Abstract

This study investigated the effect of intermittent lighting on the growth performances of a Scenedesmus dimorphus biofilm. Flashing light effect (FLE) is common in traditional suspended cultures of microalgae; yet, publications about this phenomenon, in the context of biofilm cultivation, are scarce. In this work we demonstrate that, thanks to intermittent illumination, it is possible for attached cultivations to fulfill FLE, improve photoefficiency and productivity as well as providing protection from photoinhibition using much lower flashing light frequencies than those usually required with suspended cultures. Medium frequency intermittent lighting (0.1 Hz) guaranteed excellent light integration resulting in 9.13 g m−2 d−1 biomass productivity, which was 8.9% higher than with continuous lighting. Results showed that a light fraction value of 0.5 always improved photoefficiency values as related to continuous light with a 118.8% maximum increase.

Similar content being viewed by others

Introduction

Microalgae are incredibly versatile unicellular organisms with a high potential for the production of biofuel and bioproducts. The biomass from microalgae can also be employed as a livestock feed, a biofertilizer, or as a soil amendment. The majority of information on algae cultivation available in the literature is related to suspended cultures, however algae cells can also be successfully grown as immobilized biofilm cultivation using a variety of reactor designs1,2,3,4,5,6. The biofilm cultivation method has some advantages on traditional suspended cultures such as higher aerial biomass productivity, reduced water use, simpler and cheaper harvest operations7,8,9. Regardless of the reactor design and the cultivation method employed, illumination remains the most important factor influencing the growth of microalgae10.

Continuous illumination is not strictly necessary to sustain cells growth. Consecutive cycles of light and darkness (intermittent illumination) can also be successfully employed to sustain the photosynthesis. In the context of suspended cultures, intermittent illumination, which happens especially at high biomass concentrations, is usually provided by the turbulent flow of the algae cells inside the reactors. Under these conditions the algae cells rapidly move from the surface of the reactor, where light intensity is very high, to the deeper portion of it, where light might be lower than the light compensation point (LCP). When the available light intensity is greater than the light saturation point (LSP), under intermittent lighting, with specific light fraction values (ε) and flash frequencies, microalgae cells may perform as if they were receiving an equivalent continuous illumination of lower intensity (CLeq). This phenomenon is known as “Flashing Light Effect” (FLE11). Many researches have demonstrated that when FLE occurred, the PE of algal cells grown under intermittent light may be higher than that of those grown with continuous light at PFD equal to that employed during the flash interval (TF). The term “Light Integration” (LI) is used to describe the situation where fluctuating or intermittent light is perceived as continuous, with intensity equal to the time-averaged PFD for the duration of one Light/Dark cycle time (TC). Therefore, when the growth performances of algae cells under intermittent light are the same as that obtainable under CLeq, LI has been obtained11,12. Because of this intermittent lighting and the related FLE can be considered useful tools for the protection of algae cells from physiological damage when subjected to high PFDs.

The effect of intermittent lighting on the growth performances of suspended microalgae cells has already been investigated by numerous authors, however, publications on the same topic in the context of microalgal biofilms are scarce. Due to the profound differences between the designs of the reactors employed for suspended cultures of microalgal cells and microalgal biofilms, the settings found to improve growth performances of suspensions of cells might not be appropriate with biofilm-based bioreactors. Moreover, because of the broad range of published optimal settings and sometimes contradictory results, it is difficult to extrapolate from the literature some general guidelines on how to employ intermittent lighting to take advantage of the FLE.

While in suspended cultures it is almost impossible for the algae cells to experience the same exact light exposure over time, that’s not the case when they are cultivated in the form of a biofilm. When fixed on the surface of a substrate, all of the algae cells are effectively illuminated (PFD > LCP) for up to ten days regardless of where they are located along the biofilm section13.

The cultivation of microalgae in the form of biofilms has attracted considerable interest in the present decade. The aim of this experiment was to investigate the influence of intermittent lighting on the growth performances of a Scenedesmus dimorphus attached cultivation. Various settings that define intermittent lighting were analyzed.

Results

Determination of saturating light intensity

A biofilm of Scenedesmus dimorphus algae cells was subjected to four different light intensities ranging from 80 to 400 μmol m−2 s−1. The three higher PFD values (133, 200 and 400 μmol m−2 s−1) resulted in not significantly different daily biomass productivity values (P = 0.05), higher than those induced by a PFD of 80 μmol m−2 s−1 (see Supplementary Fig. S1). Adopting a working light intensity of 400 μmol m−2 s−1 for both the CL and the intermittent light experiments, guaranteed us to be working well above LSP, determined to be at 150 μmol m−2 s−1 for Scenedesmus dimorphus6,14.

Preliminary assessment of the influence of broad range variation in flashing light frequency

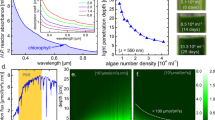

In Fig. 1 it is shown that intermittent lighting enhanced the PE of Scenedesmus dimorphus only at the highest tested frequency. Even though a significant improvement can be noticed over both continuous light and other intermittent light treatments (P = 0.05), the PE values are much lower than those obtained in the CLeq setup. This means that LI could not be obtained and at this point both flashing light frequency and light fraction values can be further refined.

The light fraction value was ε = 0.2 for all of the intermittent light setups. Made exception for the one under continuous light, every other setup received the same total amount of photons; made exception for “CLeq”, in every other setup the PFD was set to 400 μmol m−2 s−1. Error bars represent standard deviations. Different letters represent significantly different means at P = 0.05. CLeq, Equivalent continuous light delivering the same total amount of light as the various intermittent light setups (PFD = 80 μmol m−2 s−1); CL, Continuous Light at 400 μmol m−2 s−1; TC, cycle time.

The influence of different light fraction (ε) values

The light fraction, alone is not enough to characterize an intermittent light setup because the same value can be obtained with countless TC durations. Since in the previous set of experiments (see Results and discussion section; subsection Preliminary assessment of the influence of broad range variation in flashing light frequency), the frequency range delivering best PE value was defined by TF = 0.6 seconds, such value was now adopted as a measurement unit to test seven different ε values. Table 1 shows the different settings tested in this batch of experiments.

With cycle times in the range of seconds, intermittent illumination improved PE values as related to continuous light, regardless of the ε value considered (Fig. 2a). The efficiency of intermittent lighting on improving the PE of Scenedesmus d. was at first directly proportional to the increase in the duration of TD. (R2 = 0.997). Once TD started to last longer than TF (ε < 0.5) though, PE values dropped dramatically, but they were still higher than those recorded under continuous light conditions.

Effects of different light fraction values on average photoefficiency (a) and on Biomass productivity (b). The data are shown in relation to the total amount of light delivered under continuous light. The data are the means ± standard deviation of the values recorded during the first 72 hours following the beginning of the experiment. ε, light fraction.

Interestingly, given the same TC, the use of a longer TD resulted in slightly higher PE values. The improvement in PE due to intermittent lighting was not proportional to the reduction in the total amount of delivered light; for this reason lower ε values resulted in decreased biomass productivity in comparison to the continuous light setup (Fig. 2b). While PE values were always enhanced by the use of intermittent lighting as related to the CL setup, at the tested frequencies biomass productivity was only improved with ε ≥ 0.5 (Fig. 2b). Even so, as the light fraction value decreased below ε = 0.75, the biomass productivity started to decline; slowly at first, but quite rapidly at ε < 0.5. Focusing on the influence of intermittent illumination on the PE of an attached cultivation of Scenedesmus dimorphus, we selected ε = 0.5 and ε = 0.33 to be further investigated in following experiments.

The influence of flashing light frequency (refined)

Different TC durations at light fraction values of 0.5 and 0.33 induced different responses in terms of both PE and biomass productivity.

In terms of PE the algae cells responded quite differently to the two light fractions under investigation. Higher values were obtained at higher frequencies with ε = 0.33; however, at lower frequencies ε = 0.5 offered better performances (Fig. 3a). Moreover, only with ε = 0.5 intermittent lighting always increased PE values as compared to CL; for TF values between 10 seconds and 30 minutes, the use of ε = 0.33 caused the PE of Scenedesmus dimorphus to be up to 67% lower than that recorded under CL. The maximum PE value reached 5.45% with ε = 0.33 and TF = 0.1 seconds; this was more than 10% higher than the maximum PE value obtained using ε = 0.5 (TF = 5 seconds). Both ε = 0.33 and ε = 0.5 produced not significantly different PE values (P = 0.05) using TF durations between 0.4 and 0.8 seconds as well as with the traditional day/night setup.

(a) average photoefficiency, (b) average biomass productivity. Data collected during 72 hours from the beginning of the experiment have been averaged, error bars show standard deviations. Php = traditional night/day photoperiod (12 hours of darkness, 12 hours of light for ε = 0.5 and 18 hours of darkness, 8 hours of light for ε = 0.33 respectively. In both cases PFD = 400 μmol m−2 s−1); CL, Continuous Light at the same PFD used during TF (400 μmol m−2 s−1); CLeq, Equivalent continuous light delivering the same total amount of light as the various intermittent light setups (PFD = 200 and 133 μmol m−2 s−1 for ε = 0.5 and ε = 0.33 respectively); *no significant difference at P = 0.05 between the values recorded in the two tested ε values; #no significant difference at P = 0.05 among the values recorded using ε = 0.5.

Globally, faster flashing light frequencies resulted in higher light use efficiency. Considering the results shown in the Results and discussion section; subsection Preliminary assessment of the influence of broad range variation in flashing light frequency, this kind of response to the high frequency was expected. Anyway, even though ε = 0.33 allowed for higher PE values at the highest tested frequency, LI was obtained only with ε = 0.5 using TF durations between 0.1 and 0.6 seconds and between 1 and 5 seconds. Surprisingly, when TF lasted 0.8 seconds the biomass productivity of S. dimorphus was significantly lower (P = 0.05) and LI could not be obtained.

Biomass productivity values are generally higher using ε = 0.5 (Fig. 3b). The difference between the data recorded with the two tested light fraction values is lower at the extremes of the tested frequency range and higher when TF lasts between 5 and 30 seconds. Light integration could generally be obtained with TF values between 0.1 and 5 seconds, but only if ε = 0.5. The maximum biomass productivity reached 9.13 g m−2 d−1 using ε = 0.5 and TF = 5 seconds; this is 11% higher than under CLeq and more than 25% higher than the maximum biomass productivity obtained with ε = 0.33. Confirming the data from the previous set of experiments (see Results and discussion section; subsection The influence of different light fraction (ε) values and Fig. 2), inside the medium-high frequency range (TF between 0.4 and 0.8 seconds), both ε = 0.33 and ε = 0.5 did not induce significantly different results in terms of PE (P = 0.05); as the flashing light frequency further increased, using a lower light fraction value induced higher light use efficiency reaching a maximum of 5.45% (based on visible light; TF = 0.1 seconds).

Even though the use of intermittent illumination can improve the light use efficiency of S. dimorphus, as related to the CL setup, high PE values do not always translate into high net biomass yields. The increase of light use efficiency detected was not proportional to the reduction in total amount of delivered photons and ultimately resulted in lower biomass productivity values (Fig. 3b). Higher net biomass yields were obtained using TF and TD of equal duration.

Discussion

Numerous researchers already experimented with flashing light; however, it is not always easy to compare the results from different studies because these seem to change depending on the algae species considered and other set variables. Terry12 obtained LI with frequencies close to 1 Hz using Phaeodactylum tricornutum. Sforza et al.15 working with Nannochloropsis sp. reported that 1 Hz and 5 Hz flashing light frequencies with RL/D = 1/9 did not allow to obtain LI, but at higher flashing light frequencies that would be possible. Nedbal et al.16 found that, for Chlorella vulgaris, LI in terms of oxygen evolution rate was possible with TF shorter than 1 millisecond using RL/D of 1/5 and 1 (CLeq = 500 μmol m−2 s−1). Slower frequencies (TF between 50 microseconds and 200 milliseconds) still induced LI, but this time that happened in terms of growth rate, not oxygen evolution rate. In our case LI could only be achieved at much lower frequencies than those previously reported, and only when TD did not last longer than TF.

Bioreactors based on attached cultivation are drastically different from traditional ones where algae cells are cultivated suspended into a liquid environment. Since microalgae cells in biofilm bioreactors are fixed on the surface of a substrate, it is much harder to make use of intermittent lighting using sunlight as the sole illumination source without them suffering from photo-inhibition. One way to obtain intermittent lighting on a biofilm bioreactor could consist in cultivating the algae cells on top of a substrate that would constantly move from a dimly lit area to a brighter one. Revolving belts1, rotating spools2 and rotating disks17 are possible examples of how to achieve that. The ability to use lower flashing light frequencies, while still being able to improve PE values and protect algae cells from photoinhibition and physiologic damage, could translate into a lower energy input required to set the reactors’ modules in motion and obtain intermittent lighting. An increased ratio between the cultivated surface area and the reactor’s footprint might further increase the productivity of the system.

Intermittent lighting is defined by: (1) the duration of a complete Light/Dark cycle (TC) intended as the sum of the duration of the photoperiod (TF) and that of the scotoperiod (TD), and (2) by the ratio between TF and TD (RL/D). This last factor can also be expressed in terms of light fraction (ε) intended as the ratio between TF and TC. The duration of TC determines the frequency of the intermittent lighting, viz. the lower the TC value, the higher the flashing light frequency.

Theoretically, when aiming to modulate intermittent illumination, one might be tempted to merely consider the speed at which photosynthetic reactions occur. In this way the ideal frequency and ratio between the flash interval and the dark interval should keep pace with both the frequency and duration of the light-reactions and the light-independent reactions of photosynthesis, which usually occur in the range of milliseconds and seconds to hours respectively15,18. However, while some studies support this theory19,20, some others show that photoperiods as long as 0.1 seconds21, 2.02 ± 0.19 seconds22 or 5.8 minutes23 followed by dark intervals could still induce an increase in cell density, as compared to continuous light. The ability to use frequency values on a lower order of magnitude than those theoretically required to run the photosynthetic processes, while still inducing FLE, would be of great help to the mass cultivation of microalgae biofilms since lower energy input would be necessary to obtain them. Our choice of using a PFD of 400 μmol m−2 s−1 as a saturating light intensity is supported by Liu et al.6, Gris et al.14 and Chen et al.23. Liu et al.6 and Gris et al.14 reported that, regardless of the cultivation technique adopted, the growth rate of Scenedesmus sp. could not increase any further above PFD values of 150 μmol m−2 s−1 meaning that LSP had been reached. Chen et al.23 almost doubled the biomass productivity of the same microalgal species using intermittent illumination at 400 μmol m−2 s−1.

Interestingly though, when we used the same algal species, ε value, PFD, and flashing light frequency employed by Chen et al.23, intermittent lighting not only failed to increase biomass productivity as compared to the continuous light setup, but it also had a strong negative effect. Higher flashing frequencies, at the same light fraction value, performed better than both the CL and the Php setups, however, LI could not be reached. This may be due to the fact that microorganisms tend to behave differently when cultivated as a biofilm, instead of a suspended culture of cells. First of all, as mentioned previously, suspended cells experience light exposure differently from those in a biofilm. Secondly, the microenvironment surrounding the cells can be totally different; variations in nutrient concentration, distances among cells and possible interaction between them may induce different growth performances between freely dispersed cells and those growing attached to a substrate.

Another explanation to our inability to recreate the results of Chen et al.23 might have been offered by Crill24 and Pulz25 according to whom light-acclimation occurs on a timescale longer than light-inhibition. In his mini-review on photobioreactors, Pulz25 reported that while as much as 10 to 40 minutes are required for the algae cells to photoadapt to high PFDs, irreversible destruction can happen in a matter of a few minutes, with more than 50% damage after only 10 to 20 minutes. In photoautotrophic conditions, photons of light are the main source of energy for the growth of algae cells. When irradiance is too high the photosynthetic capacity is reduced because of photoinhibition and, if the same condition persist over time, it is usually followed by photodestruction of photosynthetic pigments26,27,28. Phytoplankton’s response to the exposure to high PFD (photoacclimation) is much slower than the rate at which light is absorbed and assimilate by the cell29. If algae cells are subjected to an inhibiting PFD, the net photosynthetic rate will quickly start to decline30. If light intensity is too low instead, it has been demonstrated, both with a simulated virtual photobioreactor31 and with cultures used for physiological research32 that microalgae cells’ logarithmic growth will not prevail. When the PFD is insufficiently high to support cells’ growth and no metabolizable organic carbon can be found in the medium, algae cells will metabolize their own cell components to obtain maintenance energy, thus leading to a decrease in cell weight33. In view of this it is of the utmost importance to identify the optimal ε value and flashing light frequency that allow microalgae cells to use energy light in the most efficient way.

In our case the algal cells experiencing TC of 29 seconds and 29 minutes (TF = 5.8 seconds and 5.8 minutes respectively) might not have been able to photo-adapt to the high light intensity they were receiving before the LED were switched off and in the meanwhile, they already suffered photoinhibition induced damage that ultimately resulted in low PE values. When TC lasted 24 hours instead, the algae cells were exposed to light for a few hours; such long photoperiod may have allowed them to adapt to the high light intensity, therefore they performed more efficiently than with TF in the range of seconds or minutes even though the same total amount of photons was delivered over 24 hours. This confirmed previous studies on the FLE reporting higher PE values at higher flashing light frequencies12,20,23,34,35 and also required us to investigate a range of different TC durations as well as light fraction values. Light fraction values of 0.5 and 0.33, resulted in photoefficiency of the algae cells respectively 118.8 and 143.3% higher than under continuous light. A flash duration of 5 seconds, with light fraction equal to 0.5, delivered a biomass productivity of 9.13 g m−2 d−1; 8.9% higher than under continuous light. Even though maximum photoefficiency was obtained with light fraction 0.33, light integration was only possible with light fraction of 0.5 (flash duration between 0.1 and 5 seconds). Such a limited improvement in biomass productivity in comparison with continuous lighting is not extremely encouraging for scale-up and industrial applications. However, we demonstrated on an attached cultivation of Scenedesmus dimorphus that it is possible to fulfill flashing light effect using intermittent lighting frequencies much lower than those required in suspended cultures. In addition to intermittent exposure to solar radiation, when outdoors, light dilution6 could also be employed to further improve the biomass productivity of a biofilm-based bioreactor. Liu et al.6 obtained aerial productivities up to 7 times higher than those of a conventional open pond when they increased the ratio between the cultivated surface and the land surface occupied by the reactor by a factor of 10. Additional research is still needed to verify whether is it possible to simultaneously take advantage of both the flashing light effect and the light dilution concept as a way to obtain on a contained surface high amounts of biomass easily harvestable. As mentioned previously, it is difficult to extrapolate from the literature some general guidelines on the use of intermittent light as a mean of improving the biomass productivity of microalgal biofilm cultivations. For this reason, future research will test the effect of intermittent light on other species cultivated in the form of a biofilm in order to verify whether the response to intermittent lighting in this context could be generalized.

Methods

Algal strain and inoculum preparation

The fresh water microalga Scenedesmus dimorphus used in this research was obtained from the Key laboratory of Biofuel (Qingdao, China) and maintained in BG11 medium. The inoculum cells for the attached cultivation, were multiplied inside glass bubbling columns (inner diameter is 5 cm containing 700 ml of BG11 medium) with aeration of 2% (v/v) CO2 enriched compressed air at the rate of 60 L min−1. The broth temperature was maintained at 22 ± 2 °C during cultivation. Light intensity at the surface of the column was 100 μmol m−2 s−1 (6000–6500 °K 28 w fluorescent lamps, NFLYZ28-T5, NVC, China). The algae cells were cultivated inside the glass columns for 7 days before being used to inoculate the biofilm reactor.

Biofilm cultivation system

Figure 4 shows diagrammatic and graphical representations of the experimental setup. The growth chamber for the biofilm cultivation consisted in a transparent glass box measuring, internally, 50 cm × 25 cm × 5 cm (0.5 cm thickness) and missing one of the two smallest faces. The reactor laid on a wide face, tilted about 4° on the longitudinal axis to allow gravitational flow of the growth medium across the cultivated surface. One small hole was opened on the floor plate of the reactor for drainage of the used growth medium and for gas exchange. During experiments, the open side of the box was sealed using cling film to guarantee an efficient delivery of the CO2 enriched compress air to the algae cells. The inside of the glass growth chamber was aerated with compressed air enriched with 1% CO2 (v/v) at a speed of 10 L min−1 so to deliver a non-limiting CO2 supply.

During the cultivation, the entire bench was wrapped with a black polyethylene film in order to block any unwanted environmental light from reaching the algae disks. (a) diagrammatic representation of the experimental set-up. The cultivation chamber is illuminated by an LED board connected to a controller that defines the intermittent light settings. A cooling panel connected to a thermostatic bath is installed on the back of the LED board. CO2 enriched air is inflated inside the cultivation chamber. Growth medium is not recycled. (b) Graphical representation of the experimental set-up: general view. (c) Detail of the biofilm reactor cultivation chamber and cooled LED board. The glass plate holding the algae disks can slide outside the cultivation chamber allowing the collection of samples. Cling film seals the cultivation chamber before and after collection of samples. (d) Detailed section view. The glass plate offers a rigid support to the filter paper wetted by the medium. This flows by gravity from right to left and moves upwards by capillary action through the nitrocellulose membrane providing water and nutrients to the algae cells.

A glass plate (20 cm × 45 cm) was positioned inside the glass box as a support for the attached cultivation. A polyurethane pipe (0.4 cm inner diameter) was fitted on the top brim of the support plate to act as the medium distributor. The support glass plate and the polyurethane pipe were both covered by one sheet of common filter paper. The nutrient medium was delivered with a submersible pump from an Erlenmeyer flask. During the cultivation of the biofilm, BG11 medium dripped between the support glass plate and the filter paper reaching the algae cells by capillary action. The flow rate of the culture medium was carefully regulated at 30.4 ± 4.5 ml h−1. The amount of BG11 delivered to the growth chamber was kept low enough to prevent any visible wash-off of the cultivated cells from the biofilm. In order to maintain the nutrients level constant during the cultivation, the effluent medium was discarded directly without any recirculation.

Fifteen LED strips (12 v, 6000-6500K; Shenzhen GreeThink Electronic Co., Ltd.) were installed on a 50 × 25 × 0.3 cm glass plate. The light unit was positioned above and parallel to the growth chamber (Fig. 4c); light intensity was regulated by adjusting the distance between the light panel and the cultivated surface. Intermittent lighting was provided by connecting the LEDs to a digital time relay (DH48S-S, Shanghai OFO Electrical Co., LTD). In order to prevent the LEDs from overheating, the glass plate holding the LEDs was connected to a cooling system (Fig. 4). The fluid circulating inside the cooling system was maintained at a temperature of 17 ± 0.5 °C by means of a recycling thermostatic bath (DL-4005, Ningbo Haishu Sklon Electronic Instrument Co., Ltd., China).

Cellulose acetate/nitrate membranes (pore size 0.45 μm) were inoculated via filtration of a determined amount of suspended cells from the bubbling column. The cells gathered onto the cellulose acetate/nitrate membrane formed an algal ‘disk’ with 12.3 ± 0.5 cm2 of footprint and approximately 9 g m−2 dry biomass inoculum density. Multiple algae ‘disks’ were put on the filter paper arranged close one to another in 6 rows and 3 columns leaving an empty space of equal distance toward the edges of the support plate (Fig. 4d).

The air temperature inside the glass box was 22 ± 2 °C. During the cultivation of cells, the entire bench holding the growth chamber and the light panel was wrapped with a black polyethylene film in order to block any unwanted environmental light from reaching the algae disks. No obvious contaminations were found during each batch of experiment (72 hours).

Determination of a saturating photon flux density

Given the employed light source, the highest PFD we could reach without causing condensation on the inner surface of the growth chamber was 400 μmol m−2 s−1. Condensation inside the roof of the growth chamber would have created big drops of water that could both alter the light distribution on the cultivated surface and suddenly detach washing cells off of the algal disks. Four sets of “algal disks” were subjected for 72 hours to PFD levels of 80, 133, 200 and 400 μmol m−2 s−1 respectively and the biomass productivities (referred to the cultivated surface area) were then compared to determine whether the LSP had been reached. Such light intensities corresponded respectively to those employed with intermittent light at ε = 0.2; ε = 0.33; ε = 0.5 and ε = 1 with 400 μmol m−2 s−1 during the flash interval. PFDs were measured with a light meter (LI-250A, LI-COR, Inc., US.) equipped with a quantum sensor.

Preliminary assessment of the influence of broad range variation in flashing light frequency

We refined the intermittent light settings starting from those employed by Chen et al.23. In an experiment on forced light/dark circulation of a suspended culture of Scenedesmus dimorphus they concluded that with ε = 0.2 and cycle time ≈ 29 minutes it was possible to almost double the biomass productivity as compared to a conventional open pond. Other authors also agree that TD should last longer than TF for FLE to take place12,14,20,35. As a preliminary test, the ratio between the flash interval (TF) and the dark interval (TD; RL/D) was set to 1/4 with TF = 5.8 minutes as in Chen et al.23. Given the same RL/D, other employed TF values were in the range of milliseconds (TF = 600 milliseconds), seconds (TF = 5.8 seconds) and hours (TF = 4.8 hours) respectively. Due to technical limits of the timer employed and given the chosen RL/D, it was not possible to test cycle times shorter than 3 seconds. Since RL/D and PFD were set constant among the four tests, they all received the same photon flux and illumination time over the course of 24 hours.

The influence of light fraction values

S. dimorphus cells were subjected to 7 different light fraction values in order to verify the influence of different TD durations on biomass productivity and PE. The employed TD were multiples of TF. Reciprocal RL/D values were also tested to verify whether, given the same TC, the cells would perform best being subjected to a longer TD12,14,20,35 or to a longer TF. PFD was set to 400 μmol m−2 s−1. Table 1 describes in better detail the settings tested in this batch of experiments.

The influence of intermittent light frequency values

The effect of different flashing light frequencies on the growth performances of Scenedesmus dimorphus was investigated.

The data recorded under intermittent illumination were compared with those obtained from three other experimental setups. The first one was provided with continuous light at the same PFD as for the flash interval in the intermittent lighting setups; the second and the third one received the same total amount of photons as the flashing light experiments, but in the form of: 1) a traditional night/day lighting regime (PFD of 400 μmol m−2 s−1; Php), and 2) of time-averaged light intensity (CLeq) respectively. The comparison with samples receiving CLeq was necessary to determine whether LI could be achieved or not. Table 2 describes in better detail the characteristics of the intermittent lighting tested in this batch of experiments.

All the experiments were performed in triplicate to reduce sampling errors and ensure repeatability.

Biomass yield and biomass productivity of biofilm cultivation

Biomass yield and biomass productivity of biofilm cultivation were measured according to Liu et al.6. Three samples were removed from random position inside the growing chamber. The first set of samples was collected twenty-four hours after the lights had been switched-on. After that, collection of samples was carried out every twelve hours until the end of the experiment (72 hours after the lights had been first switched-on).

Photoefficiency

Photoefficiency, based on visible light, was obtained as follows:

Where the energy contained in the net biomass production (EB) and the energy delivered with light (EL) were calculated based on the following: the energy contained in one gram of unstressed dried biomass, usually amounts to 20–23 kJ36 (we considered it to be 20 kJ g−1); 48% of the total solar radiation falls into the range of visible light37; in average, one mole of visible photons contains 217 kJ of energy36.

Statistical analysis

The results are reported as average ± standard deviation. Single factor analysis of variance (ANOVA) was used to ascertain significant differences in biomass yield, biomass productivity or photosynthetic efficiency. Tukey’s range test followed ANOVA to determine significant differences among treatments. The level of statistical significance was P < 0.05. The Microsoft Excel Data Analysis ToolPak (Microsoft Corporation, 2013) was used for all statistical analysis.

Additional Information

How to cite this article: Toninelli, A. E. et al. Scenedesmus dimorphus biofilm: Photoefficiency and biomass production under intermittent lighting. Sci. Rep. 6, 32305; doi: 10.1038/srep32305 (2016).

References

Gross, M., Henry, W., Michael, C. & Wen, Z. Development of a rotating algal biofilm growth system for attached microalgae growth with in situ biomass harvest. Bioresour. Technol. 150, 195–201 (2013).

Christenson, L. B. & Sims, R. C. Rotating algal biofilm reactor and spool harvester for wastewater treatment with biofuels by-products. Biotechnol. Bioeng. 109, 1674–1684 (2012).

Johnson, M., Villani, T. S., Azmat, A., Simon, J. E. & Both, a. J. Evaluation of algal biomass production on vertical aeroponic substrates. Algal Res. 10, 240–248 (2015).

Zhuang, L. L., Hu, H. Y., Wu, Y. H., Wang, T. & Zhang, T. Y. A novel suspended-solid phase photobioreactor to improve biomass production and separation of microalgae. Bioresour. Technol. 153, 399–402 (2014).

Blanken, W. et al. Biofilm growth of Chlorella sorokiniana in a rotating biological contactor based photobioreactor. Biotechnol. Bioeng. 111, 2436–2445 (2014).

Liu, T. et al. Attached cultivation technology of microalgae for efficient biomass feedstock production. Bioresour. Technol. 127, 216–222 (2013).

Boelee, N. C., Temmink, H., Janssen, M., Buisman, C. J. N. & Wijffels, R. H. Nitrogen and phosphorus removal from municipal wastewater effluent using microalgal biofilms. Water Res. 45, 5925–5933 (2011).

Zamalloa, C., Boon, N. & Verstraete, W. Combination of chemical biological flocculation and microalgae biofilm growth for decentralized sewage treatment. Commun. Agric. Appl. Biol. Sci. 77, 145–149 (2012).

Yin, S., Wang, J., Chen, L. & Liu, T. The water footprint of biofilm cultivation of Haematococcus pluvialis is greatly decreased by using sealed narrow chambers combined with slow aeration rate. Biotechnol. Lett. 37, 1819–1827 (2015).

Kitaya, Y. et al. Effects of temperature, photosynthetic photon flux density, photoperiod and O2 and CO2 concentrations on growth rates of the symbiotic dinoflagellate, Amphidinium sp. J. Appl. Phycol. 20, 737–742 (2008).

Weller, S. & Frank, J. Photosynthesis in Flashing Light. J. Phys. Chem. 45, 1359–1373 (1941).

Terry, K. L. Photosynthesis in modulated light: quantitative dependence of photosynthetic enhancement on flashing rate. Biotechnol. Bioeng. 28, 988–995 (1986).

Wang, J., Liu, J. & Liu, T. The difference in effective light penetration may explain the superiority in photosynthetic efficiency of attached cultivation over the conventional open pond for microalgae. 1–12 10.1186/s13068-015-0240-0 (2015).

Gris, B., Morosinotto, T., Giacometti, G. M., Bertucco, A. & Sforza, E. Cultivation of Scenedesmus obliquus in photobioreactors: effects of light intensities and light-dark cycles on growth, productivity, and biochemical composition. Appl. Biochem. Biotechnol. 172, 2377–2389 (2014).

Sforza, E., Simionato, D., Giacometti, G. M., Bertucco, A. & Morosinotto, T. Adjusted light and dark cycles can optimize photosynthetic efficiency in algae growing in photobioreactors. PLoS One 7 (2012).

Nedbal, L., Tichý, V., Xiong, F. & Grobbelaar, J. U. Microscopic green algae and cyanobacteria in high-frequency intermittent light. J. Appl. Phycol. 8, 325–333 (1996).

Sebestyén, P. et al. ALGADISK – Novel algae-based solution for CO2 capture and biomass production. in (2014).

Carvalho, A. P., Silva, S. O., Baptista, J. M. & Malcata, F. X. Light requirements in microalgal photobioreactors: An overview of biophotonic aspects. Appl. Microbiol. Biotechnol. 89, 1275–1288 (2011).

Vejrazka, C., Janssen, M., Streefland, M. & Wijffels, R. H. Photosynthetic efficiency of Chlamydomonas reinhardtii in flashing light. Biotechnol. Bioeng. 108, 2905–2913 (2011).

Kok, B. In Algal cultures - From laboratory to pilot plant (ed. Burlew, B. ) 63–158 (Carnegie Institution of Washington Publication 600, 1953).

Xue, S., Su, Z. & Cong, W. Growth of Spirulina platensis enhanced under intermittent illumination. J. Biotechnol. 151, 271–277 (2011).

Fathurrahman, L., Hajar, a. H. S., Sakinah, D., Nurhazwani, Z. & Ahmad, J. Flashing light as growth stimulant in cultivation of green microalgae, Chlorella sp. utilizing airlift photobioreactor. Pakistan J. Biol. Sci. 16, 1517–1523 (2013).

Chen, Y. et al. Forced light/dark circulation operation of open pond for microalgae cultivation. Biomass and Bioenergy 56, 464–470 (2013).

Crill, P. A. The photosynthesis-light curve: A simple analog model. J. Theor. Biol. 64, 503–516 (1977).

Pulz, O. Photobioreactors : Production systems for phototrophic microorganisms. Appl. Microbiol. Biotechnol. 57, 287–293 (2001).

Kok, B., Gassner, E. S. & Rurainski, H. J. Photoinhibition of chloroplast reactions. Photochem. Photobiol. 4, 215–227 (1965).

Satoh, K. Mechanism of photoinactivation in photosynthetic systems I. The dark reaction in photoinactivation. Plant cell Physiol. 11, 15–27 (1970).

Powles, S. B. Photoinhibition of Photosynthesis Induced by Visible Light. Annu. Rev. Plant Physiol. 35, 15–44 (1984).

Camacho, R. F., García Camacho, F., Fernández Sevilla, J. M., Chisti, Y. & Molina Grima, E. A mechanistic model of photosynthesis in microalgae. Biotechnol. Bioeng. 81, 459–473 (2003).

Harris, G. P. & Piccinin, B. B. Photosynthesis by natural phytoplankton populations. Arch. Hydrobiol. 80, 405–457 (1977).

Sato, T., Yamada, D. & Hirabayashi, S. Development of virtual photobioreactor for microalgae culture considering turbulent flow and flashing light effect. Energy Convers. Manag. 51, 1196–1201 (2010).

Wahidin, S., Idris, A. & Shaleh, S. R. M. The influence of light intensity and photoperiod on the growth and lipid content of microalgae Nannochloropsis sp . Bioresour. Technol. 129, 7–11 (2013).

Degen, J., Uebele, a., Retze, a., Schmid-Staiger, U. & Trösch, W. A novel airlift photobioreactor with baffles for improved light utilization through the flashing light effect. J. Biotechnol. 92, 89–94 (2001).

Boelee, N. C. et al. Nutrient removal and biomass production in an outdoor pilot-scale phototrophic biofilm reactor for effluent polishing. Appl. Biochem. Biotechnol. 172, 405–422 (2014).

Phillips, J. Jr., Myers, J., Phillips, J. N. & Myers, J. Growth Rate of Chlorella in Flashing Light. Plant Physiol. 29, 152–161 (1954).

Tredici, M. R. Photobiology of microalgae mass cultures: understanding the tools for the next green revolution. Biofuels 1, 143–162 (2010).

Moheimani, N. R. & Parlevliet, D. Sustainable solar energy conversion to chemical and electrical energy. Renew. Sustain. Energy Rev. 27, 494–504 (2013).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (41276144, 31572637) and Bioenergy R&D Center of ENN Sci & Tech Co. Ltd.

Author information

Authors and Affiliations

Contributions

A.E.T. and T.L. conceived the work. A.E.T. performed all the experiments. A.E.T., T.L. and J.W. interpreted the results obtained and contributed to writing the manuscript. M.L. and H.W. involved in the experimental design and results discussion. All of the authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Toninelli, A., Wang, J., Liu, M. et al. Scenedesmus dimorphus biofilm: Photoefficiency and biomass production under intermittent lighting. Sci Rep 6, 32305 (2016). https://doi.org/10.1038/srep32305

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep32305

This article is cited by

-

Microalgae Biofilm and Bacteria Symbiosis in Nutrient Removal and Carbon Fixation from Wastewater: a Review

Current Pollution Reports (2022)

-

A concise review on the cultivation of microalgal biofilms for biofuel feedstock production

Biomass Conversion and Biorefinery (2022)

-

Studies on the Attached Cultivation of Filamentous Oleaginous Microalga Tribonema minus

Journal of Ocean University of China (2020)

-

Start-up of a nutrient removal system using Scenedesmus vacuolatus and Chlorella vulgaris biofilms

Bioresources and Bioprocessing (2019)

-

Microfluidic techniques for enhancing biofuel and biorefinery industry based on microalgae

Biotechnology for Biofuels (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.