Abstract

The network structure of syndiotactic-polystyrene (sPS)- or syndiotactic-poly(styrene-co-4-R-styrene)-organic solvent gels has been quantitatively studied by means of scanning microscopic light scattering (SMILS). SMILS analysis indicated that sPS gels prepared in chloroform, benzene, toluene, and o-dichlorobenzene (ODCB) formed network structures with small mesh sizes, ~0.6–1.8 nm, and large cluster structures, ~1000–6000 nm. The cluster size in the gels increased with increasing sPS concentration. The mesh and cluster sizes of sPS gels prepared in ODCB was the smallest among the used solvents owing to its high viscosity. Gelation of the St/CH3St (MeSt)-toluene system at high temperatures induced slow gel formation and made it possible to trace the time evolution of the network structure by SMILS. tert-C4H9St (BuSt) units in St/BuSt drastically decreased the gel formation rate, and the formation process of the St/BuSt-toluene system could be traced by SMILS and FT-IR spectroscopy at room temperature. The results indicated growth of the cluster structure during gelation. St/4-hydroxystyrene formed gels in dioxane. A gel of an St copolymer containing an anthracene (An) group was prepared in toluene, and photodimerization of the An groups was induced by UV irradiation accompanied by formation of the large cluster structure.

Similar content being viewed by others

Introduction

Syndiotactic-polystyrene (sPS) forms various crystalline structures depending on the crystallization process and/or conditions. sPS forms a physical gel from solutions of various organic solvents.1, 2, 3 The clathrate or intercalate crystalline structure of sPS with organic solvents has the role of crosslinking points, which induce formation of the gels. The molecular structure of sPS in the gels has been studied using various methods. Stoichiometry of molecular complexes between sPS and solvents depends on the structure of the solvent molecules. Daniel4 and Malik et al.5 found the coexistence of clathrate and intercalate structures having plural stoichiometry in sPS with organic solvent gels. Daniel et al.6,7 prepared the sPS gels in a mixture of 1-chlorotetradecane and 1,2-dichloroethane and showed that those solvents were separated into the clathrate phase (polymer-rich phase) or network phase (polymer-poor phase).

The molecular structure of sPS in organic solvents during the gel formation process has been studied using various analytical methods. Kobayashi and Kozasa8 investigated the molecular structure and kinetics of the gel formation process using Fourier transform infrared spectroscopy (FT-IR) and found that the gel was formed by sPS molecules with highly ordered T2G2 sequences via clustered molecular segments or self-assembled T2G2 sequences. Rudder et al.9 traced the gel formation process of a sPS-bromoform system by DSC, FT-IR, and rheological studies, and proposed a two-step gel formation involving intramolecular and intermolecular conformation changes.

Studies relating the network size of the sPS gel have been reported. Shimizu et al.10 investigated the effect of solvents on the highly ordered structure of sPS in the gels. They found that the sPS gels prepared in poor solvents formed large junction points. Itagaki et al.11 determined the free volume between sPS chains in the sPS gel through the observation of solvent molecules in the gel using a fluorescent probe.

Dynamic light scattering (DLS) is a useful analytical technique to determine the size of polymer particles in solutions. Munch et al.12 reported the effect of polymer concentration in a dilute solution on the cooperative diffusion constants of atactic-polystyrene using DLS. In general, conventional DLS is rarely used to quantitatively characterize the network structure in polymer gels because a static inhomogeneity exists in the network structure. Quantitative determination of the minute mesh size of gels has been performed with scanning microscopic light scattering (SMILS).13,14 SMILS was developed for the detailed characterization of the network structure in polymer gels. The characterization of a polymer gel should be performed with in situ measurements because it is a huge macromolecule with an infinite network. SMILS enables us to perform DLS measurements at many different positions in a gel to rigorously determine a time- and space-averaged, that is, ensemble-averaged, (auto-) correlation function of fluctuating mesh size in the gel.

In this paper, we investigated the gel formation process and/or the network structure of sPS or syndiotactic-poly(styrene-co-4-R-styrene) (St/RSt) gels, where R: CH3 (Me), or tert-C4H9 (Bu) as shown in Scheme 1, in various organic solvents using SMILS. The effects of solvent, temperature, R structure of RSt, and RSt content in the copolymers on the network structure, mesh, and cluster size in the gels has been quantitatively studied using SMILS. The St/RSt gels with interactive R groups, 4-hydroxystyrene (HOSt) or 9-anthracenecarboxylicacid-4-ethenylphenylester (AnSt) as shown in Scheme 1, have also been prepared to study the effects of OH groups or dimerization of An groups on the network structure of the gels.

Experimental procedure

Materials and methods

sPS, St/MeSt, St/BuSt, and St/4-(tert-butyldimethylsilyloxy)styrene (SiOSt) were synthesized by (co)polymerization of corresponding monomer(s) with a pentamethyl(cyclopentadienyl) titanium trichloride (Cp*TiCl3)/methylaluminoxane (MAO) catalyst system (see Supplementary Material). The syndiotacticity of sPS was high, and the [rrrr] was more than 95%. The copolymerizations yielded highly syndiotactic copolymers.15 The organic solvents toluene, benzene, o-dichlorobenzene (ODCB), chloroform, and dioxane were commercially obtained and used as received.

Syntheses

Synthesis of St/HOSt

St/HOSt was synthesized by deprotection of the tert-butyldimethylsilyloxy group of SiOSt units in St/SiOSt. St/SiOSt (0.5 g), tetrahydrofuran (25 ml), and hydrochloric acid (12 N, 7.5 ml) in a 100 ml round bottom flask equipped with a condenser were refluxed for 6 h (Scheme 2). The reaction mixture was poured into a large excess of H2O, and the precipitated polymer was recovered by filtration and dried in vacuo at 60 °C for 6 h.

Synthesis of St/AnSt

St/HOSt (0.1 g), 9-anthracenecarbonyl chloride (0.06 g), toluene (2.0 ml), and pyridine (5.0 ml) in a 100 ml round bottom flask equipped with a condenser were refluxed for 4 h under a nitrogen atmosphere (Scheme 2). The reaction mixture was poured into a large excess of methanol, and the precipitated polymer was recovered by filtration and dried in vacuo at 60 °C for 6 h. The reaction was almost perfectly completed.

Preparation of gels

sPS or St/RSt and a solvent were charged in a sample tube of 4 mm diameter, and the sample tube was sealed by burning off. The sample tube was heated at approximately the boiling point of the solvent to dissolve the polymer and then cooled to room temperature or to the desired gelation temperature.

Analytical procedures

Quantitative determination of the minute mesh size of the gels was performed with the SMILS system.13,14 Scanning measurements were performed at more than 25 points for each sample to determine the ensemble-averaged dynamic structure factor. The determined correlation function was transformed to the distribution function of the relaxation time by using a numerical inverse Laplace transform calculation. For the present gels, a few peaks of relaxation modes were observed in the distribution function. All of the results were determined at a scattering angle fixed at 90°. The observed modes, as assigned to the cooperative diffusion of the gel network, were used for the determination of mesh radius (mesh size) (ξ; m) with the Einstein–Stokes formula (1),

where n, τR, KB, θ, η, and λ are the refractive index of the solvent, ensemble-averaged relaxation time (s), Boltzmann constant (1.38 × 10−23 JK−1), scattering angle (90°), viscosity coefficient of the solvent, and wave length of incident ray (4.42 × 10−7 m), respectively. SMILS measurements were normally conducted at 30 °C. Constants of solvents used in the calculations are summarized in Table 1.

FT-IR spectroscopy was conducted with a Shimadzu FT-IR 8400S (Shimadzu, Kyoto, Japan). Ultraviolet (UV)–vis absorption spectroscopy was conducted with a Shimadzu UV-1200 (Shimadzu). The gels for these measurements were prepared in a KBr cell for solution sampling.

Results and discussion

sPS-solvents gels

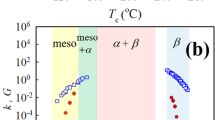

The structural and thermal properties of a sPS sample are as follows: Mn=7.8 × 104 g mol−1, Mw/Mn=1.74, and Tm=253.7, 265.3 °C. sPS-toluene, benzene, ODCB, or chloroform gels were prepared according to the method described in the experimental section. In the case of sPS-toluene, benzene, and ODCB systems, slightly white, muddy gels were generated from the solutions containing more than 0.1 wt% sPS. By contrast, PS/chloroform solutions containing less than 1.0 wt% of sPS did not form gels. The difference can be explained by interaction between sPS and the solvents as determined with their Flory–Huggins interaction parameters (δ). The calculated δ of PS is 19.1 (MJm−3)1/2, which is almost same as that of chloroform, 19.0 (MJm−3)1/2. The high solubility of sPS in chloroform should induce a high critical gelation concentration of sPS. Figure 1 shows the ensemble-averaged relaxation time distributions as a function of the relaxation time of sPS-toluene and sPS-chloroform gels, and the network structure of all of the gels is summarized in Table 2. The ensemble-averaged relaxation time distributions of those gels showed bimodal relaxation peaks. The relaxation peak at a short relaxation time (<10−5 s) corresponds to a size of ~1 nm, which should be derived from the minute mesh of the network structure. The mesh size was almost independent of the sPS concentration in the gels. Another relaxation peak at a long relaxation time, ~10−2–10−1 s, corresponds to the size of ~1000–6000 nm. The large size structure would be derived from clustered sPS polymer chains. The cluster size of sPS increased with increasing sPS content in the gels, especially in the sPS-chloroform gel. An increase of the sPS concentration in the gels should increase the deposition and/or number of crosslinking points in the sPS polymer chains, which should enhance the aggregation of the polymer chains. The cluster size of the gels decreased in the following order of the used solvents, toluene>benzene>chloroform>ODCB. The cluster size can be explained in relation to the junction point size. Okabe et al.10 determined the junction point size (ζ) in sPS-organic solvent gels. The reported size ζ in number of styrene units of sPS-toluene, -benzene, -chloroform, or -ODCB are ~35, 21, 40, or 9, respectively. The order of the cluster size of sPS-toluene, benzene, and chloroform gels determined by SMILS is same with that of the reported junction point size. Despite having the largest junction point size, the sPS-ODCB gels showed the smallest cluster size among the prepared gels. The results can best be explained by the viscosities of the solvents. The viscosity of ODCB is much higher than those of the other solvents. The high viscosity of ODCB should prevent crystallization and/or aggregation of sPS in the gels.

The sPS-toluene system rapidly formed a gel at room temperature, whereas it took ~1 h to generate the sPS-chloroform gel. The network structure of the sPS-toluene and -chloroform systems was traced by SMILS. Figure 2 shows the time evolution of the ensemble-averaged relaxation time distributions as a function of the relaxation time of the sPS-toluene and sPS-chloroform systems containing 4.0 wt% of sPS. Figure 3 shows the time evolution of mesh or cluster size, determined from the relaxation time of Figure 2. The size of the cluster structure was almost fixed in the sPS-toluene system. By contrast, the cluster size drastically increased within 2 h in the sPS-chloroform system, indicating that the cluster structure gradually grew during the gel formation. The sPS-chloroform gel formed at ~2 h. The mesh size of the gels slightly decreased immediately after the gelation. The most likely explanation is that the crystallization of sPS occurred enough to occupy all of the space in the gel within the network and formed a highly dense mesh with small size at the gelation point. The mesh size of the gel slightly increased after the gelation during the period of 5–7 h. The same phenomenon was observed in the analysis of chemical gels of our previous reports.16 Although there is room for further investigation, one explanation for the phenomenon is that the mesh in the gel would not reach the equilibrium structure immediately after the gelation point. It would take a few hours to reach the equilibrium, which involves expansion of the tightly formed mesh in the gel.

St/MeSt, St/BuSt-toluene gels

The gelation of St/MeSt and St/BuSt-toluene systems was investigated to study the effect of the R structure or content of RSt on the gel formation and network structure of the gels. The molecular structures of the St/RSt copolymers used in this experiment are summarized in Table 3. The St/MeSt-toluene system formed gels too rapidly to trace the gel formation process with SMILS at room temperature. We conducted the SMILS measurement of St/MeSt-toluene system at higher temperatures, 30 or 50 °C, to delay the gel formation process. Figure 4 shows time evolution of ensemble-averaged relaxation time distributions as a function of the relaxation time of the St/MeSt-toluene system at 50 °C. The relaxation peak derived from mesh of the network (<10−5 s) shifted to shorter times with the passage of gelation time. By contrast, the relaxation peak derived from clustered polymers (10−2–10−1 s) showed the opposite transition. The time evolution of mesh size or cluster size of the St/MeSt-toluene system at 30 or 50 °C is summarized in Figure 5. The mesh and cluster sizes detected at 30 °C were almost constant, indicating fast network formation. Although the St/MeSt-toluene gel formed within 0.5 h, the mesh size and cluster size of St/MeSt-toluene at 50 °C decreased and increased, respectively, over a time period of hours. These results show slow network formation in the St/MeSt-toluene gel at 50 °C. The cluster size of the gels prepared at 30 or 50 °C was ~6000 or 7800 nm, respectively. The slow network formation process at the high temperature should induce a large cluster size in the St/MeSt-toluene gel.

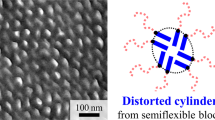

It took ~2 or 5 h to form the gels at room temperature in the St/BuSt-toluene systems containing 8.4 mol% (St/BuSt1) or 11.5 mol% (St/BuSt2) of BuSt, respectively. Although these copolymers can form a clathrate structure with toluene, the bulkiness of the Bu substituent in St/BuSt should decrease the proportion or formation rate of the clathrate structure with toluene. Slow gelation of the St/BuSt-toluene system made it possible to trace the network formation process using SMILS at room temperature. Figure 6 shows the time evolution of the ensemble-averaged relaxation time distributions as a function of the relaxation time of the St/BuSt-toluene systems. The relaxation peaks derived from the mesh of the network or clustered polymers were detected at a short relaxation time (<10−5 s) or long relaxation times (10−2–10−1 s), respectively. The time evolution of the mesh or cluster size of St/BuSt-toluene systems is summarized in Figure 7. The clear relaxation peak derived from the mesh size of the gels appeared at 2 h, and the mesh size slightly increased after the gelation at the period of 5–7 h in the systems. The cluster size increased with the passage of time, indicating growth of the cluster during the network formation process. The time evolution of the relaxation time detected by SMILS during the gel formation process is similar to that of the sPS-chloroform system, which shows slow gelation, as shown in Figure 2b.

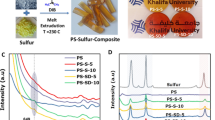

The gel formation process of the St/BuSt2 (BSt=11.5 mol%)-toluene system was traced by FT-IR spectroscopy, as shown in Figure 8. The absorption peaks were detected at 571, 549, and 536 cm−1. The former two peaks are derived from the ordered TTGG sequence. The last peak is due to the disordered TTGG sequence.8,17,18 The absorption peak at 571 cm−1 appeared 3 h after standing, and its intensity increased over time. By contrast, the peak at 536 cm−1 was detected from the early stage of the gel formation process. These results indicate that the BuSt units in St/BuSt would prevent the formation of ordered TTGG sequences, which induce gel formation. In the case of the sPS-toluene system, the intensity of all the peaks was fixed because the gelation of the system was achieved in a short period (see Supplementary Figure S1). It follows that the BuSt units in the copolymer hinder the formation of a clathlate structure and ordered TTGG sequences but form a helical structure (disordered TTGG sequence) of polymer chains.

Scheme 3 shows a proposed model of the gel formation process of the St/BuSt-toluene system based on the results described above. In the early stage of gelation, small clusters approximately 2000–3000 nm would be formed by entanglement of disordered TTGG sequences. Formation of a clathlate structure and ordered TTGG sequences in the polymer chains would induce aggregation or growth of the small clusters, leading to the formation of large clusters ~5000–6000 nm. This cluster formation turns the clear solution to a slightly white, muddy gel (see Supplementary Figure S2).

St/HOSt-toluene, dioxane gels

St/OHSt was synthesized by hydrolysis of St/SiOSt. The gelation of the St/HOSt-solvent system was investigated to study the effect of the hydrophilic OH group on the gel formation process or network structure of the gels. St/HOSt1 containing 16.8 mol% of HOSt formed a gel in toluene. By contrast, the copolymers with high HOSt content were hardly soluble in toluene because of the hydrophilic characteristic of the OH group. The gels of St/HOSt were prepared in dioxane, and the St/HOSt containing 16.8–53.1 mol% of HOSt formed slightly white, muddy gels. Figure 9 shows the ensemble-averaged relaxation time distributions as a function of the relaxation time of St/HOSt-dioxane gels. The relaxation time and network structure of the gels are summarized in Table 4. The relaxation peaks derived from the mesh of the network (0.5–0.6 nm) or clustered polymers (2000–3000 nm) were detected at a short relaxation time (<10−5 s) or long relaxation times (10−2–10−1 s), respectively. The mesh and cluster sizes of St/HOSt-dioxane gels were smaller than those of the St/MeSt, St/BuSt-toluene gels. These results could be explained by the interaction of the OH groups. Inter- and/or intramolecular hydrogen bond formation would accelerate aggregation of polymer chains in the gels.

St/AnSt gels

Anthracene is dimerized by UV irradiation. The dimerization reaction of anthracene groups was investigated in an St/AnSt-toluene gel to study the effect of the reaction on the network structure of the gel. St/AnSt was synthesized by a dehydrochlorination reaction between St/HOSt (St/HOSt1) and 9-anthracenecarbonyl chloride. It took 4 h to form the St/AnSt-toluene gel from a toluene solution containing 1.0 wt% of St/AnSt at room temperature. SMILS analysis of the gel showed the formation of a network structure with a homogeneous, small mesh of 1.7 nm and small amount of large cluster structures ~5700 nm in size. Photodimerization of anthracene groups in the gel was induced by UV irradiation. After 24 h of gelation, UV light of 375 nm was irradiated to the gel. The UV-irradiated gel was traced by UV–vis absorption spectroscopy to monitor the [4π+4π] anthracene cyclodimerization reaction. Figure 10 shows the time evolution of the UV–vis absorption spectra of the St/AnSt-toluene gel under UV irradiation. The absorption band intensity between 340 and 380 nm, derived from the anthracene moiety, gradually decreased with increasing irradiation time. The result indicates that photodimerization of anthracene occurs in the gel. The time evolution of the network structure of the UV-irradiated gel was traced by SMILS, as shown in Figure 11. The size and peak intensity of the relaxation peak at approximately 2 × 10−2 s, derived from a clustered structure approximately 5000 nm in size, increased with the passage of time. The transformation of the anthracene functional groups into dimers by UV light should induce modification of the network structure in the gel.

Conclusions

The network structure and gel formation process of sPS or St/RSt (R=Me, Bu, HO, An)-organic solvent gels were quantitatively analyzed using SMILS. The gels showed the relaxation peaks that indicated that the mesh of the network was approximately 1 nm and that the clustered structure was approximately 1000–6000 nm. The solubility parameter or viscosity of the solvent affected the network structure of sPS-organic solvent gels. Slow gel formation of the St/MeSt- and St/BuSt-toluene gels made it possible to study the time evolution of the mesh size or the cluster size in the gels using SMILS. The gelation of the St/MeSt-toluene system at high temperature (50 °C) induced large clusters. The gel formation process of St/BuSt-toluene system was traced by FT-IR spectroscopy at room temperature. FT-IR indicated that the BuSt units in St/BuSt would prevent the formation of an ordered TTGG sequence. St/HOSt copolymers formed gels in dioxane, and the gels showed relaxation peaks derived from a small mesh and large clusters in the SMILS analysis. Photodimerization of An groups occurred in the St/AnSt-toluene gel, and the dimerization reaction enhanced the formation of large clusters.

Structure of syndiotactic styrene copolymers (St/RSt).

Synthesis of St/HOSt and St/AnSt.

Model of the gel formation process of the St/BuSt-toluene system.

References

Kobayashi, M ., Nakaoki, T. & Ishihara, N. Molecular conformation in glasses and gels of syndiotactic and isotactic polystyrenes. Macromolecules 23, 78–83 (1990) ).

Daniel, C ., Deluca, M. D ., Guenet, J. M ., Brulet, A. & Menelle, A. Thermoreversible gelation of syndiotactic polystyrene in benzene. Polymer 37, 1273–1280 (1996) ).

Daniel, C ., Menelle, A ., Brulet, A. & Guenet, J. M. Thermoreversible gelation of syndiotactic polystyrene in toluene and chloroform. Polymer 38, 4193–4199 (1997) ).

Daniel, C. Structural organization and properties of syndiotactic polystyrene gels. Macromol. Symp. 251, 1–10 (2007) ).

Malik, S ., Rochas, C. & Guenet, J. M. Syndiotactic polystyrene/naphthalene intercalates: preparing thermoreversible fibrillar gels from a solid solvent. Macromolecules 38, 4888–4893 (2005) ).

Daniel, C ., Alfano, D ., Guerra, G. & Musto, P. Evaluation of the amount and composition of the polymer-rich and polymer-poor phases of syndiotactic polystyrene gels with binary solvent mixtures. Macromolecules (2003) ;36: 5742–5750.

Daniel, C ., Alfano, D ., Guerra, G. & Musto, P. Physical gelation of syndiotactic polystyrene in the presence of large molar volume solvents induced by volatile guests of clathrate phases. Macromolecules 36, 1713–1716 (2003) ).

Kobayashi, M. & Kozasa, T. Conformational Ordering Process on Physical gelation of syndiotactic polystyrene/solvent systems revealed by time-resolved infrared spectroscopy. Appl. Spectrosc. 47, 1417–1424 (1993) ).

Rudder, J. D ., Berghmans, H ., De Schryver, F. C ., Bosco, M. & Paoletti, S. Gelation mechanism of syndiotactic polystyrene in bromoform. Macromolecules 35, 9529–9535 (2002) ).

Shimizu, H ., Wakayama, T ., Wada, R ., Okabe, M. & Tanaka, F. Solvent effect on junction size in syndiotactic polystyrene physical gel. Polym. J. 37, 294–298 (2005) ).

Itagaki, H. & Mochizuki, J. Size and distribution of free volume in thermoreversible gels of syndiotactic polystyrene. Macromolecules 38, 9625–9630 (2005) ).

Munch, J. P ., Candau, S ., Herz, J. & Hild, G. Inelastic light scattering by gel modes in semi-dilute polymer solutions and permanent networks at equilibrium swollen state. Journal de Physique 38, 971–976 (1977) ).

Furukawa, H ., Horie, K ., Nozaki, R. & Okada, M. Swelling induced modulation of static and dynamic fluctuations in polyacrylamide gels observed by scanning microscopic light scattering. Phys. Rev. E 68, 031406 (2003) ).

Furukawa, H ., Kobayashi, M ., Miyashita, Y. & Horie, K. End-crosslinking gelation of poly(amide acid) gels studied with scanning microscopic light scattering. High Perform. Polym. 18, 837–847 (2006) ).

Nakatani, H ., Nitta, K ., Soga, K. & Takata, T. Synthesis and thermal properties of poly(styrene-co-4-methylstyrene) produced with syndiospecific metallocene catalysts. Polymer 38, 4751–4756 (1997) ).

Naga, N ., Kihara, Y ., Miyanaga, T. & Furukawa, H. Synthesis of organic−inorganic hybrid gels from siloxane or silsesquioxane and α,ω-nonconjugated dienes by means of a photo hydrosilylation reaction. Macromolecules 42, 3454–3462 (2009) ).

Kobayashi, M ., Yoshioka, T ., Imai, M. & Itoh, Y . Structural ordering on physical gelation of syndiotactic polystyrene dispersed in chloroform studied by time-resolved measurements of small angle neutron scattering (SANS) and infrared spectroscopy. Macromolecules 28, 7376–7385 (1995) ).

Gowd, EB ., Tashiro, K. & Ramesh, C. Structural phase transitions of syndiotactic polystyrene. Prog. Polym. Sci. (2009) ;34: 280–315.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Naga, N., Sakurai, T. & Furukawa, H. Structure and formation processes of syndiotactic-polystyrene or styrene-based copolymer-organic solvent gels studied using scanning microscopic light scattering. Polym J 47, 45–52 (2015). https://doi.org/10.1038/pj.2014.85

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.85

This article is cited by

-

Modification and thermal properties of syndiotactic-1,2-polybutadiene

Polymer Bulletin (2019)