Abstract

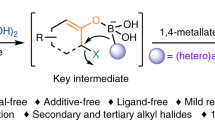

Selective cleavage and subsequent functionalization of C−C single bonds present a fundamental challenge in synthetic organic chemistry. Traditionally, the activation of C−C single bonds has been achieved using stoichiometric transition-metal complexes. Recently, examples of catalytic processes were developed in which use is made of precious metals. However, the use of inexpensive and Earth-abundant group IV metals for catalytic C−C single-bond cleavage is largely underdeveloped. Herein, the zirconium-catalyzed C−C single-bond cleavage and subsequent hydroboration reactions is realized using Cp2ZrCl2 as a catalytic system. A series of structures of various γ-boronated amines are readily obtained, which are otherwise difficult to obtain. Mechanistic studies disclose the formation of a N–ZrIV species, and then a β-carbon elimination route is responsible for C–C single bond activation. Besides zirconium, hafnium exhibits a similar performance for this transformation.

Similar content being viewed by others

Introduction

Selective cleavage and subsequent functionalization of C−C single bonds present a fundamental challenge in catalysis and synthesis1,2,3,4,5,6,7,8,9,10,11. This is mainly due to the relatively high bonding energy (BE, about 355 kJ/mol) and directional σ orbitals of C−C bonds. In addition, the competitive C−H bond activation (about 400 kJ/mol, but statistically abundant) also causes chemoselectivity problems12,13,14,15,16,17,18,19,20,21,22. Nevertheless, cleavage and functionalization of C−C single bonds are attracting increasing attention in synthetic organic chemistry because it offers a unique and straight route to target molecules/structures. Synthetic chemists have developed various strategies for the activation of C−C single bonds. They are mainly classified into two mechanistic categories: oxidative addition and β-carbon elimination, associated with metal centers (Fig. 1a). Besides the use of stoichiometric transition-metal complexes23,24,25,26, examples of catalytic processes have been reported in recent years—most involve the use of precious metals27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45.

Early-transition metals have different electron configurations from late ones. Thus, their complexes often show other or orthogonal reactivities with late-transition metal complexes46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61. In addition, they are also Earth-abundant (e.g., zirconium is almost as abundant as carbon in the Earth’s upper continental crust). However, zirconium usually exists in the ZrIV oxidation state, which is not viable for direct oxidative addition activation of a single chemical bond. Thus, in situ generated or isolable low-valent zirconocene complexes (ZrII), such as Negishi’s (Cp2ZrBu2)62 and Rosenthal’s reagents (Cp2Zr(py)Me3SiC≡CSiMe3)63, for the activation of B−H64,65, Si−H66,67,68,69 bonds were reported. C−C single bond cleavage by a zirconium species has also been reported intermittently since the 1990s70,71,72,73. In 1994, Rosenthal described the activation of conjugated C−C single bonds of a 1,3-butadiyne moiety (C≡C−C≡C) using Rosenthal’s reagent, resulting in a dimeric complex (Fig. 1b)74. Dimmock and Whitby also found that zirconocene η2-alkene and η2-imine complexes with adjacent cyclopropane rings could undergo cyclopropane ring cleavage75. Then, in 2014, Marek reported an expedient approach, including allylic C−H activations followed by C−C single bond activation (Fig. 1c)76. It is also worth mentioning that since the 1990s, Negishi, Takahashi, and Xi have studied the chemistry of zirconacycles, the transformation of which with other unsaturated molecules usually involved a β, β’-C−C bond cleavage77,78,79,80,81. All the former instances used (over) stoichiometric amounts of zirconium, and no precedents of catalytic methods using homogeneous zirconium catalysis had been developed—to the best of our knowledge (The use of heterogeneous zirconium catalysis for C−C bond cleavage was reported by Basset82,83,84). Consequently, activating C−C single bonds with zirconium catalysis for chemical transformation remains a significant challenge. It is of considerable scientific and practical interest to synthetic organic chemistry to address this. Herein, we report the development of an unprecedented catalytic system that resulted in the realization of the zirconium- and hafnium-catalyzed C−C single-bond hydroboration (Fig. 1d). Mechanistic studies support the formation of N−ZrIV species and then a β-carbon elimination route for C−C single bond activation. Our work provides an alternative catalytic method for C−C single bonds hydroboration, and establishes the bond activation models and catalytic application of group IV transition metals.

Results

Catalytic reaction investigations

As a synthetically significant transformation in organic chemistry, hydroboration of C=C bonds is well-studied. However, catalytic hydroboration of C−C single bonds remains underdeveloped. Only two systems using Ir and Rh are known for the hydroboration of cyclopropanes, as developed by Yamaguchi85 and Shi86,87. Besides making use of precious metals and N- or P-ligands, it is noticed that for the Ir system, the careful choice of a chiral tBu-Quinox ligand is crucial for the C−C bond hydroboration over the C−H boration88,89,90. For the Rh system, the PPh3 ligand is essential in inhibiting side reactions such as the formation of alkenes. Furthermore, in the former case, cleavage of Cβ−Cβ‘ bond is observed, while the latter cleavages Cα−Cβ bond. Thus, it is still highly desirable to develop a facile and inexpensive catalytic system for the hydroboration of C−C single bonds.

We commenced our investigation using 0.2 mmol of N-Piv-cyclopropylamines (1a) with 1.5 equiv. pinacolborane (HBpin) in 1 mL toluene at 120 °C as the model reaction, using 5 mol% Cp2ZrCl2 as catalyst (Table 1). Our preliminary investigations unveiled that the addition of 1 equiv. of base is the key for the zirconium-catalyzed C−C bond hydroboration (Supplementary Table 1); K2CO3 was the optimal choice (Table 1, entry 1, 81% yield of 2a). Various other zirconium complexes were then tested but were unsuccessful. There was no reaction with the sterically bulkier Cp*2ZrCl2 (Table 1, entry 2). With Cp2ZrHCl as catalyst, a 50% yield of 2a was obtained, whereas with Cp2ZrMe2 only 10% 2a was produced (Table 1, entries 3 and 4). It was evident that without Cp2ZrCl2 or K2CO3 no reaction proceeded (Table 1, entries 5 and 6). Interestingly, using Cp2TiCl2 instead of Cp2ZrCl2 also gave no reaction (Table 1, entry 7). An attempt was then made to reduce the amount of K2CO3. Pleasingly, even with 0.1 equiv. K2CO3 already had a 68% yield of 2a (Table 1, entry 8). Finally, a much higher yield of 2a (91%) was obtained with just 0.3 equiv. K2CO3 (Table 1, entry 9). In addition, 95% yield of 2a was obtained using 5 mol% Cp2ZrH2 as catalyst without K2CO3 (Table 1, entry 10). However, considering the simplicity of using readily available and inexpensive Cp2ZrCl2 as the catalyst, we conducted the following studies using Cp2ZrCl2/K2CO3 system (Table 1, entry 9). The results with Cp2ZrH2 gave us some clues for the subsequent mechanism studies (vide infra).

Substrates scope studies

Having the reaction conditions for the Zr-catalyzed hydroboration of cyclopropylamines in hand (Table 1, entry 9), various cyclopropane rings were investigated to establish the generality of our methodology (Fig. 2).

a,baReaction conditions: 0.2 mmol 1, HBpin (1.5 equiv.), K2CO3 (30 mol%), Cp2ZrCl2 (5 mol%) and 1 mL toluene in a 15 mL pressure tube at 120 °C for 24 h; bIsolated yields are given; c130 °C for 24 h; d150 °C for 24 h; eHBpin (2.0 equiv.), K2CO3 (60 mol%), Cp2ZrCl2 (10 mol%) at 150 °C for 24 h; fHBpin (2.0 equiv.), Cp2ZrH2 (5 mol%) at 150 °C for 24 h.

First, the tolerance of substituents on the para-position of the phenyl ring was studied. We found that electron-neutral, electron-donating, and electron-withdrawing groups are tolerated; moderate to good yields were obtained (2a-2k, 40-82% yields). In general, electron-donating groups (−Me, −OMe, −tBu, −SMe, 2c−2e, 2k) gave better results than electron-withdrawing groups such as −CF3 (2f). Halide substituents −F, −Cl, −Br, which likely undergo competitive hydrodehalogenation or boration reactions, are untouched in our system (2g−2i). We found that steric effects have some influence on the results, as changing the substituents from the para-position to the meta- and ortho-position, led to slightly decreased yields or the need for higher reaction temperatures (2l−2o). Significantly, naphthyl, benzodioxole, alkyne, and heteroaromatic rings such as furyl and thiophene substituents are all compatible in our system, with yields in the range of 71 − 78% (2p−2t). Similarly, good results were obtained when the phenyl group is at the β’ position (2u). Changing R1 from an aryl to an alkyl group was also successful, with both acyclic and cyclic alkyl substituents (up to 77% yield, 2v−2ac). Pleasingly, products 2q, 2ab and 2ac were obtained in 69%, 77%, and 67% yields, respectively, with no double or triple bond interference. Moreover, cyclopropane rings with two substituents on the R1 and R2 positions were also suitable (2ad−2ae).

The effect of the substituent on the amide groups was then studied. When R is 1-methylcyclohexyl, the hydroboration product 2af was obtained in 76% yield. Changing R to a sterically bulkier adamantly group resulted in a slightly lower yield (2ag, 56%). Substrates with 2,2-dimethylbutyl and 1-methylcyclopropyl, and substituents containing chloride are all converted to their corresponding hydroboration products 2ah−2aj in yields of up to 64%. Sulfonamide is also tolerated in our system, which get the hydroboration product 2ak in 66% yield. The reaction also proceeded with thioamide (2al). Finally, we found that cyclopropylamines derived from Oleanolic Acid and Gemfibrozil also reacted well in our system; the corresponding products, 2am and 2an, were obtained in yields of 49% and 59%, respectively.

Hafnium-catalyzed reaction

Compared with zirconium, hafnium has received less attention as a homogeneous catalyst in organic reactions. To our knowledge, reactivity toward C−C single bonds activation is also unknown. After successfully establishing zirconium-catalyzed C−C single bond activation of cyclopropylamines and their subsequent hydroboration, we further explored the reactivity of a hafnium complex towards C−C single bonds. We established that the base plays an essential role in tuning the reactivity. Eventually, Cs2CO3 was found to be the optimal base (Supplementary Table 5). Then, under the optimal reaction conditions, we conducted substrate scope generality studies (Fig. 3). We found that the hafnium system is not only suitable for substrates that work in the zirconium system but also for substrates that do not work there. For example, substrates with a −CN group do not react with the zirconium catalyst, but a 50% yield of product 2ao was obtained with hafnium. Product 2ap, with two fluorides on the phenyl ring, was also obtained in 51% yield. Additionally, cyclohexyl- (2aq) and phenyl-substituted substrates (2ar) were also applicable in the hafnium system.

a,b,c aReaction conditions: 0.2 mmol 1, HBpin (2.0 equiv.), Cs2CO3 (30 mol%), Cp2HfCl2 (5 mol%) and 1 mL toluene in a 15 mL pressure tube at 150 °C for 24 h; bHBpin (3.0 equiv.), Cs2CO3 (60 mol%), Cp2HfCl2 (10 mol%) and 1 mL toluene in a 15 mL pressure tube at 150 °C for 72 h; cIsolated yields are given.

Synthetic derivation

The practical utilization of our system was then demonstrated on a gram scale (Fig. 4). When we subjected 10 mmol of 1a to our standard reaction conditions, we obtained 2a in 73% yield (1.97 g). Furthermore, the synthetic derivatization of 2a was demonstrated. Using the aminoazanium of DABCO as an amination reagent91, and then protecting the amine with TFAA, the corresponding TFA-amide 3a was obtained in 66% yield. γ-Boronated amine 3b, which is otherwise difficult to obtain92, was obtained in 72% yield by reducing the amide functional group to an amine and then protecting it with TsCl. Product 2a can be transformed into potassium trifluoroborate salt 3c using KHF2 (82% yield). Treating 2a with furan-2-yllithium followed by NBS afforded the arylated product 3d in 74% yield. Finally, Pd-catalyzed Suzuki−Miyaura coupling of 2a with Estrone-derived triflate gave 3e in 45% yield.

Reaction in gram scale and further derivatization of 2a. Isolated yields are given; for detailed reaction conditions, please refer to the supplementary information.

Mechanistic studies

To shed light on the reaction mechanism, several control experiments were performed (Fig. 5). The possible formation of an alkene intermediate via ring-opening of cyclopropanes followed by hydroboration was studied. However, no alkenes were detected after 3 or 12 h under standard reaction conditions with or without HBpin (Fig. 5Aa, Supplementary Fig. 1). Utilization of alkenes 1a’ and 1a” afforded less than 6% 2a (Fig. 5Ab). When enantioenriched substrate (1S, 2R)-1as was applied, the desired product (R)-2as was obtained without erosion of the enantioselectivities (Fig. 5Ac, Supplementary Figs. 2, 3). Those results excluded a consecutive cyclopropane ring opening-hydroboration process. Then, the possibility of a reaction pathway that involved a radical species was investigated. TEMPO (2,2,6,6-tetramethylpiperidinyloxyl) (1−2 equiv) had almost no effect on the results. However, upon increasing the amount thereof (4 equiv.) the yields of 2a decreased to 44% (Fig. 5B). At this point, it should be borne in mind that TEMPO inhibition experiments can sometimes provide ambiguous results93. Thus, additional experiments with the addition of 9,10-dihydroanthracene (DHA) were conducted; no effect on the yield of 2a was detected (Fig. 5B). The results with TEMPO and DHA excluded a radical mechanism.

A possible alkene intermediate formation; B possible radical pathway; C 1H NMR spectra show the formation of Zr−H species; D 1H NMR spectra show the release of H2 or HD by reacting Cp2ZrHCl with 1a; E Control experiments to show the importance of N−H bond; F Detection of imide intermediate 2u’ by crude 13C NMR spectroscopy; G Deuterium labeling experiment by introducing D2 in the standard reaction.

Then, the active zirconium catalytic species was studied. Upon the combination of Cp2ZrCl2 and K2CO3 in d8-Tol heated at 120 °C for 12 h, a new species appeared around 6.0 ppm in the 1H NMR spectrum (Fig. 5Ca). With 2 equiv. K2CO3 and heating for a longer reaction time, the Cp2ZrCl2 was fully converted to this new species (Fig. 5Cb). Then, the isolated new species was characterized by IR spectroscopy and was currently assigned to Cp2ZrCO3 by comparation with literature data (Supplementary Fig. 4)94,95. Nevertheless, upon further adding HBpin to the above solution, we could detect the formation of Zr–H species in the 1H NMR spectrum by trapping with acetone (Fig. 5Cc, Supplementary Fig. 5). This finding, together with the fact that Cp2ZrHCl or Cp2ZrH2 can catalyze the C−C bond hydroboration process without K2CO3 (65% and 95% yields, Supplementary Table 2), we concluded that Zr−H species are essentially the active catalysts via the consecutive reactions of Cp2ZrCl2, K2CO3, and HBpin (Fig. 5Cd). According to the work from Ganem96, Rosenthal97, and Cantat98, the active Zr−H species can interact with 1a to form N−Zr species via metathesis with N−H bond. This is further proved in our case that Cp2ZrHCl reacts with the N−H group of 1a with the release of H2 or HD when 1a-D was used (Fig. 5D, Supplementary Fig. 6). To add further proof of the importance of the N−H, N-methylated analog substrate 1a-Me, and replace the N−H with CH2 or O substrates 1a-C, 1a-O were subjected to our reaction conditions. As expected, no corresponding C−C bond hydroboration product were observed (Fig. 5E). Keep in mind that β-carbon elimination is one of the main pathway for C−C bond cleavage. It is natural to think that after the formation of N−Zr species, a β-carbon elimination may proceed to cleavage the C−C bond to produce an imino propyl zirconium species. This is consistent with the fact that we can observe the presence of the putative imine intermediate both on GC/MS and 13C NMR when substrate 1 u was used (Fig. 5F, Supplementary Figs. 7, 8).

Based on the above mechanistic study and our DFT calculation results (Supplementary Fig. 9), we conclude the following general reaction pathway for our Cp2ZrCl2/K2CO3 system (Fig. 6). First, the in-situ formed Zr−H species reacts with N−H bonds of the substrates to form N−ZrIV species A via H2 release (i). Next, the C−C single bond is cleaved via β-carbon elimination of intermediate A to form the imino propyl zirconium species B (ii). Subsequently, intermediate B reacts with HBpin via C−Zr and H−B bond metathesis to give C and regenerate Zr−H species (iii). In the second catalytic cycle, Zr−H hydride transfer to intermediate C gives intermediate D (iv), which is further reduced by the previously released H2 to 2a with hydrogenolysis or H2 metathesis (v). The last step is supported by the experiment that when we introduced 1 atm of deuterium gas into the standard reaction, 29% deuterium labeling at the α-carbon adjacent to N−H of 2a could be obtained (Fig. 5G, Supplementary Fig. 10), suggesting that hydrogen metathesis occurred99,100,101.

In summary, an unprecedented zirconium- and hafnium-catalyzed C−C single bond activation and subsequent hydroboration is realized using a catalytic system based on Cp2ZrCl2 and Cp2HfCl2. Our catalytic approach applies to various cyclopropylamines. Selective cleavage of the proximal Cα−Cβ single bond was achieved, with the tolerance of multiple functional groups as well as bio- and medicine-derived substrates. Mechanistic studies disclose that the in-situ generated Zr−H species and the free N−H group of the substrates play key roles in this transformation via Zr−H and N−H metathesis to form N−ZrIV species, and the subsequent C−C single bond activation is realized via a β-carbon elimination route. Our work presents an unprecedented group IV metal-catalyzed C−C single bond activation and hydroboration reaction. The C−C single bond activation model that was well studied for late-transition metals, were also elaborated to be applicable to the group IV metals.

Methods

General procedure for the Zr-catalyzed hydroboration of cyclopropylamines

In a nitrogen-filled glovebox, to a 15 mL pressure tube with a magnetic stirrer was added catalytic amount of Cp2ZrCl2 (0.01 mmol, 2.9 mg), K2CO3 (0.06 mmol, 8.3 mg), corresponding cyclopropylamine substrates (0.2 mmol), HBpin (0.3 mmol, 43.5 μL), and toluene (1 mL) in a sequence manner. Then, the pressure tube was taken out of the glove box and allowed to stir at 120 °C for 24 h. Upon completion, all the solvent was evaporated, and the crude product was isolated on silica gel using flash chromatography with dichloromethane/ethyl acetate as the eluent to give the corresponding products.

Data availability

Experimental details, Synthetic Procedures, Tables for condition optimizations (Supplementary Tables 1–5), Figures for mechanistic studies, and DFT calculations, NMR spectra (Supplementary Figs. 1–248), products characterizations are included in the Supplementary Information. All other data are available from the corresponding author upon request.

References

Gozin, M., Weisman, A., Ben-David, Y. & Milstein, D. Activation of a carbon–carbon bond in solution by transition-metal insertion. Nature 364, 699–701 (1993).

Jennings, P. W. & Johnson, L. L. Metallacyclobutane complexes of the group eight transition metals: synthesis, characterizations, and chemistry. Chem. Rev. 94, 2241–2290 (1994).

Rybtchinski, B. & Milstein, D. Metal Insertion into C–C Bonds in Solution. Angew. Chem. Int. Ed. 38, 870–883 (1999).

Bart, S. C. & Chirik, P. J. Selective, catalytic carbon−carbon bond activation and functionalization promoted by late transition metal catalysts. J. Am. Chem. Soc. 125, 886–887 (2003).

Jun, C.-H. Transition metal-catalyzed carbon–carbon bond activation. Chem. Soc. Rev. 33, 610–618 (2004).

Rubin, M., Rubina, M. & Gevorgyan, V. Transition metal chemistry of cyclopropenes and cyclopropanes. Chem. Rev. 107, 3117–3179 (2007).

Murakami, M. & Matsuda, T. Metal-catalysed cleavage of carbon–carbon bonds. Chem. Commun. 47, 1100–1105 (2011).

Ruhland, K. Transition-metal-mediated cleavage and activation of C–C single bonds. Eur. J. Org. Chem. 2012, 2683–2706 (2012).

Chen, F., Wang, T. & Jiao, N. Recent advances in transition-metal-catalyzed functionalization of unstrained carbon–carbon bonds. Chem. Rev. 114, 8613–8661 (2014).

Souillart, L. & Cramer, N. Catalytic C–C bond activations via oxidative addition to transition metals. Chem. Rev. 115, 9410–9464 (2015).

Murakami, M. & Ishida, N. Potential of metal-catalyzed C–C single bond cleavage for organic synthesis. J. Am. Chem. Soc. 138, 13759–13769 (2016).

Murai, S. et al. Efficient catalytic addition of aromatic carbon-hydrogen bonds to olefins. Nature 366, 529–531 (1993).

Shilov, A. E. & Shul’pin, G. B. Activation of C–H bonds by metal complexes. Chem. Rev. 97, 2879–2932 (1997).

Gunsalus, N. J. et al. Homogeneous functionalization of methane. Chem. Rev. 117, 8521–8573 (2017).

He, J., Wasa, M., Chan, K. S. L., Shao, Q. & Yu, J.-Q. Palladium-catalyzed transformations of Alkyl C–H bonds. Chem. Rev. 117, 8754–8786 (2017).

Yang, Y., Lan, J. & You, J. Oxidative C–H/C–H coupling reactions between two (hetero)arenes. Chem. Rev. 117, 8787–8863 (2017).

Newton, C. G., Wang, S.-G., Oliveira, C. C. & Cramer, N. Catalytic enantioselective transformations involving C–H bond cleavage by transition-metal complexes. Chem. Rev. 117, 8908–8976 (2017).

Kim, D.-S., Park, W.-J. & Jun, C.-H. Metal–organic cooperative catalysis in C–H and C–C bond activation. Chem. Rev. 117, 8977–9015 (2017).

Yi, H. et al. Recent advances in radical C–H activation/radical cross-coupling. Chem. Rev. 117, 9016–9085 (2017).

Park, Y., Kim, Y. & Chang, S. Transition metal-catalyzed C–H amination: scope, mechanism, and applications. Chem. Rev. 117, 9247–9301 (2017).

Gandeepan, P. et al. 3d transition metals for C–H activation. Chem. Rev. 119, 2192–2452 (2019).

Dalton, T., Faber, T. & Glorius, F. C–H activation: toward sustainability and applications. ACS Cent. Sci. 7, 245–261 (2021).

Crabtree, R. H., Dion, R. P., Gibboni, D. J., McGrath, D. V. & Holt, E. M. Carbon-carbon bond cleavage in hydrocarbons by iridium complexes. J. Am. Chem. Soc. 108, 7222–7227 (1986).

Hartwig, J. F., Andersen, R. A. & Bergman, R. G. Synthesis of a highly reactive (benzyne)ruthenium complex. Carbon-carbon, carbon-hydrogen, nitrogen-hydrogen and oxygen-hydrogen activation reactions. J. Am. Chem. Soc. 111, 2717–2719 (1989).

Perthuisot, C. & Jones, W. D. Catalytic hydrogenolysis of an aryl-aryl carbon-carbon bond with a rhodium complex. J. Am. Chem. Soc. 116, 3647–3648 (1994).

Suzuki, H., Takaya, Y., Takemori, T. & Tanaka, M. Selective carbon-carbon bond cleavage of cyclopentadiene on a trinuclear ruthenium pentahydride complex. J. Am. Chem. Soc. 116, 10779–10780 (1994).

Murakami, M., Amii, H., Shigeto, K. & Ito, Y. Breaking of the C−C bond of cyclobutanones by rhodium(i) and its extension to catalytic synthetic reactions. J. Am. Chem. Soc. 118, 8285–8290 (1996).

Jun, C.-H. & Lee, H. Catalytic carbon−carbon bond activation of unstrained ketone by soluble transition-metal complex. J. Am. Chem. Soc. 121, 880–881 (1999).

Murakami, M., Itahashi, T. & Ito, Y. Catalyzed intramolecular olefin insertion into a carbon−carbon single bond. J. Am. Chem. Soc. 124, 13976–13977 (2002).

Shaw, M. H., Melikhova, E. Y., Kloer, D. P., Whittingham, W. G. & Bower, J. F. Directing group enhanced carbonylative ring expansions of amino-substituted cyclopropanes: rhodium-catalyzed multicomponent synthesis of N-heterobicyclic enones. J. Am. Chem. Soc. 135, 4992–4995 (2013).

Zhou, X. & Dong, G. (4+1) vs (4+2): catalytic intramolecular coupling between cyclobutanones and trisubstituted allenes via C–C activation. J. Am. Chem. Soc. 137, 13715–13721 (2015).

Shaw, M. H., Croft, R. A., Whittingham, W. G. & Bower, J. F. Modular access to substituted azocanes via a rhodium-catalyzed cycloaddition–fragmentation strategy. J. Am. Chem. Soc. 137, 8054–8057 (2015).

Shaw, M. H., McCreanor, N. G., Whittingham, W. G. & Bower, J. F. Reversible C–C bond activation enables stereocontrol in Rh-catalyzed carbonylative cycloadditions of aminocyclopropanes. J. Am. Chem. Soc. 137, 463–468 (2015).

Deng, L. et al. Kinetic resolution via Rh-catalyzed C–C activation of cyclobutanones at room temperature. J. Am. Chem. Soc. 141, 16260–16265 (2019).

Hou, S.-H. et al. Enantioselective type II cycloaddition of alkynes via C–C activation of cyclobutanones: rapid and asymmetric construction of [3.3.1] bridged bicycles. J. Am. Chem. Soc. 142, 13180–13189 (2020).

Yu, X., Zhang, Z. & Dong, G. Catalytic enantioselective synthesis of γ-lactams with β-quaternary centers via merging of C–C activation and sulfonyl radical migration. J. Am. Chem. Soc. 144, 9222–9228 (2022).

Nakao, Y., Oda, S. & Hiyama, T. Nickel-catalyzed arylcyanation of alkynes. J. Am. Chem. Soc. 126, 13904–13905 (2004).

Nakao, Y., Yada, A., Ebata, S. & Hiyama, T. A dramatic effect of lewis-acid catalysts on nickel-catalyzed carbocyanation of alkynes. J. Am. Chem. Soc. 129, 2428–2429 (2007).

Watson, M. P. & Jacobsen, E. N. Asymmetric intramolecular arylcyanation of unactivated olefins via C−CN bond activation. J. Am. Chem. Soc. 130, 12594–12595 (2008).

Nakai, K., Kurahashi, T. & Matsubara, S. Nickel-catalyzed cycloaddition of o-arylcarboxybenzonitriles and alkynes via cleavage of two carbon–carbon σ bonds. J. Am. Chem. Soc. 133, 11066–11068 (2011).

Matsumura, S., Maeda, Y., Nishimura, T. & Uemura, S. Palladium-catalyzed asymmetric arylation, vinylation, and allenylation of tert-cyclobutanols via enantioselective C−C bond cleavage. J. Am. Chem. Soc. 125, 8862–8869 (2003).

He, Z. & Yudin, A. K. Palladium-catalyzed oxidative activation of arylcyclopropanes. Org. Lett. 8, 5829–5832 (2006).

Chiba, S., Xu, Y.-J. & Wang, Y.-F. A Pd(II)-catalyzed ring-expansion reaction of cyclic 2-azidoalcohol derivatives: synthesis of azaheterocycles. J. Am. Chem. Soc. 131, 12886–12887 (2009).

Huffman, M. A. & Liebeskind, L. S. Nickel(0)-catalyzed synthesis of substituted phenols from cyclobutenones and alkynes. J. Am. Chem. Soc. 113, 2771–2772 (1991).

Edelbach, B. L., Lachicotte, R. J. & Jones, W. D. Mechanistic investigation of catalytic carbon−carbon bond activation and formation by platinum and palladium phosphine complexes. J. Am. Chem. Soc. 120, 2843–2853 (1998).

Takahashi, T. et al. Cycloaddition reaction of zirconacyclopentadienes to alkynes: highly selective formation of benzene derivatives from three different alkynes. J. Am. Chem. Soc. 120, 1672–1680 (1998).

Yow, S., Gates, S. J., White, A. J. P. & Crimmin, M. R. Zirconocene dichloride catalyzed hydrodefluorination of C–F bonds. 51, 12559–12563 (2012).

Masarwa, A. et al. Merging allylic carbon–hydrogen and selective carbon–carbon bond activation. Nature 505, 199 (2013).

Gansäuer, A. et al. Substituent effects and supramolecular interactions of titanocene(III) chloride: implications for catalysis in single electron steps. J. Am. Chem. Soc. 136, 1663–1671 (2014).

Yan, X. & Xi, C. Multifaceted zirconate complexes in organic synthesis. Coord. Chem. Rev. 308, 22–31 (2016).

Zhang, Y.-Q., Vogelsang, E., Qu, Z.-W., Grimme, S. & Gansäuer, A. Titanocene-catalyzed radical opening of N-acylated aziridines. Angew. Chem. Int. Ed. 56, 12654–12657 (2017).

Yao, C., Dahmen, T., Gansäuer, A. & Norton, J. Anti-Markovnikov alcohols via epoxide hydrogenation through cooperative catalysis. Science 364, 764–767 (2019).

Reiß, F. et al. 1-Titanacyclobuta-2,3-diene—an elusive four-membered cyclic allene. Chem. Sci. 10, 5319–5325 (2019).

Weweler, J., Younas, S. L. & Streuff, J. Titanium(III)-catalyzed reductive decyanation of geminal dinitriles by a non-free-radical mechanism. Angew. Chem. Int. Ed. 58, 17700–17703 (2019).

Zhang, Z. et al. Titanocenes as photoredox catalysts using green-light irradiation. Angew. Chem. Int. Ed. 59, 9355–9359 (2020).

Rosenthal, U. Equilibria and mesomerism/valence tautomerism of group 4 metallocene complexes. Chem. Soc. Rev. 49, 2119–2139 (2020).

Matt, C., Kern, C. & Streuff, J. Zirconium-catalyzed remote defunctionalization of alkenes. ACS Catal. 10, 6409–6413 (2020).

Manßen, M. & Schafer, L. L. Titanium catalysis for the synthesis of fine chemicals—development and trends. Chem. Soc. Rev. 49, 6947–6994 (2020).

Bahena, E. N., Griffin, S. E. & Schafer, L. L. Zirconium-catalyzed hydroaminoalkylation of alkynes for the synthesis of allylic amines. J. Am. Chem. Soc. 142, 20566–20571 (2020).

Bielefeld, J. & Doye, S. Fast titanium-catalyzed hydroaminomethylation of alkenes and the formal conversion of methylamine. Angew. Chem. Int. Ed. 59, 6138–6143 (2020).

Zhang, Z., Stuckrath, J. B., Grimme, S. & Gansäuer, A. Titanocene-catalyzed [2+2] cycloaddition of bisenones and comparison with photoredox catalysis and established methods. Angew. Chem. Int. Ed. 60, 14339–14344 (2021).

Negishi, E.-i, Cederbaum, F. E. & Takahashi, T. Reaction of zirconocene dichloride with alkyllithiums or alkyl grignard reagents as a convenient method for generating a “zirconocene” equivalant and its use in zirconium-promoted cyclization of alkenes, alkynes, dienes, enynes, and diynes. Tetrahedron Lett. 27, 2829–2832 (1986).

Rosenthal, U. et al. Transformation of the first zirconocene alkyne complex without an additional phosphane ligand into a dinuclear σ-alkenyl complex by hydrogen transfer from η5-C5H5 to the alkyne ligand. Angew. Chem. Int. Ed. 32, 1193–1195 (1993).

Pun, D., Lobkovsky, E. & Chirik, P. J. Amineborane dehydrogenation promoted by isolable zirconium sandwich, titanium sandwich and N2 complexes. Chem. Commun. 31, 3297–3299 (2007).

Beweries, T., Hansen, S., Kessler, M., Klahn, M. & Rosenthal, U. Catalytic dehydrogenation of dimethylamine borane by group 4 metallocene alkyne complexes and homoleptic amido compounds. Dalton Trans. 40, 7689–7692 (2011).

Takahashi, T. et al. Zirconium-catalyzed highly regioselective hydrosilation reaction of alkenes and X-ray structures of silyl(hydrido)zirconocene derivatives. J. Am. Chem. Soc. 113, 8564–8566 (1991).

Peulecke, N., Thomas, D., Baumann, W., Fischer, C. & Rosenthal, U. Dehydrocoupling of silanes catalyzed by zirconocene- and titanocene alkyne complexes. Tetrahedron Lett. 38, 6655–6656 (1997).

Peulecke, N. et al. Si-H activation in titanocene and zirconocene complexes of alkynylsilanes RC≡CSiMe2H (R = tBu, Ph, SiMe3, SiMe2H): a model to understand catalytic reactions of hydrosilanes. Chem. Eur. J. 4, 1852–1861 (1998).

Lamač, M. et al. Si−H bond activation of alkynylsilanes by group 4 metallocene complexes. J. Am. Chem. Soc. 132, 4369–4380 (2010).

Harada, S. et al. Complexation of vinylcyclopropanes with zirconocene−1-butene complex: application to the stereocontrolled synthesis of steroidal side chains. J. Org. Chem. 62, 3994–4001 (1997).

Wang, C. et al. Zirconocene-mediated ligand-switched selective cleavage of active and inert carbon–carbon bonds in allylcyclopropanes. Chem. Commun. 29, 4414–4416 (2009).

Vasseur, A., Perrin, L., Eisenstein, O. & Marek, I. Remote functionalization of hydrocarbons with reversibility enhanced stereocontrol. Chem. Sci. 6, 2770–2776 (2015).

Bruffaerts, J. et al. Zirconocene-mediated selective C–C bond cleavage of strained carbocycles: scope and mechanism. J. Org. Chem. 83, 3497–3515 (2018).

Rosenthal, U. et al. Synthesis and structure of the smallest cyclic cumulene; reaction of 1,3-diynes with zirconocene complexes. Angew. Chem. Int. Ed. 33, 1605–1607 (1994).

Dimmock, P. W. & Whitby, R. J. Zirconium-mediated ring-opening of cyclopropanes. J. Chem. Soc., Chem. Commun. 20, 2323–2324 (1994).

Masarwa, A. et al. Merging allylic carbon–hydrogen and selective carbon–carbon bond activation. Nature 505, 199–203 (2014).

Takahashi, T. et al. Selective skeletal rearrangement by carbon–carbon bond activation. J. Chem. Soc., Chem. Commun. 2, 182–183 (1990).

Takahashi, T., Kageyama, M., Denisov, V., Hara, R. & Negishi, E. Facile cleavage of the Cβ–Cβ′ bond of zirconacyclopentenes. Convenient method for selectively coupling alkynes with alkynes, nitriles, and aldehydes. Tetrahedron Lett. 34, 687–690 (1993).

Takahashi, T. et al. Selective intermolecular coupling of alkynes with nitriles and ketones via β,β‘-carbon−carbon bond cleavage of zirconacyclopentenes. J. Org. Chem. 63, 6802–6806 (1998).

Takahashi, T., Kotora, M., Hara, R. & Xi, Z. Carbon–carbon bond cleavage and selective transformation of zirconacycles. Bull. Chem. Soc. Jpn. 72, 2591–2602 (2005).

Takahashi, T. et al. Zirconium mediated regioselective carbon-carbon bond formation reactions. Chem. Lett. 21, 331–334 (2006).

Corker, J. et al. Catalytic cleavage of the C-H and C-C bonds of alkanes by surface organometallic chemistry: an EXAFS and IR characterization of a Zr-H catalyst. Science 271, 966–969 (1996).

Dufaud, V. & Basset, J.-M. Catalytic hydrogenolysis at low temperature and pressure of polyethylene and polypropylene to diesels or lower alkanes by a zirconium hydride supported on silica-alumina: a step toward polyolefin degradation by the microscopic reverse of Ziegler–Natta polymerization. Angew. Chem. Int. Ed. 37, 806–810 (1998).

Basset, J.-M., Coperet, C., Soulivong, D., Taoufik, M. & Cazat, J. T. Metathesis of alkanes and related reactions. Acc. Chem. Res. 43, 323–334 (2010).

Kondo, H. et al. σ-Bond hydroboration of cyclopropanes. J. Am. Chem. Soc. 142, 11306–11313 (2020).

Wang, Y. et al. Rhodium-catalysed selective C–C bond activation and borylation of cyclopropanes. Chem. Sci. 12, 3599–3607 (2021).

Wang, T. et al. Ligand cooperativity enables highly enantioselective C–C σ-bond hydroboration of cyclopropanes. Chem. 9, 130–142 (2022).

Liskey, C. W. & Hartwig, J. F. Iridium-catalyzed borylation of secondary C–H bonds in cyclic ethers. J. Am. Chem. Soc. 134, 12422–12425 (2012).

Murakami, R., Tsunoda, K., Iwai, T. & Sawamura, M. Stereoselective C–H borylations of cyclopropanes and cyclobutanes with silica-supported monophosphane–Ir catalysts. Chem. Eur. J. 20, 13127–13131 (2014).

Miyamura, S., Araki, M., Suzuki, T., Yamaguchi, J. & Itami, K. Stereodivergent synthesis of arylcyclopropylamines by sequential C–H borylation and Suzuki–Miyaura coupling. Angew. Chem. Int. Ed. 54, 846–851 (2015).

Liu, X. et al. Aminoazanium of DABCO: an amination reagent for alkyl and aryl pinacol boronates. Angew. Chem. Int. Ed. 59, 2745–2749 (2020).

Zhao, H., Gao, Q., Zhang, Y., Zhang, P. & Xu, S. Iridium-catalyzed γ-selective hydroboration of γ-substituted allylic amides. Org. Lett. 22, 2861–2866 (2020).

Albéniz, A. C., Espinet, P., López-Fernández, R. & Sen, A. A warning on the use of radical traps as a test for radical mechanisms: they react with palladium hydrido complexes. J. Am. Chem. Soc. 124, 11278–11279 (2002).

Li, F. et al. Highly efficient transfer hydrogenation of levulinate esters to γ-valerolactone over basic zirconium carbonate. Ind. Eng. Chem. Res. 57, 10126–10136 (2018).

Bohre, A., Saha, B. & Abu-Omar, M. M. Catalytic upgrading of 5-hydroxymethylfurfural to drop-in biofuels by solid base and bifunctional metal–acid catalysts. ChemSusChem 8, 4022–4029 (2015).

Schedler, D. J. A., Li, J. & Ganem, B. Reduction of secondary carboxamides to imines. J. Org. Chem. 61, 4115–4119 (1996).

Haehnel, M. et al. Four-membered heterometallacyclic d0 and d1 complexes of group 4 metallocenes with amidato ligands. Chem. Eur. J. 20, 7752–7758 (2014).

Donnelly, L., Berthet, J.-C. & Cantat, T. Selective reduction of secondary amides to imines catalysed by Schwartz’s reagent. Angew. Chem. Int. Ed. 61, e202206170 (2020).

Gell, K. I. & Schwartz, J. Hydrogenation of d0 complexes: zirconium(IV) alkyl hydrides. J. Am. Chem. Soc. 100, 3246–3248 (1978).

Gell, K. I., Posin, B., Schwartz, J. & Williams, G. M. Hydrogenation of alkylzirconium(IV) complexes: heterolytic activation of hydrogen by a homogeneous metal alkyl. J. Am. Chem. Soc. 104, 1846–1855 (1982).

Jordan, R. F., Bajgur, C. S., Dasher, W. E. & Rheingold, A. L. Hydrogenation of cationic dicyclopentadienylzirconium(IV) alkyl complexes. Characterization of cationic zirconium(IV) hydrides. Organometallics 6, 1041–1051 (1987).

Acknowledgements

We are grateful to the National Natural Science Foundation of China (22271295, L.W.); Gansu Provincial Natural Science Foundation Key Project (23JRRA606, L.W.), Major Program of the Lanzhou Institute of Chemical Physics, CAS (No. ZYFZFX-9, L.W.); State Key Laboratory Program of the Lanzhou Institute of Chemical Physics (CHGZ-202208, L.W.) for generous financial support.

Author information

Authors and Affiliations

Contributions

L.Wu, S. Li conceived the project and designed the experiments. S. Li performed the experiments and analyzed the data. H. Jiao performed computational chemistry. L.Wu, H. Jiao and X. Shu wrote the manuscript. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yiming Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, S., Jiao, H., Shu, XZ. et al. Zirconium and hafnium catalyzed C–C single bond hydroboration. Nat Commun 15, 1846 (2024). https://doi.org/10.1038/s41467-024-45697-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-45697-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.