Abstract

A (001)-epitaxial-BiFeO3/CoFe2O4 bilayer was grown by self-assembly on SrTiO3 (100) substrates by just coating a mixture precursor solution. The thickness ratio of the bilayer could be controlled by adjusting the composition ratio. For example, a BiFeOx:CoFe2Ox = 4:1 (namely Bi4CoFe6Ox) mixture solution could make a total thickness of 110nm divided into 85-nm-thick BiFeO3 and 25-nm-thick CoFe2O4. Self-assembly of the bilayer occurred because the perovskite BiFeO3 better matched the lattice constant (misfit approximately 1%) and crystal symmetry of the perovskite SrTiO3 than the spinel CoFe2O4 (misfit approximately 7%). The magnetic domains of the hard magnet CoFe2O4 were switched by the polarization change of BiFeO3 due to an applied vertical voltage and the switched magnetic domain size was approximately 100nm in diameter. These results suggest that self-assembled BiFeO3/CoFe2O4 bilayers are interesting in voltage driven nonvolatile memory with a low manufacturing cost.

Similar content being viewed by others

Non-volatile memories such as hard-disk drives (HDDs) and spin-transfer-torque magnetic random access memory (spin-MRAM) have been significantly developed over the last decade. The recording density of HDDs is the highest of the non-volatile memories used for commercial products. In general, the operation for writing these memories is carried out by applying an electrical current. From the viewpoint of electrical power consumption, the writing operation should essentially be performed by an electric field. Recently, the magnetic state of an ultrathin film was modulated by applying an electric field1, which can be used for the writing process by applying a voltage. Moreover, this modulation phenomenon is advantageous in terms of the device-fabrication process because it can use the process of magnetic tunnel junctions (MTJs)2. The manipulation of magnetic properties required a large voltage and the thermal stability of the magnetic layer might be small because the layer is ultrathin. Therefore, these two issues need to be resolved before practical application becomes possible. Another approach is to utilize multiferroic materials as one way to generate the voltage required for the writing process. Spin-frustration type multiferroics such as RMnO3 (where R = Tb, Dy, etc.) and CuFeO2 have ferroelectric and magnetic-order parameters3,4,5. These multiferroics exhibit breaking of space inversion symmetry by magnetic ordering and this broken symmetry induces ferroelectricity, which implies strong magneto-electric (ME) coupling. However, most multiferroics show transition temperatures lower than room temperature (RT). BiFeO3 is a one of the very few multiferroic materials that has a ferroelectric Curie temperature of 850C and an antiferromagnetic Nel temperature of 370C. The ME effect between antiferromagnetism and spontaneous polarization owing to the Dzyaloshinskii-Moriya (DM) interaction by an asymmetric crystal structure has also been observed at RT. In the case of a BiFeO3/ferromagnetic bilayer, magnetization switching was clearly observed at RT through an antiferromagnetic coupling6 by reversal of polarization7. In this report, an electric field was applied to BiFeO3 in the horizontal direction; therefore, a large voltage had to be applied to reverse the polarization. A voltage applied in the vertical direction can be reduced compared with one applied in the horizontal direction. When BiFeO3 is used as a tunnel barrier in MTJs, the writing operation performed by an electric field is carried out in the vertical direction. However, magnetization switching by polarization reversal using a bilayer structure under applied vertical voltage has been investigated in a few works8.

As for the process for fabricating solid-state memory devices, most are fabricated using an ultra-high-vacuum process; therefore, expensive fabrication equipment is necessary. If these devices could be fabricated using a wet chemical process, the low cost of investment in facilities at the start of research would be an advantage. In addition, using spray coating or chemical solution deposition (CSD) would lower the fabrication cost per unit. In a previous report, when a Bi-rich BiFeO3 target was used, BiFeO3 was epitaxially grown on the SrTiO3 (001) substrate and excess Bi was grown on the BiFeO3 as Bi2O39. Due to the large lattice mismatch between Bi2O3 and SrTiO3 compared with that of BiFeO3 and SrTiO3, Bi2O3 formed at the surface of the film. This result suggested that by adjusting the lattice misfit between a SrTiO3 substrate and a ferromagnet or BiFeO3, a BiFeO3/ferromagnet bilayer can be prepared even by a one-time-only liquid phase process. CoFe2O4 is a candidate material for a ferromagnetic layer because the lattice mismatch between CoFe2O4 and SrTiO3 is 7.3%, which is much larger than that between BiFeO3 and SrTiO3 (1.4%). These material combinations are expected to enable fabrication of a BiFeO3/CoFe2O4 bilayer on a SrTiO3 substrate by utilizing the differences in lattice mismatch. Whether the magnetization can be reversed by the ME effect of BiFeO3 when using materials with high-magnetic-anisotropy has yet to be verified in the case of a bilayer system. Without that verification, it is not possible to apply BiFeO3 to high-density memories. From the viewpoint of the magnetocrystalline anisotropy energy (Ku), CoFe2O4 is one of the candidate hard magnetic materials (K1 of approximately 3 106erg/cm3 in bulk). Self-assembled CoFe2O4-BiFeO3 (or BaTiO3) epitaxially grown on SrTiO3 substrates using pulsed laser deposition (PLD) has been reported10,11,12,13,14,15,16. In many of these reports, the CoFe2O4 nanopillars were embedded in the BiFeO3 matrix; namely, it is a nano-composite structured film. The CoFe2O4 nanopillars were complexly influenced by the exchange bias from the BiFeO3 matrix; moreover, they might be influenced by a strain effect13 from the BiFeO3 because a nanopillar has a degree of freedom to move in the vertical direction of the film. In the case of a bilayer structure, the ME effect becomes simpler than that in the case of a nanopillar structure. However, polarization reversal using a BiFeO3/CoFe2O4 bilayer has not been phenomenologically investigated much in terms of magnetization switching. In the meantime, the minimum magnetic domain size in the case of a layered structure is not clear. It can be considered that the growth of the PLD process is not strongly influenced by the differences between the lattice misfits of CoFe2O4 and SrTiO3 substrates because, for example, PLD can prepare a non-equilibrium phase. A wet chemical process of thermal equilibration (such as CSD) is expected to more effectively expose the influence of lattice misfit of materials.

In this study, we demonstrated a novel chemical solution method; namely, introducing lattice misfit in relation to a single crystal SrTiO3 substrate using a BiFeO3/CoFe2O4 bilayer film, is proposed. The BiFeO3/CoFe2O4 bilayer was microfabricated as a vertical device structure to reduce the operation voltage based on the ME effect and it was experimentally verified that CoFe2O4 magnetic domains (of 100-nm-diameter scale) with relatively high magnetocrystalline anisotropy could be switched.

Enhanced metalorganic decomposition (EMOD) solutions (Kojundo Chemical Laboratory Co., Ltd.) were used in this study. Two metal-diethylhexanoate compositions were used as the starting precursor solutions. As for the first, the ratio of Bi3+ and Fe3+ precursors was even in terms of atomic percent (PBFO) (i.e., a typical condition for preparing BiFeO3 films). For the second, the ratio of Co2+ and Fe3+ precursors was 1:2 in terms of atomic percent (PCFO) (i.e., a typical condition for preparing CoFe2O4 films). Each precursor solution was mixed to form an atomic percent ratio (PBFO:PCFO) of 4:1. The mixed precursor solution ratio (%), i.e., Bi3+:Fe3+:Co2+, was 36:55:9. The solution was spin-coated at 6000rpm for 50sec on a 5-at.% La-doped SrTiO3 (La-SrTiO3) (001) conductive single crystal substrate. The spin-coated films were dried at 150C for 1min and calcined at 350C for 5min using hot plates in air. This process was repeated six times. Sintering for crystallization was carried out at 650C for 10min in air using an infrared lamp heating system. Circular Pt top electrodes (with a diameter of 100m and a thickness of 60nm) were deposited on the film surface by DC magnetron sputtering. The crystal structures of the films were evaluated by X-ray diffraction (XRD; Philips, Xpert-Pro MRD). The cross sections of the films were observed by transmission electron microscopy (TEM; Hitachi HF-2000, FEI Company Tecnai G2 F20). The ferroelectric properties of the films were evaluated at 90K using a ferroelectric tester (TOYO Corporation, FCE-1A). The temperatures of the films were measured using a thermocouple contacted with silver paste. The ferroelectric domains were observed by piezoelectric force microscopy (PFM; Asylum Technology Cypher). Various poling methods were carried out before ferroelectric measurement. The magnetic hysteresis loops were measured using a superconducting quantum interference device (SQUID; Quantum Design MPMS). The magnetic domains were observed by magnetic force-microscopy (MFM; Bruker AXS Digital instruments, NanoScope IVa, Dimension 3100 stage AFM system).

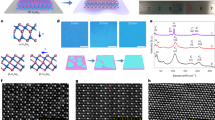

The cross-sectional TEM observations of the film on the La-SrTiO3 (100) substrate are shown in Figs. 1(a) to 1(g). A bright-field TEM image is shown in Fig. 1(a). A slight bumpy contrast between the film surface (bright) and film body (dark) was obvious. The nanobeam electron diffraction patterns of the regions indicated by circles (i) to (iv) in Fig. 1(a) are shown in Figs. 1(b)1(e), respectively. At the surface area, randomly oriented CoFe2O4 diffraction spots were observed in Fig. 1(b). BiFeO3 diffraction spots were observed in Fig. 1(d) and these diffraction spots corresponded to those of the La-SrTiO3 (100) substrates Fig. 1(e). This correspondence indicated that BiFeO3 was epitaxially grown on the La-SrTiO3 substrates in a cube-on-cube crystal relationship (under the assumption of a pseudo-cubic-perovskite structure in BiFeO3). Both epitaxial BiFeO3 and randomly oriented CoFe2O4 diffraction spots coexisted at the interface Fig. 1(c). The high-resolution TEM image in Fig. 1(f) revealed that the interface between CoFe2O4 and BiFeO3 was clear and no intermixing interfacial layer of these two materials occurred. It should be noted that although a mixture precursor solution was used and the film was deposited only once, the film was separated into two layers, namely, an epitaxial BiFeO3 layer and a polycrystalline CoFe2O4 layer. The lattice misfit between BiFeO3 and the SrTiO3 substrate (1.4%) is smaller than that between CoFe2O4 and the SrTiO3 substrate (7.3%). It is therefore considered that the small lattice misfit of BiFeO3 was the reason for its precedential growth in regard to CoFe2O4, which meant that bilayer samples can be produced by utilizing the lattice mismatch with respect to the substrate materials. We believe that bilayer films formed instead of nanopillar composite films9,10,14 because crystal growth by CSD is in a thermal equilibrium state in comparison with that by PLD; as a result, the influence of the differences between lattice misfits of the substrates and epitaxial films was strong in the case of CSD. The total film thickness was estimated to be 110nm and the thicknesses of the BiFeO3 and CoFe2O4 layers were estimated to be 85nm (tBFO) and 25nm (tCFO), respectively. It is noteworthy that the thickness ratio (tBFO:tCFO = 3.4:1.0) approximately corresponded to the precursor-solution ratio under the assumption that the ratio of BiFeO3 and CoFe2O4 was given as PBFO:PCFO = 4.0:1.0. This result indicated that the thickness ratio of BiFeO3 and CoFe2O4 can be controlled by adjusting the composition ratio of PBFO and PCFO. The - 2 X-ray diffraction (XRD) pattern is shown in Fig. 1(h) and grazing incident XRD (GI-XRD) patterns are shown in Figs. 1(i) and 1(j). The incident angle was fixed at 1.5 for the GI-XRD measurements. The diffractions by the (311) and (440) planes related to CoFe2O4 and indicated random orientation of the CoFe2O4 layer, which was consistent with the TEM analyses. Figs. 1(b) and 1(c) The positions of the (311) and (440) diffraction patterns corresponded to the bulk CoFe2O4 diffraction angles, indicating that CoFe2O4 in the BiFeO3/CoFe2O4 bilayer film was not strained in the as-grown state. BiFeO3 showed an ME effect based on the switching of three different polarizations due to its rhombohedral distorted BiFeO37,8. In the case of tetragonal symmetry, only polarization of the (001) plane switched and symmetry of the antiferromagnetic plane does not change; therefore, the ME effect does not occur. The crystal symmetry of BiFeO3 is strongly influenced by the type of substrate and the conditions of the sputtering; therefore, determine the crystal symmetry in film form is a key factor in using the ME effect. X-ray reciprocal space maps (RSMs) around the 004 and 204 spots are shown in Figs. 1(k) and 1(l), respectively. When BiFeO3 has a tetragonal symmetry, only one spot is observed in the 204 RSM regions,and two spots are observed along the Qz axis if BiFeO3 has a rhombohedral symmetry. The split of diffraction spots related to the rhombohedral symmetry were clearly observed; thus, the BiFeO3 layer had a rhombohedral crystal symmetry with a space group of R3c. The lattice parameters of BiFeO3 (estimated from the RSMs) were a = 0.396nm and = 89.5, which corresponded to those of bulk BiFeO317.

(a) Cross-sectional TEM image of a wide area of the sample, (b)(e) electron-diffraction patterns taken from circles (i)(iv) and cross-sectional high-resolution TEM images taken at the (f) BiFeO3/La-SrTiO3 and (g) CoFe2O4/BiFeO3 interfaces. (h) Out-of-plane /2 XRD pattern, GI-XRD patterns around (i) (311) and (j) (440) of the CoFe2O4 diffraction peaks and RSMs around the (d) 004 and (e) 204 spots of the (001)-epitaxial-BiFeO3/CoFe2O4 film.

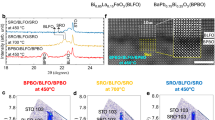

The polarization-electric field (P-E) hysteresis loops of the (001)-epitaxial-BiFeO3/CoFe2O4 bilayer film is shown in Figs. 2(a). TheP-E loop with a rounded shape measured at 2kHz became sharp as frequency increased above 5kHz. The leakage current was linear as a function of time; however, ferroelectric switching occurred within a few tens of nanoseconds. Sharp P-E loops were therefore obtained at high frequency due to the reduction of the leakage current. The polarization value of the BiFeO3/CoFe2O4 bilayer film estimated from the 20kHz loop was 91C/cm2. Toconfirm the polarization of the BiFeO3/CoFe2O4 bilayer film, the electrical displacement was measured by the positive-up-negative-down (PUND) method. Fig. 2(c) Schematic illustrations of the PUND responses for positive and up pulses are divided into four components: spontaneous polarization (SPC), initial increment (IC), paraelectric (PC) and leakage (LC) components. Fig. 2(d) For comparison of time scale, the wave forms of the applied voltage to the samples for the P-E (2kHz) and PUND are illustrated in Fig. 2(b). SPC and PC increased when the electric field applied and LC linearly increased. SPC remains; however, PC and LC disappear when the electric field was removed. SPC can be calculated by subtracting PC from IC. It is considered that the PUND method may express spontaneous polarization more accurately than with the P-E loops measured by a ferroelectric tester. The PUND measurement was discussed in detail elsewhere18. The spontaneous polarization evaluated by PUND was 84C/cm2, which is almost same as that evaluated by P-E loops. The spontaneous polarizations determined by the different ferroelectric measurement methods coincided; thus, it can be considered that the polarization of BiFeO3 in the BiFeO3/CoFe2O4 bilayer film was completely switched by the applied electric field. The magnetization v.s. magnetic field (M-H) curves of the BiFeO3 and BiFeO3/CoFe2O4 bilayer films are shown in Fig. 2(e). The inset shows the entire hysteresis loop. The saturated magnetization (Ms) and magnetic coercive field (Hc) were estimated to be 118emu/cm3 and 510Oe, respectively, which were consistent with previously reported values19 for polycrystalline BiFeO3-CoFe2O4 nano-composite films. The P-E and M-H hysteresis measurements showed that the electrical and magnetic properties of the BiFeO3/CoFe2O4 bilayer film originated in BiFeO3 and CoFe2O4, respectively.

(a) P-E hysteresis loops of the (001)-epitaxial-BiFeO3/CoFe2O4 bilayer film at 90K at various measurement frequencies, (b) illustration of wave-forms when applying voltage to the samples for ferroelectric measurement, (c) positive-up-negative-down (PUND) response of the BiFeO3/CoFe2O4 bilayer film at 90K and (d) schematic illustration of the PUND response for ferroelectric materials with coexisting paraelectric and leakage components. SPC = IC PC16. (e) M-H hysteresis loops of the (001) epitaxial BiFeO3 and the BiFeO3/CoFe2O4 bilayer film measured at 300K. The inset shows the entire hysteresis loop.

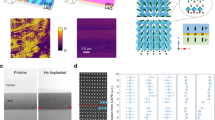

The ferroelectric switching characteristics of the local area and the influence of the surface potential on the magnetic stray field were evaluated by scanning probe microscopy (SPM). A PFM phase loop and amplitude loops taken by switching spectroscopy (SS) are shown in Fig. 3(a) and Fig. 3(b) for the BiFeO3/CoFe2O4 bilayer film. A SS-PFM phase loop and amplitude loop are shown in Fig. 3(e) and Fig. 3(f) and the PFM phase mapping image and amplitude mapping image are shown in Fig. 3(g) and Fig. 3(h) for a 90-nm-thick (001)-epitaxial-BiFeO3 film. The PFM information corresponded to the vertical response and the SS-PFM loops were the result of the second loop of two continuous measurements. The 90-nm-thick (001)-epitaxial-BiFeO3 film had ferroelectric domains varying in diameter between several dozen and one hundred nanometers. For example, a relatively small ferroelectric domain (diameter of 60nm) with respect to the vertical direction was measured by SS-PFM. Figs. 3(e) and 3(f) The switching electric fields estimated by the SS-PFM phase and amplitude loops were the same, namely, -0.6 and 0.4MV/cm, respectively, which produced negative shift of approximately 0.1MV/cm. The shift of the SS-PFM loops might be attributed to the charge injection at the one-side interface20 due to the low measurement frequency (0.3Hz) of the SS-PFM method. Fig. 3(i)21 The SS-PFM phase loops showed that the ferroelectric domain showed a small coercive electric field compared with that observed in the P-E hysteresis loops. In the case of the P-E measurement, the diameter of the Pt electrode was 100m which included the various types of ferroelectric domains. In contrast, the SS-PFM measurement selected the ferroelectric domains having active responses to the vertical direction, which might be the reason for small coercive electric field in SS-PFM to the vertical direction compared with those obtained from the P-E measurement. Before the ME effect was measured, images of the BiFeO3/CoFe2O4 bilayer film were taken using MFM and Kelvin force microscopy (KFM). Figs. 3(e) and 3(f) MFM is detected in the tapping mode of the phase shift of the resonance frequency of the cantilever due to attractive (or repulsive) forces between the magnetized cantilever and the magnetic moment at the film surface. AFM and KFM are also used in tapping mode to observe the surface morphology and surface electrical potential, respectively. To clarify the influence of the surface electrostatic potential and the surface morphology on the MFM measurement, first obtained the surface morphology image by AFM and then the cantilever distant from surface, KFM measurements were performed using an electrical feedback circuit. Finally, MFM measurements were carried out. The difference in the contrasts of the MFM image and the KFM image revealed that the surface electrostatic potential was not necessary taken into consideration for the ME effect measurement.

(a) and (b) SS-PFM phase and amplitude loops of the BiFeO3 (85nm)/CoFe2O4 (25nm) bilayer film. The surface potential and stray magnetic field were measured by (c) KFM and (d) MFM of the BiFeO3/CoFe2O4 bilayer film. MFM and KFM images of the same area were taken and the contrasts in the magnetic and surface electrostatic potentials were different. The SS-PFM (e) phase loop and (f) amplitude loop and their PFM mapping images (g) and (h) of a 90-nm-thick BiFeO3 epitaxial film. (i) Illustration of the voltage wave form v.s. time.

To reduce the switching voltage and understand the phenomenology of the ME effect in the vertical direction, a two-step electrode was designed. A thick top electrode is necessary to prevent penetration of an electrode by the detection needle used for measuring the ferroelectric polarization reversal, where a thin electrode is necessary for MFM to detect the stray-magnetic-field signal. To solve these two contradictory matters, the needles for detecting the ferroelectric polarization reversal were connected to 60-nm-thick electrodes and the MFM tips were connected to 5-nm-thick electrodes. A two-step Pt electrode was prepared by manually shifting the shadow mask slightly when the Pt electrode was sputtered for the first and second times. A schematic diagram of the setup for evaluating the ferroelectric and magnetic properties is shown in Fig. 4(a). The reversal of the ferroelectric domains in the 60-nm-thick electrode area was confirmed by investigating the relationship between the electrode size and the polarization reversal charge. For theME measurements, the polarization of BiFeO3 was switched in the upward direction by applying a voltage of 20V (1.8MV/cm) and then the magnetization reversal was observed by MFM. As described in Fig. 2(a), 20V (1.8MV/cm) could reverse the ferroelectric polarization. To confirm the polarization reversibility, the polarization of BiFeO3 was switched in the downward direction and the magnetization reversal in the same area was again observed by MFM. The switched polarization in BiFeO3 was stable for several weeks at RT in air. MFM observation was carried out in taping mode with a CoCr coated cantilever and the magnetization direction (magnetic north) of the cantilever was upward to the film plane. The space resolution deduced from the digital data points (256 points/1.0m) is 4nm. In fact, the space resolution of MFM observation depends on the distance between the cantilever and the film surface; therefore, the actual space resolution was a few tens of nanometers. In order to reduce the influence of the atomic force in tapping mode, the distance of the cantilever was slightly increased during MFM observation compared with AFM observation. The gap between the cantilever and the film surface was kept at approximately 20nm during the MFM observation; that is, the actual distance between the CoFe2O4 and the cantilever was approximately 25nm. The observed area was 2.0 by 2.0m. MFM images of CoFe2O4 with upward and downward polarizations of BiFeO3 are shown in Figs. 4(b) and 4(c), respectively and the subtracted upward- and downward-MFM images are shown in Fig. 4(d), which showed many dot-like contrast changes. Here, the influence of piezoelectric strain due to the polarization reversal in BiFeO3 domains on magnetization in CoFe2O4 was explained as follows. Piezoelectric intrinsically cannot conserve their strain without an electric field; therefore, a large piezoelectric constant is necessary for the polarization reversal. The piezoelectric constant (d33) estimated from the slope of the SS-PFM amplitude in the case of the BiFeO3 and CoFe2O4/BiFeO3 bilayer films was approximately 15pm/V and 10pm/V, respectively were smaller than the reported range of 50 to 100pm/V22. The piezoelectric strain under an applied electric field of 1.0MV/cm was less than 1%, which meant that the piezoelectric strain from the BiFeO3 layer could not reverse the magnetization of CoFe2O4. It may be noted that interface of the CoFe2O4 and BiFeO3 layers was slightly wavy, Fig. 1(a) which might make the strain influence on the ME effect enhanced at the interface edge. It can thus be considered that the magnetization switching of CoFe2O4 was basically derived from polarization switching of BiFeO3 and exchange coupling between antiferromagnetic BiFeO3 and ferromagnetic CoFe2O4; moreover, the strain effect at the edge of interfaces possibility enhanced theME effect. In Fig. 4(d), the polarization was partially reversed; however, the contrast did not change across the whole area because the BiFeO3 epitaxial film has three ferroelectric domains and only the 180 ferroelectric domains can not switch the magnetization by the ME effect. Therefore, the 71 and 109 ferroelectric domains might have respond to the ME effect23,24. Another possible reason is that even though the magnetization was switched by the 71 and 109 domains, the magnetization change of CoFe2O4 was not always in a state that was not directly detected as a change in the cantilever direction of MFM; Enlarged MFM images with typical upward and downward polarizations area, indicated as green squares (i) in Figs. 4(b) and 4(c), are shown in Figs. 4(e) and 4(f). The gradation of brown contrast differed in the cases of upward and downward polarization. Line profiles taken from the areas of the MFM images indicated as green squares (i), (ii) and (iii) are shown in Fig. 4(g). These line profiles showed that the magnetic domains were reversed by the electric field in three areas; in particular, the smaller magnetic domains indicated by areas (i) and (ii) were approximately 100nm in diameter. As mentioned above, the actual space resolution of MFM was a few tens of nanometers; therefore, a magnetization-switching signal from an area with diameter of approximately 100nm was within the measurement range. As for the size of a magnetic domain Fig. 4(d), the minimum size of a switched magnetic domain was around a few dozen nano meters in diameter. These reversed magnetic domain sizes were roughly consistent with ferroelectric domain size of BiFeO3. Figs. 3(a) and 3(c) The ferromagnetic and ferroelectric domains seemed to couple in a one-to-one relationship8. However, the MFM resolution is lower than that of the PFM contact measurement; accordingly, small magnetic domains are necessary for further investigation. In this study, the relatively large magnetocrystalline anisotropy of CoFe2O4 could be reversed by applying an electric field through exchange bias and this result indicated that materials with higher magnetocrystallinity (such as an L10-ordered alloy) can be expected to be applied to solid-state memories in the near future.

(a) Schematic diagram of evaluation of the ME effect; MFM images of a domain with CoFe2O4 for (b) upward and (c) downward polarizations. (d) The black-contrast area indicates a stray field changed by a polarization reversal. (e) and (f) Enlarged MFM images of the area marked by green squares (i) indicated in Figs. 4(b) and 4(c). (g) MFM line profiles taken from the upward and downward polarized areas (i), (ii) and (iii).

BiFeO3/CoFe2O4 bilayer films were formed on La-SrTiO3 (001) substrates by a one-time-only liquid phase process that involved spin coating of a mixed precursor solution. Cross-sectional TEM analysis confirmed that the BiFeO3 was epitaxially grown on the La-SrTiO3 substrates and that polycrystalline CoFe2O4 was grown on the BiFeO3 layer. The bilayer could be formed by an all-at-once chemical process in which BiFeO3 (i.e., not CoFe2O4) preferentially grew on the La-SrTiO3 (001) substrate because the lattice mismatch between BiFeO3 and La-SrTiO3 is much smaller than that between CoFe2O4 and La-SrTiO3. Two-step top electrodes were used to evaluat the ME effect generated by applying a vertical electric field. The orientation of the small magnetic domains of CoFe2O4 changed when the polarization of BiFeO3 was switched to the opposite direction by applying a voltage. The key points regarding the ME effect are twofold: a material such as CoFe2O4 with relatively large magnetocrystalline anisotropy could be switched through ME coupling with BiFeO3 and the orientation of the magnetic domains of CoFe2O4 (namely, 100nm in diameter) could be reversed. These results suggest that a novel, low power, high-density MRAM and HDDs, which can be written by applying a voltage, can be created on the basis of the two points described above.

References

Weisheit, M. et al. Electric field-induced modification of magnetism in thin-film ferromagnets. Science 349, 51 (2007).

Maruyama, T. et al. Large voltage-induced magnetic anisotropy change in a few atomic layers of iron. Nature Nanotechnology 4, 158 (2009).

Kimura, T. et al. Magnetic control of ferroelectric Polarization. Nature 426, 55 (2003).

Goto, T. et al. Ferroelectricity and giant magnetocapacitance in perovskite rare-earth manganites. Phys. Rev. Lett. 92, 257201 (2004).

Kimura, T., Lashley, J. C. & Ramirez, A. P. Inversion-symmetry breaking in the noncollinear magnetic phase of the triangular-lattice antiferromagnet CuFeO2 . Phys. Rev. B 73, 220401 (2006).

Qi, X., Kim, H. & Blamire, M. G. M. G. Exchange bias in bilayers based on the ferroelectric antiferromagnet BiFeO3 . Philosophical Mag. Lett. 87, 175 (2007).

Chu, Y.-H. et al. Electric-field control of local ferromagnetism using a magnetoelectric multiferroic. Nature Mater. 7, 478 (2008).

Wu, S. M. Reversible electric control of exchange bias in a multiferroic field-effect device. Nature Mater. 9, 756 (2008).

Naganuma, H. et al. Structural characterization of epitaxial multiferroic BiFeO3 films grown on SrTiO3 (100) substrates by crystallizing amorphous BiFeOx . J. Cer. Soc. Jpn. 118, 648 (2010).

Zheng, H. et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 303, 661 (2004).

Zavaliche, F. et al. Electric field-induced magnetization switching in epitaxial columnar nanostructures. Nano Letters 5, 1793 (2005).

Haimei, Z. et al. Controlling Self-Assembled Perovskite-Spinel Nanostructures. Nano Letters 6, 1401 (2006).

Dix, N. et al. On the strain coupling across vertical interfaces of switchable BiFeO3CoFe2O4 multiferroic nanostructures. Appl. Phys. Lett. 95, 062907 (2009).

Weal, E. et al. Coexistence of strong ferromagnetism and polar switching at room temperature in Fe3O4-BiFeO3 nanocomposite thin films. Appl. Phys. Lett. 97, 153121 (2010).

Aimon, N. M., Kim, D., Choi, H. & Ross, C. Deposition of epitaxial BiFeO3/CoFe2O4 nanocomposites on (001) SrTiO3 by combinatorial pulsed laser deposition. Appl. Phys. Lett. 100, 092901 (2012).

Zhang, W. et al. Strain relaxation and enhanced perpendicular magnetic anisotropy in BiFeO3:CoFe2O4 vertically aligned nanocomposite thin films. Appl. Phys. Lett. 104, 062402 (2014).

Kubel, F. & Schmid, H. Structure of a Ferroelectric and Ferroelastic monodomain crystal of the perovskite BiFeO3 . Acta Cryst. B 46, 698 (1990).

Naganuma, H., Inoue, Y. & Okamura, S. Evaluation of electrical properties of leaky BiFeO3 films in high electric field region by high-speed positive-up-negative-down measurement. Appl. Phys. Exp. 1, 061601 (2008).

Sone, K. et al. Magnetic properties of CoFe2O4 nanoparticles distributed in a multiferroic BiFeO3 matrix. J. Appl. Phys. 111, 124101 (2012).

Tagantsev, A. K., Stolichnov, I., Setter, N. S. & Cross, J. S. Nature of nonlinear imprint in ferroelectric films and long-term prediction of polarization loss in ferroelectric memories. J. Appl. Phys. 96, 6616 (2004).

Jesse, S., Baddorf, P. A. & Kalinina, V. S. Switching spectroscopy piezoresponse force microscopy of ferroelectric materials. Appl. Phys. Lett. 88, 062908 (2006).

Wang, J. et al. Epitaxial BiFeO3 multiferroic thin film heterostructures. Science 299, 1719 (2003).

Zhao, T. et al. Electrical control of antiferromagnetic domains in multiferroic BiFeO3 films at room temperature. Nature Mater. 5, 823 (2006).

Lebeugle, D. et al. Electric field switching of the magnetic anisotropy of a ferromagnetic layer exchange coupled to the multiferroic compound BiFeO3 . Phys. Rev. Lett. 103, 257601 (2009).

Acknowledgements

We thank Dr. Koji Ishii in Asylum Technology and Dr. A. F. Begum and Ph. D student T. Ichinose in Tohoku University for supporting PFM measurements. This work was partly supported by Grant-in-Aid for Challenging Exploratory Research from Japan Society for the Promotion of Science (Grant No. 23656025), the Strategic International Cooperative Program (Joint Research Type), Japan Science and Technology Agency Advanced Spintronic Materials and Transport Phenomena (ASPIMATT), the Funding Program for World-Leading Innovative R&D on Science and Technology (FIRST Program) program and by NEDO program.

Author information

Authors and Affiliations

Contributions

K.S., H.N. and S.O. carried out the experiments design. H.N. basically planed the direction of Multiferroic research theme. K.S. prepared samples and measured and analyzed XRD. K.S., T.N. and H.N. measured and analyzed ferroelectric properties. H.N. measured and analyzed magnetic properties and observed piezoelectric properties. T.M. and H.N. carried out TEM observation. K.S. and H.N. analyzed data and wrote the manuscript with suggestions from S.O. H.N. wrote revised manuscript. All the authors contributed through scientific discussion.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Sone, K., Naganuma, H., Ito, M. et al. 100-nm-sized magnetic domain reversal by the magneto-electric effect in self-assembled BiFeO3/CoFe2O4 bilayer films. Sci Rep 5, 9348 (2015). https://doi.org/10.1038/srep09348

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep09348

This article is cited by

-

Development of highly reliable BiFeO3/HfO2/Silicon gate stacks for ferroelectric non-volatile memories in IoT applications

Journal of Materials Science: Materials in Electronics (2020)

-

Short range biaxial strain relief mechanism within epitaxially grown BiFeO3

Scientific Reports (2019)

-

A simple, one-step hydrothermal approach to durable and robust superparamagnetic, superhydrophobic and electromagnetic wave-absorbing wood

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.