroxyacetic acid, guaranteed grade, Kanto Chemical Co. Inc., Tokyo, Japan) using 5 wt% p-toluenesulfonic acid (monohydrate, guaranteed grade, Nacalai Tesque Inc., Kyoto, Japan) as the catalyst, as reported previously [15]. The polycondensation was performed at 130 °C under atmospheric pressure for 5 h (1st step) and then under reduced pressure (1.8–4.0 kPa) for 1–24 h (2nd step). The polycondensation conditions are summarized in Table 1. The relatively short reaction times for the 2nd step of the polymerization for the crystallizable PLLA, LLA- or GA-rich P(LLA-GA) copolymers and PGA were due to their crystallization, which disturbed further polymerization, whereas the relatively short reaction time for amorphous P(LLA-GA) synthesized with 50 mol% LLA in the feed was to avoid further colorization due to oxidation. The LLA used for synthesis of the PLLA and P(LLA-GA) copolymers was prepared by hydrolytic degradation of l-lactide (assay 99.5% Purac Biochem, Gorinchem, The Netherlands) with distilled water [l-lactide/water (mol/mol) = 1/2] at 98 °C for 30 min. The synthesized polymers were purified by reprecipitation using chloroform (guaranteed grade, Nacalai Tesque Inc.) for the PLLA and LLA-rich P(LLA-GA) copolymers synthesized with 50–100 mol% LLA in the feeds and 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP) (HPLC grade, Nacalai Tesque Inc.) for the PGA and GA-rich P(LLA-GA)s synthesized with 0–30 mol% LLA in the feeds as the solvents and methanol (guaranteed grade, Nacalai Tesque Inc.) as the nonsolvent. The precipitated polymers were collected by centrifugation using a Hitachi (Tokyo, Japan) SCR20B centrifuge at 5000 rpm for 5 min [15]. The volume ratio of the solvent and nonsolvent was 3/30 (mL/mL). The polymers purified by precipitation were dried under reduced pressure for at least 6 days. The thus-purified samples are the “precipitated samples” [15]. Melt-crystallization of the precipitated samples sealed in test tubes under reduced pressure was performed at a crystallization temperature of 80 °C for 24 h after melting the samples at 230 °C for 3 min [15]. The samples after crystallization were quenched at 0 °C for at least 5 min to stop further crystallization [15]. We call the thus-prepared samples “melt-crystallized samples” [15]. In the present study, two representative methods of precipitation and crystallization from the melt were utilized to crystallize samples. Neither casting (solution-crystallization) nor heating of melt-quenched samples was utilized because a previous study found that the crystallizability of poly(l-lactic acid-co-l-2-hydroxybutanoic acid) is higher for precipitation and melt-crystallization than for casting and heating of melt-quenched samples [15].

Physical measurements and observation

The weight- and number-average molecular weights (Mw and Mn, respectively) of the purified polymers were evaluated in chloroform at 40 °C using a Tosoh (Tokyo, Japan) gel permeation chromatography (GPC) system with two TSK gel columns (GMHXL) and polystyrene standards [15]. The specific optical rotation ([α]25589) of the polymers was measured in chloroform, HFIP, or their mixture [90/10 (v/v)] at a concentration of 1 g dL–1 and at 25 °C using a JASCO (Tokyo, Japan) P-2100 polarimeter at a wavelength of 589 nm with an optical path length of 10 cm [15]. The monomer compositions of the synthesized P(LLA-GA) copolymers were determined from the 1H NMR spectra obtained in deuterated chloroform (50 mg mL–1) by a Bruker BioSpin (Kanagawa, Japan) AVANCE III 400 using tetramethylsilane as the internal standard [15]. The molecular characteristics of the polymers synthesized in the present study are shown in Table 1. P(LLA-GA) copolymers are abbreviated as LLAX, where X indicates the mol% of LLA units in the copolymer.

Based on the random addition of LLA and GA during polycondensation, the P(LLA-GA) copolymers are expected to have a random monomer distribution. To confirm this, 13C NMR measurement was performed for one of the P(LLA-GA) copolymers, LLA73. According to previous literature [16], the monomer sequence lengths of LLA and GA (lLLA and lGA, respectively) were estimated. The carbonyl peaks of the LLA units at 169.4–169.7 ppm and 169.7–170.0 ppm are ascribed to the LLA-LLA and LLA-GA sequences, respectively, whereas the carbonyl peaks of the GA units at 166.5–166.8 ppm and 166.8–167.2 ppm are ascribed to the GA-LLA and GA-GA sequences, respectively. Here, the ester group direction between the two monomer units is -CO-O- not -O-CO-. The signal intensities for LLA-LLA and LLA-GA are abbreviated as ILLA-LLA and ILLA-GA, respectively, whereas the signal intensities for GA-LLA and GA-GA are abbreviated as IGA-LLA and IGA-GA, respectively. Using the signal intensities, experimental lLLA and lGA values [lLLA(exp) and lGA(exp), respectively] were calculated by the following equations: [16]

In addition, theoretical lLLA and lGA values [lLLA(th) and lGA(th), respectively] were calculated assuming random addition of monomers and using the LLA fraction in the feed [xLLA (mol%)] with the following equations [17]:

It should be noted that the pair addition of cyclic dimers is assumed in the literature, so a coefficient of 2 is included in the equations [17]. The lLLA(exp) and lGA(exp) values obtained are 3.3 and 1.5, respectively, which are in good agreement with the lLLA(th) and lGA(th) values (3.3 and 1.4, respectively). This result supports that the synthesized copolymers have random distributions of two monomer units.

The glass transition, cold crystallization, and melting temperatures (Tg, Tcc, and Tm, respectively) and the enthalpies of cold crystallization and melting (ΔHcc and ΔHm, respectively) were determined with a Shimadzu (Kyoto, Japan) DSC-60 differential scanning calorimeter [15]. The samples (ca. 3 mg) were heated from –10 to 250 °C at a rate of 10 °C min−1 under a nitrogen gas flow at a rate of 50 mL min–1. WAXD measurements were carried out at 25 °C using a RINT-2500 (Rigaku Co., Tokyo, Japan) instrument equipped with a Cu-Kα source (λ = 1.5418 Å) [15].

Results and discussion

Wide-angle X-ray diffractometry

To estimate the crystalline species, d, lattice parameters (a, b, and c) and crystallinity (Xc) of the PLLA, P(LLA-GA) copolymers, and PGA, WAXD measurements were performed (Fig. 2). The presence and absence of crystalline peaks indicated that the precipitated and melt-crystallized PLLA, P(LLA-GA) copolymers, and PGA with LLA unit contents of 0–20 mol% and 78–100 mol% were crystallizable, whereas P(LLA-GA) copolymers with LLA unit contents of 31–73 mol% were non-crystallizable. It is surprising that these crystallizable ranges are similar to those of P(LLA-GA) copolymers synthesized by ROP of cyclic dimers (0–20 mol% and 80–100 mol% during heating of melt-quenched samples [6], 73–100 mol% for as-purified samples [14], and 77–100 mol% during casting [8]), which should have monomer sequence lengths twice those of the P(LLA-GA) copolymers synthesized by monomer polycondensation in the present study (Fig. 1) and are expected to have wider crystallizable ranges. The probable explanation for this result that the crystallizability of the P(LLA-GA) copolymers is higher with precipitation and melt-crystallization in the present study than it would be with heating of melt-quenched samples and casting, which were used in the previous studies. The former methods might have compensated the low crystallizability of the P(LLA-GA) copolymers synthesized from the monomers in the present study, resulting in the similar crystallizable LLA unit content ranges. The relatively higher crystallizability of the P(LLA-GA) copolymers, especially with precipitation, in the present study is attributable to the fact that crystallization occurs with a relatively low concentration of polymers in the presence of a non-solvent compared to the relatively high concentration of polymers required in the absence of a non-solvent (i.e., casting). The broadening of each crystalline peak or the increase in the half-width upon approaching an equimolar monomer composition indicates the crystalline size decrease.

Both the precipitated and melt-crystallized PLLA homopolymer samples exhibit main crystalline diffractions at 16.7° and 19.0°, which can be attributed to the (110)/(200) and (113)/(203) planes of the α- and δ- (or α‘-)form, respectively [18, 22], but the crystalline peaks at ~12.5, 15, and 22.5°, which are specific only to the α-form [18,19,20,21,22], were observed only for the precipitated PLLA. These results indicated the precipitated and melt-crystallized PLLA samples had the α- and δ-forms, respectively. The precipitated and melt-crystallized LLA-rich LLA89 copolymer samples showed main crystalline peaks at 16.5, 17.3, and 19.7°, whereas the precipitated and melt-crystallized LLA-rich LLA78 copolymer samples exhibited main crystalline peaks at 16.4, 17.6, and 20.0°. These three crystalline diffraction peaks of the LLA-rich P(LLA-GA) copolymers are ascribed to the (200), (110), and (113) planes, respectively [13, 22]. The crystalline diffraction peaks for the (110)/(200) planes of the PLLA homopolymers with a 100% LLA unit content split into peaks for the (200) and (110) planes in the LLA-rich LLA89 and LLA78 copolymers. The diffraction angle difference between the (200) and (110) planes became wider, and the crystalline diffraction for the (113) plane shifted to a higher angle with decreasing LLA unit content or increasing GA unit content. In previous studies, a crystalline lattice change upon incorporation of GA units in the lattice of LLA unit segments was reported for P(LLA-GA) copolymers with LLA unit contents down to 89 and 88 mol% in the polymers synthesized by polycondensation [12, 13]. In the present study, the crystallizability and diffraction angle changes were observed for the P(LLA-GA) copolymers with the lower LLA unit contents, i.e., down to 78 mol% in the polymers synthesized by polycondensation. The reported diffraction angle changes of the (110) and (113) planes, i.e., from 16.7 and 19.1° at 100 mol% LLA unit content in the polymer to 17.2 and 19.6° at 88 mol% LLA unit content in the polymer [14], were lower than those in the present study.

On the other hand, both the precipitated and melt-crystallized PGA homopolymer samples showed the main crystalline diffraction peaks at 22.4° and 29.1°, which can be ascribed to the (110) and (020) planes, respectively [14]. These two peaks shifted to lower angles with the increasing LLA unit content and were 22.1 and 28.6° (precipitated sample) and 22.0 and 28.5° (melt-crystallized sample) with LLA unit contents of 6 mol% in the copolymer and 10 mol% in the feed and 22.1 and 28.5° (precipitated sample) and 21.8 and 28.5° (melt-crystallized sample) with LLA unit contents of 20 mol% in the polymer and in the feed. This exhibits that the further incorporation of LLA units above 6 mol% in the polymers did not change the crystalline diffraction angles. However, despite the fact that the maximum value of LLA content (30 mol% in the feed) [14] for crystallizable GA-rich P(LLA-GA) copolymers was much higher than that in the present study (20 mol% in the feed), a previous paper reported that the incorporation of LLA units caused the diffraction angle changes from 22.2 and 28.9° at 0 mol% LLA unit content in the feed to 22.1 and 28.5° at 10 mol% LLA unit content in the feed and to 22.0° at 30 mol% in the feed (the peak at ~29° was not detected), which were insignificant or much smaller changes compared to those observed in the present study [14].

The d values were estimated from the WAXD profiles in Fig. 2 and are plotted in Fig. 3 as a function of the LLA unit content in the polymers. For the precipitated and melt-crystallized samples, the d values of (110) plane of PGA (d110, PGA) at 3.98 and 3.97 Å for 0 mol% LLA unit content increased to 4.03 and 4.07 Å for 20 mol% LLA unit content, whereas the d values of the PGA (020) plane (d020, PGA) at 3.07 and 3.07 Å for 0 mol% LLA unit content increased to 3.14 and 3.14 Å for 20 mol% LLA unit content. For the precipitated and melt-crystallized samples, the d values of the (110)/(200) planes of PLLA at 5.29 and 5.35 Å for 100 mol% LLA unit content split into those of the (110) and (200) planes (i.e., d110, PLLA and d200, PLLA), respectively, and reached 5.00 and 5.40 Å (precipitated sample) and 5.05 and 5.42 Å (melt-crystallized sample) at 78 mol% LLA unit content. The splitting of the (110)/(200) planes indicates the disappearance of the pseudo-hexagonal symmetry of PLLA upon incorporation of GA units [13]. For precipitated and melt-crystallized samples, the d values of the (113) plane of PLLA (d113, PLLA) at 4.64 and 4.70 Å for 100 mol% LLA unit content decreased to 4.44 and 4.45 Å at 78 mol% LLA unit content. The aforementioned d value changes with the increasing minor monomer unit content indicate that the major and minor monomer units in the P(LLA-GA) copolymers cocrystallized in the same crystalline lattices, irrespective of the crystallization method. In other words, the GA units of the LLA-rich P(LLA-GA) copolymers were included in the lattice of the LLA unit segments, and the LLA units of the GA-rich P(LLA-GA) copolymers were included in the lattice of the GA unit segments. It should be noted that the incorporation of large LLA units in the lattice of small GA unit segments for a wide range of LLA unit contents, i.e., up to 20 mol%, is reported for the first time in the present study. The cocrystallization of LLA and GA units in P(LLA-GA) copolymers is ascribed to the structural similarity between LLA and GA. That is, LLA and GA are both 2-hydroxyalkanoic acids with slightly different side chains.

Interplanar distance (d) values for the (110) and (020) planes of PGA (d110,PGA and d020,PGA) (a), lattice parameters a and b of PGA (aPGA and bPGA, respectively) (b, c), d values for the (110), (200), and (113) planes of PLLA (d110,PLLA, d200,PLLA, and d113,PLLA) (d), and lattice parameters a and b of PLLA (aPLLA and bPLLA, respectively) (e, f) for precipitated and melt-crystallized PLLA, P(LLA-GA) copolymers, and PGA, as a function of the LLA unit content in the polymers. Dashed lines show the d, a, and b values for PGA (0 mol% LLA unit content) or PLLA (100 mol% LLA unit content). The solid lines are to guide the viewer

The lattice parameters a and b for the PGA crystal (aPGA and bPGA, respectively) and a and b for PLLA crystal (aPLLA and bPLLA, respectively) were obtained by the following equations, assuming orthorhombic crystals for the PLLA, P(LLA-GA) copolymers, and PGA:

The obtained lattice parameters are plotted in Fig. 3 (aPGA, bPGA, aPLLA, and bPLLA) for PLLA and PGA as a function of the LLA unit content in the polymers. The aPGA and bPGA values increased with an increase in the LLA unit content, except for the aPGA of the precipitated LLA20 sample, whereas the aPLLA values increased and the bPLLA values decreased with a decrease in the LLA unit content or an increase in the GA unit content. Although the present results are consistent with the reported results [12, 13], the changes in aPGA, bPGA, aPLLA, and bPLLA are much larger than the reported changes due to the larger LLA unit content ranges in the present study.

The Xc values were evaluated from the WAXD profiles in Fig. 2. The Xc values are plotted in Fig. 4 as a function of the LLA unit content in the polymers and are tabulated in Table 2. The Xc values decreased with a deviation from 0 or 100 mol% and were nil for LLA unit contents of 20–73 mol%. This finding reflects that the incorporation of too many minor monomer units, i.e., >20 mol% LLA units or >27 mol% GA units, precludes the crystallization of P(LLA-GA) copolymers, which is in marked contrast with the results reported for poly(l-lactic acid-co-l-2-hydroxybutanoic acid) [15] and poly(d-lactic acid-co-d-2-hydroxybutanoic acid); [23] i.e., wherein the copolymers were crystallizable for all comonomer unit contents.

Differential scanning calorimetry

To estimate the thermal properties of P(LLA-GA) copolymers, DSC measurements were carried out (Fig. 5). The thermal properties obtained from the DSC thermograms in Fig. 5 are tabulated in Table 2. In the case of the precipitated samples, only a glass transition peak was observed in the range of 25–40 °C for LLA unit contents of 31–65 mol%, whereas for LLA unit contents of 0–20 and 73–100 mol%, melting peaks were seen in the range of 75–205 °C in addition to a glass transition peak in the range of 25–60 °C. For the melt-crystallized samples, only a glass transition peak was observed in the range of 30–50 °C for LLA unit contents of 31–73 mol%, and for LLA unit contents of 0–20 and 78–100 mol%, melting peaks were seen in the range of 95–215 °C in addition to a glass transition peak in the range of 25–45 °C. The presence of cold crystallization for the precipitated LLA89 and melt-crystallized LLA6 and PGA samples indicates the crystallization during DSC heating. In addition, the multiple melting peaks observed for the precipitated LLA78 and LLA89 samples are likely due to melting of disordered crystallites and more ordered crystallites formed by recrystallization.

The ΔH(tot) = ΔHcc + ΔHm values, which can be crystallinity indexes, and the highest Tm values are plotted in Fig. 4 as a function of the LLA unit content in the polymers and summarized in Table 2. As seen in Fig. 4, the overall trend of the ΔH(tot) values are very similar to that of the Xc values, except for the precipitated LLA73 sample. The highest Tm values of the PLLA, P(LLA-GA) copolymers, and PGA decreased as the LLA unit content deviated from 0 or 100 mol%. This trend is quite different from that observed for poly(l-lactic acid-co-l-2-hydroxybutanoic acid). Although a large decrease in the Tm (approximately 60 °C) was observed for LLA-rich poly(l-lactic acid-co-l-2-hydroxybutanoic acid) when 27 mol% of relatively large-sized l-2-hydroxybutanoic acid units were incorporated in the lattice of relatively small-sized LLA unit segments, a very small decrease in the Tm (ca 10 °C) was observed for l-2-hydroxybutanoic acid-rich poly(l-lactic acid-co-l-2-hydroxybutanoic acid) when 26 mol% of relatively small-sized LLA units were incorporated in the lattice of relatively large-sized l-2-hydroxybutanoic acid unit segments [15]. A similar trend was observed for biosynthesized d-configured copolymers [23]. The present and reported results indicate that even the incorporation of relatively small-sized GA minor units in the lattice of relatively large-sized LLA unit segments strongly induces the structural strain or disorder in the crystalline lattices.

Conclusions

P(LLA-GA) random copolymers were synthesized by polycondensation of monomers (LLA and GA), and their crystallization behavior was investigated by two representative crystallization methods of precipitation and melt-crystallization. P(LLA-GA) copolymers with LLA unit contents in the ranges of 0–20 and 73–100 mol% crystallized during precipitation or melt-crystallization. It is surprising that these crystallizable ranges are similar to those of P(LLA-GA) copolymers synthesized by ROP of cyclic dimers (l-lactide and glycolide), which should have monomer sequence lengths twice those reported for the P(LLA-GA) copolymers synthesized from the monomers in the present study and are expected to have wider crystallizable ranges than those in the present study. It is probable that the crystallizability of the P(LLA-GA) copolymers is higher than for precipitation and melt-crystallization in the present study than it would be for heating of melt-quenched samples and casting, which were used in the previous studies. This might compensate the low crystallizability of the P(LLA-GA) copolymers synthesized by polycondensation of monomers (LLA and GA) in the present study, resulting in the similar crystallizable LLA unit content ranges. The pseudohexagonal symmetry of PLLA disappeared upon incorporation of GA units. The d, aPGA, and bPGA values of the GA unit segment lattice for the precipitated and melt-crystallized samples increased with an increase in the LLA unit content for the GA-rich P(LLA-GA) copolymers, whereas the d200,PLLA and aPLLA values increased but the d110,PLLA, d113,PLLA and bPLLA values of the LLA unit segment lattice for the precipitated and melt-crystallized samples decreased with a decrease in the LLA unit content or an increase in the GA unit content for the LLA-rich P(LLA-GA) copolymers. These results indicated that the GA units of the LLA-rich P(LLA-GA) copolymers were incorporated in the lattice of the LLA unit segments, whereas the LLA units of the GA-rich P(LLA-GA) copolymers were incorporated in the lattice of the GA unit segments. It should be noted that the latter incorporation of relatively large-sized LLA units in the lattice of relatively small-sized GA unit segments for a wide range of LLA unit contents, i.e., up to 20 mol%, were reported for the first time in the present study. The crystalline size and Tm of the P(LLA-GA) copolymers decreased with the deviation of the LLA unit content from 0 or 100 mol%. A comparison between the Tm values in the present study and those reported for poly(l-lactic acid-co-l-2-hydroxybutanoic acid) indicates that even the incorporation of relatively small-sized GA units in relatively large-sized LLA unit segments strongly induces a structural strain or disorder in the crystalline lattices.

References

Jain RA. The manufacturing techniques of various drug loaded biodegradable poly(lactide-co-glycolide) (PLGA) devices. Biomaterials. 2000;21:2475–90.

Södergård A, Stolt M. Properties of lactic acid based polymers and their correlation with composition. Prog Polym Sci. 2002;27:1123–63.

Panyam J, Labhasetwar V. Biodegradable nanoparticles for drug and gene delivery to cells and tissue. Adv Drug Deliv Rev. 2003;55:329–47.

Danhier F, Ansorena E, Silva JM, Coco R, Le Breton A, Préat V. PLGA-based nanoparticles: An overview of biomedical applications. J Control Release. 2012;161:505–22.

Tsuji H. Hydrolytic degradation. In: Auras R, Lim L-T, Selke SEM, Tsuji H, Eds. Poly(lactic acid): Synthesis, Structures, Properties, Processing, and Applications (Wiley Series on Polymer Engineering and Technology). Chapter 21. NJ: John Wiley & Sons, Inc; 2010. p. 345–81.

Gilding K, Reed AM. Biodegradable polymers for use in surgery-polyglycolic/poly(lactic acid) homo- and copolymers: 1. Polymer. 1979;20:1459–64.

Grijpma DW, Nijenhuis AJ, Pennings AJ. Synthesis and hydrolytic degradation behaviour of high-molecular-weight l-lactide and glycolide copolymers. Polymer. 1990;31:2201–6.

Tsuji H, Ikada Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. X. Binary blends from poly(D-lactide-co-glycolide) and poly(L-lactide-co-glycolide). J Appl Polym Sci. 1994;53:1061–71.

Wang Z-G, Hsiao BS, Zong X-H, Yeh F, Zhou JJ, Dormier E, Jamiolkowski DD. Morphological development in absorbable poly(glycolide), copolymers during isothermal crystallization. Polymer. 2000;41:621–8.

Tsuji H, Tezuka Y, Saha SK, Suzuki M, Itsuno S. Spherulite growth of l-lactide copolymers: Effects of tacticity and comonomers. Polymer. 2005;46:4917–27.

Li SM, Garreau H, Vert M. Structure-property relationships in the case of the degradation of massive poly(α-hydroxy acid) in aqueous media, Part 2 Degradation of lactide-glycolide copolymers: PLA37.5GA25 and PLA75GA25. J Mater Sci Mater Med. 1990;1:131–9.

Chatani Y, Suehiro K, Okita Y, Tadokoro H, Chujo K. Structual studies of polyersters. I. Crystal structure of polyglycolide. Makromol Chem. 1968;113:215–29.

Marubayashi H, Asai S, Hikima T, Takata M, Iwata T. Biobased copolymers composed of L-lactic acid and side-chain-substituted lactic acids: synthesis, properties, and solid-state structure. Macromol Chem Phys. 2013;214:2546–61.

Wang Z-Y, Zhao Y-M, Wang F, Wang J. Syntheses of Poly(lactic acid-co-glycolic acid) serial biodegradable polymer materials via direct melt polycondensation and their characterization. J Appl Polym Sci. 2006;99:244–52.

Tsuji H, Sobue T. Cocrystallization of monomer units in lactic acid-based biodegradable copolymers, poly(L-lactic acid-co-L-2-hydroxybutanoic acid)s. Polymer. 2015;72:202–11.

Kricheldorf HR, Kreiser I. Polylactones, 11. Cationic Polym glycolide L,L-dilactide Macromol Chem Phys. 1987;188:1861–73.

Tsuji H, Ikada Y. Crystallization from the melt of poly(lactide)s with different optical purities and their blends. Macromol Chem Phys. 1996;197:3483–99.

Pan P, Zhu B, Kai W, Dong T, Inoue Y. Effect of crystallization temperature on crystal modifications and crystallization kinetics of poly(L-lactide). J Appl Polym Sci. 2008;107:54–62.

Tsuji H, Tashiro K, Bouapao L, Hanesaka M. Separate crystallization and cocrystallization of Poly(L-lactide) in the presence of L-lactide-based copolymers with low crystallizability, Poly(L-lactide-co-glycolide) and Poly(L-lactide-co-D-lactide). Macromol Chem Phys. 2012;213:2099–112.

Zhang J, Tashiro K, Tsuji H, Domb AJ. Investigation of phase transitional behavior of Poly(L-lactide)/Poly(D-lactide) blend used to prepare the highly-oriented stereocomplex. Macromolecules. 2007;40:1049–54.

Pan P, Kai W, Zhu B, Dong T, Inoue Y. Polymorphous crystallization and multiple melting behavior of Poly(L-lactide): molecular weight dependence. Macromolecules. 2007;40:6898–905.

Wasanasuk K, Tashiro K. Crystal structure and disorder in Poly(L-lactic acid) δ form (α‘ form) and the phase transition mechanism to the ordered α form. Polymer. 2011;52:6097–109.

Kabe T, Matsumoto K, Terai S, Hikima T, Takata M, Miyake M, Taguchi S, Iwata T. Co-crystallization phenomena in biosynthesized isotactic poly[(R)-lactate-co-(R)-2-hydroxybutyrate]s with various lactate unit ratios. Polym Degrad Stab. 2016;132:137–44.

Acknowledgements

This research was supported by JSPS KAKENHI Grant Number 16K05912.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Tsuji, H., Kikkawa, K. & Arakawa, Y. Cocrystallization of monomer units of biobased and biodegradable Poly(l-lactic acid-co-glycolic acid) random copolymers. Polym J 50, 1079–1088 (2018). https://doi.org/10.1038/s41428-018-0093-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0093-z

This article is cited by

-

Efficient synthesis, characterization, and application of biobased scab-bionic hemostatic polymers

Polymer Journal (2020)

-

A Synchrotron in situ X-ray Study on the Multiple Melting Behaviors of Isomorphous Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (P(HB-co-HV)) with Middle HV Content

Chinese Journal of Polymer Science (2020)