Abstract

Flexible transparent electrodes on flexible plastic sheets are in significant demand for use in flexible perovskite solar cells (f-PSCs). However, the combination of the broadband high optical transparency and low electrical resistivity required for the tandemization of f-PSCs sets a stringent requirement on flexible transparent electrodes that are based on traditional Sn-doped In2O3 (ITO) films, owing to the high free-carrier concentration needed to reduce the electrical resistivity. Herein, we used excimer laser irradiation to achieve a Ce and H codoped In2O3 (ICO:H) film on flexible polyethylene terephthalate (PET) that had ultrahigh electron mobility of 133 cm2/Vs, which is the highest among those reported for flexible transparent electrodes, and low sheet resistance of 14.2 Ω/□, which is approximately three times lower than the 40 Ω/□ sheet resistance of commercially available ITO/PET. Furthermore, compared to ITO, this ICO:H film had higher infrared transparency. These nontrivial performances were achieved by an optimized excimer-laser solid-phase crystallization process guided by the correlation between laser pulse counts and the volume fractions of the amorphous and crystalline phases in the films. These high performances resolved the problems faced by ITO films, thus facilitating the performance of flexible solar cells and optoelectronic devices.

Similar content being viewed by others

Introduction

Transparent conducting oxide (TCO) films have been widely used as transparent electrodes in optoelectronic applications, such as displays, light-emitting diodes, solar cells, and other optoelectronic devices1,2,3,4. In recent years, flexible transparent electrodes on flexible plastics, such as polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and polyimide, have been in significant demand for use in flexible perovskite solar cells (f-PSCs)5,6,7,8,9. Among all solar cells, f-PSCs produce the most competitive power-per-weight and thus are specifically attractive for applications in wearable, portable electronic devices, building-integrated photovoltaics, and drones. State-of-the-art f-PSCs can reach an efficiency of 19.51%10. A promising method for further increasing f-PSC efficiency is to construct tandem structures11. For example, the integration of a wide-bandgap (near-infrared (NIR)-transparent) perovskite front cell and a narrow-bandgap perovskite or Cu(In,Ga)Se2 (CIGS) rear cell allowed a more efficient utilization of solar light with different photon energies12,13,14,15.

Historically, magnetron-sputtered Sn-doped In2O3 (ITO) has been widely used as a TCO material1,2,3,4,9. However, using ITO films as transparent electrodes in f-PSCs with tandem structures limits the device performance. Due to the difficulty in achieving high carrier mobility (μ) by Sn doping, a high carrier concentration (N) by heavy Sn doping is necessary to reduce electrical resistivity (ρ)9. However, such doping usually results in high optical losses in the NIR wavelength region due to reflectance and/or absorption attributed to free-carrier electrons16,17. This optical loss induces a total photocurrent loss of several mA/cm2 for perovskite tandem structures18. Therefore, the successful fabrication of f-PSCs with tandem structures requires high-μ TCO films (because a high μ results in a low ρ at a low N) to thus provide high transparency with alleviated parasitic optical losses in the visible and NIR regions.

Conventional polycrystalline ITO films exhibit a low μ of 40 cm2/Vs19, whereas In2O3-ZnO (IZO) films with amorphous structures exhibit a μ of 60 cm2/Vs20,21. In contrast, solid-phase crystallized H-doped In2O3 (spc-IO:H) thin films22,23 and spc-Ce and H codoped In2O3 (spc-ICO:H)24,25 thin films achieve very high μ values of over 100 cm2/Vs and suitable low-N values ranging from 1 × 1020 to 2 × 1020 cm-3, leading to low optical losses over a wide optical range22,23,24,25. These excellent optoelectronic properties have been demonstrated in high-efficiency rigid solar cells, such as silicon heterojunctions22,26,27,28, CIGS29,30,31, and perovskite-based tandem solar cells32,33,34,35,36,37. However, these attractive films (spc-IO:H and spc-ICO:H) have never been adopted in flexible solar cells because they have a fabrication-temperature issue, namely, a high-temperature annealing process for solid-phase crystallization is necessary to obtain the high μ that is an attractive feature of H and/or Ce dopants. Both spc-IO:H and spc-ICO:H films are fabricated by a two-step process. In the first step, amorphous precursor films are deposited on a substrate without intentional heating or at low temperature (100 °C) via ion plating with direct current arc discharge24,25 (i.e., reactive plasma deposition (RPD)38), magnetron sputtering22,23, or atomic layer deposition31,39. During deposition, water is introduced into the deposition chamber to induce the formation of an amorphous structure. In the second step, either thermal annealing at a temperature higher than 150–200 °C or flash lamp annealing40 is performed to induce spc (solid-phase crystallization) and to achieve a high μ. Such a high processing temperature, however, limits the formation and adoption of these films on heat-sensitive flexible substrates such as PET, whose process temperature is less than 70–110 °C7.

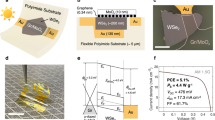

To resolve this temperature issue, we used an excimer laser irradiation (ELI) technique. Excimer lasers have high photon energies. For example, KrF (wavelength λ = 248 nm) excimer lasers can achieve photon energy of 5 eV, which should be sufficient to induce a photothermal reaction for crystallization41,42,43. Photothermal effects are achieved when the maximum temperature inside the film exceeds 400 °C; the temperature then decays over several hundreds of nanoseconds44,45. The temperature inside the film exceeds the crystallization temperature, but only during a very short irradiation time, and therefore thermal damage to the underlayer can be avoided. As a result, because high temperature is no longer a requirement for the fabrication of spc-ICO:H films, these films can be adopted in flexible solar cells, with the expectation of a significant improvement in conversion efficiency. As a proof of concept (Fig. 1), we fabricated an spc-ICO:H film on a flexible PET sheet by using ELI. In this work, we successfully obtained the highest μ of 133 cm2/Vs among reported flexible TCO films and obtained a low sheet resistance (Rs) of 14.2 Ω/□ (ρ = 2.13 × 10−4 Ωcm) with a high average optical transmittance (Tav) of 83.7% in the visible to NIR region (λ = 400–2100 nm). This successful Rs value is much lower than that of commercially available flexible 150-nm-thick ITO/PET sheets (Rs of 40 Ω/□, and Tav of 74.3%). The demonstrated high performance of a flexible spc-ICO:H film and its low fabrication-temperature process have resolved the problems encountered by conventional flexible ITO films. Flexible spc-ICO:H films are therefore potential components for flexible optoelectronics, thus facilitating the performance of flexible solar cells and optoelectronic devices.

Here, the carrier mobility μ depends on the relaxation time (τ) and electron effective mass (m) as μ = τ/m. The spc-ICO:H films exhibited an m similar to that of conventional polycrystalline ITO films, indicating that high μ is achieved via a larger τ rather than a smaller m23,25. Two origins are responsible for the large τ (= high μ) obtained for the spc-ICO:H films. One is that the Ce dopant can be suppressed to promote the formation of oxygen vacancies. These vacancies act as doubly charged donors, VO•• (i.e., ionized impurity scattering centers), because Ce has larger binding energy with oxygen than does the In atom with Sn dopant (case of ITO). Another origin is that hydrogen can be passivated for the grain boundary states, thus leading to lower trap densities, which would consequently decrease the potential barriers at grain boundaries for electron transport23,25.

Results

Texture evolution

First, the relationship between the crystallization temperature of ICO:H films and the heat resistance of a PET sheet needs to be addressed. The as-deposited ICO:H film that formed on a glass substrate under the same deposition conditions as on the PET sheet started crystallization at approximately 190 °C, which was confirmed by in situ X-ray diffraction measurements. At that temperature, the film on the PET sheet was significantly deformed. This demonstrates the difficulty in achieving the crystallization of an ICO:H/PET sheet without heat damage to the PET sheet by conventional heat treatment.

The main result of our study is the crystallization process under ELI. Figure 2a shows plan-view SIM (scanning ion microscope) images of ICO:H under various laser pulse counts (PC) for ELI. Due to the purely amorphous-phase formation, the nonlaser-irradiated (as-deposited) ICO:H film exhibited featureless structures with smooth surfaces. This observation is consistent with the absence of crystalline peaks in the X-ray diffraction patterns of the films (not shown here). At PC = 2500 shots, crystal nucleation occurred, and numerous small grains (300 nm) were observed on the ICO:H film surface. At PC = 5000 shots, the film had a structure with embedded larger crystalline grains (870 nm) together with small grains (300 nm) in the amorphous matrix. At PC > 5000 shots, grain growth proceeded. The grain density for a film with PC = 12,500 shots was much higher than that with PC = 10,000 shots. At PC = 15,000 shots, the crystallization of the film was complete, and the film exhibited a surface covered with large grains (>2 μm). At PC > 15,000 shots, crystallization did not continue, and the texture at PC = 30,000 shots was similar to that at 15,000 shots.

a Plan-view SIM images of ICO:H films with various laser pulse counts (PCs). EBSD analysis data: b IPF maps along the normal direction of ICO:H films with PC = 2500, 5000, 10,000, and 15,000 shots; c Number of grains as a function of grain size (diameter); d Total number of grains; and e Total area of grains as a function of PC. f PFs of the 111 reflections.

To obtain a better understanding of the crystallization process under ELI, we quantitatively determined the texture evolution by using electron backscatter diffraction (EBSD) measurements. Figure 2b shows inverse pole figure (IPF) maps along the normal direction for ICO:H films with PC = 2500, 5000, 10,000, and 15,000 shots. These IPF maps reveal that with increasing PC, the black area corresponding to the amorphous phase decreased due to the increase in the crystalized area. Figure 2c shows the grain size distribution, namely, the number of grains as a function of the grain size diameter. Figure 2d, e summarize the total number and area of grains, respectively, as a function of PC. At PC = 2500 shots, the grain size was small (0.1 to 0.6 μm in diameter), and the number of grains was low (157 grains); thus, the ratio of grains occupying the evaluation area (i.e., crystallized area) was ~5.1%. Taking into account that the adhesion of water molecules at growing surfaces suppresses the growth of crystallites23, crystallite nuclei might have been created at the film surface due to the desorption of water molecules caused by a rapid rise in the temperature at the film surface region during the early stages of irradiation, i.e., when PC ≤2500 shots. At 5000 shots, the number of grains rapidly increased to 1035 grains, and the grain size increased to a maximum diameter of 1.5 μm. Therefore, the crystallized area was ~74%. These changes might be due to nucleation and grain growth. With a further increase in PC to 15,000 shots, the maximum grain size increased from 1.5 to 2.4 μm. Furthermore, the number of small grains (0.1–0.6 μm) decreased, whereas that of large grains (>1.2 μm) increased. Note that with this increase in PC, the total number of grains decreased to 593 grains, whereas the crystallized area increased to 99.7%. These data reveal that the grain growth during the increase in PC from 5000 to 15,000 shots was mainly caused by coalescence among grains. If two grains coalesce, they should form a grain boundary because the two grains typically have different orientations. However, no grain boundaries were identified within a single domain in the IPF maps in our study (Fig. 2b). This means that the orientation of the captured grains was transformed to that of the capturing grains. Figure 2f shows the pole figures (PFs) of the 111 reflections obtained from the IPF maps (Fig. 2b). In these PFs, the distribution of the poles for the 111 reflections appears as a spot in the center of the figure together with a ring. These results are evidence that most of the grains in the ICO:H film had a texture with a slight orientation in the <111> direction normal to the surface. This slight orientation might be caused by the (111) surface energy being the lowest among the low-indexed surfaces in In2O3, including the (100), (110), and (111) surfaces46.

Electrical and optical properties

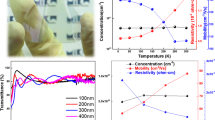

In particular, this anomalous grain growth is very effective for enhancing the carrier transport properties. Figure 3a and Table 1 summarize the electrical properties of the ICO:H film under various PCs with ELI. Commercially available magnetron-sputtered 150-nm-thick ITO/PET sheets were used for comparison. At PC = 2500 shots, the ICO:H film showed a decrease in N from 2.72 × 1020 to 2.12 × 1020 cm−3 while showing a slight increase in Hall mobility (μH) from 43.3 to 45.6 cm2/Vs. At PC > 5000 shots, the ICO:H film showed a large increase in μH (decreases in Rs and ρ) with increasing PC. This change in μH was mainly caused by the texture change from the amorphous phase to the polycrystalline phase (discussed in the Texture evolution section above). N remained relatively constant, suggesting that the changes in Rs and ρ after ELI were governed by μH. At PC = 30,000 shots, the fully crystalized ICO:H film, therefore, achieved a high μH of 126 cm2/Vs, and thereby achieved a low Rs (ρ) of 17.2 Ω/□ (2.59 × 10−4 Ωcm). Furthermore, the ICO:H film under thermal-assisted ELI (i.e., low-temperature heating at 100 °C) achieved an ultrahigh μH of 133 cm2/Vs, and thereby a very low Rs (ρ) of 14.2 Ω/□ (2.13 × 10−4 Ωcm). To the best of our knowledge, these successful μH values are the highest among those reported for TCO/PET flexible sheets, as summarized in Table 2. This successful Rs value of 14.2 Ω/□ is much lower than that of commercially available 150-nm-thick ITO/PET sheets (~40 Ω/□).

Figure 3b compares the optical transmittance (T) and reflectance (R) spectra of a nonlaser-irradiated ICO:H film (hereafter denoted as an a-ICO:H film) and a fully crystalized ICO:H film with PC = 15,000 shots (hereafter denoted as an ELI-spc-ICO:H film). Additionally, the T and R spectra of ITO film with the same layer structure as the ICO:H film are shown. High transparency was measured across the visible and NIR range for the ELI-spc-ICO:H/SiO2/PET and then compared with that for the ITO/SiO2/PET. The average T (Tav) in the λ range from 400 to 2100 nm for the ELI-spc-ICO:H/SiO2/PET was 83.7%, whereas that for the ITO/SiO2/PET was 74.3%. This higher Tav was mainly caused by the fact that the ICO:H film had a higher NIR transparency compared to that of the ITO film. This increased Tav in the NIR wavelength region was due to a lower R caused by the suitably low N of the ELI-spc-ICO:H film compared to that of ITO film16,17. For the ELI-spc-ICO:H film, the Tav in the absorption edge region slightly increased compared with that for the a-ICO:H and ITO films. This slight increase in Tav was due to the expansion of the optical bandgap. The difference in the positions of the absorption edges can also be attributed to the difference in N, namely, the blueshift due to the Burstein–Moss effect47. However, this is contrary to the Burstein–Moss shift for the ELI-spc-ICO:H film because the ITO film had the highest N and should therefore have the largest optical bandgap. A possible explanation for this is that the as-deposited ICO:H and ITO films were amorphous. Due to the disorder in the amorphous phase, optical transitions that usually do not occur due to both the top of the valence band and bottom of the conduction band being in parity with cubic bixbyite In2O3 structure could occur and thus lead to an optical bandgap similar to the fundamental gap48,49,50,51. Confirmation of such reduced disorder can be obtained by determining the electronic structure of the films by photoelectron spectroscopy (PES) measurements (discussed next).

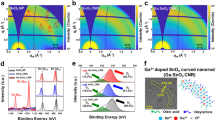

Electronic structure

The electronic states of the a-ICO:H and ELI-spc-ICO:H films were investigated by using bulk-sensitive PES, i.e., hard-X-ray photoelectron spectroscopy (HAXPES) measurements. Figure 4a shows the valence band (VB) spectra of these films. The spectral intensity is normalized to each respective value at a binding energy of 6 eV. Note that the tail state at the valence band maximum (VBM) and the sharpness of the 9-eV peak in the VB spectra were affected by ELI. The VBM of the ELI-spc-ICO:H films was 2.88 eV (determined by linear extrapolation), and that of the a-ICO:H films was 2.66 eV. These features might be due to the laser irradiation-induced52 enhancement in the crystallization of the films. Based on these results, we conclude that the increased T in the absorption edge by ELI (Fig. 3b) was driven by an increase in symmetry of the bixbyite structure due to the enhanced crystallization.

A weak peak near the Fermi energy (EF of 0 eV in Fig. 4a) was also affected by ELI. The intensity of this effect was enhanced for the a-ICO:H films with a high N of 2.72 × 1020 cm−3 compared with the ELI-spc-ICO:H films with a low N of 1.91 × 1020 cm−3. This peak is associated with occupied conduction-band states, and the intensity of this peak depends on the N of the film53,54. The phenomenon of N reduction upon crystallization of the a-ICO:H film was observed not only in laser crystallization but also in conventional heat-treatment crystallization23,25. For the IO:H films, Koida et al. explained that this phenomenon is due to the doubly charged donors (oxygen vacancies; VO••) being exchanged by singly charged donors (interstitial H (Hi•) and/or to H being substituted for O (HO•)) during the crystallization process that results in an approximately twofold reduction of N23. However, in the ICO:H films, possible carrier generation from Ce atoms must also be considered. Ce ions are well known to take on several electropositive charged states, such as Ce2+, Ce3+, and Ce4+, in compounds. Note that in the +4 oxidation state (Ce4+ ion), Ce can act as an In-substituted (In3+) dopant as a singly charged donor (CeIn•). However, in the +3 oxidation state (Ce3+ ion), Ce can act as a neutral defect. Figure 4b shows the Ce 3d core spectra of the a-ICO:H and ELI-spc-ICO:H films. The Ce 3d spectra were fitted by 10 Voigt components after subtracting the background. All 10 features were observed in both films, indicating a mixture of the two oxidation states (+3 and +4). The observed peaks are attributed to Ce3+ and Ce4+. These series of peaks are labeled “u” and “v”, which are due to 3d3/2 and 3d5/2 spin–orbit states, respectively55. The four peaks labeled v0, v′, u0, and u′ (gray-shaded areas) are characteristic peaks of Ce3+, whereas the peaks labeled v, v″, v″′, u, u″, and u″′ (yellow-shaded areas) are characteristic peaks of Ce4+55. The ratio of the area intensities of the features attributed to Ce3+ (gray) and Ce4+ (yellow) was 27:73 for the ELI-spc-ICO:H films and 74:26 for the a-ICO:H films. This inversion ratio reveals that Ce4+ was formed preferentially after ELI application; thus, Ce atoms might be involved in the carrier generation in the polycrystalline phase rather than in the amorphous phase. However, the value of N raises doubt about the contribution of carriers from Ce donors. Further research that involves studying the effects of the precursor formation conditions, such as the H2O pressure and O2 gas flow rates, on the properties of ELI-spc-ICO:H films will provide further elucidation.

Conclusion

In summary, we systematically investigated the effect of the PC of the ELI technique on the solid-phase crystallization (spc) of a 150-nm-thick ICO:H film on a flexible PET sheet. With increasing PC, the film showed a large increase in μΗ from 42 to 126 cm2/Vs with a large decrease in ρ (Rs) from 5.31 × 10−4 to 2.59 × 10−4 Ωcm (35.4 to 17.2 Ω/□). This change in μΗ was strongly correlated with the volume fractions of the amorphous and crystalline phases in the films. In the early stages of laser irradiation (PC < 2500 shots), crystallite nuclei were created by a rapid rise in the temperature. With increasing PC, these crystallites grew in addition to the nucleation of new crystallites. Grain growth by coalescence then progressed until the entire film was completely crystallized. At PC > 15,000 shots, the film was completely crystallized and consisted of slightly (111) oriented grains that had a maximum size of 2.4 μm. We also found that heat-assisted ELI was more effective for enhancing μΗ, and successfully obtained an ultrahigh μH of 133 cm2/Vs compared with that of reported flexible TCO films and a low ρ (Rs) of 2.13 × 10−4 Ωcm (14.2 Ω/□) with exceptionally low absorptance in the near-UV-to-NIR part of the spectrum. This successful Rs value is much lower than that of commercially available 150-nm-thick ITO/PET sheets (Rs of 40 Ω/□). This study provides an exciting method for addressing the major challenge faced by existing flexible ITO films and replacing traditional ITO films, thus facilitating high-performance flexible optoelectronic devices.

Methods

Film deposition and crystallization

Reactive plasma deposition (RPD; Sumitomo Heavy Industries) without intentional heating was used to deposit 150-nm-thick a-ICO:H films onto 188-μm-thick PET sheets that had a 150-nm-thick a-SiO2 coating. Here, the critical role of the a-SiO2 layer was to adjust the thermal expansion between the ICO:H layer and the PET sheet and thus suppress the formation of cracks on the ICO:H films during laser irradiation56. We used ceramic tablets (Sumitomo Metal Mining) with In2O3 with a CeO2 content of 2 wt.%. The deposition gases were Ar, O2, and H2O at a total pressure of 0.4 Pa. The flow ratio of O2 to Ar was fixed at 31%, whereas the pressure of H2O was ~1 × 10-4 Pa before deposition25. After deposition, the a-ICO:H films were irradiated with PCs of 2500, 5000, 10,000, 12,500, 15,000, and 30,000 shots by a KrF excimer laser (COMPex, Coherent Inc.) in an air atmosphere at room temperature or at 100 °C controlled by a hot plate. The two irradiation parameters, namely, the energy density and the frequency of the laser, were set at 40 mJ/cm2 and 50 Hz, respectively52.

Characterization

The microscopic morphology of the ICO:H film samples was evaluated using SIM (Hitachi FB-2100), and the crystallographic texture was characterized based on EBSD (JEOL JSM-7100F with EDAX Velocity Super). The N, μH, and ρ were determined by Hall effect measurements (Toyo Corporation, Resi Test 8300) at room temperature using the van der Pauw method. The optical properties were measured using a spectrophotometer (Hitachi, U-4000). The optical transmittance (T) and reflectance (R) spectra of the films in the wavelength range of 250–2500 nm were obtained using a spectrophotometer with an incident angle of 12°. The electronic states were estimated by using synchrotron HAXPES at beamline BL46XU at SPring-8 (photon energy, hν = 7.939 keV). The Ce charge state was determined using a laboratory HAXPES system, which consisted of monochromatized Cr Kα (hν = 5.4 keV). The EF of the sample referred to that of the gold plate on the sample holder.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Klein, A. Transparent conducting oxides: electronic structure–property relationship from photoelectron spectroscopy with in situ sample preparation. J. Am. Ceram. Soc. 96, 331–345 (2013).

Calnan, S. & Tiwari, A. N. High mobility transparent conducting oxides for thin film solar cells. Thin Solid Films 518, 1839–1849 (2010).

Porch, A., Morgan, D. V., Perks, R. M., Jones, M. O. & Edwards, P. P. Electromagnetic absorption in transparent conducting films. J. Appl. Phys. 95, 4734–4737 (2004).

Granqvist, C. G. & Hultåker, A. Transparent and conducting ITO films: new developments and applications. Thin Solid Films 411, 1–5 (2002).

Lu, Q. et al. A review on encapsulation technology from organic light emitting diodes to organic and perovskite solar cells. Adv. Funct. Mater. 31, 2100151 (2021).

Kaltenbrunner, M. et al. Flexible high power per-weight perovskite solar cells with chromium oxide-metal contacts for improved stability in air. Nat. Mater. 14, 1032–1039 (2015).

Jung, H. S., Han, G. S., Park, N.-G. & Ko, M. J. Flexible perovskite solar cells. Joule 3, 1850–1880 (2019).

Zhang, J., Zhang, W., Cheng, H.-M. & Silva, S. R. P. Critical review of recent progress of flexible perovskite solar cell. Mater. Today 39, 66–88 (2020).

Dixon, S. C., Scanlon, D. O., Carmalt, C. J. & Parkin, I. P. n-Type doped transparent conducting binary oxides: an overview. J. Mater. Chem. C. 4, 6946–6961 (2016).

Huang, K. et al. High-performance flexible perovskite solar cells via precise control of electron transport layer. Adv. Energy Mater. 9, 1901419 (2019).

Jiang, Y. & Qi, Y. Metal halide perovskite-based flexible tandem solar cells: next-generation flexible photovoltaic technology. Mater. Chem. Front. 5, 4833–4850 (2021).

Wang, C., Song, Z., Li, C., Zhao, D. & Yan, Y. Low-bandgap mixed tin-lead perovskites and their applications in all-perovskite tandem solar cells. Adv. Funct. Mater. 29, 1808801 (2019).

Leijtens, T., Bush, K. A., Prasanna, R. & McGehee, M. D. Opportunities and challenges for tandem solar cells using metal halide perovskite semiconductors. Nat. Energy 3, 828–838 (2018).

Yang, Z. et al. Stable low-bandgap Pb–Sn binary perovskites for tandem solar cells. Adv. Mater. 28, 8990–8997 (2016).

Palmstrom, A. F. et al. Enabling flexible all-perovskite tandem solar cells. Joule 3, 2193–2204 (2019).

Coutts, T. J., Young, D. L. & Li, X. Characterization of transparent conducting oxides. MRS Bull. 25, 58–65 (2000).

Fujiwara, H. & Kondo, M., Effects of carrier concentration on the dielectric function of ZnO:Ga and In2O3:Sn studied by spectroscopic ellipsometry: analysis of free-carrier and band-edge absorption. Phys. Rev. B 71, 075109 (2005).

Kothandaraman, R. K., Jiang, Y., Feurer, T., Tiwari, A. N. & Fu, F. Near-infrared-transparent perovskite solar cells and perovskite-based tandem photovoltaics. Small Methods 4, 2000395 (2020).

Shigesato, Y., Takaki, S. & Haranoh, T. Electrical and structural properties of low resistivity tin-doped indium oxide films. J. Appl. Phys. 71, 3356–3364 (1992).

Martins, R., Barquinha, P., Pimentel, A., Pereira, L. & Fortunato, E. Transport in high Mobility amorphous wide band gap indium zinc oxide films. Phys. Status Solidi A 202, R95–R97 (2005).

Leenheer, A. J. et al. General mobility and carrier concentration relationship in transparent amorphous indium zinc oxide films. Phys. Rev. B 77, 115215 (2008).

Koida, T., Fujiwara, H. & Kondo, M. Reduction of optical loss in hydrogenated amorphous silicon/crystalline silicon heterojunction solar cells by high-mobility hydrogen-doped In2O3 transparent conductive oxide. Appl. Phys. Express 1, 041501 (2008).

Koida, T. et al. Hydrogen-doped In2O3 transparent conducting oxide films prepared by solid-phase crystallization method. J. Appl. Phys. 107, 033514 (2010).

Kobayashi, E., Watabe, Y. & Yamamoto, T. High-mobility transparent conductive thin films of cerium-doped hydrogenated indium oxide. Appl. Phys. Express 8, 015505 (2015).

Koida, T., Ueno, Y. & Shibata, H. In2O3-based transparent conducting oxide films with high electron mobility fabricated at low process temperatures. Phys. Status Solidi A 215, 1700506 (2018).

Barraud, L. et al. Hydrogen-doped indium oxide/indium tin oxide bilayers for high-efficiency silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 115, 151–156 (2013).

Kobayashi, E., Watabe, Y., Yamamoto, T. & Yamada, Y. Cerium oxide and hydrogen co-doped indium oxide films for high-efficiency silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 149, 75–80 (2016).

Tutsch, L. et al. The sputter deposition of broadband transparent and highly conductive cerium and hydrogen co-doped indium oxide and its transfer to silicon heterojunction solar cells. Prog. Photovolt. Res. Appl. 29, 835–845 (2021).

Jäger, T. et al. Improved open-circuit voltage in Cu(In,Ga)Se2 solar cells with high work function transparent electrodes. J. Appl. Phys. 117, 225303 (2015).

Steigert, A. et al. Sputtered Zn(O,S)/In2O3:H window layers for enhanced blue response of chalcopyrite solar cells. Phys. Status Solidi RRL 9, 627–630 (2015).

Keller, J. et al. Direct comparison of atomic layer deposition and sputtering of In2O3:H used as transparent conductive oxide layer in CuIn1-xGaxSe2 thin film solar cells. Sol. Energy Mater. Sol. Cells 157, 757–764 (2016).

Zhang, D., Soppe, W. & Schropp, R. E. I. Design of 4-terminal solar modules combining thin-film wide-bandgap top cells and c-Si bottom cells. Energy Procedia 77, 500–507 (2015).

Fu, F. et al. Low-temperature-processed efficient semi-transparent planar perovskite solar cells for bifacial and tandem applications. Nat. Commun. 6, 8932 (2015).

Yin, G., Steigert, A., Manley, P., Klenk, R. & Schmid, M., Enhanced absorption in tandem solar cells by applying hydrogenated In2O3 as electrode. Appl. Phys. Lett. 107, 211901 (2015).

Schultes, M. et al. Sputtered transparent electrodes (IO:H and IZO) with low parasitic near-infrared absorption for perovskite–Cu(In,Ga)Se2 tandem solar cells. ACS Appl. Energy Mater. 2, 7823–7831 (2019).

Jiang, Y. et al. High-mobility In2O3:H electrodes for four-terminalperovskite/CuInSe2 tandem solar cells. ACS Nano 14, 7502–7512 (2020).

Moghadamzadeh, S. et al. In2O3:H-based hole-transport-layer-free tin/lead perovskite solar cells for efficient four-terminal all-perovskite tandem solar cells. ACS Appl. Mater. Interfaces 13, 46488–46498 (2021).

Kitami, H., Miyashita, M., Sakemi, T., Aoki, Y. & Kato, T. Quantitative analysis of ionization rates of depositing particles in reactive plasma deposition using mass-energy analyzer and Langmuir probe. Jpn. J. Appl. Phys. 54, 01AB05 (2015).

Macco, B. et al. On the solid phase crystallization of In2O3:H transparent conductive oxide films prepared by atomic layer deposition. J. Appl. Phys. 120, 085314 (2016).

Scherg-Kurmes, H. et al. Optimization of the post-deposition annealing process of high-mobility In2O3:H for photovoltaic applications. Thin Solid Films 599, 78–83 (2016).

Hosono, H., Kurita, M. & Kawazoe, H. Excimer laser crystallization of amorphous indium-tin-oxide and its application to fine patterning. Jpn. J. Appl. Phys. 37, L1119–L1121 (1998).

Tsuchiya, T. et al. Characterization of tin-doped indium oxide films prepared by coating photolysis process. Appl. Surf. Sci. 197-198, 512–515 (2002).

Chung, W., Thompson, M. O., Wickboldt, P., Toet, D. & Carey, P. G. Room temperature indium tin oxide by XeCl excimer laser annealing for flexible display. Thin Solid Films 460, 291–294 (2004).

Nakajima, T., Tsuchiya, T., Ichihara, M., Nagai, H. & Kumagai, T. Epitaxial growth mechanism for perovskite oxide thin films under pulsed laser irradiation in chemical solution deposition process. Chem. Mater. 20, 7344–7351 (2008).

Nakajima, T., Shinoda, K. & Tsuchiya, T. A universal value of effective annealing time for rapid oxide nucleation and growth under pulsed ultraviolet laser irradiation. Phys. Chem. Chem. Phys. 15, 14384–14389 (2013).

Walsh, A. & Catlow, C. R. A. Structure, stability and work functions of the low index surfaces of pure indium oxide and Sn-doped indium oxide (ITO) from density functional theory. J. Mater. Chem. 20, 10438–10444 (2010).

Hamberg, I. & Granqvist, C. G. Transparent and infrared-reflecting indium-tin-oxide films: quantitative modeling of the optical properties. Appl. Opt. 24, 1815–1819 (1985).

Walsh, A. et al. Nature of the band gap of In2O3 revealed by first-principles calculations and X-ray spectroscopy. Phys. Rev. Lett. 100, 167402 (2008).

Wardenga, H. F., Frischbier, M. V., Morales-Masis, M. & Klein, A. In situ Hall effect monitoring of vacuum annealing of In2O3:H thin films. Materials 8, 561–574 (2015).

Aliano, A., Catellani, A. & Cicero, G., Characterization of amorphous In2O3: An ab initio molecular dynamics study. Appl. Phys. Lett. 99, 211913 (2011).

Rosen, J. & Warschkow, O. Electronic structure of amorphous indium oxide transparent conductors. Phys. Rev. B 80, 115215 (2009).

Nomoto, J., Matsui, H., Yamaguchi, I., Nakajima, T. & Tsuchiya, T. Origin of simultaneous enhancement of work function and carrier concentration in In2O3 films by excimer-laser irradiation. Appl. Phys. Lett. 118, 101602 (2021).

Gassenbauer, Y. et al. Surface states, surface potentials, and segregation at surfaces of tin-doped In2O3. Phys. Rev. B 73, 245312 (2006).

Körber, C. et al. Electronic structure of In2O3 and Sn-doped In2O3 by hard x-ray photoemission spectroscopy. Phys. Rev. B 81, 165207 (2010).

Bêche, E., Charvin, P., Perarnau, D., Abanades, S. & Flamant, G. Ce 3d XPS investigation of cerium oxides and mixed cerium oxide (CexTiyOz). Surf. Interface Anal. 40, 264–267 (2008).

Nomoto, J., Yamaguchi, I., Nakajima, T., Matsubayashi, Y. & Tsuchiya, T. Excimer laser annealing method for achieving low electrical resistivity and high work function in transparent conductive amorphous In2O3:Zn films on a polyethylene terephthalate substrate. Thin Solid Films 698, 1378677 (2020).

Kim, J.-G., Na, S.-I. & Kim, H.-K. Flexible and transparent IWO films prepared by plasma arc ion plating for flexible perovskite solar cells. AIP Advances 8, 105122 (2018).

Lee, J.-H. & Kim, H.-K. Flexible W-doped In2O3 films grown on ion beam treated polyethylene terephthalate substrate using roll to roll sputtering. Mater. Sci. Semicond. Process. 89, 176–185 (2019).

Kim, J. H. et al. Flexible ITO films with atomically flat surfaces for high performance flexible perovskite solar cells. Nanoscale 10, 20587–20598 (2018).

Lan, Y. F., Peng, W. C., Lo, Y. H. & He, J. L. Durability under mechanical bending of the indium tin oxide films deposited on polymer substrate by thermionically enhanced sputtering. Org. Electron. 11, 670–676 (2010).

Miyazaki, Y., Maruyama, E., Jia, J., Machinaga, H. & Shigesato, Y. Indium oxide-based transparent conductive films deposited by reactive sputtering using alloy targets. Jpn. J. Appl. Phys. 56, 045503 (2017).

Cho, D.-Y., Shin, Y.-H. & Kim, H.-K. Highly transparent Si-doped In2O3 films prepared on PET substrate using roll-to-roll sputtering. Surf. Coat. Technol. 259, 109–112 (2014).

Dekkers, J. M., Rijnders, G. & Blank, D. H. A. Role of Sn doping in In2O3 thin films on polymer substrates by pulsed-laser deposition at room temperature. Appl. Phys. Lett. 88, 151908 (2006).

Acknowledgements

This research was supported by the Japan Society for the Promotion of Science, a Grant-in-Aid for Scientific Research (C) (Kakenhi Grant Number JP21K04148), and the AMADA Foundation (AF-2021242-C2). SIM measurements were conducted at the AIST Nano-Processing Facility supported by the “Nanotechnology Platform” of the Ministry of Education, Culture, Sports, Science and Technology (MEXT). The synchrotron radiation experiments were performed using beamline BL46XU at SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal No. 2020A1876). The authors express their sincere gratitude to Dr. Satoshi Yasuno of JASRI for their assistance with the HAXPES measurements.

Author information

Authors and Affiliations

Contributions

J.N., T.K., and I.Y. conceived and designed the experiments. J.N., T.K., I.Y., and H.M. performed the experiments and the characterization of materials. T.N. and Y.K. contributed to the discussion of the results. T.T. supervised the project. J.N. wrote the manuscript, and all authors discussed the results and contributed to the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nomoto, J., Koida, T., Yamaguchi, I. et al. Over 130 cm2/Vs Hall mobility of flexible transparent conductive In2O3 films by excimer-laser solid-phase crystallization. NPG Asia Mater 14, 76 (2022). https://doi.org/10.1038/s41427-022-00421-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-022-00421-4