Abstract

Developing atomically synergistic bifunctional catalysts relies on the creation of colocalized active atoms to facilitate distinct elementary steps in catalytic cycles. Herein, we show that the atomically-synergistic binuclear-site catalyst (ABC) consisting of \({{{{{\rm{Zn}}}}}}^{\delta+}\)-O-Cr6+ on zeolite SSZ-13 displays unique catalytic properties for iso-stoichiometric co-conversion of ethane and CO2. Ethylene selectivity and utilization of converted CO2 can reach 100 % and 99.0% under 500 °C at ethane conversion of 9.6%, respectively. In-situ/ex-situ spectroscopic studies and DFT calculations reveal atomic synergies between acidic Zn and redox Cr sites. \({{{{{\rm{Zn}}}}}}^{\delta+}\) (\(0 \, < \, \delta \, < \, 2\)) sites facilitate β-C-H bond cleavage in ethane and the formation of Zn-Hδ- hydride, thereby the enhanced basicity promotes CO2 adsorption/activation and prevents ethane C-C bond scission. The redox Cr site accelerates CO2 dissociation by replenishing lattice oxygen and facilitates H2O formation/desorption. This study presents the advantages of the ABC concept, paving the way for the rational design of novel advanced catalysts.

Similar content being viewed by others

Introduction

The synergistic effects generated by mixed or supported bifunctional catalysts are often claimed to promote the catalytic performance of traditional heterogeneous catalysts1,2,3,4,5,6,7,8,9. Recently, the construction of synergistic pair-sites with colocalized metal atoms to facilitate distinct elementary steps in the catalytic reaction has been established as a crucial step toward atomically synergistic bifunctional catalyst development10,11,12. The interaction between these adjacent metal atoms, similar to the metal-support interaction of traditional heterogeneous catalysts3,13, offers the possibility to modulate their respective electronic structure to further enhance their catalytic activity11,14,15,16,17. However, precisely controlling their colocalization requires a complicated synthesis process with multiple synthesis steps to load single atoms10,18. Moreover, the stability of the well-defined synergistic sites is debatable, especially under harsh reaction conditions such as high reaction temperatures18,19. The benefits and remaining challenges of atomically synergistic bifunctional catalysts motivate us to further explore new synthesis routes, new reaction applications, and their synergistic effects with the goals to accelerate the development of next-generation atomically synergistic catalysts.

Growing CO2 emissions and abundant shale gas reserves have prompted a significant amount of research to explore efficient approaches for co-utilizing the products to produce value-added chemicals20,21,22. Ethane, the second-largest component of shale gas, is an ideal alternative hydrogen source for CO2 conversion. The co-conversion of ethane and CO2 (C2H6 + CO2 → C2H4 + CO + H2O) is a viable alternative to the ethane steam cracking for ethylene production under the goal of net negative CO2 emissions21. Furthermore, iso-stoichiometric co-conversion of ethane and CO2 (ICEC) to ethylene and CO is crucial for direct downstream processes such as the hydroformylation reaction to produce aldehyde23 and polymerization process to produce polyketones24,25,26,27. However, the ICEC process lacks a viable catalyst for achieving high ethylene selectivity and CO2 utilization simultaneously. Metal-based catalysts suffer from the inevitable cleavage of C-C bonds through dry reforming pathways and lower the ethylene selectivity22,28,29,30. Oxide-based catalysts exhibit the great merit of preferential C–H bond scission over C–C bond scission pathways but require excessive CO2 cofeeding to reduce ethane adsorption and scavenge the surface H species31,32. Specifically, Zn and Cr oxide-based catalysts were widely studied for co-conversion of ethane and CO2. The acidic Zn2+ site displayed high activity for C-H bond cleavage in ethane and CO2 activation, requiring the participation of adjacent active sites to form binuclear sites33,34,35. The challenge is that acidified Zn2+-H hydride displays a capacity for C-C bond scission of ethane, leading to undesired production of methane. Redox Cr6+ sites require lattice oxygen as a H acceptor to dissociate C-H bonds but trigger the formation of less active Cr3+ species. The reoxidation of Cr3+ to Cr6+ is limited by slow O abstraction from CO220. The above analyses thus indicate the need for the development of an atomically-synergistic binuclear Zn–O–Cr site catalyst for ICEC, with Zn facilitating CO2 adsorption and activation to provide O species for Cr6+ regeneration and adjacent Cr as an electron donor reducing the acidity of Zn2+ to facilitate its activity and selectivity for C-H bond scission6,36,37,38,39. More generally, exploring a cooperative redox and acid-base catalytic mechanism for ICEC is highly desirable.

In this work, we show the successful fabrication and demonstration of a Zn-O-Cr atomically-synergistic binuclear-site catalyst (ABC) that is highly efficient for ICEC with high ethylene selectivity and utilization of converted CO2 (\({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\)). As we will show, compared with pure Zn and Cr catalysts, Zn-O-Cr ABC displays ~1.5 and ~4-fold higher catalytic activity with 100% ethylene selectivity and 99.0% \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) under optimized reaction conditions. Key to this high performance is the discovery that Cr facilitates the formation of a \({{{{{\rm{Zn}}}}}}^{\delta+}\) (\(0 \, < \, \delta \, < \, 2\)) site to enhance the β-C-H bond cleavage of ethane, while the resulting Lewis base Zn-Hδ- hydride favors CO2 adsorption and activation, and prevents C-C bond scission of ethane. The redox Cr site accelerates CO2 dissociation and facilitates H2O formation/desorption. The apparent activation energies of ethane conversion and CO2 conversion are ~70.9 and ~74.0 kJ/mol, which demonstrates the rate matching achieved in ICEC.

Results

Controlling Zn and Cr coordination structure

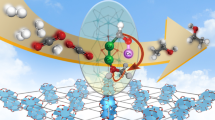

Catalysts were synthesized by mixing a constant total amount of zinc (II) acetate and chromium (III) acetate hydroxide on a SSZ-13 zeolite support with varying Zn/Cr molar ratios, followed by direct decomposition at 550°C and then Na+ neutralization of acidic site on supports (Fig. 1a). The catalyst synthesis method developed here will be referred to as the dry-deposition method (The experimental details are summarized in Methods). The catalysts are denoted as ZnxCry/SSZ-13, where x/y refers to the ratio of Zn/Cr (x = 1, y = 0; x/y = 1/2, 1, 2, 3, 4; x = 0, y = 1). The textural properties, composition analysis, and surface acidity of SSZ-13 and synthesized catalysts are characterized by N2 physisorption, X-ray fluorescence (XRF), and attenuated total reflection Fourier transform infrared (ATR-FTIR) measurements (Supplementary Figs. 1-2 and Tables 1-2). Transmission electron microscopy (TEM), scanning TEM (STEM) images, and energy dispersive spectroscopy (EDS) elemental mappings (Fig. 1b and Supplementary Figs. 3-5) demonstrate high dispersion of Zn and/or Cr oxide phases, with no observable sintering of oxide nanoparticles. The X-ray diffraction (XRD) results reveal the absence of spinel ZnCr2O4 and zincite ZnO for all dry-deposition synthesized catalysts. Cr2O3 phases with R3c space group were only observed in Cr/SSZ-13 and Zn1Cr2/SSZ-13 (Supplementary Fig. 6). The control samples with same amount Zn and Cr precursors were prepared via a co-precipitation method (CP), followed by Na+ neutralization. ZnCrOx nanoparticles are observed in CP-synthesized samples (Supplementary Fig. 7). And a phase transition from spinel ZnCr2O4 to ZnO (Supplementary Fig. 8) was detected on CP-synthesized catalysts with Zn/Cr ratios varying from 1/2 to 3/140,41,42.

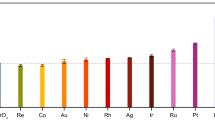

a Schematic illustration of the fabrication process of Zn-O-Cr ABC. b Representative TEM and HAADF-STEM images and EDS mapping of Zn-O-Cr ABC with Zn/Cr ration of 3/1; c The proportion of Znδ+ \((0 \, < \, \delta \, < \, 2)\) (left) and Cr6+ (right) with varying Zn/Cr ratios (Results derived from Auger spectra of Zn LMM and Cr 2p3/2 XPS spectra); d Enlarged electron transition features in Zn and Cr K-edge XANES spectra; e k3-weighted Fourier-transformed extended X-ray absorption fine structure (FT-EXAFS) spectra (Zn K-edge) of Zn-O-Cr ABCs with varying Zn/Cr ratios, with Zn foil and ZnO as references; f Coordination number (CN) of Zn-O-Cr(Zn) and Cr-O in Cr6+ state in Zn-O-Cr ABCs with varying Zn/Cr ratios.

Figure 1c, Supplementary Figs. 9-11 and Supplementary Table 3 show X-ray photoelectron spectroscopy (XPS) results for Zn 2p, Zn LMM Auger and Cr 2p3/2 spectra. The formation of Znδ+ (0 < δ < 2) was confirmed through Auger spectra of Zn LMM. The subpeaks at 987.5 and 990.0 eV in Auger spectra of Zn LMM (Supplementary Fig. 10) are assigned to the Zn2+ and \({{{{{\rm{Zn}}}}}}^{\delta+}\) (\(0 \, < \, \delta \, < \, 2\)), respectively;43 And the subpeaks at ~576 and ~580 eV in Cr 2p3/2 XPS (Supplementary Fig. 11) were assigned to the Cr3+ and Cr6+, correspondingly44. Figure 1c shows the proportion of \({{{{{\rm{Zn}}}}}}^{\delta+}\) 0 < δ < 2 and Cr6+ relative to the total amount of \(({{{{{\rm{Zn}}}}}}^{\delta+}+{{{{{\rm{Zn}}}}}}^{2+})\) and (Cr6++Cr3+) in ZnxCry/SSZ-13 catalysts, respectively. These proportions vary with Zn/Cr ratios, with the highest Znδ+(0 < δ < 2) proportion generated at Zn/Cr ratio of 3/1 and the highest Cr6+ proportions produced at Zn/Cr ratios of 3/1 and 4/1. We hypothesize that the proximal electronic interactions between Zn and Cr could modify their respective oxidation states. This is consistent with the Zn L3-edge X-ray absorption near-edge structure (XANES) spectra analyses (Supplementary Fig. 12), which suggests a decrease in the oxidation state of Zn in ZnxCry/SSZ-13 samples compared to pure Zn/SSZ-13 sample. The \({{{{{\mathrm{Zn}}}}}}^{\delta+}\) and Cr6+ content in the CP-synthesized Zn3Cr1/SSZ-13 sample is similar to those of pure Zn/SSZ-13 and Cr-SSZ-13 samples, respectively (Supplementary Fig. 13).

XANES spectra (Fig. 1d and Supplementary Fig. 14) and extended X-ray absorption fine structure (EXAFS) spectra (Fig. 1e, f, Supplementary Figs. 15–18, Supplementary Tables 4-5) were used to study coordination structures of Zn and Cr sites. As shown in Fig. 1d and Supplementary Fig. 14, the electron transition from Zn 1s to Zn 4p unoccupied orbitals (Feature A) is revealed in Zn K-edge XANES spectra; and Cr K-edge XANES spectra exhibits the peak of electron transition from Cr 1s to Cr 3d-O 2p unoccupied orbitals (Feature B). As the Zn/Cr ratio increases from 1/1 to 4/1 in ZnxCry/SSZ-13 catalysts, the intensity of feature A decreases, suggesting electron occupation in Zn 4p unoccupied orbitals, while the intensity of feature B increases, which suggests electrons transfer out of Cr 3d-O 2p orbitals near the conduction band minimum. We hypothesize a link between these observations, that electronic charge transfers from Cr 3d-O 2p character in the conduction band to Zn 4p45,46, due to a strong Zn-Cr interaction. Thus, the charge transfer decreases the oxidative state of Zn2+ to \({{{{{\rm{Zn}}}}}}^{\delta+}\) (\(0 \, < \, \delta \, < \, 2\)), which is consistent with XPS and Auger results (Fig. 1c). In Fig. 1e, the scattering peaks at 1.50 Å are assigned to Zn-O coordination in the first shell. The pure Zn/SSZ-13 and ZnxCry/SSZ-13 samples exhibited a significantly lower intensity for this Zn-O scattering peak than the ZnO reference, suggesting a higher degree of crystal disorder47,48. The scattering peaks at ~2.85 Å are assigned to Zn-O-Zn coordination in the second shell. Compared to Zn/SSZ-13 and the ZnO reference, Zn1Cr1/SSZ-13 and Zn3Cr1/SSZ-13 exhibited no peak for Zn-O-Zn coordination. Instead, a new peak at ~3.08 Å should be attributed to the Zn-O-Cr bond41. Differently, Zn4Cr1/SSZ-13 sample has both Zn-O-Cr and Zn-O-Zn bonds. Cr K-edge Fourier transformed EXAFS (FT-EXAFS) spectra of Cr-containing samples (Supplementary Fig. 15) displayed Cr-O scattering peaks located at 1.51 Å, which is similar to standard peak of Cr-O scattering 1.50 Å in CrIII2O3; but as Zn/Cr ratio increase to 3/1 and 4/1, a visible shoulder peak corresponding to standard peak of Cr-O scattering at 1.20 Å in K2CrVI2O7 appeared, indicating that Zn3Cr1/SSZ-13 and Zn4Cr1/SSZ-13 samples have two types of Cr-O coordination. Supplementary Tables 4-5 show the EXAFS-derived fitting parameters. ZnxCry/SSZ-13 catalyst (x/y = 1, 3, 4) samples show Zn-O-Cr coordination with a bond distance ~3.4 Å in phase-corrected space, which corresponds to the emergent peak at ~3.08 Å in Fig. 1e41. These results provide solid evidence for the formation of a Znδ+-O-Cr6+ structure in ZnxCry/SSZ-13. Notice that ZnxCry/SSZ-13 samples also exhibited lower coordination numbers (CNs) for Zn-O and Zn-O-Cr compared to the pure Zn/SSZ-13 sample (Fig. 1f and Supplementary Table 4), which results from Cr colocalization. Especially, for the Zn3Cr1/SSZ-13 and Zn4Cr1/SSZ-13 samples, the CNs of Zn-O and Zn-O-Cr are 3.94 and 0.86, and 3.77 and 1.07, respectively. And Zn3Cr1/SSZ-13 has the highest CN for the Cr-O bond in hexavalent (Cr6+) states. Therefore, these results confirm the formation of hetero binuclear Znδ+-O-Cr6+ sites, and Zn3Cr1/SSZ-13 exhibits the highest population of the Znδ+-O-Cr6+ site.

Catalytic performance of Zn-O-Cr ABC for ICEC

Figure 2a, b and Supplementary Fig. 19 and Table 6 show the ICEC catalytic performance of Zn-O-Cr ABCs under the reaction conditions of weight hourly space velocity (WHSV) of 7500 mL g−1cat h−1 and a CO2/ethane ratio of 1 at 550 °C. The Zn3Cr1/SSZ-13 ABC catalyst displayed the best performance among all tested catalysts, with the highest C2H6 conversion (19.8%), CO2 conversion (18.7%), turnover frequency (TOF) of C2H4 formation (0.77 mol molZn+Cr−1 h−1), as well as excellent C2H4 selectivity (93.0%) and \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) (94.4%). Previous studies have mainly focused on achieving high ethane conversion and ethylene selectivity in co-conversion of ethane and CO2 by co-feeding excess CO2 at CO2/ethane ratios of 2–649,50,51,52,53. In the ICEC process the C2H4 selectivity and \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) are two important factors for evaluating the success of catalyst development. Utilization of converted CO2 (\({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\)) is defined as the ratio of CO2 conversion to ethane conversion on an iso-stoichiometric basis. Compared with previous studies in Supplementary Table 7 and Fig. 21, the Zn3Cr1/SSZ-13 catalyst displays the highest space-time yield (STY) of C2H4 formation (0.086 kg h−1 kgcat−1) and the highest \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) at 550 °C, which clearly shows the superiority of Zn–O–Cr ABCs. Furthermore, Fig. 2c and Supplementary Table 7 show C2H4 selectivity can achieve 100% and \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) is 99.0% under the reaction temperature of 500 °C, with ethane conversion of 9.6% and CO2 conversion of 9.5%. These results further demonstrate the advantage of Zn-O-Cr ABCs suitable for ICEC. In ICEC, the reaction system includes the reactants’ (ethane and CO2) adsorption, activation, reaction, and products’ (ethylene, CO, and H2O) formation, and desorption. The apparent activation energies (Ea) for ethane conversion and CO2 conversion are key to evaluating the rate matching of both reactions. Figure 2d shows similar Ea (results were calculated based on Fig. 2c and Supplementary Fig. 22) for ethane dehydrogenation (70.9 kJ/mol) and CO2 hydrogenation (74.0 kJ/mol). This further demonstrates the feasibility and success of the Zn-O-Cr ABCs concept for desired ICEC catalyst development.

a Catalytic performance of Zn-O-Cr ABCs (Reaction condition: Temperature = 550 °C; Reactant composition = 5% C2H6 + 5% CO2 + 90% Ar; WHSV = 7500 mL g−1cat h−1); b C2H6 and CO2 conversion, utilization of converted CO2 (\({{{\mbox{U}}}}_{{{{{{\rm{CO}}}}}}_{2}}\)) of Cr/SSZ-13, Zn/SSZ-13, and Zn3Cr1/SSZ-13 catalysts in ICEC at 550 °C; c Reaction temperature dependent performance of Zn3Cr1/SSZ-13 catalyst. d Arrhenius plots of Zn3Cr1/SSZ-13 catalyst (obtained when both C2H6 and CO2 conversions are <10 %). e C2H6 conversion and C2H4 selectivity over Zn3Cr1/SSZ-13, Zn/SSZ-13, and Cr/SSZ-13 with (green columns) /without (gray columns) CO2 at 550 °C.

Figure 2a and Supplementary Fig. 19 reveal that there is a clear correlation between the proportion of Znδ+-O-Cr6+ sites and ICEC performance. Pure Cr/SSZ-13 catalyst displayed slightly higher ethylene selectivity (95.4%) and higher \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) (96.0%) than Zn3Cr1/SSZ-13 sample, but has the lowest C2H6 conversion (5.1 %), CO2 conversion (4.9%), TOF of C2H4 formation (0.20 mol molZn+Cr−1 h−1). Increasing Zn contents in Zn-O-Cr ABCs, with Zn/Cr ratios from 1/2 to 3/1, has little effect on ethylene selectivity and \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\). Instead, increased Zn contents promote higher conversion of C2H6 and CO2, and leads to increased TOF of ethylene formation. Further increasing the Zn content to Zn/Cr ratio of 4/1, triggers lower ethane (14.4%) and CO2 (11.7%) conversions, resulting in a much lower \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) (81.5 %). Pure Zn/SSZ-13 exhibited further decreased C2H6 (12.1%) and CO2 (10.2%) conversions, compared with Zn4Cr1/SSZ-13. Therefore, we hypothesize that the Znδ+ in the binuclear site of Znδ+-O-Cr6+ is the primary active site for C2H6 dehydrogenation. Interestingly, the Znδ+ proportion also displays a correlation with CO2 conversion, which indicates that the Znδ+ sites are also involved in CO2 adsorption, activation, or reaction. In previous studies, binuclear Zn-O-Zn catalysts have been reported to have a high activity in ethane or propane dehydrogenation, but lack the capacity of efficient CO2 activation, leading to insufficient CO2 utilization35,54,55. In our study, the Zn3Cr1/SSZ-13 ABC with the highest amount of Znδ+-O-Cr6+ sites displayed ~1.5 and ~4-fold higher ethane dehydrogenation and CO2 conversion performance than pure Zn and Cr catalysts, respectively (Fig. 2b), which indicates the Cr6+ site of Znδ+-O-Cr6+ is also involved in the activation and reaction of C2H6 and CO2. From the above analyses, we conclude that the unique performance of Zn-O-Cr ABCs for ICEC relies on the atomic synergies within the Znδ+-O-Cr6+ site.

To study the atomic synergies between Znδ+-O-Cr6+ site in ICEC, we compared the C2H6 dehydrogenation performance of Zn3Cr1/SSZ-13 with pure Zn/SSZ-13 and Cr/SSZ−13 samples in the presence and absence of CO2. In Fig. 2e, we found the CO2 co-feeding significantly improved C2H6 conversion (19.8% vs. 10.7%) and C2H4 selectivity (93.0% vs. 85.0%) for Zn3Cr1/SSZ-13, with a high \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) up to 94.4%. By contrast, for Zn/SSZ−13, CO2 addition fails to enhance its C2H6 conversion (12.1% vs. 13.3%) but results in an increase in C2H4 selectivity (94.6% vs. 86.0%). The higher C2H4 selectivity is due to competitive adsorption of CO2 over C2H6, preventing the ethane cracking reaction, which has been reported previously56. Compared with Zn/SSZ−13, the improved C2H6 conversion of the Zn3Cr1/SSZ-13 catalyst is due to the generation of Znδ+ in Znδ+-O-Cr6+. For the Cr/SSZ−13 sample, CO2 introduction results in a higher C2H6 conversion (5.1% vs 4.0%) with a high \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) of 96%, but it did not change the C2H4 selectivity (95.4% vs 95.1%). Cr-based catalysts are reported to catalyze CO2 and ethane conversion through the redox (or MvK) mechanism20. CO2 introduction could favor lattice oxygen replenishment to regenerate highly reactive Cr6+ species and shift the reaction equilibrium of C2H6 dehydrogenation, thus leading to a higher activity. These results indicate that a reaction synergy between ethane and CO2 conversions could only occur at the atomically synergistic Znδ+-O-Cr6+ site.

To further validate the superiority of Zn-O-Cr ABCs, we compared the performance of Zn3Cr1/SSZ−13 prepared by the dry-deposition method with the sample synthesized by the traditional co-precipitation (CP) method. Supplementary Fig. 23 shows that the dry-deposition synthesized Zn3Cr1/SSZ-13 catalyst exhibited >4-fold higher ethane conversion (19.8% vs 4.5%) and higher \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) (94.4% vs 83.2%). The CP-synthesized Zn3Cr1/SSZ-13 sample was found to contain large Zn/Cr oxide particles and separate ZnCr2O4 and ZnO phases, resulting in loss of the atomic synergies of the Znδ+-O-Cr6+ site, which we correlate with its poor performance. We also studied the stability and regeneration ability of the Zn3Cr1/SSZ-13 ABC catalyst. Supplementary Fig. 24 shows that the ethylene selectivity and \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) remained nearly 100% during a total of 150 h in 3 cycles. And the decayed conversion of ethane and CO2 can be totally regenerated by oxidative treatment in air at 500 °C. This excellent durability and regeneration ability demonstrates the structural stability of Znδ+-O-Cr6+ site.

Electronic structure of binuclear Znδ+-O-Cr6+ sites during the reaction

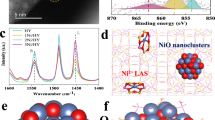

In situ ambient pressure X-ray photoelectron spectroscopy (APXPS) was employed to examine the electronic structure of binuclear Znδ+-O-Cr6+ sites and study the atomic synergies between Znδ+ and Cr6+ sites in ICEC. Figure 3a–c shows ambient pressure spectra indicating C 1s binding energies, Zn LMM Auger kinetic energies, and Cr 2p3/2 binding energies.

In situ ambient pressure X-ray photoelectron spectroscopy (APXPS): a C 1s spectra, b Auger spectra of Zn LMM, and c Cr 2p3/2 spectra as a function of reaction conditions for Zn3Cr1/SSZ-13. T = 550 °C: ultra-high vacuum (UHV), C2H6 (50 mTorr) + CO2 (50 mTorr), C2H6 (100 mTorr), and CO2 (100 mTorr) in sequence. d Electron transfer from Zn to H after the 2nd C-H bond scission in ethane (H: white; Zn: gray), where electron accumulation and depletion are represented by yellow (Δρ = +1 × 10−3 e bohr−3) and cyan (Δρ = −1 × 10−3 e bohr−3) respectively. e The oxidation of Cr in Zn-O-Cr when decomposing COOH* intermediate.

Step 1: Zn3Cr1/SSZ-13 was first tested under 550 °C in an ultra-high vacuum (UHV). The temperature of 550 °C was used to match the reaction temperature in Fig. 2. In Auger spectra of Zn LMM (Fig. 3b), both Zn2+ (dark blue) and Znδ+ (green) species were detected with a percentage distribution of 72.4% and 27.6%, respectively. In Fig. 3c, Cr3+ (dark red) and Cr6+ (light blue) were detected with a proportion of 50.6% and 49.4%, respectively.

Step 2: Then the Zn3Cr1/SSZ-13 was subjected to simulated reaction conditions of ICEC by co-feeding 50 mTorr C2H6 and 50 mTorr CO2 under 550 °C. The signals of gaseous C2H6 and CO2 were detected in Fig. 3a. Notably, adsorbed CO species (COads) at 285.5 eV were observed57,58, which indicates the ICEC reaction occurred. Under the reaction conditions, the proportion of Znδ+ decreased (from 27.6% to 22.8%) and Cr6+ ratio increased (from 49.4% to 54.4%). DFT calculations (Fig. 3d) indicate that the oxidation from Znδ+ to Zn2+ is due to the formation of Zn-Hδ- hydride during the ethane dehydrogenation, with more negative charge accumulated on Hδ-. The oxidation of Cr3+ to Cr6+ may result from lattice oxygen replenishment via CO2 dissociation20. These results indicate both Znδ+ and Cr6+ were involved in the ICEC reaction.

Steps 3 and 4 were designed to understand the role of individual Znδ+ or Cr6+ in ICEC. When feeding 100 mTorr C2H6 (without CO2) in step 3 (Fig. 3a, b), the signals of CO2 and COads species disappeared, which indicates that only ethane dehydrogenation could occur. The proportions of Zn2+ and Znδ+ remain similar to the case of co-feeding C2H6 and CO2 in step 2, indicating the formation of Zn-Hδ- hydride during the ethane dehydrogenation. Notice that the proportions of Znδ+ and Zn2+ are comparable between step 1 (UHV) and step 4 (feeding 100 mTorr CO2 without ethane), ruling out the likelihood of oxidation of Znδ+ to Zn2+ by CO2 or its derived intermediates.

In the case of Cr 2p3/2 XPS spectra (Fig. 3c), the oxidation of Cr3+ to Cr6+ only occurs when CO2 was fed (steps 2 and 4). Previous studies have demonstrated the oxidation of Cr3+ to Cr6+ in Cr-based catalysts suffers from sluggish O abstraction from CO220,59. In our cases, the facile reoxidation of Cr3+ to Cr6+ may be due to the possibility that nearby \({{{{{\rm{Zn}}}}}}^{\delta+}\) facilitate the CO2 activation to enable easier O abstraction. The COads species at 285.5 eV were detected in the presence/co-presence of CO2 in the C 1 s spectra (Fig. 3a, steps 2 and 4), which further demonstrates facile CO2 dissociation over the Znδ+-O-Cr6+ site. Our DFT calculation (Fig. 3e) indicates that the intermediate of CO2 activation is carboxyl (COOH*). The decomposition of COOH* requires the participation of the Cr site through the formation of a new Cr-O bond (d(Cr-O) = 2.08 Å), which will maintain its high oxidation state. In summary, the APXPS results show that binuclear Znδ+-O-Cr6+ sites serve as atomically synergistic sites for ICEC.

Atomically synergistic mechanism

We developed atomically synergistic mechanisms for ICEC on binuclear Zn-O-Cr sites (Fig. 4 and Supplementary Fig. 30-35, Supplementary Tables 8-10). Figure 4a shows that the catalytic cycle is initiated by C2H6 adsorption on Zn ([1] [2]), then heterolytic cleavage of the first C-H bond (0.93 eV) by breaking a Zn-O-Cr bond to form Zn-CH2-CH3 and Cr-OH ([2] [3]), followed by a homolytic scission of the β-C-H bond (2.11 eV) ([3] [4]), and finally, C2H4 desorption and Zn-Hδ- hydride formation ([4] [5]). C2H6 activation at the Cr of Zn-O-Cr sites has higher energy barriers for the first C-H cleavage (1.78 eV vs 0.93 eV) and β-C-H bond dissociation (>3.0 eV vs 2.11 eV), leading to a kinetically unfavorable pathway (Supplementary Figs. 31 and 32). In the second stage (Fig. 4a), CO2 prefers to adsorb at Zn-Hδ- site (−0.35 eV) than the Cr site (−0.05 eV) through acid-base interaction (Supplementary Fig. 33) ([5][6])60,61; CO2 adsorption energy (−0.35 eV) at Zn-Hδ- site is lower than ethane adsorption (−0.17 eV), which will help prevent the C2H6 cracking reaction (Supplementary Table 5). Then Zn-Hδ- enables CO2 hydrogenation ([6][7]) to carboxyl (COOH*), followed by CO-OH cleavage and migration of -OH to be shared with Cr ([7][8]). Finally, after CO desorption from the Zn site and the formation and desorption of H2O from the Cr site to replenish lattice oxygen ([8][10]), the ICEC catalytic cycle is closed.

The simulated catalytic cycles of Zn/SSZ-13 and Cr/SSZ-13 are shown in Supplementary Figs. 34 and 35, and the calculated energy profiles of ICEC over Zn3Cr1/SSZ-13, Zn/SSZ-13, and Cr/SSZ-13 are presented in Fig. 4b. The rate-determining step of ICEC is the homolytic cleavage of the β-C-H bond in ethane activation [TS2] (Fig. 4b, Supplementary Table 9). Zn3Cr1/SSZ-13 exhibited a lower activation barrier (2.11 eV) than Zn/SSZ-13 (2.37 eV) and Cr/SSZ-13 (2.23 eV). Moreover, Zn3Cr1/SSZ-13 also displayed a much lower energy barrier (1.12 eV, 0.73 eV) for CO2 activation [TS3] and H2O formation [TS5] than Zn/SSZ-13 (1.53 eV, 0.94 eV). This explained the much higher CO2 conversion and utilization of Zn3Cr1/SSZ-13 catalyst than Zn/SSZ-13 catalyst (Fig. 2b). We also found that Zn3Cr1/SSZ-13 exhibited the most favorable energetics of reactants adsorption and products desorption which also helps accelerate catalytic reactions (Supplementary Table 10). Therefore, the kinetically and thermodynamically favorable elementary steps in the ICEC catalytic cycle result in the highest catalytic performance of Zn3Cr1/SSZ-13. Its superior performance in ICEC is due to the atomic synergies between the acidic Zn site and the redox Cr site of ABC.

Discussion

In this study, we demonstrated the advantages of an atomically-synergistic binuclear-site catalyst (ABC) synthesized by colocalizing Zn and Cr sites on a zeolite SSZ-13 support (ZnCr/SSZ-13) for the iso-stoichiometric co-conversion of ethane and CO2 (ICEC) reaction. This ZnCr ABC catalyst exhibited exceptional catalytic performance, with 100% ethylene selectivity and 99.0% \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) under optimized conditions. The combined results of XAS, AP-XPS, and DFT studies show that the electronic properties and catalytic activity of ZnCr/SSZ-13 can be precisely assigned to unique atomic synergies between neighboring Zn and Cr atoms resulting from colocalization. The redox Cr site facilitates the formation of Znδ+, which is the active site for easier adsorption and activation of both ethane and CO2. Furthermore, the Cr site accelerates CO2 dissociation, due to its redox properties, and facilitates the formation and desorption of H2O. This combination thus results in rate matching between ethane dehydrogenation and CO2 hydrogenation. Our study highlights the importance of atomic synergy, providing guidance for developing novel catalysts with potential economic and ecological benefits in CO2 conversion and olefin production.

Methods

Materials synthesis. ZnxCry/SSZ-13 (x = 1, y = 0; x/y = 1/2, 1, 2, 3, and 4; x = 0, y = 1) catalysts were prepared by the dry-deposition method62. The total amount of Zn and Cr in all catalysts was set at 0.8 mmol per 1 g of support materials. In a typical synthesis, the SSZ-13 zeolite support was pretreated in a vacuum at 120 °C for 3 h to remove moisture. The stoichiometric amount of Zinc (II) acetate and/or chromium (III) acetate hydroxide (Zn + Cr = 0.8 mmol) was thoroughly mixed with 1 g of SSZ-13 zeolites using an analog vortex mixer. The resulting solid mixtures were sufficiently ground in glove box for 20 min. Subsequently, the samples are heated in flowing N2 (100 mL/min) at 550 °C for 3 h at a ramping rate of 2 °C/min and subsequently in flowing air (100 mL/min) for another 3 h. Both N2 and air were purified by moisture trap (Restek). Afterward, the resulting materials were pretreated through Na+-neutralization. Typically, the sample was firstly dispersed in deionized water and then dropwise addition of sodium bicarbonate solution (0.01 M, pH = 8) was performed until the solution reached a pH of 7. The slurry was then collected and dried at 110 °C overnight. The samples were finally calcined in static air at 500 °C for 2 h with a ramping rate of 2 °C/min. The final products were stored in an N2 box. The control samples of ZnxCr/SSZ-13 (x = 1/2, 1, and 3) were synthesized using the traditional co-precipitation (CP) method according to the reported recipe41, followed by Na+ neutralization.

Materials characterization. Nitrogen physisorption was performed on the Quantachrome Autosorb iQ2 instrument at 77 K to obtain textural information. The surface area (SBET) was determined from the N2 isotherms using the Brunauer-Emmett-Teller (BET) method. X-ray fluorescence (XRF) measurements were performed with a EDAX Orbis Micro-XRF Spectrometer. The attenuated total reflection Fourier transform infrared (ATR-FTIR) measurements were conducted by a Thermo Nicolet iS50 FTIR spectrometer with a diamond crystal ATR module. Powder X-ray diffraction (XRD) analysis was performed on a Rigaku MiniFlex 6 G X-Ray Diffractometer (Cu Kα radiation with wavelength of 1.5406 Å). The transmission electron microscopy (TEM) experiments were performed on a FEI ThemIS aberration-corrected TEM at the National Center for Electron Microscopy (NCEM) of the Molecular Foundry (MF), Lawrence Berkeley National Laboratory (LBNL). The microscope was operated at 300 keV with a Super-X energy dispersive X-ray spectroscopy (EDS) detector, allowing for rapid chemical identification. X-ray photoelectron spectroscopy (XPS) measurement was conducted at a K-Alpha Plus XPS spectrometer (Thermo Scientific), which consists of a monochromatic Al X-ray source (Al Kα = 1,486.68 eV) with variable spot size ranging from 30 microns to 400 microns. Powder samples were placed on a double-sided silver tape and the spectra were acquired using the flood-gun source to account for surface charging. All the spectra were analyzed using the CasaXPS software package.

Zn L3-edge soft X-ray absorption spectroscopy (sXAS) measurement was performed at Beamline 7.3.1 of the Advanced Light Source (ALS) at Lawrence Berkeley National Laboratory (LBNL). sXAS measurement was collected at room temperature through total electron yield (TEY) mode with a probe depth of no more than 10 nm. All the TEY spectra were normalized to the beam flux.

The measurements of Zn K-edge and Cr K-edge XAS spectra including X-ray absorption near edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) were performed at TPS 44 A beamline in National Synchrotron Radiation Research Center (NSRRC) in Taiwan. The data were collected in fluorescence mode by using 7-element silicon drift detector and the Zn and Cr metal foil were used as references for the energy calibration. The data were processed according to standard procedures using Demeter program package.

Ambient-pressure XPS (AP-XPS) analysis was conducted at Sandia National Laboratories (Livermore, CA) using a differentially-pumped Al Kα source (Specs model XR50) with a photon energy of 1486.6 keV. Emitted photo- (and Auger) electrons were detected using a near-ambient pressure hemispherical analyzer (Specs model Phoibos 150) mounted in a custom designed system capable of measuring XPS under sample gas pressures up to 10 Torr. We used baked steel gas lines and leak valves to introduce C2H6 (99.995% pure) and CO2 (99.999% pure) from Matheson Tri-Gas Inc. XPS/Auger peak locations, widths, and areas were obtained using a Shirley background subtraction and by fitting the data to mixed Gaussian-Lorentzian line shapes using CasaXPS software.

Performance Tests. The catalytic performance of iso-stoichiometric co-conversion of ethane and CO2 (ICEC) was conducted on a continuous fix-bed reactor in the temperature range of 400–550 °C and under ambient pressure, which is held inside an electric furnace with temperature controlled by a K-type thermocouple. In a typical catalytic measurement, a total of 200 mg catalyst diluted by 800 mg sand was loaded into the middle of the reactor plugged by quartz wool on two sides. Before the catalytic test, the catalyst bed was pretreated under a flow of Argon (25 sccm) at 550 °C for 1 h with a ramping rate of 10 °C from room temperature. Afterward, the reactant mixtures consisting of 5% CO2, and 5% C2H6 balanced with Argon were introduced with a total flow rate of 25 sccm. Argon is used as an internal standard. The reaction products were analyzed by online GC (Agilent 5890, ShinCarbon ST Packed Columns) equipped with thermal conductivity detector (TCD) and flame ionization detector (FID). To better reveal the reaction kinetics, apparent activation barriers were determined in the temperature range of 400–475 °C (The conversions of CO2 and C2H6 are less than 10%). The carbon and oxygen balances were within 100 ± 2% for all tests. The conversions of CO2 and C2H6, C2H4 selectivity, utilization of converted CO2 (\({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\)), C2H4 yield, the turnover frequency (TOF) of C2H4 formation, and the space time yield (STY) of C2H4 formation were calculated as follows (where n denotes molar flow of substance (mol/min), nZn+Cr means the total molar loading of Zn and/or Cr, \({{{{{\rm{M}}}}}}_{{{{{{\rm{C}}}}}}_{2}{{{{{\rm{H}}}}}}_{4}}\) is the molecular weight of C2H4 (28 g/mol) and mcat stands for catalyst mass (kg)):

It is noted that calculations of \({{{{{\rm{U}}}}}}_{{{{{{\rm{CO}}}}}}_{2}}\) were also calibrated and examined by the equation:

Computational Methods. All DFT calculations were performed using Vienna ab initio simulation package (VASP)63,64. The projector-augmented wave (PAW) method was used to represent the core-valence electron interaction65,66. The generalized gradient approximation (GGA) with the Perdew–Burke–Ernzerhof (PBE) exchange-correlation functional was used with D3 dispersion correction67,68. The cutoff energy for the planewave basis was 500 eV. To accurately treat the highly localized transition metal 3d orbitals, the spin-polarized DFT + U approach69,70 was employed: Ueff = 4.7 and 3.0 eV were applied to the Zn 3d and Cr 3d state, respectively71,72. Electronic energies were converged to within 10−4 eV and the atomic positions were relaxed until the force on each atom was less than 0.05 eV/Å. The climbing-image nudged elastic band (CI-NEB) method73 was used to search for the transition states. A hexagonal unit cell of the SSZ-13 molecular sieve74 was used as the support: a = b = 13.72 Å, c = 14.95 Å; composition: Na1Al1Si35O72. Only the Γ-point was used to sample the Brillouin zone. The unit cell contains two hexagonal prisms; two units of Zn2O2 and Cr2O3 were placed on the two prisms, to create the models of Zn/SSZ-13 and Cr/SSZ-13, respectively; one Zn2O2 unit was placed on one of the prisms and one ZnCrO2 unit on the other, to create the model of Zn3Cr1/SSZ-13 (see Supplementary Fig. 30).

Data availability

The data that supports the findings of this study are available from the corresponding authors upon request.

References

Wang, H. et al. Strong metal–support interactions on gold nanoparticle catalysts achieved through Le Chatelier’s principle. Nat. Catal. 4, 418–424 (2021).

Parastaev, A. et al. Boosting CO2 hydrogenation via size-dependent metal–support interactions in cobalt/ceria-based catalysts. Nat. Catal. 3, 526–533 (2020).

Van Deelen, T. W., Hernández Mejía, C. & De Jong, K. P. Control of metal-support interactions in heterogeneous catalysts to enhance activity and selectivity. Nat. Catal. 2, 955–970 (2019).

Chen, A. et al. Structure of the catalytically active copper–ceria interfacial perimeter. Nat. Catal. 2, 334–341 (2019).

Lunkenbein, T., Schumann, J., Behrens, M., Schlögl, R. & Willinger, M. G. Formation of a ZnO overlayer in industrial Cu/ZnO/Al2O3 catalysts induced by strong metal-support interactions. Angew.Chem. Int. Ed. 54, 4544–4548 (2015).

Pu, T., Zhang, W. & Zhu, M. Engineering heterogeneous catalysis with strong metal–support interactions: characterization, theory and manipulation. Angew. Chem. Int. Ed. 62, e202212278 (2023).

Li, Y., Zhang, Y., Qian, K. & Huang, W. Metal-support interactions in metal/oxide catalysts and oxide-metal interactions in oxide/metal inverse catalysts. ACS Catal. 12, 1268–1287 (2022).

Zhang, L., Zhou, M., Wang, A. & Zhang, T. Selective hydrogenation over supported metal catalysts: from nanoparticles to single atoms. Chem. Rev. 120, 683–733 (2020).

Shi, J. On the synergetic catalytic effect in heterogeneous nanocomposite catalysts. Chem. Rev. 113, 2139–2181 (2013).

Ro, I. et al. Bifunctional hydroformylation on heterogeneous Rh-WOx pair site catalysts. Nature 609, 287–292 (2022).

Gao, R. et al. Pt/Fe2O3 with Pt–Fe pair sites as a catalyst for oxygen reduction with ultralow Pt loading. Nat. Energy 6, 614–623 (2021).

Liu, C. et al. Catalytic activity enhancement on alcohol dehydrogenation via directing reaction pathways from single- to double-atom catalysis. J. Am. Chem. Soc. 144, 4913–4924 (2022).

Yang, J. et al. Modulating the strong metal-support interaction of single-atom catalysts via vicinal structure decoration. Nat. Commun. 13, 4244 (2022).

Li, W. H., Yang, J. & Wang, D. Long-range interactions in diatomic catalysts boosting electrocatalysis. Angew. Chem. Int. Ed. 61, e202213318 (2022).

Pan, Y., Zhang, C., Liu, Z., Chen, C. & Li, Y. Structural regulation with atomic-level precision: from single-atomic site to diatomic and atomic interface. Catal. Matter 2, 78–110 (2020).

Zeng, Z. et al. Orbital coupling of hetero-diatomic nickel-iron site for bifunctional electrocatalysis of CO2 reduction and oxygen evolution. Nat. Commun. 12, 4088 (2021).

Zheng, X. et al. Ru–Co pair sites catalyst boosts the energetics for the oxygen evolution reaction. Angew. Chem. Int. Ed. 61, e202205946 (2022).

Guan, E. et al. Supported metal pair-site catalysts. ACS Catal. 10, 9065–9085 (2020).

Mitchell, S. & Pérez-Ramírez, J. Atomically precise control in the design of low-nuclearity supported metal catalysts. Nat. Rev. Mater. 6, 969–985 (2021).

Gomez, E., Yan, B., Kattel, S. & Chen, J. G. Carbon dioxide reduction in tandem with light-alkane dehydrogenation. Nat. Rev. Chem. 3, 638–649 (2019).

Biswas, A. N., Xie, Z. & Chen, J. G. Can CO2-assisted alkane dehydrogenation lead to negative CO2 emissions? Joule 6, 269–273 (2022).

Myint, M. N. Z., Yan, B., Wan, J., Zhao, S. & Chen, J. G. Reforming and oxidative dehydrogenation of ethane with CO2 as a soft oxidant over bimetallic catalysts. J. Catal. 343, 168–177 (2016).

Xie, Z. et al. Reactions of CO2 and ethane enable CO bond insertion for production of C3 oxygenates. Nat. Commun. 11, 1887 (2020).

Chatani, Y., Takizawa, T., Murahashi, S., Sakata, Y. & Nishimura, Y. Crystal structure of polyketone (1: 1 Ethylene/Carbon Monoxide Copolymer). J. Polym. Sci. 55, 811–819 (1961).

Brubaker, M. M., Coffman, D. D. & Hoehn, H. H. Synthesis and characterization of ethylene/carbon monoxide copolymers, a new class of polyketones. J. Am. Chem. Soc. 74, 1509–1515 (1952).

Chen, S. et al. Cationic P,O‐coordinated Nickel(II) catalysts for carbonylative polymerization of ethylene: unexpected productivity via subtle electronic variation. Angew. Chem. Int. Ed. 61, e202204126 (2022).

Ortmann, P., Wimmer, F. P. & Mecking, S. Long-spaced polyketones from ADMET copolymerizations as ideal models for ethylene/CO copolymers. ACS Macro Lett. 4, 704–707 (2015).

Xie, Z., Wang, X., Chen, X., Liu, P. & Chen, J. G. General descriptors for CO2-assisted selective C-H/C-C bond scission in ethane. J. Am. Chem. Soc. 144, 4186–4195 (2022).

Kattel, S., Chen, J. G. & Liu, P. Mechanistic study of dry reforming of ethane by CO2 on a bimetallic PtNi(111) model surface. Catal. Sci. Technol. 8, 3748–3758 (2018).

Guo, H., Xie, Z., Wang, X., Chen, J. G. & Liu, P. Descriptor-based identification of bimetallic-derived catalysts for selective activation of ethane with CO2. EES Catal. 1, 17–25 (2023).

Li, G., Liu, C., Cui, X., Yang, Y. & Shi, F. Oxidative dehydrogenation of light alkanes with carbon dioxide. Green Chem. 23, 689–707 (2021).

Najari, S. et al. Oxidative dehydrogenation of ethane: catalytic and mechanistic aspects and future trends. Chem. Soc. Rev. 50, 4564–4605 (2021).

Zhao, D. et al. Controlling reaction-induced loss of active sites in ZnOx/Silicalite-1 for durable nonoxidative propane dehydrogenation. ACS Catal. 12, 4608–4617 (2022).

Schweitzer, N. M. et al. Propylene hydrogenation and propane dehydrogenation by a single-site Zn2+ on silica catalyst. ACS Catal. 4, 1091–1098 (2014).

Zhao, D. et al. In situ formation of ZnOx species for efficient propane dehydrogenation. Nature 599, 234–238 (2021).

Liu, X. et al. In situ spectroscopic characterization and theoretical calculations identify partially reduced ZnO1-x/Cu interfaces for methanol synthesis from CO2. Angew. Chem. Int. Ed. 134, e202202330 (2022).

Consonni, M., Jokic, D., Murzin, D. Y. & Touroude, R. High performances of Pt/ZnO catalysts in selective hydrogenation of crotonaldehyde. J. Catal. 188, 165–175 (1999).

Hsu, J. Y. et al. Probing local structural changes by sharp luminescent infrared nanophosphor for application in light-emitting diodes. Chem. Mater. 34, 11093–11100 (2022).

Liu, B. M. et al. A High-efficiency blue-LED-excitable NIR-II-emitting MgO:Cr3+,Ni2+ phosphor for future broadband light source toward multifunctional NIR spectroscopy applications. Chem. Eng. J. 452, 139313 (2023).

Jiao, F. et al. Selective conversion of syngas to light olefins. Science. 351, 1065–1068 (2016).

Yang, F. et al. One-step alkylation of benzene with Syngas over non-noble catalysts mixed with modified HZSM-5. Ind. Eng. Chem. Res. 58, 13879–13888 (2019).

Song, H. et al. Spinel-structured ZnCr2O4 with excess Zn is the active ZnO/Cr2O3 catalyst for high-temperature methanol synthesis. ACS Catal. 7, 7610–7622 (2017).

Li, S. et al. Low-valence Znδ+ (0<δ<2) single-atom material as highly efficient electrocatalyst for CO2 reduction. Angew. Chem. Int. Ed. 60, 22826–22832 (2021).

Li, X. et al. Improved catalytic performance of ethane dehydrogenation in the presence of CO2 over Zr-promoted Cr/SiO2. ACS Omega 4, 22562–22573 (2019).

Dadlani, A. et al. Revealing the bonding environment of Zn in ALD Zn(O,S) buffer layers through X-ray absorption spectroscopy. ACS Appl. Mater. Interfaces 9, 39105–39109 (2017).

Qiao, L. et al. The impact of crystal symmetry on the electronic structure and functional properties of complex lanthanum chromium oxides. J. Mater. Chem. C 1, 4527–4535 (2013).

Ramirez, A. et al. Multifunctional catalyst combination for the direct conversion of CO2 to propane. JACS Au 1, 1719–1732 (2021).

Pinilla-Herrero, I. et al. High Zn/Al ratios enhance dehydrogenation vs hydrogen transfer reactions of Zn-ZSM-5 catalytic systems in methanol conversion to aromatics. J. Catal. 362, 146–163 (2018).

Thirumala Bai, P. et al. Oxidative dehydrogenation of ethane with carbon dioxide over Cr2O3/SBA-15 catalysts: the influence of sulfate modification of the support. Appl. Petrochem. Res. 7, 107–118 (2017).

Talati, A., Haghighi, M. & Rahmani, F. Oxidative dehydrogenation of ethane to ethylene by carbon dioxide over Cr/TiO2–ZrO2 nanocatalyst: effect of active phase and support composition on catalytic properties and performance. Adv. Powder Technol. 27, 1195–1206 (2016).

Shen, Z. et al. Dehydrogenation of ethane to ethylene over a highly efficient Ga2O3/HZSM-5 catalyst in the presence of CO2. Appl. Catal. A Gene. 356, 148–153 (2009).

Bugrova, T. A. et al. Oxidative dehydrogenation of ethane with CO2 over CrOx catalysts supported on Al2O3, ZrO2, CeO2 and CexZr1-xO2. Catal. Today 333, 71–80 (2019).

Koirala, R., Buechel, R., Krumeich, F., Pratsinis, S. E. & Baiker, A. Oxidative dehydrogenation of ethane with CO2 over flame-made Ga-loaded TiO2. ACS Catal. 5, 690–702 (2015).

Liu, J. et al. Influence of the zeolite surface properties and potassium modification on the Zn-catalyzed CO2-assisted oxidative dehydrogenation of ethane. Appl. Catal. B Environ. 304, 120947 (2022).

Liu, J. et al. Highly-dispersed zinc species on zeolites for the continuous and selective dehydrogenation of ethane with CO2 as a soft oxidant. ACS Catal. 11, 2819–2830 (2021).

Tu, C. et al. CO2-assisted ethane aromatization over zinc and phosphorous modified ZSM-5 catalysts. Appl. Catal. B Environ. 304, 120956 (2022).

Miller, A. V., Kaichev, V. V., Prosvirin, I. P. & Bukhtiyarov, V. I. Mechanistic study of methanol decomposition and oxidation on Pt(111). J. Phys. Chem. C 117, 8189–8197 (2013).

Wu, C. H., Eren, B., Bluhm, H. & Salmeron, M. B. Ambient-pressure X-ray photoelectron spectroscopy study of cobalt foil model catalyst under CO, H2, and their mixtures. ACS Catal. 7, 1150–1157 (2017).

Mimura, N., Takahara, I., Inaba, M., Okamoto, M. & Murata, K. High-performance Cr/H-ZSM-5 catalysts for oxidative dehydrogenation of ethane to ethylene with CO2 as an oxidant. Catal. Commun. 3, 257–262 (2002).

Álvarez, A. et al. CO2 activation over catalytic surfaces. ChemPhysChem 18, 3135–3141 (2017).

Zimmerman, P. M., Zhang, Z. & Musgrave, C. B. Simultaneous two-hydrogen transfer as a mechanism for efficient CO2 reduction. Inorg. Chem. 49, 8724–8728 (2010).

Peeters, E. et al. Highly dispersed Sn-beta zeolites as active catalysts for Baeyer-Villiger oxidation: the role of mobile, in situ Sn(II)O species in solid-state stannation. ACS Catal. 11, 5984–5998 (2021).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E., Jepsen, O. & Andersen, O. K. Improved tetrahedron method far Brilleuin-zane integrations. Phys. Rev. B 49, 16223–16233 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Anisimov, V. I., Aryasetiawan, F. & Lichtenstein, A. I. First-principles calculations of the electronic structure and spectra of strongly correlated systems: the LDA + U method. J. Phys. Condens. Matter 9, 767–808 (1997).

Anisimov, V. I., Zaanen, J. & Andersen, O. K. Band theory and Mott insulators: Hubbard U instead of Stoner I. Phys. Rev. B 44, 943–954 (1991).

Jin, J., Chen, J., Wang, H. & Hu, P. Insight into room-temperature catalytic oxidation of NO by CrO2(110): A DFT study. Chin. Chem. Lett. 30, 618–623 (2019).

Janotti, A. & Van De Walle, C. G. Native point defects in ZnO. Phys. Rev. B 76, 165202 (2007).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Zhang, R. et al. NO chemisorption on Cu/SSZ-13: a comparative study from infrared spectroscopy and DFT calculations. ACS Catal. 4, 4093–4105 (2014).

Acknowledgements

The research was supported financially by the Division of Chemical Sciences, Geosciences, and Biosciences, Office of Basic Energy Sciences, US Department of Energy (Award No. DE-SC0022273). Spectroscopic and microscopic experiments were performed at the BL7.3.1 at the Advanced Light Source (ALS) and Molecular Foundry at LBNL under contract no. DE-AC02-05CH11231. This research used resources of the National Energy Research Scientific Computing Center, a DOE Office of Science User Facility supported by the Office of Science of the U.S. Department of Energy under contract no. DE-AC02-05CH11231. J.W. and H.Z. acknowledge the support of the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences (BES), Materials Sciences and Engineering Division under Contract No. DE-AC02-05-CH11231 within the in-situ TEM program (KC22ZH). J.L.C. acknowledges the support of the Ministry of Science and Technology, Taiwan (110-2112-M-213-006). Work at Sandia National Laboratories supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences (BES) under Field Work Proposal Number 23-024168. Sandia National Laboratories is a multimission laboratory managed and operated by the National Technology & Engineering Solutions of Sandia, LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA0003525. This paper describes objective technical results and analysis. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of the U.S. Department of Energy or the U.S. Government. D.L. acknowledges the Kwanjeong Study Abroad Scholarship from the KEF (Kwanjeong Educational Foundation) (KEF-2019).

Author information

Authors and Affiliations

Contributions

J.S. and S.S. designed the experiments and D.-E.J. designed the DFT calculations. J.Y. synthesized the catalysts and evaluated the catalytic performance, and analyzed the data. L.W. did the DFT calculations. J.W. performed TEM experiments for sample screening, and analyzed the data. F.E.G. and A.F.C. did APXPS experiments and analyzed the data. B.E.M. performed XRF measurements. J.L.C. and L.C.H. performed the XAFS measurements and analyzed the data. D.L. did XRD measurements. X.Z. did XPS experiment. C.W. performed N2 physisorption measurements. Z.D. contributed to characterization analysis. F.R. and H.B. performed thermodynamic limit analysis. H.Z., M.S., G.A.S., H.L. and D.P. provides suggestions with project design. J.S., S.S., D.-E.J., J.Y., L.W., J.W. and F.E.G. wrote the manuscript, and all the authors contributed to the overall scientific interpretation and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Stavros Theofanidis, Nikolay Nesterenko and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, J., Wang, L., Wan, J. et al. Atomically synergistic Zn-Cr catalyst for iso-stoichiometric co-conversion of ethane and CO2 to ethylene and CO. Nat Commun 15, 911 (2024). https://doi.org/10.1038/s41467-024-44918-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-44918-8

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.