Abstract

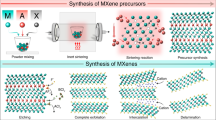

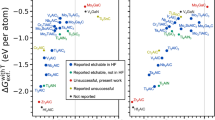

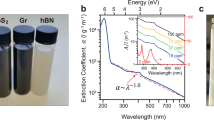

MXenes are a large family of two-dimensional materials that have attracted attention across many fields due to their desirable optoelectronic, biological, mechanical and chemical properties. There currently exist many synthesis procedures that lead to differences in flake size, defects and surface chemistry, which in turn affect their properties. Herein, we describe the steps to synthesize Ti3C2Tx—the most important and widely used MXene, from a Ti3AlC2 MAX phase precursor. The procedure contains three main sections: synthesis of Ti3AlC2 MAX, wet chemical etching of the MAX in hydrofluoric acid/HCl solution to yield multilayer Ti3C2Tx and its delamination into single-layer flakes. Three delamination options are described; these use LiCl, tertiary amines (tetramethyl ammonium hydroxide/ tetrabutyl ammonium hydroxide) and dimethylsulfoxide respectively. These procedures can be adapted for the synthesis of MXenes beyond Ti3C2Tx. The MAX phase synthesis takes about 1 week, with the etching and delamination each requiring 2 d. This protocol requires users to have experience working with hydrofluoric acid, and it is recommended that users have experience with wet chemistry and centrifugation; characterization techniques such as X-ray diffraction and particle size analysis are also essential for the success of the protocol. While alternative synthesis methods, such as minimally intensive layer delamination, are desirable for certain MXenes (such as Ti2CTx) or specific applications, this protocol aims to standardize the more commonly used hydrofluoric acid/HCl etching method, which produces Ti3C2Tx with minimal concentration of defects and the highest conductivity and serves as a guideline for those working with MXenes for the first time.

Key points

-

MXenes are two-dimensional materials, the best known of which is Ti3C2Tx. Many diverse and unique properties have been described for MXenes, but it is difficult to compare the data because their physical characteristics depend on their synthesis.

-

This protocol provides a detailed guideline for the synthesis of a Ti3AlC2 MAX phase precursor, wet chemical etching of MAX to yield multilayer Ti3C2Tx and its delamination into single-layer flakes.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data from experiments are summarized in Supporting Information. All data of importance for this protocol have been included either in the main manuscript or supporting information.

References

Naguib, M. et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 23, 4248–4253 (2011).

Downes, M. et al. M5X4: a family of MXenes. ACS Nano 17, 17158–17168 (2023).

Deysher, G. et al. Synthesis of Mo4VAlC4 MAX phase and two-dimensional Mo4VC4 MXene with five atomic layers of transition metals. ACS Nano 14, 204–217 (2020).

Maleski, K., Shuck, C. E., Fafarman, A. T. & Gogotsi, Y. The broad chromatic range of two-dimensional transition metal carbides. Adv. Opt. Mater. 9, 2001563 (2021).

Salles, P. et al. Electrochromic effect in titanium carbide MXene thin films produced by dip-coating. Adv. Funct. Mater. 29, 1809223 (2019).

Jiang, X. et al. Broadband nonlinear photonics in few-layer MXene Ti3C2Tx (T = F, O, or OH). Laser Photonics Rev. 12, 1700229 (2018).

Lipatov, A. et al. Electrical and elastic properties of individual single-layer Nb4C3Tx MXene flakes. Adv. Electron. Mater. 6, 1901382 (2020).

Lipatov, A. et al. Elastic properties of 2D Ti3C2Tx MXene monolayers and bilayers. Sci. Adv. 4, eaat0491 (2018).

Rosenkranz, A., Righi, M. C., Sumant, A. V., Anasori, B. & Mochalin, V. N. Perspectives of 2D MXene tribology. Adv. Mater. 35, 2207757 (2023).

Zhang, J. et al. Single platinum atoms immobilized on an MXene as an efficient catalyst for the hydrogen evolution reaction. Nat. Catal. 1, 985–992 (2018).

Ding, H. et al. Chemical scissor-mediated structural editing of layered transition metal carbides. Science 379, 1130–1135 (2023).

Lipatov, A. et al. High electrical conductivity and breakdown current density of individual monolayer Ti3C2Tx MXene flakes. Matter 4, 1413–1427 (2021).

Hantanasirisakul, K. & Gogotsi, Y. Electronic and optical properties of 2D transition metal carbides and nitrides (MXenes). Adv. Mater. 30, 1804779 (2018).

El-Demellawi, J. K. et al. Tuning the work function of Ti3C2Tx MXene by molecular doping without changing its surface functional groups. ACS Mater. Lett. 4, 2480–2490 (2022).

Zhang, C. (John) et al. Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 10, 1795 (2019).

Maleski, K., Mochalin, V. N. & Gogotsi, Y. Dispersions of two-dimensional titanium carbide MXene in organic solvents. Chem. Mater. 29, 1632–1640 (2017).

Akuzum, B. et al. Rheological characteristics of 2D titanium carbide (MXene) dispersions: A guide for processing MXenes. ACS Nano 12, 2685–2694 (2018).

Shuck, C. E. et al. Scalable synthesis of Ti3C2Tx MXene. Adv. Eng. Mater. 22, 1901241 (2020).

Shuck, C. E. & Gogotsi, Y. Taking MXenes from the lab to commercial products. Chem. Eng. J. 401, 125786 (2020).

Chen, N. et al. Supercritical etching method for the large-scale manufacturing of MXenes. Nano Energy 107, 108147 (2023).

Li, X. et al. MXene chemistry, electrochemistry and energy storage applications. Nat. Rev. Chem. 6, 389–404 (2022).

Li, K. et al. 3D MXene architectures for efficient energy storage and conversion. Adv. Funct. Mater. 30, 2000842 (2020).

Huang, K., Li, Z., Lin, J., Han, G. & Huang, P. Two-dimensional transition metal carbides and nitrides (MXenes) for biomedical applications. Chem. Soc. Rev. 47, 5109–5124 (2018).

Feng, W. et al. Ultrathin molybdenum carbide MXene with fast biodegradability for highly efficient theory-oriented photonic tumor hyperthermia. Adv. Funct. Mater. 29, 1901942 (2019).

Unal, M. A. et al. 2D MXenes with antiviral and immunomodulatory properties: a pilot study against SARS-CoV-2. Nano Today 38, 101136 (2021).

He, S. et al. Preparation strategies and applications of MXene-polymer composites: a review. Macromol. Rapid Commun. 42, 2100324 (2021).

Gong, K., Zhou, K., Qian, X., Shi, C. & Yu, B. MXene as emerging nanofillers for high-performance polymer composites: a review. Compos. Part B Eng. 217, 108867 (2021).

Iqbal, A., Sambyal, P. & Koo, C. M. 2D MXenes for electromagnetic shielding: a review. Adv. Funct. Mater. 30, 2000883 (2020).

Shahzad, F. et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 353, 1137–1140 (2016).

Han, M. et al. Beyond Ti3C2Tx: MXenes for electromagnetic interference shielding. ACS Nano 14, 5008–5016 (2020).

VahidMohammadi, A., Rosen, J. & Gogotsi, Y. The world of two-dimensional carbides and nitrides (MXenes). Science 372, eabf1581 (2021).

Mathis, T. S. et al. Modified MAX phase synthesis for environmentally stable and highly conductive Ti3C2 MXene. ACS Nano 15, 6420–6429 (2021).

Zhao, X. et al. Annealed Ti3C2Tz MXene films for oxidation-resistant functional coatings. ACS Appl. Nano Mater. 3, 10578–10585 (2020).

Zhang, J. et al. Scalable manufacturing of free-standing, strong Ti3C2Tx MXene films with outstanding conductivity. Adv. Mater. 32, 2001093 (2020).

Zeraati, A. S. et al. Improved synthesis of Ti3C2Tx MXenes resulting in exceptional electrical conductivity, high synthesis yield, and enhanced capacitance. Nanoscale 13, 3572–3580 (2021).

Alhabeb, M. et al. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 29, 7633–7644 (2017).

Zhao, X. et al. Antioxidants unlock shelf-stable Ti3C2Tx (MXene) nanosheet dispersions. Matter 1, 513–526 (2019).

Habib, T. et al. Oxidation stability of Ti3C2Tx MXene nanosheets in solvents and composite films. NPJ 2D Mater. Appl. 3, 8 (2019).

Shuck, C. E. et al. Effect of Ti3AlC2 MAX phase on structure and properties of resultant Ti3C2Tx MXene. ACS Appl. Nano Mater. 2, 3368–3376 (2019).

Chae, Y. et al. An investigation into the factors governing the oxidation of two-dimensional Ti3C2 MXene. Nanoscale 11, 8387–8393 (2019).

Huang, S. & Mochalin, V. N. Understanding chemistry of two-dimensional transition metal carbides and carbonitrides (MXenes) with gas analysis. ACS Nano 14, 10251–10257 (2020).

Natu, V. et al. Edge capping of 2D-MXene sheets with polyanionic salts to mitigate oxidation in aqueous colloidal suspensions. Angew. Chem. 131, 12785–12790 (2019).

Huang, S. et al. Understanding the effect of sodium polyphosphate on improving the chemical stability of Ti3C2Tz MXene in water. J. Mater. Chem. A 10, 22016–22024 (2022).

Jolly, S., Paranthaman, M. P. & Naguib, M. Synthesis of Ti3C2Tz MXene from low-cost and environmentally friendly precursors. Mater. Today Adv. 10, 100139 (2021).

Bärmann, P. et al. Scalable synthesis of MAX phase precursors toward titanium-based MXenes for lithium-ion batteries. ACS Appl. Mater. Interfaces 13, 26074–26083 (2021).

Pang, Z. et al. Molten salt electrochemical synthesis of ternary carbide Ti3AlC2 from titanium-rich slag. Adv. Eng. Mater. 22, 1901300 (2020).

Bao, W. et al. Boosting performance of Na–S batteries using sulfur-doped Ti3C2Tx MXene nanosheets with a strong affinity to sodium polysulfides. ACS Nano 13, 11500–11509 (2019).

Li, C., Kota, S., Hu, C. & Barsoum, M. W. On the synthesis of low-cost, titanium-based MXenes. J. Ceram. Sci. Tech. 7, 301–306 (2016).

von Treifeldt, J. E. et al. The effect of Ti3AlC2 MAX phase synthetic history on the structure and electrochemical properties of resultant Ti3C2 MXenes. Mater. Des. 199, 109403 (2021).

Pazniak, A. et al. Ti3C2Tx MXene characterization produced from SHS-ground Ti3AlC2. Mater. Des. 183, 108143 (2019).

Wang, X. et al. Structure and electromagnetic properties of Ti3C2Tx MXene derived from Ti3AlC2 with different microstructures. Ceram. Int. 47, 13628–13634 (2021).

Chen, B. et al. Subsize Ti3C2Tx derived from molten-salt synthesized Ti3AlC2 for enhanced capacitive deionization. Ceram. Int. 47, 3665–3670 (2021).

Shekhirev, M. et al. Ultralarge flakes of Ti3C2Tx MXene via soft delamination. ACS Nano 16, 13695–13703 (2022).

Choi, S. B. et al. Role of oxygen in the Ti3AlC2 MAX phase in the oxide formation and conductivity of Ti3C2-based MXene nanosheets. ACS Appl. Mater. Interfaces 15, 8393–8405 (2023).

Michałowski, P. P. et al. Oxycarbide MXenes and MAX phases identification using monoatomic layer-by-layer analysis with ultralow-energy secondary-ion mass spectrometry. Nat. Nanotechnol. 17, 1192–1197 (2022).

Gao, Q. et al. Tracking ion intercalation into layered Ti3C2 MXene films across length scales. Energy Environ. Sci. 13, 2549–2558 (2020).

Seredych, M. et al. High-temperature behavior and surface chemistry of carbide MXenes studied by thermal analysis. Chem. Mater. 31, 3324–3332 (2019).

Benchakar, M. et al. One MAX phase, different MXenes: a guideline to understand the crucial role of etching conditions on Ti3C2Tx surface chemistry. Appl. Surf. Sci. 530, 147209 (2020).

Zhao, Q. et al. Adsorption of uremic toxins using Ti3C2Tx MXene for dialysate regeneration. ACS Nano 14, 11787–11798 (2020).

Kim, Y.-J. et al. Etching mechanism of monoatomic aluminum layers during MXene synthesis. Chem. Mater. 33, 6346–6355 (2021).

Hope, M. A. et al. NMR reveals the surface functionalisation of Ti3C2 MXene. Phys. Chem. Chem. Phys. 18, 5099–5102 (2016).

Sang, X. et al. Atomic defects in monolayer titanium carbide (Ti3C2Tx) MXene. ACS Nano 10, 9193–9200 (2016).

Anayee, M. et al. Kinetics of Ti3AlC2 etching for Ti3C2Tx MXene synthesis. Chem. Mater. 34, 9589–9600 (2022).

Maleski, K., Ren, C. E., Zhao, M.-Q., Anasori, B. & Gogotsi, Y. Size-dependent physical and electrochemical properties of two-dimensional MXene flakes. ACS Appl. Mater. Interfaces 10, 24491–24498 (2018).

Hart, J. L. et al. Control of MXenes’ electronic properties through termination and intercalation. Nat. Commun. 10, 522 (2019).

Inman, A. et al. Shear delamination of multilayer MXenes. J. Mater. Res. 37, 4006–4016 (2022).

Shekhirev, M. et al. Delamination of Ti3C2Tx nanosheets with NaCl and KCl for improved environmental stability of MXene films. ACS Appl. Nano Mater. 5, 16027–16032 (2022).

Wang, D. et al. Direct synthesis and chemical vapor deposition of 2D carbide and nitride MXenes. Science 379, 1242–1247 (2023).

Jawaid, A. et al. Halogen etch of Ti3AlC2 MAX phase for MXene fabrication. ACS Nano 15, 2771–2777 (2021).

Yang, S. et al. Fluoride-free synthesis of two-dimensional titanium carbide (MXene) using a binary aqueous system. Angew. Chem. 130, 15717–15721 (2018).

Kamysbayev, V. et al. Covalent surface modifications and superconductivity of two-dimensional metal carbide MXenes. Science 369, 979–983 (2020).

Li, Y. et al. A general lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nat. Mater. 19, 894–899 (2020).

Urbankowski, P. et al. Synthesis of two-dimensional titanium nitride Ti4N3 (MXene). Nanoscale 8, 11385–11391 (2016).

Natu, V. et al. 2D Ti3C2Tz MXene synthesized by water-free etching of Ti3AlC2 in polar organic solvents. Chem 6, 616–630 (2020).

Shi, H. et al. Ambient-stable two-dimensional titanium carbide (MXene) enabled by iodine etching. Angew. Chem. Int. Ed. 60, 8689–8693 (2021).

Naguib, M. et al. Two-dimensional transition metal carbides. ACS Nano 6, 1322–1331 (2012).

Naguib, M., Mochalin, V. N., Barsoum, M. W. & Gogotsi, Y. 25th anniversary article: MXenes: a new family of two-dimensional materials. Adv. Mater. 26, 992–1005 (2014).

Hart, J. L. et al. Multimodal spectroscopic study of surface termination evolution in Cr2TiC2Tx MXene. Adv. Mater. Interfaces 8, 2001789 (2021).

Hong, W., Wyatt, B. C., Nemani, S. K. & Anasori, B. Double transition-metal MXenes: atomistic design of two-dimensional carbides and nitrides. MRS Bull. 45, 850–861 (2020).

Pinto, D. et al. Synthesis and electrochemical properties of 2D molybdenum vanadium carbides—solid solution MXenes. J. Mater. Chem. A 8, 8957–8968 (2020).

Han, M. et al. Tailoring electronic and optical properties of MXenes through forming solid solutions. J. Am. Chem. Soc. 142, 19110–19118 (2020).

Ahmed, B., Ghazaly, A. E. & Rosen, J. i-MXenes for energy storage and catalysis. Adv. Funct. Mater. 30, 2000894 (2020).

Lim, K. R. G. et al. Fundamentals of MXene synthesis. Nat. Synth. 1, 601–614 (2022).

Ghidiu, M. et al. Synthesis and characterization of two-dimensional Nb4C3 (MXene). Chem. Commun. 50, 9517–9520 (2014).

Ghidiu, M., Lukatskaya, M. R., Zhao, M.-Q., Gogotsi, Y. & Barsoum, M. W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 516, 78–81 (2014).

Anayee, M. et al. Role of acid mixtures etching on the surface chemistry and sodium ion storage in Ti3C2Tx MXene. Chem. Commun. 56, 6090–6093 (2020).

Driscoll, N. et al. Two-dimensional Ti3C2 MXene for high-resolution neural interfaces. ACS Nano 12, 10419–10429 (2018).

Mashtalir, O. et al. Intercalation and delamination of layered carbides and carbonitrides. Nat. Commun. 4, 1716 (2013).

Lukatskaya, M. R. et al. Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science 341, 1502–1505 (2013).

Mashtalir, O., Lukatskaya, M. R., Zhao, M.-Q., Barsoum, M. W. & Gogotsi, Y. Amine-assisted delamination of Nb2C MXene for Li-ion energy storage devices. Adv. Mater. 27, 3501–3506 (2015).

Lipatov, A. et al. Effect of synthesis on quality, electronic properties and environmental stability of individual monolayer Ti3C2 MXene flakes. Adv. Electron. Mater. 2, 1600255 (2016).

Naguib, M., Barsoum, M. W. & Gogotsi, Y. Ten years of progress in the synthesis and development of MXenes. Adv. Mater. 33, 2103393 (2021).

Wei, Y., Zhang, P., Soomro, R. A., Zhu, Q. & Xu, B. Advances in the synthesis of 2D MXenes. Adv. Mater. 33, 2103148 (2021).

Verger, L. et al. Overview of the synthesis of mxenes and other ultrathin 2D transition metal carbides and nitrides. Curr. Opin. Solid State Mater. Sci. 23, 149–163 (2019).

Verger, L., Natu, V., Carey, M. & Barsoum, M. W. MXenes: an introduction of their synthesis, select properties, and applications. Trends Chem. 1, 656–669 (2019).

Shekhirev, M., Shuck, C. E., Sarycheva, A. & Gogotsi, Y. Characterization of MXenes at every step, from their precursors to single flakes and assembled films. Prog. Mater. Sci. 120, 100757 (2021).

Shuck, C. E. et al. Safe synthesis of MAX and MXene: guidelines to reduce risk during synthesis. ACS Chem. Health Saf. 28, 326–338 (2021).

Lakhe, P. et al. Process safety analysis for Ti3C2Tx MXene synthesis and processing. Ind. Eng. Chem. Res. 58, 1570–1579 (2019).

Kotasthane, V. et al. Selective etching of Ti3AlC2 MAX phases using quaternary ammonium fluorides directly yields Ti3C2Tz MXene nanosheets: implications for energy storage. ACS Appl. Nano Mater. 6, 1093–1105 (2023).

Li, M. et al. Element replacement approach by reaction with Lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. J. Am. Chem. Soc. 141, 4730–4737 (2019).

Chen, J. et al. Molten salt-shielded synthesis (MS3) of MXenes in air. Energy Environ. Mater. 6, e12328 (2023).

Liu, L. et al. Exfoliation and delamination of Ti3C2Tx MXene prepared via molten salt etching route. ACS Nano 16, 111–118 (2022).

Arole, K. et al. Water-dispersible Ti3C2Tz MXene nanosheets by molten salt etching. iScience 24, 103403 (2021).

Li, T. et al. Fluorine-free synthesis of high-purity Ti3C2Tx (T = OH, O) via alkali treatment. Angew. Chem. Int. Ed. 57, 6115–6119 (2018).

Wang, C. et al. HCl-based hydrothermal etching strategy toward fluoride-free MXenes. Adv. Mater. 33, 2101015 (2021).

Yang, Y. et al. Correlating electronic properties with M-site composition in solid solution TiyNb2-yCTx MXenes. 2D Mater. 10, 014011 (2022).

Matthews, K., Zhang, T., Shuck, C. E., VahidMohammadi, A. & Gogotsi, Y. Guidelines for synthesis and processing of chemically stable two-dimensional V2CTx MXene. Chem. Mater. 34, 499–509 (2022).

Mendoza-Sánchez, B. et al. Systematic study of the multiple variables involved in V2AlC acid-based etching processes, a key step in MXene synthesis. ACS Appl. Mater. Interfaces https://doi.org/10.1021/acsami.3c01671 (2023).

Alhabeb, M. et al. Selective etching of silicon from Ti3SiC2 (MAX) to obtain 2D titanium carbide (MXene). Angew. Chem. 130, 5542–5546 (2018).

Forsberg, K., Van den Borre, A., Henry, N. III & Zeigler, J. P. Quick Selection Guide to Chemical Protective Clothing 7th edn (John Wiley & Sons, 2020).

Acknowledgements

This work was supported by the US National Science Foundation, grant CHE- 2318105. The authors affirm the human participants provided informed consent for publication for Supplementary Fig. 4. R.J. Wang is thanked for proofreading the manuscript. XRD and SEM analyses were performed using instruments in the Materials Characterization Core at Drexel University.

Author information

Authors and Affiliations

Contributions

M.D., C.E.S. and Y.G. conceived the experimental plan. B.M. and J.B. took the experimental setup photographs for figures and measured film conductivity. M.D., C.E.S. and B.M. synthesized the large batch to test the different delaminating agents. M.D. and C.E.S. prepared the MAX phase precursors, performed XRD characterization and drafted the manuscript. M.D. and B.M. performed the DLS measurements. All authors reviewed and edited the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Protocols thanks Junwei Gu, Hao-Bin Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Key references using this protocol

Naguib, M. et al. Adv. Mater. 23, 4248–4253 (2011): https://doi.org/10.1002/adma.201102306

Alhabeb, M. et al. Chem. Mater. 29, 7633–7644 (2017): https://doi.org/10.1021/acs.chemmater.7b02847

Shekhirev, M. et al. Prog. Mater. Sci. 120, 100757 (2021): https://doi.org/10.1016/j.pmatsci.2020.100757

Mathis, T. S. et al. ACS Nano 15, 6420–6429 (2021): https://doi.org/10.1021/acsnano.0c08357

Shuck, C. E. et al. ACS Chem. Health Saf. 28, 326–338 (2021): https://doi.org/10.1021/acs.chas.1c00051

Sarycheva, A. et al. ACS Nano, 16, 6858–6865 (2022): https://doi.org/10.1021/acsnano.2c01868

Supplementary information

Supplementary Information

Supplementary Figs. 1–5, Tables 1 and 2 and Discussion.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Downes, M., Shuck, C.E., McBride, B. et al. Comprehensive synthesis of Ti3C2Tx from MAX phase to MXene. Nat Protoc (2024). https://doi.org/10.1038/s41596-024-00969-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41596-024-00969-1

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.