Abstract

This focus review introduces recent progress made in microphase-separated structures under three-dimensional (3D) confinement. Block copolymers spontaneously form unique structures when the polymer molecules are assembled in confined spaces. The polymers are frustrated because of the limited space for phase separation, resulting in morphologies that are more complex than those of bulk films. In addition to conventional parameters such as volume fraction, molecular weight and interactions of constituent polymers, the confinement effect is a significant parameter for controlling the morphologies. Here I give an overview of experimental and theoretical results for spherical 3D confinement and discuss the prospects for this area of research.

Similar content being viewed by others

Introduction

Microphase-separated structures formed by block copolymers have received much attention for their potential use in basic science and industrial applications.1, 2 Block copolymers are composed of dissimilar polymer segments linked end-to-end via covalent bonds. If these segments are immiscible, then they prefer to separate from each other but are unable to do so because of the covalent bonds linking the segments. Because of this dilemma, block copolymers spontaneously form periodic phase-separated structures. The characteristic lengths of the structures depend on their molecular weights and generally range from 10 to 100 nm. Highly ordered nanostructures can be prepared by simple methods such as spin coating and thus microphase-separated structures have been investigated for diverse nanotechnology applications, for example, etching masks in lithography,3 photonic crystals,4 laser devices,5 filtration6 and photovoltaic devices.7 To control the performance and function of materials, the morphologies of microphase-separated structures have been studied in terms of the conventional parameters of volume fraction, molecular weight and interactions of constituent polymers.

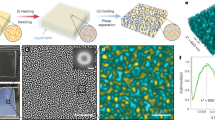

Microphase-separated structures in confined geometries have received much attention, because block copolymers form morphologies very different from those of bulk films due to spatial constraints. Dimensionality is a crucial factor for categorizing the confinement systems for microphase-separated structures (Figure 1a). A thin film is defined as a one-dimensional confinement system, in which the boundary condition is determined by one spatial limitation, that is, the thickness of the film.8, 9, 10, 11, 12 A film with thickness that is not an integer multiple of the period of a microphase-separated structure induces frustration of the block copolymers. Consequently, the resulting morphologies depend on the film thickness. For example, the orientation of cylindrical structures were changed with the film thicknesses. It is noteworthy that perforated lamellar structures were induced by the confinement effect.12 The cylindrical pore of an anodic aluminum oxide membrane and nanofibers prepared by electrospinning are examples of two-dimensional (2D) systems, because they have two boundary conditions, dx and dy, where d is a diameter of cylinder in x and y directions.13, 14, 15, 16, 17, 18, 19 When the dx is equal to the dy, the 2D confinement space has complete cylinders without distortion, Similar to one-dimensional confinement systems, the morphologies under 2D confinement strongly depend on the diameters of the confined spaces. For example, a cylinder-forming diblock copolymer formed stacked disks and torus-like structures in anodic aluminum oxide pores as a 2D confinement system. Notably, a helical structure can form in cylindrical pores with a specific diameter even though the block copolymer has no chirality.19 Three-dimensional (3D) confinement systems, which are higher hierarchical confinement systems, have garnered considerable attention because of their potential to form unique and novel morphologies.20, 21, 22, 23, 24, 25 In spherical nanoparticles as 3D confinement systems, the block copolymers form various distinct structures that differ from those in one-dimensional and 2D confinement systems.

(a) Schematic illustration of types of confinement with dimensionality, symmetry and interface stiffness. (b) Size effect of confinement is defined as D/L0, where L0 is the equilibrium period of the microphase-separated structure in the bulk state and D is a confinement size of boundary condition. (c) Schematic illustration of chemical interactions between polymer segments of block copolymer and confinement matrices. A full colour version of this figure is available at the Polymer Journal journal online.

This focus review introduces an overview of experimental and theoretical results for microphase-separated structures under 3D confinement. Here, the effects of 3D confinement on static microphase-separated structures and the dynamic transformations of the structures are introduced, and the prospects for this area of research are discussed.

3D confinement

Shape and size

Figure 1a shows various types of confinement, including one-dimensional, 2D and 3D systems. The confinement spaces are classified as symmetrical or asymmetrical. In the case of 3D confinement systems, spheres24, 25, 26 and inverted spheres (for example, inversed opals;23, 27) have been used as confinement spaces. Recently, a hemispherical space has been reported for asymmetrical confinement.28, 29

In any confinement system, the size of the confined space is the most important parameter. The size effect of confinement is defined as D/L0, where L0 is the equilibrium period of the microphase-separated structure in the bulk state and D is the confinement size of the boundary conditions (Figure 1b). The value of D/L0 indicates the strength of the size effect; for example, a small D/L0 induces strong frustration for polymers. The degree of the size effect can be categorized as weak or strong confinement (see ‘Morphology under soft 3D confinement’). When D/L0 is >3 (that is, weak confinement), the morphology is usually similar to the bulk state, because the confining space is much larger than the periodicity of the microphase-separated structure at equilibrium. On the other hand, when D/L0 is <2 (that is, strong confinement), unique structures that differ from those of the bulk state are formed by the confining effect.

Stiffness of interface

The stiffness of the interface is also important in controlling the morphology under confinement. Confinement matrices made of rigid materials are classified as ‘hard confinement,’ because the confinement size and the interface between the polymer and matrix are clearly defined. Arsenault et al.21 reported using colloidal crystals and inversed opals to realize 3D hard confinement for the first time. On the other hand, liquid or gas phases are defined as ‘soft confinement,’ because the matrices can be deformed. In soft confinement, the polymers have greater freedom than those in hard confinement, meaning that the shape of interface between polymer and matrix may change to reduce the free energy. The details of soft confinement systems are described in ‘Morphology under soft 3D confinement’.

Interface chemistry

In any confinement system, the interaction energy between the polymer and confinement matrix strongly affects the morphology (Figure 1c). When the confinement matrix interacts equally with the polymer segments of diblock copolymers, both the polymer segments appear at the interface, which is called a ‘neutral surface.’ Conversely, matrices are fully covered by one polymer segment when the matrices strongly interact with the segment. To achieve the desired interfaces of matrices, the surfaces of materials used for confinement spaces have been modified with self-assembled monolayers30 and polymer brushes.31 Random copolymers are grafted onto the surfaces of hard confinement matrices to prepare neutral surfaces.32 In the case of soft confinement, poor solvents for polymers can be used to form confinement spaces with weak interaction, although ideal neutral surfaces are difficult to prepare.33, 34 By adding surfactant molecules or nanoparticles into the dispersion media, interactions between the polymers and surfaces of soft confinement systems can be controlled.35, 36

Morphology under soft 3D confinement

Preparation of block copolymer nanoparticle

Block copolymer nanoparticles have been prepared by using synthetic and non-synthetic techniques. In the early stages of research in this area, amphiphilic block copolymers were investigated as an extension of surfactants of small molecules.1 Amphiphilic copolymers spontaneously form micelles with various shapes in selective solvents; the micelles are considered spherical nanoscale spaces. Although the micelles are much larger than conventional surfactants, the morphologies are similar, which indicates that amphiphilic block copolymers are not frustrated in the micelles. Therefore, most research interest has been focused on the application of micelles for drug delivery systems and so on.37 On the other hand, research into hydrophobic block copolymer nanoparticles is limited due to difficulties in their preparation. As the synthesis of block copolymer requires high purity chemicals to control the polymerization, it is difficult to prepare block copolymer nanoparticles by conventional emulsion polymerization. Kitayama et al.38 have reported that ARGET–ATRP (activators regenerated by electron transfer–atom transfer radical polymerization) in miniemulsion produces nanoparticles from poly(iso-butyl methacrylate-b-styrene). Although ARGET–ATRP enables the synthesis of block copolymer nanoparticles, sophisticated synthetic controls are still required.

Several research groups have investigated the preparation of hydrophobic block copolymer nanoparticles by non-synthetic techniques. The precipitation of block copolymers in emulsion droplets can produce block copolymer nanoparticles dispersed in water.39 The block copolymers are dissolved in a water-immiscible organic solvent and the polymer solution is emulsified in water by adding a small amount of surfactants. Then, the organic solvent in the emulsion droplets is gradually evaporated. The resulting polymer nanoparticles have diameters of several hundred nanometers and the surfaces of nanoparticles are covered with the surfactant molecules. Transmission electron microscopy has revealed that various microphase-separated structures are formed in the nanoparticles, which depend on D/L0. The results indicate that emulsion droplets affect the internal morphologies as a spherical soft 3D confinement. In this 3D confinement system, the morphologies are similar to those of bulk state, because the smallest D/L0 is ~3, which is weak confinement (see ‘Shape and size’).

We have investigated block copolymer nanoparticles prepared by a simple solvent evaporation method.20 Hydrophobic block copolymers (for example, poly(styrene-b-isoprene, PS-b-PI) are dissolved in a good solvent (for example, tetrahydrofuran). A small amount of poor solvent (for example, water), which is miscible in the good solvent, is stirred into the polymer solution. The good solvent is gradually evaporated within 2 days and the boiling point of the poor solvent must be higher than that of the good solvent. After complete evaporation of the good solvent, the block copolymers are precipitated as nanoparticles in the poor solvent. This preparation method, which is called self-organized precipitation, has several advantages. First, particle diameters can be controlled from several tens of nanometers to several micrometers by changing the preparation conditions (for example, concentration of the polymers, mixing ratio of good and poor solvents, and the evaporation speed of the good solvent). Second, the surfaces of the block copolymer nanoparticles obtained have no surfactant, meaning bare polymers are exposed on the particle surfaces. Third, this method can be universally applied to versatile block copolymers by choosing suitable solvents for the polymers.

We systematically prepared lamella-forming PS-b-PI nanoparticles with a range of D/L0 values.24 Figure 2 shows dark-field scanning transmission electron microscopy images of PS-b-PI nanoparticles. When D/L0 is >2.0, one-directional stacked lamellar structures are formed in the nanoparticles. In contrast, various frustrated structures are formed in the nanoparticles in the case of 1.0<D/L0<2.0. These results indicate that the boundary between weak and strong confinement cah be drawn at D/L0=2.0 for spherical soft 3D confinement. This was the first report to experimentally find frustrated structures under soft 3D confinement.

Microphase-separated structures in nanoparticles as a function of block copolymer molecular weight and the D/L0 ratios of 3D confinement systems. The figure is adapted from Higuchi et al.24 Reprinted with permission from Higuchi et al.24 Copyright 2008, Wiley-VCH Verlag GmbH & Co. A full colour version of this figure is available at the Polymer Journal journal online.

3D structure of block copolymer nanoparticle

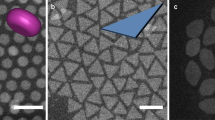

As shown in Figure 2, the frustrated structures are very complicated, so their morphologies cannot be observed by conventional transmission electron microscopy. To determine the frustrated structures in three dimensions, transmission electron microtomography (TEMT) was applied to observe the block copolymer nanoparticles.25 TEMT is a powerful tool for 3D visualization of specimens based on computed tomography.40, 41, 42 Figure 3 shows the 3D structures of block copolymer nanoparticles with D/L0 from 0.66 to 1.89 in the weak confinement regime (D/L0<2) The reconstructed 3D images of lamella-forming PS-b-PI (fPI=0.65) nanoparticles presented in Figures 3a1–a7 are shown in Figures 3b1–d7 along with D/L0 values. In the 3D images, the blue and green phases correspond to the PS and PI phases, respectively. By focusing on the structures of the PS phase, the frustrated structures can be categorized into three types; ring (D/L0=0.66), helix (0.97≤D/L0≤1.52) or branched helix (1.52≤D/L0≤1.89). Although PS-b-PI has no chirality in the molecular structure, it is intriguing that the resulting morphologies are twisted on the surfaces of the nanoparticles. Furthermore, the PS phases twist more intricately as the particle diameters increase (thus D/L0). TEMT revealed the 3D structures of the nanoparticles as strong soft 3D confinement.

(a1–a7) Transmission electron microscopy (TEM) images of diblock copolymer (PS-b-PI) nanoparticles. (b1–b7) 3D structures of nanoparticles having different particle diameters, in which PS and PI phases are shown in blue and green, respectively. The PI (c1–c7) and PS (d1–d7) phases of the nanoparticles are shown separately. The figure is adapted from Higuchi et al.25 Reprinted with permission from Higuchi et al.25 Copyright 2012, The Royal Society of Chemistry.

Simulation of morphology under soft 3D confinement

Before the experimental discovery of frustrated structures under 3D confinement, several groups simulated the theoretical morphologies of diblock copolymers.43, 44, 45, 46, 47 In these simulations, various morphologies including stacked lamellar, onion-like and other complicated structures were predicted; however, it is difficult to make a direct comparison between experimental and simulation results under 3D confinement.48 We recently reported a joint experimental and computer simulation study of the frustrated structures under soft 3D confinement.49 Figure 4 shows a direct comparison of the morphologies in the PS-b-PI nanoparticles between the experimental reults (Figures 4a2–h3) and simulation reults (Figures 4i1–p2). The actual D/L0, fPI and surface areas of the nanoparticles were quantitatively measured from 3D structures obtained by TEMT. These structural parameters were used for the simulation. As shown in Figure 4, our results showed remarkable agreement between the experiments and simulations. However, the exact values of D/L0 differed, which is likely to be due to the fact that the model boundary conditions of the simulations cannot be perfectly reflected in the actual nanoparticles. When our D/L0 values are compared with those of another simulation results by using a different simulation technique,45 the experimental values were in disagreement with the simulation. This suggests that the mismatch of D/L0 is universal problems underlying in any simulations. Although the values of D/L0 in the simulation are still under discussion, the results show the same sequence of structures in both the experiments and simulations, which indicates that simulation using the structural parameters extracted from experimental results enabled the morphologies under 3D confinement to be predicted.

(a1–h1) Transmission electron microscopy (TEM) and (a2–h2 and a3–h3) 3D structures of diblock copolymer (PS-b-PI) nanoparticles obtained by TEMT. The blue and green phases in the 3D images correspond to the PS and PI phases, respectively. (i1–p1 and i2–p2) Simulated structures of diblock copolymer in spherical confinement. Scale bars in (a1–h1) indicate 100 nm. The figure is adapted from Higuchi et al.49 Reprinted with permission from Higuchi et al.49 Copyright 2016, Wiley-VCH Verlag GmbH & Co.

Phase transformation under soft 3D confinement

The dynamic transformations of the morphologies and the static structures of microphase-separated structures in the bulk state have been investigated. In this section, we introduce morphological transformation under 3D confinement.33, 34 In as-cast block copolymer films, the microphase-separated structures are frozen in a non-equilibrium state because of the rapid evaporation of solvents. Various techniques have been developed to lead them to equilibrium structures.50, 51, 52, 53, 54, 55, 56 In general, block copolymer films are thermally annealed at temperatures above the glass transition temperature (Tg) over a long period (for example, 2 days to several weeks). Thermal annealing is applied to the block copolymer nanoparticles, similar to bulk films.33 Lamella-forming PS-b-PI nanoparticles with random structures are prepared by self-organized precipitation method at 10 °C and then the nanoparticle dispersion is annealed stepwise up to 40 °C, which is below Tg of PS. The dispersion is annealed at each temperature for 2 weeks. After annealing at 20 °C, the morphologies in nanoparticles are changed to one-directional stacked lamellar structures. Furthermore, onion-like structures form in the nanoparticles when they are annealed at 40 °C. To determine the transformation process from one-directional stacked lamellar to onion-like structure, a structural analysis was carried out by scanning transmission electron microscopy and TEMT (Figure 5). As indicated by the white arrow in Figure 5b, the transformation began from the polar layer of one-directional stacked lamellar structures and propagated toward the opposite polar region (Figures 5c and d). Eventually, all layers were transformed to onion-like structures (Figure 5f). The 3D structure of the nanoparticles in the transformation state was directly visualized by TEMT (Figures 5g–i). The cross-sectional images revealed that the layers bend along the nanoparticle surface. These results show that morphological transformation in the nanoparticles is induced by thermal annealing, even though the annealing temperature is below the glass transition temperature of a polymer segment. Such unusual transformations imply that the thermal properties of block copolymers under 3D confinement differ from those in the bulk state. As thermal annealing is considered another dimension in a confinement system, the morphological transformation in the nanoparticle may be defined as a four-dimensional confinement system.

Dark-field scanning transmission electron microscopy (STEM) images of lamella-forming diblock copolymer nanoparticles prepared at 35 °C. Nanoparticles with (a) one-directional stacked lamellar, (b–e) various transformed lamellar, and (f) onion-like structures were observed. Scale bars indicate 100 nm. (g) 3D structures of the nanoparticles and (h and i) cross-sectional image of nanoparticles with transformed lamellar structures obtained by TEMT. The blue and green regions correspond to PS and PI moieties, respectively. Scale bars indicate 100 nm. The figure is adapted from Higuchi et al.33 Reprinted with permission from Higuchi et al.33 Copyright 2016, Wiley-VCH Verlag GmbH & Co.

Future prospects

In this review, I have presented an overview of the experimental and theoretical results under spherical soft 3D confinement. To complete our review, we discuss the prospects for future developments of block copolymers under 3D confinement.

In this research field, an important goal is to obtain a fundamental understanding of the effect of confinement shape on microphase-separated structures. Although my review has focused on spherical nanoparticles as a 3D confinement space, various shapes of 3D confinement spaces are possible. Even lamella-forming diblock copolymers, which represent the simplest morphology of block copolymer, form a wide variety of complicated structures in the nanoparticles and have the simplest confinement shape. The effect of confinement shape originates in the mismatch between the intrinsic interfacial curvature of the block copolymer and the curvature of the confinement space. A hemispherical shape can form unique frustrated morphologies, because it is composed of curved and flat curvatures.

Recent developments in polymerization techniques have enabled the synthesis of block copolymers with various chemical structures including stars, grafts, multiblocks, gradient block copolymers and so on.57, 58, 59, 60, 61, 62 For example, the morphologies of linear triblock terpolymers (A-b-B-b-C), with one polymer segment added to the diblock copolymer (A-b-B), diversify even in bulk states.63, 64, 65, 66 The morphologies of triblock terpolymers under 3D confinement are expected to be more complicated compared with those of diblock copolymers. TEMT and related 3D microscopy are essential techniques for the analysis of these morphologies. Novel characterization techniques may help improve our understanding of the 3D confinement effect. In addition to the development of experimental techniques, it is important to improve the computational accuracy of morphological simulation. As described in ‘Simulation of morphology under soft 3D confinement’, simulation results are not perfectly consistent with the actual morphologies under 3D confinement. If simulation could predict the true morphologies with reasonable accuracy, it would be possible to form tailored structures under 3D confinement by using the experiential conditions suggested by the simulations.

Nanoparticles with unique microphase-separated structures have the potential to become novel materials for optical, photonic, electronic and biological applications in the fields of nanoscience and nanotechnology. Hybrids of polymer nanoparticles and inorganic materials, such as metals and semiconductor nanoparticles, can also be used for these applications.67, 68 In 2D and 3D confinement systems, the helical structures are induced by the confinement effect as reported in the literature19 (2D) and Figure 3 (3D), respectively. However, their helical handedness cannot currently be controlled. If handedness could be controlled, it would be possible to prepare novel chiral metamaterials by metalization of helical polymer phases.

References

Hamley, I. Developments in Block Copolymer Science and Technology, (John Wiley & Sons Ltd, Chichester, 2004).

Bates, S. F. & Fredrickson, H. G. Block copolymer thermodynamics: theory and experiment. Annu. Rev. Phys. Chem. 41, 525–557 (1990).

Park, M., Harrison, C., Chaikin, P. M., Register, R. A. & Adamson, D. H. Block copolymer lithography: periodic arrays of ~1011 holes in 1 square centimeter. Science 276, 1401–1404 (1997).

Kang, C., Kim, E., Baek, H., Hwang, K., Kwak, D., Kang, Y. & Thomas, E. L. Full color stop bands in hybrid organic/inorganic block copolymer photonic gels by swellingfreezing. J. Am. Chem. Soc. 131, 7538–7539 (2009).

Yoon, J., Lee, W. & Thomas, E. L. Optically pumped surface-emitting lasing using self-assembled block-copolymer-distributed Bragg reflectors. Nano Lett. 6, 2211–2214 (2006).

Yang, S., Ryu, I., Kim, H., Kim, J., Jang, S. & Russell, T. P. Nanoporous membranes with ultrahigh selectivity and flux for the filtration of viruses. Adv. Mater. 18, 709–712 (2006).

Johnson, K., Huang, Y. S., Huettner, S., Sommer, M., Brinkmann, M., Mulherin, R., Niedzialek, D., Beljonne, D., Clark, J., Huck, W. T. & Friend, R. H. Control of intrachain charge transfer in model systems for block copolymer photovoltaic materials. J. Am. Chem. Soc. 135, 5074–5083 (2013).

Russell, T. P., Menelle, A., Anastasiadis, S., Satija, S. & Majkrzak, C. Unconventional morphologies of symmetric, diblock copolymers due to film thickness constraints. Macromolecules 24, 6263–6269 (1991).

Lambooy, P., Russell, T. P., Kellogg, G. J., Mayes, A. M., Gallagher, P. D. & Satija, S. K. Observed frustration in confined block copolymers. Phys. Rev. Lett. 72, 2899–2902 (1994).

Koneripalli, N., Singh, N., Levicky, R., Bates, F. S., Gallagher, P. D. & Satija, S. K. Confined block copolymer thin films. Macromolecules 28, 2897–2904 (1995).

Kellogg, G., Walton, D., Mayes, A., Lambooy, P., Russell, T. P., Gallagher, P. & Satija, S. Observed surface energy effects in confined diblock copolymers. Phys. Rev. Lett. 76, 2503–2506 (1996).

Knoll, A., Horvat, A., Lyakhova, K., Krausch, G., Sevink, G., Zvelindovsky, A. V. & Magerle, R. Phase behavior in thin films of cylinder-forming block copolymers. Phys. Rev. Lett. 89, 035501 (2002).

Shin, K., Xiang, H., Moon, S., Kim, T., McCarthy, T. & Russell, T. P. Curving and frustrating flatland. Science 306, 76–76 (2004).

Wu, Y., Cheng, G., Katsov, K., Sides, S., Wang, J., Tang, J., Fredrickson, G., Moskovits, M. & Stucky, G. Composite mesostructures by nano-confinement. Nat. Mater. 3, 816–822 (2004).

Xiang, H., Shin, K., Kim, T., Moon, S., McCarthy, T. J. & Russell, T. P. The influence of confinement and curvature on the morphology of block copolymers. J. Polym. Sci. Polym. Phys. 43, 3377–3383 (2005).

Xiang, H., Shin, K., Kim, T., Moon, S. I., McCarthy, T. J. & Russell, T. P. From cylinders to helices upon confinement. Macromolecules 38, 1055–1056 (2005).

Ma, M., Krikorian, V., Yu, J. H., Thomas, E. L. & Rutledge, G. C. Electrospun polymer nanofibers with internal periodic structure obtained by microphase separation of cylindrically confined block copolymers. Nano Lett. 6, 2969–2972 (2006).

Kalra, V., Mendez, S., Lee, J. H., Nguyen, H., Marquez, M. & Joo, Y. L. Confined assembly in coaxially electrospun block copolymer fibers. Adv. Mater. 18, 3299–3303 (2006).

Dobriyal, P., Xiang, H., Kazuyuki, M., Chen, J.-T., Jinnai, H. & Russell, T. P. Cylindrically confined diblock copolymers. Macromolecules 42, 9082–9088 (2009).

Yabu, H., Higuchi, T. & Shimomura, M. Unique phase-separation structures of block-copolymer nanoparticles. Adv. Mater. 17, 2062–2065 (2005).

Arsenault, A. C., Rider, D. A., Tetreault, N., Chen, J. I. L., Coombs, N., Ozin, G. A. & Manners, I. Block copolymers under periodic, strong three-dimensional confinement. J. Am. Chem. Soc. 127, 9954–9955 (2005).

Saito, N., Takekoh, R., Nakatsuru, R. & Okubo, M. Effect of stabilizer on formation of ‘onionlike’ multilayered polystyrene-block-poly(methyl methacrylate) particles. Langmuir 23, 5978–5983 (2007).

Rider, D. A., Chen, J. I. L., Eloi, J.-C., Arsenault, A. C., Russell, T. P., Ozin, G. A. & Manners, I. Controlling the morphologies of organometallic block copolymers in the 3-dimensional spatial confinement of colloidal and inverse colloidal crystals. Macromolecules 41, 2250–2259 (2008).

Higuchi, T., Tajima, A., Motoyoshi, K., Yabu, H. & Shimomura, M. Frustrated phases of block copolymers in nanoparticles. Angew. Chem. Int. Ed. 47, 8044–8046 (2008).

Higuchi, T., Motoyoshi, K., Sugimori, H., Jinnai, H., Yabu, H. & Shimomura, M. Three-dimensional observation of confined phase-separated structures in block copolymer nanoparticles. Soft Matter 8, 3791–3797 (2012).

Wyman, I., Njikang, G. & Liu, G. When emulsification meets self-assembly: the role of emulsification in directing block copolymer assembly. Prog. Polym. Sci. 36, 1152–1183 (2011).

Fu, J., Wang, J., Li, Q., Kim, D. H. & Knoll, W. 3D hierarchically ordered composite block copolymer hollow sphere arrays by solution wetting. Langmuir 26, 12336–12341 (2010).

Bae, D., Jeon, G., Jinnai, H., Huh, J. & Kim, J. K. Arrangement of block copolymer microdomains confined inside hemispherical cavities. Macromolecules 46, 5301–5307 (2013).

Lee, D., Kim, M. H., Bae, D., Jeon, G., Kim, M., Kwak, J., Park, S. J., Kim, J. U. & Kim, J. K. Arrangement of lamellar microdomains of block copolymer confined in hemispherical cavities having two controlled interfaces. Macromolecules 47, 3997–4003 (2014).

Jeong, S.-J., Xia, G., Kim, B. H., Shin, D. O., Kwon, S.-H., Kang, S.-W. & Kim, S. O. Universal block copolymer lithography for metals, semiconductors, ceramics, and polymers. Adv. Mater. 20, 1898–1904 (2008).

Cheng, J. Y., Ross, C. A., Smith, H. I. & Thomas, E. L. Templated self-assembly of block copolymers: top-down helps bottom-up. Adv. Mater. 18, 2505–2521 (2006).

Bang, J., Bae, J., Lowenhielm, P., Spiessberger, C., Given-Beck, S. A., Russell, T. P. & Hawker, C. J. Facile routes to patterned surface neutralization layers for block copolymer lithography. Adv. Mater. 19, 4552–4557 (2007).

Higuchi, T., Motoyoshi, K., Sugimori, H., Jinnai, H., Yabu, H. & Shimomura, M. Phase transition and phase transformation in block copolymer nanoparticles. Macromol. Rapid Commun. 31, 1773–1778 (2010).

Higuchi, T., Shimomura, M. & Yabu, H. Reorientation of microphase-separated structures in water-suspended block copolymer nanoparticles through microwave annealing. Macromolecules 46, 4064–4068 (2013).

Jang, S. G., Audus, D. J., Klinger, D., Krogstad, D. V., Kim, B. J., Cameron, A., Kim, S. W., Delaney, K. T., Hur, S. M., Killops, K. L., Fredrickson, G. H., Kramer, E. J. & Hawker, C. J. Striped, ellipsoidal particles by controlled assembly of diblock copolymers. J. Am. Chem. Soc. 135, 6649–6657 (2013).

Klinger, D., Wang, C. X., Connal, L. A., Audus, D. J., Jang, S. G., Kraemer, S., Killops, K. L., Fredrickson, G. H., Kramer, E. J. & Hawker, C. J. A facile synthesis of dynamic, shape-changing polymer particles. Angew. Chem. Int. Ed. 53, 7018–7022 (2014).

Kataoka, K., Harada, A. & Nagasaki, Y. Block copolymer micelles for drug delivery: design, characterization and biological significance. Adv. Drug Deliv. Rev. 47, 113–131 (2001).

Kitayama, Y., Kagawa, Y., Minami, H. & Okubo, M. Preparation of micrometer-sized, onionlike multilayered block copolymer particles by two-step AGET ATRP in aqueous dispersed systems: effect of the second-step polymerization temperature. Langmuir 26, 7029–7034 (2010).

Jeon, S.-J., Yi, G.-R., Koo, C. M. & Yang, S.-M. Nanostructures inside colloidal particles of block copolymer/homopolymer blends. Macromolecules 40, 8430–8439 (2007).

Kawase, N., Kato, M., Nishioka, H. & Jinnai, H. Transmission electron microtomography without the “missing wedge” for quantitative structural analysis. Ultramicroscopy 107, 8–15 (2007).

Jinnai, H., Spontak, R. J. & Nishi, T. Transmission electron microtomography and polymer nanostructures. Macromolecules 43, 1675–1688 (2010).

Jinnai, H., Tsuchiya, T., Motoki, S., Kaneko, T., Higuchi, T. & Takahara, A. Transmission electron microtomography in soft materials. Microscopy 62, 243–258 (2013).

Fraaije, J. & Sevink, G. Model for pattern formation in polymer surfactant nanodroplets. Macromolecules 36, 7891–7893 (2003).

Sevink, G. J. A. & Zvelindovsky, A. V. Self-assembly of complex vesicles. Macromolecules 38, 7502–7513 (2005).

Yu, B., Li, B., Jin, Q., Ding, D. & Shi, A.-C. Self-assembly of symmetric diblock copolymers confined in spherical nanopores. Macromolecules 40, 9133–9142 (2007).

Chen, P., Liang, H. & Shi, A.-C. Microstructures of a cylinder-forming diblock copolymer under spherical confinement. Macromolecules 41, 8938–8943 (2008).

Yang, R., Li, B. & Shi, A.-C. Phase behavior of binary blends of diblock copolymer/homopolymer confined in spherical nanopores. Langmuir 28, 1569–1578 (2012).

Pinna, M., Hiltl, S., Guo, X., Boeker, A. & Zvelindovsky, A. V. Block copolymer nanocontainers. ACS Nano 4, 2845–2855 (2010).

Higuchi, T., Pinna, M., Zvelindovsky, A. V., Jinnai, H. & Yabu, H. Multipod structures of lamellae-forming diblock copolymers in three-dimensional confinement spaces: experimental observation and computer simulation. J. Polym. Sci. Part B Polym. Phys. 54, 1702–1709 (2016).

Amundson, K., Helfand, E., Quan, X., Hudson, S. D. & Smith, S. D. Alignment of lamellar block copolymer microstructure in an electric field. 2. Mechanisms of alignment. Macromolecules 27, 6559–6570 (1994).

Bodycomb, J., Funaki, Y., Kimishima, K. & Hashimoto, T. Single-grain lamellar microdomain from a diblock copolymer. Macromolecules 32, 2075–2077 (1999).

Honeker, C. C. & Thomas, E. L. Impact of morphological orientation in determining mechanical properties in triblock copolymer systems. Chem. Mater. 8, 1702–1714 (1996).

Auschra, C. & Stadler, R. Polymer alloys based on poly(2,6-dimethyl-1,4-phenylene ether) and poly(styrene-co-acrylonitrile) using poly(styrene-b-(ethylene-co-butylene)-b-methyl methacrylate) triblock copolymers as compatibilizers. Macromolecules 26, 6364–6377 (1993).

Park, S., Lee, D. H., Xu, J., Kim, B., Hong, S. W., Jeong, U., Xu, T. & Russell, T. P. Macroscopic 10-terabit-per-square-inch arrays from block copolymers with lateral order. Science 323, 1030–1033 (2009).

Pinheiro, B. & Winey, K. Mixed parallel-perpendicular morphologies in diblock copolymer systems correlated to the linear viscoelastic properties of the parallel and perpendicular morphologies. Macromolecules 31, 4447–4456 (1998).

Kimura, M., Misner, M. J., Xu, T., Kim, S. H. & Russell, T. P. Long-range ordering of diblock copolymers induced by droplet pinning. Langmuir 19, 9910–9913 (2003).

Alward, D., Kinning, D., Thomas, E. & Fetters, L. Effect of arm number and arm molecular-weight on the solid-state morphology of poly(styrene-isoprene) star block copolymers. Macromolecules 19, 215–224 (1986).

Aoshima, S. & Higashimura, T. Living cationic polymerization of vinyl monomers by organoaluminum halides. 3. Living polymerization of isobutyl vinyl ether by ethyldichloroaluminum in the presence of ester additives. Macromolecules 22, 1009–1013 (1989).

Borner, H., Beers, K., Matyjaszewski, K., Sheiko, S. & Moller, M. Synthesis of molecular brushes with block copolymer side chains using atom transfer radical polymerization. Macromolecules 34, 4375–4383 (2001).

Higaki, Y., Otsuka, H. & Takahara, A. Synthesis of well-defined poly(styrene)-b-poly(p-tert-butoxystyrene) multiblock copolymer from poly(alkoxyamine) macroinitiator. Polymer 44, 7095–7101 (2003).

Lee, S. B., Russell, A. J. & Matyjaszewski, K. ATRP synthesis of amphiphilic random, gradient, and block copolymers of 2-(dimethylamino)ethyl methacrylate and n-butyl methacrylate in aqueous media. Biomacromolecules 4, 1386–1393 (2003).

Matyjaszewski, K. Atom transfer radical polymerization (ATRP): current status and future perspectives. Macromolecules 45, 4015–4039 (2012).

Abetz, V. & Goldacker, T. Formation of superlattices via blending of block copolymers. Macromol. Rapid Commun. 21, 16–34 (2000).

Schacher, F., Yuan, J., Schoberth, H. G. & Müller, A. H. E. Synthesis, characterization, and bulk crosslinking of polybutadiene-block-poly(2-vinyl pyridine)-block-poly(tert-butyl methacrylate) block terpolymers. Polymer 51, 2021–2032 (2010).

Jinnai, H., Kaneko, T., Matsunaga, K., Abetz, C. & Abetz, V. A double helical structure formed from an amorphous, achiral ABC triblock terpolymer. Soft Matter 5, 2042–2046 (2009).

Higuchi, T., Sugimori, H., Jiang, X., Hong, S., Matsunaga, K., Kaneko, T., Abetz, V., Takahara, A. & Jinnai, H. Morphological control of helical structures of an ABC-type triblock terpolymer by distribution control of a blending homopolymer in a block copolymer microdomain. Macromolecules 46, 6991–6997 (2013).

Yabu, H., Koike, K., Motoyoshi, K., Higuchi, T. & Shimomura, M. A novel route for fabricating metal-polymer composite nanoparticles with phase-separated structures. Macromol. Rapid Commun. 31, 1267–1271 (2010).

Yabu, H., Endo, A., Koike, K., Motoyoshi, K., Higuchi, T. & Shimomura, M. Hierarchical assembly of CdS nanoparticles in polymer particles with phase separation structures. Polym. J. 43, 301–305 (2011).

Acknowledgements

I thank all colleagues and collaborators on this research project, in particular Professor M Shimomura, Professor H Yabu and Professor H Jinnai. This work was partially supported by JSPS KAKENHI Grant Number 16H06040, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The author declares no conflict of interest.

Rights and permissions

About this article

Cite this article

Higuchi, T. Microphase-separated structures under spherical 3D confinement. Polym J 49, 467–475 (2017). https://doi.org/10.1038/pj.2017.13

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.13

This article is cited by

-

Simulation of Surface-Induced Morphology Transition and Phase Diagram of Linear Triblock Copolymers under Spherical Confinement

Chinese Journal of Polymer Science (2023)