Abstract

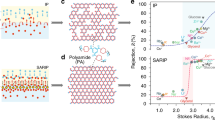

Highly permeable and selective membranes are desirable for energy-efficient gas and liquid separations. Microporous organic polymers have attracted significant attention in this respect owing to their high porosity, permeability and molecular selectivity. However, it remains challenging to fabricate selective polymer membranes with controlled microporosity that are stable in solvents. Here we report a new approach to designing crosslinked, rigid polymer nanofilms with enhanced microporosity by manipulating the molecular structure. Ultrathin polyarylate nanofilms with thickness down to 20 nm are formed in situ by interfacial polymerization. Enhanced microporosity and higher interconnectivity of intermolecular network voids, as rationalized by molecular simulations, are achieved by using contorted monomers for the interfacial polymerization. Composite membranes comprising polyarylate nanofilms with enhanced microporosity fabricated in situ on crosslinked polyimide ultrafiltration membranes show outstanding separation performance in organic solvents, with up to two orders of magnitude higher solvent permeance than membranes fabricated with nanofilms made from non-contorted planar monomers.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Gin, D. L. & Noble, R. D. Designing the next generation of chemical separation membranes. Science 332, 674–676 (2011).

Marchetti, P., Jimenez Solomon, M. F., Szekely, G. & Livingston, A. G. Molecular separation with organic solvent nanofiltration: a critical review. Chem. Rev. 114, 10735–10806 (2014).

Guiver, M. D. & Lee, Y. M. Polymer rigidity improves microporous membranes. Science 339, 284–285 (2013).

Freeman, B. D. Basis of permeability/selectivity tradeoff relations in polymeric gas separation membranes. Macromolecules 32, 375–380 (1999).

Park, H. B. et al. Polymers with cavities tuned for fast selective transport of small molecules and ions. Science 318, 254–258 (2007).

Du, N. et al. Polymer nanosieve membranes for CO2-capture applications. Nature Mater. 10, 372–375 (2011).

Carta, M. et al. An efficient polymer molecular sieve for membrane gas separations. Science 339, 303–307 (2013).

Song, Q. et al. Photo-oxidative enhancement of polymeric molecular sieve membranes. Nature Commun. 4, 1918 (2013).

Song, Q. et al. Controlled thermal oxidative crosslinking of polymers of intrinsic microporosity towards tunable molecular sieve membranes. Nature Commun. 5, 4813 (2014).

Rodenas, T. et al. Metal–organic framework nanosheets in polymer composite materials for gas separation. Nature Mater. 14, 48–55 (2014).

Karan, S., Jiang, Z. & Livingston, A. G. Sub-10 nm polyamide nanofilms with ultrafast solvent transport for molecular separation. Science 348, 1347–1351 (2015).

Karan, S. et al. Ultrafast viscous permeation of organic solvents through diamond-like carbon nanosheets. Science 335, 444–447 (2012).

Li, H. et al. Ultrathin, molecular-sieving graphene oxide membranes for selective hydrogen separation. Science 342, 95–98 (2013).

Nair, R. R. et al. Unimpeded permeation of water through helium-leak–tight graphene-based membranes. Science 335, 442–444 (2012).

Peng, Y. et al. Metal-organic framework nanosheets as building blocks for molecular sieving membranes. Science 346, 1356–1359 (2014).

Kim, H. W. et al. Selective gas transport through few-layered graphene and graphene oxide membranes. Science 342, 91–95 (2013).

Yaghi, O. M. et al. Reticular synthesis and the design of new materials. Nature 423, 705–714 (2003).

Kitagawa, S., Kitaura, R. & Noro, S.-i. Functional porous coordination polymers. Angew. Chem. Int. Ed. 43, 2334–2375 (2004).

El-Kaderi, H. M. et al. Designed synthesis of 3D covalent organic frameworks. Science 316, 268–272 (2007).

Côté, A. P. et al. Porous, crystalline, covalent organic frameworks. Science 310, 1166–1170 (2005).

Jones, J. T. A. et al. Modular and predictable assembly of porous organic molecular crystals. Nature 474, 367–371 (2011).

Tozawa, T. et al. Porous organic cages. Nature Mater. 8, 973–978 (2009).

Song, Q. et al. Porous organic cage thin films and molecular-sieving membranes. Adv. Mater. 28, 2629–2637 (2016).

Li, Y. S. et al. Controllable synthesis of metal-organic frameworks: from MOF nanorods to oriented MOF membranes. Adv. Mater. 22, 3322–3326 (2010).

Brown, A. J. et al. Interfacial microfluidic processing of metal-organic framework hollow fiber membranes. Science 345, 72–75 (2014).

Dobrzańska, L., Lloyd, G. O., Esterhuysen, C. & Barbour, L. J. Guest-induced conformational switching in a single crystal. Angew. Chem. Int. Ed. 45, 5856–5859 (2006).

McKeown, N. B. & Budd, P. M. Polymers of intrinsic microporosity (PIMs): organic materials for membrane separations, heterogeneous catalysis and hydrogen storage. Chem. Soc. Rev. 35, 675–683 (2006).

McKeown, N. B. et al. Polymers of intrinsic microporosity (PIMs): bridging the void between microporous and polymeric materials. Chem. Eur. J. 11, 2610–2620 (2005).

Carta, M. et al. Triptycene induced enhancement of membrane gas selectivity for microporous Tröger’s base polymers. Adv. Mater. 26, 3526–3531 (2014).

Ghanem, B. S., Swaidan, R., Litwiller, E. & Pinnau, I. Ultra-microporous triptycene-based polyimide membranes for high-performance gas separation. Adv. Mater. 26, 3688–3692 (2014).

McKeown, N. B. & Budd, P. M. Exploitation of intrinsic microporosity in polymer-based materials. Macromolecules 43, 5163–5176 (2010).

Budd, P. M. et al. Solution-processed, organophilic membrane derived from a polymer of intrinsic microporosity. Adv. Mater. 16, 456–459 (2004).

Budd, P. M. et al. Gas separation membranes from polymers of intrinsic microporosity. J. Membr. Sci. 251, 263–269 (2005).

Fritsch, D. et al. High performance organic solvent nanofiltration membranes: development and thorough testing of thin film composite membranes made of polymers of intrinsic microporosity (pims). J. Membr. Sci. 401–402, 222–231 (2012).

Tsarkov, S. et al. Solvent nanofiltration through high permeability glassy polymers: effect of polymer and solute nature. J. Membr. Sci. 423–424, 65–72 (2012).

Gorgojo, P. et al. Ultrathin polymer films with intrinsic microporosity: anomalous solvent permeation and high flux membranes. Adv. Funct. Mater. 24, 4729–4737 (2014).

Murphy, T. M. et al. Physical aging of layered glassy polymer films via gas permeability tracking. Polymer 52, 6117–6125 (2011).

Ichinose, I., Kurashima, K. & Kunitake, T. Spontaneous formation of cadmium hydroxide nanostrands in water. J. Am. Chem. Soc. 126, 7162–7163 (2004).

Karan, S. et al. Ultrathin free-standing membranes from metal hydroxide nanostrands. J. Membr. Sci. 448, 270–291 (2013).

Qian, H., Zheng, J. & Zhang, S. Preparation of microporous polyamide networks for carbon dioxide capture and nanofiltration. Polymer 54, 557–564 (2013).

Jimenez Solomon, M. F., Bhole, Y. & Livingston, A. G. High flux membranes for organic solvent nanofiltration (OSN)—interfacial polymerization with solvent activation. J. Membr. Sci. 423–424, 371–382 (2012).

Ameloot, R. et al. Interfacial synthesis of hollow metal–organic framework capsules demonstrating selective permeability. Nature Chem. 3, 382–387 (2011).

Chung, J. Y., Lee, J.-H., Beers, K. L. & Stafford, C. M. Stiffness, strength, and ductility of nanoscale thin films and membranes: a combined wrinkling–cracking methodology. Nano Lett. 11, 3361–3365 (2011).

Weber, J., Su, Q., Antonietti, M. & Thomas, A. Exploring polymers of intrinsic microporosity—microporous, soluble polyamide and polyimide. Macromol. Rapid Commun. 28, 1871–1876 (2007).

Robeson, L. M. The upper bound revisited. J. Membr. Sci. 320, 390–400 (2008).

Du, N., Park, H. B., Dal-Cin, M. M. & Guiver, M. D. Advances in high permeability polymeric membrane materials for CO2 separations. Energy Environ. Sci. 5, 7306–7322 (2012).

Abbott, L. & Colina, C. Polymatic: A Simulated Polymerization Algorithm (2013); https://nanohub.org/resources/17278

See Toh, Y. H., Lim, F. W. & Livingston, A. G. Polymeric membranes for nanofiltration in polar aprotic solvents. J. Membr. Sci. 301, 3–10 (2007).

Stafford, C. M. et al. A buckling-based metrology for measuring the elastic moduli of polymeric thin films. Nature Mater. 3, 545–550 (2004).

See Toh, Y. H. et al. In search of a standard method for the characterisation of organic solvent nanofiltration membranes. J. Membr. Sci. 291, 120–125 (2007).

Song, Q. et al. Zeolitic imidazolate framework (ZIF-8) based polymer nanocomposite membranes for gas separation. Energy Environ. Sci. 5, 8359–8369 (2012).

Abbott, L., Hart, K. & Colina, C. Polymatic: a generalized simulated polymerization algorithm for amorphous polymers. Theor. Chem. Acc. 132, 1–19 (2013).

Hart, K. E., Abbott, L. J., McKeown, N. B. & Colina, C. M. Toward effective CO2/CH4 separations by sulfur-containing pims via predictive molecular simulations. Macromolecules 46, 5371–5380 (2013).

Abbott, L. J., Hughes, J. E. & Colina, C. M. Virtual synthesis of thermally cross-linked copolymers from a novel implementation of polymatic. J. Phys. Chem. B 118, 1916–1924 (2014).

Abbott, L. J. & Colina, C. M. Porosity and ring formation in conjugated microporous polymers. J. Chem. Eng. Data 59, 3177–3182 (2014).

Sun, H. Force field for computation of conformational energies, structures, and vibrational frequencies of aromatic polyesters. J. Comput. Chem. 15, 752–768 (1994).

Frisch, M. J. et al. Gaussian 09. Revision A.02 (Gaussian, 2009).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Willems, T. F. et al. Algorithms and tools for high-throughput geometry-based analysis of crystalline porous materials. Micropor. Mesopor. Mater. 149, 134–141 (2012).

Pinheiro, M., Martin, R. L., Rycroft, C. H. & Haranczyk, M. High accuracy geometric analysis of crystalline porous materials. CrystEngComm 15, 7531–7538 (2013).

Acknowledgements

This work was financially supported by the Engineering and Physical Sciences Research Council (EPSRC, UK), 7th Framework Programme of the European Commission’s Marie Curie Initiative, NEMOPUR Project (M.F.J.-S.), Imperial College Junior Research Fellowship (Q.S.), and Royal Society University Research Fellowship (K.E.J.). The authors are grateful to P. R. J. Gaffney for assisting with monophasic reactions.

Author information

Authors and Affiliations

Contributions

M.F.J.-S. and A.G.L. conceived the idea. M.F.J.-S., Q.S. and A.G.L. designed the research. M.F.J.-S. and Q.S. performed experiments, including synthesis of materials and membranes, and characterization analyses. M.F.J.-S. carried out organic solvent nanofiltration. Q.S. performed gas permeation measurements. K.E.J. performed molecular simulations. M.M.-I. assisted with synthesis of PAR/PI nanofilm composite membranes. M.F.J.-S., Q.S. and A.G.L. wrote the manuscript. A.G.L. guided the project. All of the authors participated in the discussion and read the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 5186 kb)

Rights and permissions

About this article

Cite this article

Jimenez-Solomon, M., Song, Q., Jelfs, K. et al. Polymer nanofilms with enhanced microporosity by interfacial polymerization. Nature Mater 15, 760–767 (2016). https://doi.org/10.1038/nmat4638

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4638

This article is cited by

-

Sub-micro porous thin polymer membranes for discriminating H2 and CO2

Nature Communications (2024)

-

Ultrathin organosiloxane membrane for precision organic solvent nanofiltration

Nature Communications (2024)

-

Hydrogel particles for CO2 capture

Polymer Journal (2024)

-

Machine learning for membrane design in energy production, gas separation, and water treatment: a review

Environmental Chemistry Letters (2024)

-

Cascaded compression of size distribution of nanopores in monolayer graphene

Nature (2023)