Abstract

Main chain-type liquid crystalline (LC) polyrotaxanes were synthesized via the ene-thiol copolymerization of pseudorotaxane and LC monomers. The effects of the rotaxane moiety and its content on the LC properties were investigated using differential scanning calorimetry. Introduction of the rotaxane moiety on the LC polymer reduced the stabilization of the LC phase. Neutralization of the rotaxane moiety also destabilized the LC phase, most likely due to the movable wheel components of the rotaxane on the axle LC polymer chain.

Similar content being viewed by others

Introduction

Interlocked polymers such as polyrotaxanes and polycatenanes have received great attention not only with respect to the synthesis of these mechanically linked polymers but also because of the unique properties that are derived from these structures. The synthesis of polyrotaxane was initially reported by Harada et al.1 Additionally, many studies on the synthesis of polyrotaxanes using cyclodextrin (CD)2, 3, 4, 5, 6, 7 or crown ethers8, 9, 10, 11, 12, 13 as a wheel component have been reported in the last two decades. With respect to CD-based polyrotaxanes, the efficient synthesis of polyrotaxanes has progressed because of the achievement of effective complexation and end-capping reactions.6, 7 The focus of polyrotaxane synthesis efforts is now shifting to the development of functional soft materials such as molecular nanotubes,14 molecular wires,15 slide-ring gels,16 polyrotaxane networks17 and multivalent-binding recognition molecules.18

On the other hand, there are many reports on the synthesis of rotaxanes using a crown ether as a wheel component8, 9, 10, 11, 12, 13 to control the location of the wheel component, that is, to achieve the free movement of the crown ether along the axle molecule. This active control of the location of the wheel component is called rotaxane switch, and it has been applied to the development of supramolecular nanotechnologies such as molecular machines,19 molecular elevators20 and molecular shuttles.21, 22, 23 We have recently reported the application of rotaxane switches in a polymer system that involved the conformational change of a polyacetylene with pendant rotaxane moieties from a one-handed helix to a random helix via control of the location of the crown ether.24, 25 This result revealed the potential of rotaxanes to be used in stimuli-responsive polymer materials, even though the rotaxane moiety was introduced as a pendant group. To investigate the influence of the rotaxane moiety existing on the main chain, a main chain-type polyrotaxane was designed in which the liquid crystalline (LC) polymer was used as an axle polymer. There are a few reports26, 27, 28, 29, 30 on the synthesis of liquid crystals with rotaxane structures, to the best of our knowledge. Aprahamian et al.26 reported the synthesis of a switchable [2] rotaxane with LC components to build up the rotaxane moieties in a smectic A phase. A CD-based polyrotaxane with a number of mesogenic side chains was first synthesized by Kidowaki et al.27 to explore the effects of movable mesogenic groups. Terao et al.28 reported on the synthesis of CD-based polyrotaxanes with a conjugated polymer as an axle polymer to develop insulated molecular wires and found a lyotropic LC phase in concentrated chloroform solution due to the rigidity of the main chain polymer. However, no reports exist regarding investigation of the effects of rotaxane structures on main chain-type LC polymers. Herein, crown ether-type polyrotaxanes containing a main chain-type LC polymer (PR-LCPs) as the axle polymer were synthesized via ene-thiol polymerization, and the effects of the rotaxane moiety on the LC properties were investigated.

Materials and methods

Materials

All solvents were dried and distilled before use according to general purification procedures. Commercially available reagents were used without further purification unless otherwise noted. A radical generator with a low decomposition temperature, V-70 (2,2′-azobis(4-methoxy-2,4-dimethyl valeronitrile)), was purchased from Wako Pure Chemical Industries, Ltd., Osaka, Japan. All reactions were carried out in inert atmosphere. Silica gel column chromatography was performed using silica gel N60 (grain size 40–50 μm) (Kanto Chemical Co. Inc., Tokyo, Japan). The axle monomer (1′), LC monomers (2, 3) and end-capping agents (4, 5) were synthesized according to the literature.31, 32, 33, 34

Synthesis of LC polyrotaxanes

Scheme 1 shows the synthetic pathway of PR-LCPs. The synthesis of PR5·PF6 is described here as the typical procedure. To a solution of axle monomer 1′ (82.1 mg, 0.150 mmol) and dibenzo-24-crown-8-ether (DB24C8; 82.4 mg, 0.150 mmol) in dried chloroform (31 ml) treated with sonication to form the pseudorotaxane complex, LC monomer 2 (538 mg, 1.36 mmol), LC monomer 3 (701 mg, 1.50 mmol) and V-70 (64.4 mg, 0.210 mmol) were added and stirred for 24 h at 30 °C. The end-cap agent 4 (143 mg, 0.940 mmol) and V-70 (32.2 mg, 0.110 mmol) were added to the reaction mixture and stirred for 24 h at 30 °C. In addition, the end-cap agent 5 (765 mg, 3.70 mmol) and V-70 (127 mg, 0.410 mmol) were added to the reaction mixture and stirred for another 24 h at 30 °C. The reaction mixture was poured into methanol (20 ml). The precipitate was collected by filtration and dried in vacuo to give PR5·PF6 (94%, 1.32 g) as a white solid.

Neutralization of LC polyrotaxanes

To a solution of PR5·PF6 (100 mg) in chloroform (10 ml) was added tetra(n-butyl)ammonium chloride trihydrate (8.34 mg, 0.0300 mmol) at room temperature. After stirring for 6 h, the mixture was washed with water (30 ml) and aqueous Na2CO3 (10 wt%). The organic layer was dried over Na2SO4, filtered and concentrated in vacuo to give PR5 (77%, 77.2 mg) as a white solid.

Characterization

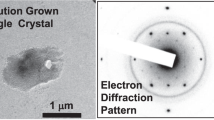

1H (400 MHz) and 13C (100 MHz) nuclear magnetic resonance (NMR) spectra were recorded on a JEOL AL-400 spectrometer (JEOL Ltd., Tokyo, Japan) using CDCl3 as the solvent, calibrated using tetramethylsilane as the internal standard. NMR chemical shifts were recorded in delta units (δ). IR spectra were recorded on a JASCO FT/IR-230 spectrometer (JASCO Corporation, Tokyo, Japan). Melting points were measured on Stuart melting point apparatus SMP3 (Stuart Scientific, Bibby Scientific Limited, Staffordshire, UK) and Shimazdu DSC-60 instrument (Shimadzu Corporation, Kyoto, Japan). Size exclusion chromatography (gel permeation chromatography (GPC)) was performed using JASCO PU-2080 Plus HPLC pump with JASCO UV-1570 UV detector and JASCO RI-1530 RI detector equipped with consecutive TOSOH TSKgel GMHXL and G5000HXL linear polystyrene gel columns at 30 °C in CHCl3 (1.0 ml min−1). The number average molecular weight (Mn), weight average molecular weight (Mw) and polydispersity index (Mw/Mn) of the polymers were calculated on the basis of polystyrene standards. Differential scanning calorimetry (DSC) analysis was carried out with Shimadzu DSC-60 instrument under nitrogen (flow rate of 50 ml min−1), with liquid nitrogen as a refrigerant to determine the phase transition temperature. Elemental analysis was performed with J-Science JM10 (Kyoto, Japan), Yanaco HSU-20+ICS-1100 (Kyoto, Japan) and Elementar Vario EL. Elementar Analysensysteme GmbH (Hanau, Germany) LC texture was observed with a polarizing optical microscope (POM) equipped with self-produced hot stage and temperature controller. Wide-angle X-ray powder diffraction (WAXD) measurement was carried out with Bruker AXS D8 DISCOVER μHR Bruker Corporation (Billerica, MA, USA) equipped with 2D PSPC Hi-STAR, with CuKα radiation at 50 kV and 22 mA.

Results and Discussion

Synthesis of LC polyrotaxanes

The PR-LCPs were synthesized via the copolymerization of the diolefin-type pseudorotaxane monomer 1 with LC monomers 2 and 3. The pseudorotaxane monomer 1 was prepared via the complexation of the diolefin-type ammonium hexafluorophosphate (PF6) axle molecule (1′) and DB24C8 in dichloromethane at room temperature (see Supplementary Information) as a result of the favorable complexation of ammonium PF6 and DB24C8 in less polar solvents (chloroform and dichloromethane) at ambient temperature. The content of the rotaxane moiety in PR-LCPs was controlled by adjusting the feed ratio of the pseudorotaxane monomer 1 to the LC monomers 2 and 3 (1/2/3) ranging from 5/45/50 to 30/20/50. The polymerization of the mixture proceeded in dichloromethane at 30 °C for 24 h in an inert atmosphere using V-70 as the radical initiator (half-life at 30 °C=10 h). After the completion of polymerization, the end-capping agents 4 and 5 and additional V-70 were added sequentially to the reaction mixture and with stirring for 24 h after each addition. As a result, several PR-LCPs were obtained.

LC monomers 2 and 3 were chosen to form the axle polymers of the polyrotaxanes because the resultant polymers were expected to be sufficiently thin to penetrate the cavity of DB24C8. In addition, a PR-LCP without the rotaxane moiety (PR0) was synthesized as a control sample via the step-growth ene-thiol polymerization using an equivalent amount of diolefin monomer 2 and dithiol monomer 3. PR0 has been reported to show crystalline–nematic–isotropic phase transitions.35, 36

Table 1 summarizes the feed conditions and the data of the resultant PR-LCPs, which are labeled as PRx·PF6, where x denotes the feed ratio of the pseudorotaxane monomer 1. The content of the rotaxane moiety in the polymer chain was found to be related to the feed ratio, but the difference between the feed ratio and the composition gradually increased as the amount of 1 in the feed increased because of its relatively poor solubility in dichloromethane. The polymerization yield was moderate regardless of the feed ratio, and the molecular weight of the obtained polymers was sufficiently high to allow stable phase transitions independent of the molecular weight.

The chemical structure of the PR-LCPs was determined using 1H NMR, GPC and elemental analyses. Figure 1 shows the 1H NMR and GPC spectra for PR5·PF6 and PR5. In the 1H NMR spectrum of PR5·PF6, specific characteristic peaks for both the benzyl protons adjacent to the ammonium (b) and the protons in the wheel component (α, γ, φ) were identified and were in accord with the literature for the peaks of rotaxane structures.23 In addition, the characteristic mesogenic peaks for the neighboring carbonyl group (a) confirmed the existence of LC moieties. The GPC profile of PR5·PF6 shows a monomodal peak with a rather broad molecular weight distribution. Consequently, we concluded that a main chain-type LC polymer bearing a rotaxane structure in the main chain was successfully synthesized via the ene-thiol copolymerization of pseudorotaxane and LC monomers.

Neutralization of LC polyrotaxanes

Conversion of the ammonium salt of the rotaxane moiety to amine was performed to remove the strong interaction between the ammonium moiety and DB24C8 and to release the wheel component. The rotaxane moiety of PRx·PF6 was neutralized using a counteranion exchange method that was recently developed by our group.22, 37, 38, 39, 40 Thus, the polymers PRx·PF6 were treated with tetra-n-butylammonium chloride (TBACl) in DMF and then saturated aqueous NaHCO3 to give the corresponding PR-LCPs with non-ionic rotaxane (PRx) groups. The successful neutralization was confirmed by 1H NMR, as shown in Figure 1a. The signals for the benzyl protons (b) of PR5·PF6 at 4.4 p.p.m. disappeared or were shifted upfield with the neutralization. In addition, two of the DB24C8 signals (γ, ϕ) were shifted downfield by the removal of the restraining effect of the DB24C8 group by the ammonium salt group. The GPC profile of PR5 (Figure 1b) implies that no side reactions, such as chain scission, occurred. Based on these results, it was concluded that the PRx·PF6 polymers were neutralized and converted to PRx along with the release of the wheel components from the interaction with the ammonium moiety.

To confirm the free movement of DB24C8 on the main chain, PR-LCP without end-cap groups was prepared and neutralized. After the neutralization, specific 1H NMR signals for isolated DB24C8 were observed, indicating slippage from the axle polymer (see Supplementary Information). This result supports the likelihood that the ring size of DB24C8 is large enough to move over the mesogenic groups.

Effect of the rotaxane composition on the LC properties

The effect of the rotaxane component on the LC properties of the PR-LCPs was investigated by DSC, POM and WAXD. In the DSC thermograms of the second heating scan with a heating rate of 10 °C min−1, PR5·PF6 and PR10·PF6 showed two transition peaks corresponding to the crystal-LC and LC-isotropic transitions as shown in Figure 2, while PR20·PF6 had one broad peak. In the region between the crystal phase and the isotropic phase, PR5·PF6 and PR10·PF6 exhibited LC phases by the POM observation (see Supplementary Information). Furthermore, the WAXD profiles (see Supplementary Information) showed similar diffraction patterns to PR0 in the same region, indicating the formation of a nematic phase. The temperatures and enthalpies (ΔH) of the transitions are summarized in Table 2.

Focusing on the transition peak temperature of the nematic to isotropic phase (TNI), PR5·PF6 showed a lower transition temperature than PR0, implying the destabilization of the LC phase due to the introduction of the rotaxane moiety. PR10·PF6 exhibited a broader transition peak at a similar peak temperature to PR5·PF6, which had a lower onset temperature of the peak than that of PR5·PF6. Moreover, the transition peak temperature of the crystal to nematic phase (TCrN) increased from 76 to 95 °C for PR5·PF6 and PR10·PF6, making the temperature range of the LC phase narrower. In the case of further introduction of rotaxane moieties in the LC polymer represented as PR20·PF6, no LC phase was observed.

These results suggested that the LC properties were affected by the presence of the rotaxane moiety. As a bulky group, the rotaxane structure was assumed to destabilize the LC phase in a manner similar to that observed when alkyl substituents were introduced on a mesogenic group.41, 42, 43

Effect of the mobility of the wheel components on the LC properties

The effects of the delocalized wheel components on the LC properties were also investigated. Figure 3 shows the DSC thermograms of PRx·PF6 and PRx. The phase transition temperatures are summarized in Table 2. Comparing PR5·PF6 with PR5, it was observed that TNI decreased from 124 to 120 °C, while TCrN increased from 76 to 80 °C after neutralization of the ammonium moiety to make the wheel components movable. In the case of PR10, no significant transition peak indicating the LC phase was detected in the DSC thermogram, although the LC phase was actually observed for PR10·PF6. No LC phase was observed for both PR20·PF6 and PR20. In summary, it could be a tendency of the LC phase to be destabilized after neutralization. The reason for this tendency remains unclear, but it may be attributed to the fact that the delocalized wheel components can be positioned at any place on the polymer chain, even at the alkyl spacer or the mesogenic groups. Therefore, the presence of the wheel components on the mesogenic groups might interfere with their alignment to destabilize the LC phase.

Effect of the wheel component on the LC properties

To further explore the effects of the wheel components on the LC properties, a LC polymer bearing ammonium groups but without any wheel components, AX5·PF6, was synthesized by a similar copolymerization of 1′ instead of 1 (see Supplementary Information). The polymer AX5·PF6 was also neutralized to give AX5, and the thermal properties of these polymers were investigated using DSC (Figure 4). As mentioned above, the destabilization of the LC phase was observed after the neutralization of PR5·PF6, with shifts in TCrN and TNI. In contrast to PR5, the peak temperatures of TCrN and TNI for AX5 were similar to those of AX5·PF6, as summarized in Table 2. However, the peaks for AX5 were broader, possibly because of the destabilization of the LC phase by the neutralized dibenzyl amine, which does not behave as a mesogenic group. Taking into account the DSC thermogram of AX5, the effect of the neutralization on the destabilization of the LC phase might be derived not only from the mobility of the wheel component but also from the chemical structure change of the ammonium moiety.

Conclusions

We have successfully synthesized main chain-type LC polymers bearing rotaxane structures on the main chain, and investigated the effects of the rotaxane moiety on the transition temperatures. Introduction of the rotaxane moiety on the LC polymer reduced the stability of the LC phase, and neutralization of the ammonium moiety also destabilized the LC phase, suggesting the effect of the movable wheel components on the axle LC polymer chain. To the best of our knowledge, this is the first example of LC polymers whose phase transition temperatures can be controlled using a rotaxane switch. However, because other influences of the introduction of the rotaxane moiety on the LC properties, such as the structure of the LC phase and the degree of liquid crystallinity, are conceivable, further investigations of the effects of rotaxanes on LC properties are now in progress.

Synthesis of liquid crystalline polyrotaxanes. A full color version of this scheme is available at Polymer Journal online.

References

Harada, A., Li, J. & Kamachi, M. The molecular necklace: a rotaxane containing many threaded α-cyclodextrins. Nature 356, 325–327 (1992).

Nepogodiev, S. A. & Stoddart, J. F. Cyclodextrin-based catenanes and rotaxanes. Chem. Rev. 98, 1959–1976 (1998).

Wenz, G., Han, B. H. & Muller, A. Cyclodextrin rotaxanes and polyrotaxanes. Chem. Rev. 106, 782–817 (2006).

Araki, J. & Ito, K. Recent advances in the preparation of cyclodextrin-based polyrotaxanes and their applications to soft materials. Soft Matter 3, 1456–1473 (2007).

Harada, A., Hashidzume, A., Yamaguchi, H. & Takashima, Y. Polymeric rotaxanes. Chem. Rev. 109, 5974–6023 (2009).

Jang, K., Miura, K., Koyama, Y. & Takata, T. Catalyst- and solvent-free click synthesis of cyclodextrin-based polyrotaxanes exploiting a nitrile N-oxide. Org. Lett. 14, 3088–3091 (2012).

Iguchi, H., Uchida, S., Koyama, Y. & Takata, T. Polyester-containing α-cyclodextrin-based polyrotaxane: synthesis by living ring-opening polymerization, polypseudorotaxanation, and end capping using nitrile N-oxide. ACS Macro Lett. 2, 527–530 (2013).

Gibson, H. W., Bheda, M. C. & Engen, P. T. Rotaxanes, catenanes, polyrotaxanes, polycatenanes and related materials. Prog. Polym. Sci. 19, 843–945 (1994).

Raymo, F. M. & Stoddart, J. F. Interlocked macromolecules. Chem. Rev. 99, 1643–1663 (1999).

Takata, T., Kihara, N. & Furusho, Y. Polyrotaxanes and polycatenanes: recent advances in syntheses and applications of polymers comprising of interlocked structures. Adv. Polym. Sci. 171, 1–75 (2004).

Huang, F. H. & Gibson, H. W. Polypseudorotaxanes and polyrotaxanes. Prog. Polym. Sci. 30, 982–1018 (2005).

Takata, T. Polyrotaxane and polyrotaxane network: supramolecular architectures based on the concept of dynamic covalent bond chemistry. Polym. J. 38, 1–20 (2006).

Fang, L., Olson, M. A., Benitez, D., Tkatchouk, E., Goddard, W. A. & Stoddart, J. F. Mechanically bonded macromolecules. Chem. Soc. Rev. 39, 17–29 (2010).

Harada, A., Li, J. & Kamachi, M. Synthesis of a tubular polymer from threaded cyclodextrins. Nature 364, 516–518 (1993).

Frampton, M. J. & Anderson, H. L. Insulated molecular wires. Angew. Chem. Int. Ed. 46, 1028–1064 (2007).

Okumura, Y. & Ito, K. The polyrotaxane gel: a topological gel by figure-of-eight cross-links. Adv. Mater. 13, 485–487 (2001).

Arai, T., Jang, K., Koyama, Y., Asai, S. & Takata, T. Versatile supramolecular cross-linker: a rotaxane cross-linker that directly endows vinyl polymers with movable cross-links. Chem. Eur. J 19, 5917–5923 (2013).

Yui, N. & Ooya, T. Molecular mobility of interlocked structures exploiting new functions of advanced biomaterials. Chem. Eur. J 12, 6730–6737 (2006).

Champin, B., Mobian, P. & Sauvage, J. P. Transition metal complexes as molecular machine prototypes. Chem. Soc. Rev. 36, 358–366 (2007).

Badjic, J. D., Balzani, V., Credi, A., Silvi, S. & Stoddart, J. F. A molecular elevator. Science 303, 1845–1849 (2004).

Panman, M. R., Bodis, P., Shaw, D. J., Bakker, B. H., Newton, A. C., Kay, E. R., Brouwer, A. M., Buma, W. J., Leigh, D. A. & Woutersen, S. Operation mechanism of a molecular machine revealed using time-resolved vibrational spectroscopy. Science 328, 1255–1258 (2010).

Suzuki, S., Nakazono, K. & Takata, T. Selective transformation of a crown ether/sec-ammonium salt-type rotaxane to N-alkylated rotaxanes. Org. Lett. 12, 712–715 (2010).

Abe, Y., Okamura, H., Nakazono, K., Koyama, Y., Uchida, S. & Takata, T. Thermoresponsive shuttling of rotaxane containing trichloroacetate ion. Org. Lett. 14, 4122–4125 (2012).

Ishiwari, F., Fukasawa, K., Sato, T., Nakazono, K., Koyama, Y. & Takata, T. A rational design for the directed helicity change of polyacetylene using dynamic rotaxane mobility by means of through-space chirality transfer. Chem. Eur. J 17, 12067–12075 (2011).

Ishiwari, F., Nakazono, K., Koyama, Y. & Takata, T. Rational control of a polyacetylene helix by a pendant rotaxane switch. Chem. Commun. 47, 11739–11741 (2011).

Aprahamian, I., Yasuda, T., Ikeda, T., Saha, S., Dichtel, W. R., Isoda, K., Kato, T. & Stoddart, J. F. A liquid-crystalline bistable [2]rotaxane. Angew. Chem., Int. Ed. 46, 4675–4679 (2007).

Kidowaki, M., Nakajima, T., Araki, J., Inomata, A., Ishibashi, H. & Ito, K. Novel liquid crystalline polyrotaxane with movable mesogenic side chains. Macromolecules 40, 6859–6862 (2007).

Terao, J., Tsuda, S., Tanaka, Y., Okoshi, K., Fujihara, T., Tsuji, Y. & Kambe, N. Synthesis of organic-soluble conjugated polyrotaxanes by polymerization of linked rotaxanes. J. Am. Chem. Soc. 131, 16004–16005 (2009).

Sakuda, J., Yasuda, T. & Kato, T. Liquid-crystalline catenanes and rotaxanes. Isr. J. Chem. 52, 854–862 (2012).

Suhan, N. D., Loeb, S. J. & Eichhorn, S. H. Mesomorphic [2]rotaxanes: sheltering ionic cores with interlocking components. J. Am. Chem. Soc. 135, 400–408 (2013).

Walsh, D. A., Franzyshen, S. K. & Yanni, J. M. Synthesis and antiallergy activity of 4-(diarylhydroxymethyl)-1-[3-(aryloxy)propyl]piperidines and structurally related-compounds. J. Med. Chem. 32, 105–118 (1989).

Wissner, A., Carroll, M. L., Johnson, B. D., Kerwar, S. S., Pickett, W. C., Schaub, R. E., Torley, L. W., Trova, M. P. & Kohler, C. A. Analogs of platelet-activating-factor.7. Bis-aryl amide and bis-aryl urea receptor antagonists of Paf. J. Med. Chem. 35, 4779–4789 (1992).

Kitching, W., Olszowy, H. A. & Harvey, K. Further-studies of substitution-reactions of stannyl and germyl anionoids with alkyl bromides—rearrangement of the 6-hepten-2-Yl moiety. J. Org. Chem. 47, 1893–1904 (1982).

Hardy, A. D. U., Macnicol, D. D., Swanson, S. & Wilson, D. R. Design of inclusion-compounds—systematic structural modification of the hexa-host molecule hexakis(benzylthiomethyl)benzene. J. Chem. Soc. Perkin Trans. 2, 999–1005 (1980).

Wilderbeek, H. T. A., Goossenst, J. G. P., Bastiaansen, C. W. M. & Broer, D. J. Photoinitiated bulk polymerization of liquid crystalline thiolene monomers. Macromolecules 35, 8962–8968 (2002).

Wilderbeek, H. T. A., van der Meer, M. G. M., Bastiaansen, C. W. M. & Broer, D. J. Photo-initiated polymerization of liquid crystalline thiol-ene monomers in isotropic and anisotropic solvents. J. Phys. Chem. B 106, 12874–12883 (2002).

Kihara, N., Tachibana, Y., Kawasaki, H. & Takata, T. Unusually lowered acidity of ammonium group surrounded by crown ether in a rotaxane system and its acylative neutralization. Chem. Lett. 29, 506–507 (2000).

Tachibana, Y., Kawasaki, H., Kihara, N. & Takata, T. Sequential O- and N-acylation protocol for high-yield preparation and modification of rotaxanes: synthesis, functionalization, structure, and intercomponent interaction of rotaxanes. J. Org. Chem. 71, 5093–5104 (2006).

Kihara, N., Koike, Y. & Takata, T. Effect of steric barrier on the shuttling of rotaxane having crown ether wheel. Chem. Lett. 36, 208–209 (2007).

Nakazono, K., Kuwata, S. & Takata, T. Crown ether-tert-ammonium salt complex fixed as rotaxane and its derivation to nonionic rotaxane. Tetrahedron Lett. 49, 2397–2401 (2008).

Gray, G. W. Influence of molecular structure on liquid crystalline properties. Mol. Cryst. 1, 333–349 (1966).

Osman, M. A. Molecular-structure and mesomorphic properties of thermotropic liquid-crystals. 3. Lateral substituents. Mol. Cryst. Liq. Cryst. 128, 45–63 (1985).

Fearon, J. E., Gray, G. W., Ifill, A. D. & Toyne, K. J. The effect of lateral fluoro-substitution on the liquid-crystalline properties of some 4-normal-alkyl-cyanobiphenyls, 4-normal-alkoxy-cyanobiphenyls and related 4-substituted-4'-cyanobiphenyls. Mol. Cryst. Liq. Cryst. 124, 89–103 (1985).

Acknowledgements

This work was financially supported by a Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology, Japan (No. 23245031).

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Abe, Y., Okamura, H., Uchida, S. et al. Synthesis of main chain-type liquid crystalline polyrotaxanes: influence of the wheel components and their mobility on liquid crystalline properties. Polym J 46, 553–558 (2014). https://doi.org/10.1038/pj.2014.23

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.23