Abstract

Ceramic Al4O4C, which has few active functions, has been used as an additive in carbon-containing refractory materials to improve their oxidation resistance and thermal properties. Herein, the crystal and electronic structures of this novel material were systematically investigated for opto-electrical applications, which revealed interesting fluorescence features via photoluminescence (PL) and cathode luminescence (CL). When a 325 nm laser was focused on one end of a single Al4O4C needle, the entire needle was illuminated by the blue emission, which implies that this material exhibits excellent waveguide properties. Interestingly, the thin end exhibited the highest light intensity even though the excited region was located at the thick end. We believe the reason for this observed behaviour is related to the excellent waveguide behaviour as well as to the needle shape, which induces this intriguing blue-light convergence effect. Ab initio calculations demonstrated that the emission light emanates from the interband transition.

Similar content being viewed by others

Introduction

The rapid growth of industry in modern society provides us with ever-increasing numbers of highly technological products that make our lives more convenient. Researchers have created liquid-crystal displays (LCDs) as well as telecommunication, artificial intelligence and clean-energy devices due to the emergence of various new functional materials. Because of the extensive focus of researchers on semiconductor materials, such as ZnO1,2,3,4,5 and GaN6,7,8, attractive properties have been discovered and applied to commercial products. In the same way, it is important to focus our attention on the design of new materials and the exploitation of lesser-known materials that exhibit novel properties.

Previously, we investigated the potential photoelectric functionality of Al–C-based mechanical ceramic materials, such as Al4C39,10,11 and Al3CON12. For Al4C3, we synthesised various 1-D nanostructures and reported their potential application as field electron emitters. We systematically investigated the mechanical properties and photoelectric response behaviour of a single Al3CON nanobelt. Recently, we introduced oxygen into the Al–C-based material, which resulted in the formation of Al4O4C. Al4O4C exhibits properties typical of a ceramic material, such as a high melting point. In general, ceramic materials of Al4O4C are used as an additive in carbon-containing refractory materials to improve their oxidation resistance and thermal properties and they are commonly synthesised via the solid-state reaction method at temperatures as high as 2000°C13,14. Although little attention has been focused on this material, this type of ternary oxide would be of great use in the photoelectric field because of its characteristics. Because of the introduction of carbon atoms, the electrons of Al4O4C are not as inert as those of Al2O3, exhibit characteristics similar to those of wide band gap semiconductor materials and possess highly efficient light emission properties. Therefore, Al4O4C is a potential candidate for use as a photoelectric functional material, especially to meet the demands of modern society for a highly efficient blue light source.

In this work, we report the synthesis of needle-like Al4O4C micro–nano structures that exhibit intense blue light emission behaviour even under a weakly excited condition. Using a confocal microscope coupled with a CCD (Charge-coupled Device), we recorded a light-emitting image that corresponds to a single structure under 325 nm laser irradiation, which suggests that Al4O4C is a waveguide-type material in which the emission light is transported along the needle structure and converges at the thin end, similar to a convex. A xenon lamp was employed as the light source to excite the sample, which resulted in high-intensity blue emission that is visible to the human eye. Different spectra collected under the same excited condition at various temperatures (12 K–300 K) were recorded. Under a scanning electron microscope operating platform, a needle was excited with a cathode electron beam. In addition, using the ab initio method, we calculated the Raman spectrum of Al4O4C, which is in good agreement with the experimental results. The band gap obtained from electronic structure calculations was approximately 3.8 eV, which demonstrates that the light emission may occur from the electronic transition from the conduction-band minimum to the valence band maximum.

Results

Characterisation of Al4O4C micro–nano needles

The morphology investigation was performed using SEM (scanning electron microscopy), as shown in Fig. 1 . Figs. 1a and 1b show typical low-magnification images, which indicate the distribution of the Al4O4C needle wires. All of the wires lay uniformly on the Si substrate after being transferred from the ceramic sheet. Figs. 1(c–h) show a single wire with different sizes and shapes. All of the wires exhibit a needle shape with catalytic droplets at the thick end. In addition, some of the nanowires have irregular shapes, such as curved bodies. In fact, the sizes of the needle wires are restricted by the catalytic heads and the final shapes are also controlled by the catalytic droplet motion, both the size and shape of the wires originate from the growth mechanism illustrated below.

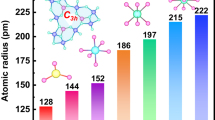

Structural analysis of the product was performed using X-ray diffraction (XRD, Bruker D8 Advance) after it was transferred from the ceramic sheet to the silicon substrate and the results are shown in Fig. 2 . The main signal peaks were attributed to Al4O4C (PDF#48-1583) and are marked by the blue lines. In addition, weak signals corresponding to Al2O3 and Al were also detected. These signals are indicated by lines with different colours, as shown in Fig. 2a . Based on the lattice parameter and atomic coordinates, we determined the optimised structure of Al4O4C, which is shown in the inset in Fig. 2 .

The phonon calculations were performed using a plane-wave pseudopotential scheme within linear response density-functional theory, as implemented in the QUANTUM-ESPRESSO package. The local density approximation (LDA) exchange-correlation function was employed. The Troullier–Martins normcon pseudopotentials were generated with valence atomic configurations of 3s2p, 2s22p4 and 2s22p2 for Al, O and C, respectively. The electronic wave functions and the electron density were expanded by the plane-wave basis sets with a cut-off energy of 70 Ry. Convergence tests indicated that 9 × 6 × 6 Monkhorst–Pack grids in the Brillouin zone were required to obtain a total energy convergence better than 2 meV/atom. In addition, the choices of the above computational parameters ensured that the convergence of the phonon frequencies were within 0.08 THz. The Raman intensities were computed from the second-order derivative of the electronic density matrix with respect to a uniform electric field. The Raman spectrum calculated with 10 cm−1 Gaussian smearing is shown in Fig. 3b . These Raman spectra indicate that Al4O4C has very rich molecular vibrational energy levels, which leads to complicated Raman modes. In addition, the experimental spectrum was obtained using a 514 nm laser as the excited source directed at a single needle, as shown in the inset of Fig. 3a . The experimental result is in good agreement with the calculated result. Most of the main vibration modes share the same position even though several vibration modes shifted slightly.

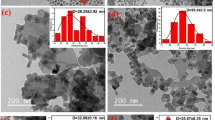

To investigate the crystal structure of a single structure, TEM (transmission electron microscopy) analysis was performed and the results are shown in Fig. 4 . Fig. 4a shows the bright-field low-magnification image of a single wire and the inset is the SAED (selected area electron diffraction) pattern, which indicates a high degree of crystallinity. A corresponding high-resolution TEM image of an Al4O4C wire with large d-spacing and clear lattice sites is shown in Fig. 4b . Notably, our TEM is equipped with magnetic inclination. Therefore, the low-magnification image and the HRTEM image do not have the same orientation. According to the XRD results and the HRTEM analyses, we can easily conclude that the wire is orthorhombic Al4O4C and the stack direction is indicated in Fig. 4b . EDS elemental mapping analysis of a piece of the wire was performed during the TEM analysis. Figs. 4(d–f) display the elemental distribution along the wire corresponding to O, C and Al; on the basis of these results, the three elements are distributed symmetrically across the whole wire. To confirm its structure and explore the growth mechanism, we employed SAED at the catalytic head, as shown in Fig. 4h . Combined with the EDS analysis in Fig. 4i , we determined that the catalyst is primarily composed of metallic Al, which is the origin of the Al signal in the XRD result.

TEM analysis of a single Al4O4C wire.

(a) The low magnification image of the wire used in the analysis. The inset shows the SAED pattern of the wire. (b) Corresponding HRTEM image of the wire. (c) The piece of nanowire chosen for EELS mapping analysis. (d–f) Elemental distribution of O, C and Al obtained from the EELS mapping analysis. (g) The low-magnification image of the catalytic head of the analysed wire. (h) The SAED pattern of the head, which was confirmed to be metallic Al. (i) The EDS result for the catalytic head.

Growth mechanism of needle micro–nano Al4O4C structures

On the basis of the previously described series of experiments and characterisations, we hypothesised that the formation of the Al4O4C needle wires occurs via the vapour–liquid–solid growth (VLS) mechanism. However, some differences were observed compared to the conventional VLS mechanism, which states that a nanowire is catalysed by an alloying droplet through active atoms precipitating from the liquid droplet15,16. Here, the catalytic Al droplets play an important role in collecting various clusters, such as Al, C, Al2O3 and Al4O4C, via surface absorption and serve as the reaction sites. In detail, when the temperature is increased to more than 800°C17, the Al atoms evaporate from the Al sheet and integrate as droplets in a low-temperature zone. At the same time, when the temperature is greater than 1000°C active carbon atoms form in the atmosphere due to CH4 cracking18. In this case, there are various atomic radicals, including Al, AlOx, C, Al4O4C and perhaps other Al-C-O-based clusters, are present in the atmosphere. Through a series of reactions, a stable Al4O4C phase eventually forms. The Al4O4C molecules and clusters are collected by the liquid Al droplet via surface absorption and float on the surface of the Al liquid, which nucleates and grows larger at suitable sites as they coalesce together continuously. Simultaneously, excess Al atoms also combine with the liquid Al droplet. Therefore, the sizes of the catalytic Al heads increase, which results in nanowires with needle shapes. The detailed growth process is illustrated in Fig. S2 (Supplementary). In this process, Al heads play a critical role in inducing the one-dimensional growth of Al4O4C and in adjusting the size of the nanowires to themselves. If the nanowire and the Al head do not have axial symmetry, the nanowire deviates from its original growth tendency and changes its axial symmetry to adapt to the Al droplet. The change in axial symmetry of the nanowire can be attributed to two factors: I. Al droplets in the liquid state are not stationary; however, they frequently change their shapes and positions. II. The sites with more Al4O4C clusters grow faster, which influences the axial symmetry. Therefore, it is common for some nanowires to grow with several warps or in a zigzag shape, as shown in Fig. 1 . The prepared Al4O4 micro–nano needle wires are shown on a blank area of the ceramic sheet as black ellipses in Fig. S2 (Supplementary).

Discussion

The synthesised Al4O4C needle wires were first characterised using the photoluminescence (PL) method. In the experiment, the sample was excited by a xenon lamp light source and the emission signal was collected by a blue-sensitive light detector. The sample can be excited by 266 nm light, which results in the emission of intense blue light with wavelengths that range from 350 nm to 550 nm with an emission peak at 415 nm. Fig. 5a contains two curves: the left one is the excitation spectrum and the right one corresponds to the emission signal. Notably, even under irradiation by a xenon lamp, the bright emission area in blue is visible, as shown in the inset in Fig. 5a . This result indicates that Al4O4C is an excellent blue emitter with a high emission efficiency. Next, the temperature-dependent emission behaviour was investigated. Emission spectra at different temperatures that ranged from 12 K to 360 K under the same excitation conditions were obtained and are shown in Fig. 5b . All of the spectra have the same profile and no emission shift was detected, which further implies that the material exhibits stable blue light emission upon temperature variation. The emission intensity increases from 360 K to 12 K, which is the phenomenon expected to result from the low nonradiative loss of photon energy at low temperatures. The acute peak located at approximately 455 nm is not the emission signal from the sample; it is rather an unwanted signal from the xenon lamp due to the absence of a filter. In this experiment, no filter was added to facilitate the accurate detection of the emission signal and to avoid any influence of a filter plate in the detection of weak signals at higher temperatures.

PL properties at various temperatures under excitation by a 266-nm xenon lamp.

(a) The blue emission behaviour of the as-synthesised sample at room temperature. The left is the emission spectrum and the right is the excitation spectrum. The inset shows the optical image captured by a common camera during the luminescence process. (b) The emission behaviour of the sample at different temperatures, which ranged from 12 K to 360 K. The acute peak located at 455 nm corresponds to an unwanted light signal from the xenon lamp source.

To further analyse the band structure with greater accuracy and to trace the PL origin, we performed ab initio structural relaxations and electronic band structure calculations in the framework of density functional theory within the generalised gradients approximations (GGA) and the all-electron projector-augmented wave (PAW) method, as implemented in the VASP code. The PAW potentials were taken from the VASP library in which 3s2p, 2s22p4 and 2s22p2 are treated as valence electrons for Al, O and C atoms, respectively. The cut-off energy for the expansion of the wavefunctions into plane waves was set to 800 eV in this calculation and appropriate Monkhorst–Pack k meshes (9 × 6 × 6) were chosen to ensure that enthalpy calculations were well converged. The band structure shown in Fig. S3 (Supplementary) was obtained from these calculations. The conduction band minimum is located at the G point and the band gap was determined to be 3.8 eV, which is approximately 0.8 eV higher than the energy of the emitting photons because of the differences between the ideal model and the real sample.

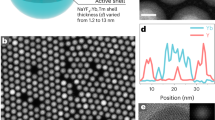

To investigate the light emission behaviour of a single needle, we employed microdomain PL analysis under a confocal microscope equipped with an ultraviolet lens and a CCD using a 325 nm laser as the excitation source. Due to the design of the light path, the ultraviolet light beam from the laser source converged to a light spot with diameter of approximately 2 μm. In this case, it was possible to obtain the light-emission information from a single wire. Fig. 6a shows the image captured by the CCD, where we chose a needle wire with a length of approximately 50 μm and a diameter of the thick end of approximately 5 μm to obtain a reliable emission signal. The inset in Fig. 6a shows the dark-field image of the needle excited by the 325 nm light spot. Although the light spot was focused on the thinner end of the needle, the entire wire displayed blue except for the catalyst area, which indicates the excellent light waveguide property of Al4O4C. All of these advantages suggest the potential application of the ceramic Al4O4C needle wire as a micro–nano blue light source with a controllable size prepared via the growth of needle wires with different diameters. Figure 6b displays the emission spectrum of the single needle wire. This emission spectrum contains two peaks located at 415 nm and 464 nm, which is similar to the spectrum excited by the 266-nm xenon lamp. The 464 nm light emission can be attributed to electron transition relative to the defect energy level.

The light emission behaviour of a single needle wire excited by a 325-nm laser.

(a) Illustration of the experimental process. The insets display the image of the wire and blue body illuminated by the emitted light. The yellow light is not the real signal but is rather the trace of the 325-nm light recorded by the CCD. (b) The spectrum of the needle excited by the 325-nm laser recorded by the spectrometer.

Except in the PL analysis, we applied a cathode electron beam to excite a single wire under a scanning electron microscope operating platform and the results are shown in Fig. 7 . Two needle wires with different sizes were chosen for CL characterisation and the resulting images are shown in Fig. 7a . There is a high contrast ratio between the bodies of the wires and the background, which implies intense fluorescence behaviour of the bright area. By collecting the fluorescence emission information with the assembled spectrometer, we obtained the emission spectrum, which is shown in Fig. 7a . This emission spectrum is the same as the PL result when the sample was excited by the 266-nm radiation from the xenon lamp. The cathode electron beam with its low accelerated voltage excited the Al4O4C wires, which indicates that this ternary ceramic material is appropriate for use as a blue light source excited by a low-energy electron beam. In addition, to investigate the size dependent emission behaviour, we focused the electron beam on several sites with varying diameters and the results are shown in Fig. 7b . The emission spectra for all of the spots exhibited the same behaviour even though the intensities varied, which demonstrates the stability of the light emission and transportation upon size variation.

The CL performance of a single needle.

(a) The emission spectrum of a single Al4O4C needle along with the corresponding SEM image and CL emission image. (b) The CL emission spectrum for six positions with different sizes of a thinner needle. The right shows the corresponding SEM image and the emission profile.

Based on the previously described light emission investigation, the Al4O4C micro–nano structures could be easily excited by a 266-nm xenon lamp, a 325-nm laser beam or a low-energy electron beam, resulting in stable emission of intense blue light irrespective of the size and temperature, which was as low as 12 K. Considering the needle profile and the excellent waveguide property of Al4O4C, we hypothesised that a very intense blue light nanobeam could be obtained from the thin end of the needle. First, we focused the 325-nm light spot on the thick end and observed the optical image through the CCD. As shown in Fig. 8a , the thin end was the brightest region along the needle. This result may be due to the highly efficient emission of the thick end or, as a consequence of the needle profile, the restriction of the light when the light is transported along the needle. Although there is loss due to scattering at the interface between the structure and air, we believe it is possible to obtain a nanosize light beam with high intensity due to the converging effect, which is illustrated in Fig. 8b .

In summary, the structural ceramic material Al4O4C has not attracted much attention for photoelectric applications. In this work, we synthesised Al4O4C needle wires via the CVD method in a high-vacuum reaction chamber and demonstrated its blue emission behaviour. Different methods were employed to excite a single wire. The Al4O4C was found to be an excellent blue light source as well as a potential candidate use as a light waveguide material. In addition, the Raman spectrum and band structure were determined using ab initio calculations. We expect that Al4O4C could be used in future photoelectric devices and as a micro–nano light source.

Methods

Synthesis of Al4O4C needle

The Al4O4C micro–nano structures were prepared in a horizontal tube furnace connected to a turbo molecular pump. After the pre-vacuum procedure, the backing pressure of the reaction chamber was as high as 2 × 10−5 Pa. The illustration of the furnace is shown in Fig. S1 (Supplementary). The starting materials were placed on a ceramic plate (160 mm × 10 mm × 1 mm), which is a Five Aluminium (Al) sheet (10 × 10 × 0.5 mm) located symmetrically on the right side of the ceramic plate that was more than 12 cm in length. The whole setup was placed in a semi-closed corundum protective tube with the idle load side towards the open end. Then, the corundum protective tube was pushed into the furnace. After the pre-vacuum process, the tube was heated to 1310°C stepwise over a period of 60 minutes. The temperature was subsequently held at 1310°C for 120 minutes. When the temperature was increased to 350°C, CH4 and H2 were simultaneously introduced at a flow of 5 sccm and 100 sccm, respectively and the chamber pressure was maintained at 500 Pa until the temperature-control process was completed. Then, the chamber was rapidly cooled to room temperature using a water-cycling system. Micro–nano Al4O4C needle structures were found on the blank side of the ceramic plate, as shown.

Structural and photoluminescence characterizations

The crystal structure and the phase of the synthesized product was characterized using X-ray diffraction (XRD, Bruker D8 Advance). The morphology was investigated by field emission scanning electron microscope (FESEM, FEI Quanta 400F). The micro-structure analysis was further employed using high resolution transmission electron microscope (HRTEM, FEI Tecnai G2 F30). The photoluminescence test using Xenon lamp as excitation light source was carried out by applying Combined Fluorescence Lifetime and Steady State Spectrometer (EDINBURGH INSTRUMENTS LTD FLS920). Raman analysis and photoluminescence test upon a single needle was done on Laser Micro-Raman Spectrometer (Renishaw inVia) analysis platform.

References

Wang, R. C., Lin, H. Y., Wang, C. H. & Liu, C. P. Fabrication of a large-area Al-doped ZnO nanowire array photosensor with enhanced photoresponse by straining. Adv. Funct. Mater. 22, 3875–3881 (2012).

Zhang, Y. et al. Scanning probe study on the piezotronic effect in ZnO nanomaterials and nanodevices. Adv. Mater. 24, 4647–4655 (2012).

Chen, G. et al. Resistive switching and magnetic modulation in Cobalt-doped ZnO. Adv. Mater. 24, 3515–3520 (2012).

Qi, J. et al. Resistive switching in single epitaxial ZnO nanoislands. ACS nano. 6, 1051–1058 (2012).

Wang, N. W. et al. General strategy for nanoscopic light source fabrication. Adv. Mater. 23, 2937–2940 (2011).

Akasaka, T., Gotoh, H., Kobayashi, Y. & Yamamoto, H. Extremely narrow violet photoluminescence line from iltrathin InN single quantum well on step-free GaN surface. Adv. Mater. 24, 4296–4300 (2012).

Chen, C. Y. et al. Gallium nitride nanowire based nanogenerators and light-emitting diodes. ACS nano. 6, 5687–5692 (2012).

Yoo, H. et al. Microstructures of GaN thin films grown on graphene layers. Adv. Mater. 24, 515–518 (2012).

Sun, Y. et al. Carbon-in-Al4C3 nanowire superstructures for field emitters. ACS nano. 5, 932–941 (2011).

Sun, Y. et al. Field nanoemitter: one-dimension Al4C3 ceramics. Nanoscale. 3, 2978–2982 (2011).

Sun, Y., Cui, H., Gong, L., Chen, J. & Wang, C. X. Synthesis of Al4C3 nanowalls via thermal evaporation and potential application in vacuum microelectronic devices as cold electron emitters. CrystEngComm. 14, 7951–7957 (2012).

Cui, H. et al. Ultralong one-dimension Al3CON nanostructures: synthesis, elastic deformation behavior and photoelectric properties. J. Mater. Chem. 22, 12830–12836 (2012).

Zhao, J. L., Lin, W., Yamaguchi, A., Ommyoji, J. J. & Sun, J. L. Influence of heating temperature, keeping time and raw material grain size on Al4O4C synthesis in carbon thermal reduction process and oxidation of Al4O4C. J. Ceram. Soc. Jpn. 115, 654–660 (2007).

Lihrmann, J. M. Thermodynamics of the Al2O3–Al4C3 system: I. Thermochemical functions of Al oxide, carbide and oxycarbides between 298 and 2100 K. J. Eur. Ceram. Soc. 28, 633–642 (2008).

Sun, Y. et al. The synthesis and mechanism investigations of morphology controllable 1-D SiC nanostructures via a novelapproach. Cryst Eng Comm. 12, 1134–1138 (2010).

Alegria, L. D. et al. Structural and electrical characterization of Bi2Se3 nanostructures grown by metal−organic chemical vapor deposition. Nano lett. 12, 4711–4714 (2012).

Sun, Y., Cui, H., Jin, S. X. & Wang, C. X. Eutectic solidification applied to nanofabrication: a strategy to prepare large-scale tungsten carbide nanowalls. J. Mater. Chem. 22, 16566–16571 (2012).

Rizk, S. et al. Synthesis of carbon coated β-SiC nanofibers by microwave plasma assisted chemical vapour deposition in CH4/H2 gas mixture. Diamond Relat. Mater. 17, 1660–1665 (2008).

Acknowledgements

This work was financially supported by the National Nature Science Foundation of China (51125008, 11274392).

Author information

Authors and Affiliations

Contributions

C.-X. W. conceived and provided critical ideas for the work. Y. S. and C.-R. D. performed the optical experiments, including the results shown in Figures 5, 6 and 8. Y.-Z. C. and Y.-M. M. performed ab initio calculations to generate the Raman spectra and electronic structures shown in Figures 3 and Figure S3 (Supplementary). G.-W. Y. analysed the experimental results. Y. S. and C.-X. W. performed analyses and wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information for One-Dimensional Al4O4C Ceramics: A New Type of Blue Light Emitter

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Sun, Y., Chen, Y., Ding, C. et al. One-Dimensional Al4O4C Ceramics: A New Type of Blue Light Emitter. Sci Rep 3, 1749 (2013). https://doi.org/10.1038/srep01749

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01749

This article is cited by

-

Structurally Efficient Three-dimensional Metamaterials with Controllable Thermal Expansion

Scientific Reports (2016)

-

Si-Doped Ceramic Al4O4C Nanowires: Full-Color Emission and Optical Waveguide Behavior

Scientific Reports (2014)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.