Abstract

Soft magnetic films with a wide-range tunable ferromagnetic resonance frequency are suitable for miniaturization and multifunctionalization of microwave integrated circuits. Fabrication of these films for high-frequency applications is usually complicated and difficult. We demonstrate a simple method to fabricate patterned FeNi soft magnetic strip films by magnetron sputtering and photolithography. Films prepared by this method exhibits a tunable in-plane uniaxial magnetic anisotropy (IPUMA) for different strip widths and gaps. As the strip widths changing from 500 to 2 μm, the IPUMA field increases monotonically from 2.2 to 576 Oe and resonance frequency from 1 to 10.6 GHz(which covers four microwave bands, including the L,S,C and X bands) respectively. This ultra-wide-range adjustability of resonance frequency can be attributed to shape anisotropy of strips. Considering that FeNi alloy has relatively low magnetocrystalline anisotropy, so a wider adjustable range of resonance frequency could be obtained using materials with stronger magnetocrystalline anisotropy.

Similar content being viewed by others

Introduction

With rapid developments of wireless communications and high-frequency technologies in gigahertz range1, soft magnetic films materials have been widely studied in various fields such as radio-frequency2, electromagnetic compatibility devices3, electromagnetic interference problems and microwave absorption4,5,6. Resonance frequency (fr) is the most important factor which affects applications of these soft magnetic films. To obtain a higher fr and its wider tunable range are the primary objectives for many studies4,7,8. Based on the Kittle equation  , there are two factors to determine the fr of the films, the saturation magnetization (Ms) and anisotropy filed (Hk) also called the in-plane uniaxial magnetic anisotropy (IPUMA) field6. In comparison with soft magnetic ferrites, magnetic metals have larger Ms, thus various magnetic metals and alloys are used in high-frequency field7,6,9. Mainly, three anisotropies can be used to adjust the IPUMA of metal-soft-magnetic films. The first is the magnetocrystalline anisotropy. There are several methods to adjust this anisotropy, using different substrates10, oblique magnetron sputtering8,11, applying a magnetic field during deposition12 and magnetic field annealing13. All these methods require that the materials have strong magnetocrystalline anisotropy and sometimes right lattice constants. The second is the stress anisotropy of the film, which can be used to yield tunable fr from 6.3 to 12.96 GHz7,14. The third is the shape anisotropy, such as patterned films with different strips6,10,15,16,17,18,19. The method works for materials either with or without strong magnetocrystalline anisotropy or stress anisotropy. Thus, the shape anisotropy is one of the most effective and versatile methods to tune the IPUMA of metal soft magnetic films. The shape anisotropy can usually be realized as the patterned strip films.

, there are two factors to determine the fr of the films, the saturation magnetization (Ms) and anisotropy filed (Hk) also called the in-plane uniaxial magnetic anisotropy (IPUMA) field6. In comparison with soft magnetic ferrites, magnetic metals have larger Ms, thus various magnetic metals and alloys are used in high-frequency field7,6,9. Mainly, three anisotropies can be used to adjust the IPUMA of metal-soft-magnetic films. The first is the magnetocrystalline anisotropy. There are several methods to adjust this anisotropy, using different substrates10, oblique magnetron sputtering8,11, applying a magnetic field during deposition12 and magnetic field annealing13. All these methods require that the materials have strong magnetocrystalline anisotropy and sometimes right lattice constants. The second is the stress anisotropy of the film, which can be used to yield tunable fr from 6.3 to 12.96 GHz7,14. The third is the shape anisotropy, such as patterned films with different strips6,10,15,16,17,18,19. The method works for materials either with or without strong magnetocrystalline anisotropy or stress anisotropy. Thus, the shape anisotropy is one of the most effective and versatile methods to tune the IPUMA of metal soft magnetic films. The shape anisotropy can usually be realized as the patterned strip films.

Patterned films with narrow strip arrays in a periodic structure that are used to control the IPUMA have been studied by many groups. Perrin et al. shifted fr from 1 to 3 GHz for the amorphous CoZrNb and CoFeMoMnSiB strip patterned films which are fabricated by magnetron sputtering on a Kapton substrate16. Zhuang et al. obtained resonance frequency range of 1 to 5.3 GHz for the micropatterned FeNi films prepared by electroplating and lithography17. Han et al. studied the magnetization reversal mechanism of FeTa patterned strip films in 20136. All previous studies indicate that shape anisotropy plays a key role in changing the resonance frequency of the soft magnetic patterned films. It is well known that the FeNi alloy has very low magnetocrystalline anisotropy17, thus it is an ideal system to adjust the IPUMA only by shape anisotropy. We studied micropatterned strip FeNi films (Ni8Fe2) fabricated by photolithography and magnetron sputtering with different shape anisotropies. An ultra-large range from 1 to 10.6 GHz of fr were achieved in this work.

Results

Micrographs, thickness and roughness of the FeNi strip array film

Different strips were fabricated to yield different shape anisotropies. The diagram and a typical scanning electron microscopy (SEM) image of the strip arrays are shown in Fig. 1a,b, respectively. The length(L) and thickness(t) of the FeNi strips are fixed as 5000 μm and 120 nm repectively. The strip width (W) and gap size (d) range from 2 to 500 μm to obtain different demagnetization fields. Detailed data sets are provided in Tables 1 and 2. There are two sample sets. For the frist one, d is fixed while W varies. For the second one, d and W vary simultaneously with a constraint d = W. The SEM micrograph shows that strips are parallel and no one is broken.

Several instruments such as a step profiler, SEM and TEM were used to measure the film thickness of nanometers. A step profiler can measure the film thickness when the film has clear steps. SEM mainly observes the sample surface, so the film thickness can be measured when the film cross section is prepared. TEM can be used to study very thin films. It is difficult to obtain the exact thickness and roughness of the single layers buried in a multilayer film by conventional methods without serious damages. Fortunately, neutrons can penetrate deep into the matter, which makes it a unique probe for investigating bulk materials. We firstly investigated the total thickness of prepared Ta/FeNi/Ta via a step profiler. Fig. 1c shows a typical measurement result of the step profile for the FeNi strip film. The strip W and d are 15 and 30 μm respectively and the total thickness is 130 nm. The results are consistent with the original design(Ta/FeNi/Ta:5 nm/120 nm/5 nm).

Figure 1d shows the atomic force microscopy (AFM)image of the Ta/FeNi/Ta film, its surface undulation is about 2 nm based on a linear sweep model, whereas the root mean square roughness is 0.9 nm. The inner layer thickness and roughness of the Ta/FeNi/Ta multilayer film were studied by neutron reflectrometer at the China Mianyang Research Reactor (CMRR). Figure 2 shows a typical neutron reflectivity (R)–scatter vector (Q) curve and scattering length density (SLD, inset figure) of the Ta/FeNi/Ta film. The experimental data, error bar and fitting result are shown as the black dots, green sold line and red line, respectively. R decreased rapidly with Q. Nice neutron peaks indicate that the sample is well prepared. The SLD profile can be obtained by fitting the reflectivity data. As the neutrons see there are three layers of Ta/FeNi/Ta on the silicon substrate with thicknesses of 4, 118 and 4 nm respectively. The SLD profile also shows that the upper surface roughness of the FeNi film(interface A in Fig. 2) is about 2 nm, whereas that of the lower surface is about 1 nm (interface B in Fig. 2). The main reason for this phenomenon is due to accumulation of the surface roughness. The magnetic moment is parallel to the plane of the magnetic film for strong shape anisotropy cases, thus the magnetic moments near the surface will be difficult to rotate due to the surface roughness.

FeNi film with various strip widths (W)

Static magnetic properties of the patterned FeNi strip film

To obtain different shape factor (N) of the magnetic strips, we changed the strip widths W as gap size d fixed to 30 μm. Based on the magnetism theory, N depends on the ratio between length (L) and W. Here, the length is always 5000 μm and W = 500, 150, 60, 30 and 15 μm.

Figure 3 shows a typical normalized magnetic hysteresis loop of the FeNi strip in two directions using vibrating sample magnetometer (VSM). The detailed measuring process is described in the section of Methods. All samples exhibit good soft magnetic properties. All samples have saturation magnetic fields of less than 10 Oe when the applied magnetic field is parallel to the long-axis of the strip as in Fig. 3a. However, when the applied magnetic fields are perpendicular to the long-axis of the strip, the saturation magnetic fields increase gradually from 5 to 300 Oe as W decreasing. Samples have very different saturation magnetic fields in different magnetization directions, which means that IPUMA is successfully induced through changing strip widths. To study IPUMA field in more detail, effective Hk are calculated from hysteresis loops and the results are listed in Table 1. Hk increases from 2.2 to 172.4 Oe when the width decreases from 500 to 15 μm, so it is a useful method to adjust the IPUMA field by changing N which is related to the demagnetization field20.

Dynamic magnetic properties of the patterned FeNi strip film

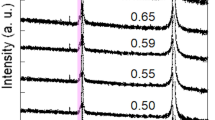

fr of the film depends on Ms and Hk. The static magnetic properties indicate that the Hk was adjusted successfully. Since the IPUMA field changes with the magnetic strip width, the dynamic magnetic properties of the FeNi strip films can be adjusted by changing the strip width. We investigated the dynamic magnetic properties for frequency ranges from 0.5 to 12 GHz. Figure 4 shows the typical real (μ′) and imaginary parts (μ′′) of the permeability of the patterned FeNi film with strip widths W = 500, 60, 30 and 15 μm. The experimental results are fitted to the Laudau-Liftshitz-Gilbert (LLG) equation. The resonance peak of the imaginary parts (μ′′) changes from 1 to 6.35 GHz as the W decreases from 500 to 15 μm. This means that fr decreases with W. Detailed results are given in Table 1. The real part(μ′) of the permeabilities are also shown in Fig. 4. μ′ decreases with the frequency, which is consistent with the result of 8. fr of FeNi strip films were adjusted easily by changing strip width.

FeNi films with different strip width W and gap d = W

Static and dynamic magnetic properties of patterned FeNi strip films

The above study indicates the significant influence of W to fr. Higher fr could be obtained for a narrower sample width which has a larger IPUMA field. In this section, We fabricated samples with W = d = 2, 5, 15, 30 μm. The length and thickness of the strips are 5000 μm and 120 nm, respectively. A stronger shape anisotropy is expected in this system, which would induce larger Hk and fr.

Figure 5a shows the in-plane normalized magnetic hysteresis loops of the FeNi strip films. All saturation magnetic fields are also less than 10 Oe when the applied magnetic field is parallel to the long-axis of the strip. When the applied magnetic field is perpendicular to the long-axis of the strip, the magnetic saturation field reaches 1000 Oe for W = 2 μm. The calculated Hk change from 87.8 to 576 Oe shown in Table 2. A wider range tunable IPUMA field was obtained by decreasing the strip W and d of the strips. Based on the Kittle equation, a higher fr of the soft magnetic film can be obtained for a larger IPUMA field. Figure 5b shows the permeability spectra of the four samples for W = 30, 15, 5, 2 μm. The resonance peaks of μ′′ are located at 2.84 GHz, 5.56 GHz, 8.45 GHz and 10.6 GHz for W = 30, 15, 5 and 2 μm, respectively (see Table 2). As for the VSM results, fr changes in the same way with Hk, which is due to the shape anisotropy. This indicates that shape anisotropy is crucial to adjust fr from 2.84 to 10.6 GHz. In comparation with the previous results, an ultra-wide range of resonance frequency shift from 2.84 to 10.6 GHz is obtained by changing IPUMA which is originated from the shape anisotropy in magnetic strips. Wider fr ranges can be obtained by adjusting the strip width more. This kind of adjustment might induce the shape anisotropy to cooperate or compete with the other anisotropies, such as magnetocrystalline and stress anisotropies.

Discussion

We found the IPUMA is induced mainly by shape anisotropy which can be changed for different W and d. Ultra-large ranges of fr from 1 to 10.6 GHz have been achieved. We further applied the bi-anisotropy theory to simulate the measured magnetic spectrum5. The magnetic resonance frequency can be expressed as  , where Ha1 and Ha2 are the effective anisotropy field when the magnetization deviates from the easy axis in the the easy and hard plane, respectively. So it is convenient to change the fr by adjusting Ha1 and Ha2 over a wide range. For the magnetic thin films, Ha1 equals to in-plane the effective anisotropy field Hk and Ha2 the out-of-plane Hk and there is relation Ha2 = Ha1 + 4πMs. Thus the ferromagnetic resonance frequency of the patterned strip films can be obtained as:

, where Ha1 and Ha2 are the effective anisotropy field when the magnetization deviates from the easy axis in the the easy and hard plane, respectively. So it is convenient to change the fr by adjusting Ha1 and Ha2 over a wide range. For the magnetic thin films, Ha1 equals to in-plane the effective anisotropy field Hk and Ha2 the out-of-plane Hk and there is relation Ha2 = Ha1 + 4πMs. Thus the ferromagnetic resonance frequency of the patterned strip films can be obtained as:

The permeability can be calculated theoretically by the Landau-Lifshitz-Gilbert equation21:

where α is the damping factor and, γ is gyromagnetic ratio.

All experimental data were fitted to Eqs (1) and (2) and the fitting results are given in Figs 4 and 5 (solid line). The damping factors (α) of different samples are listed in Tables 1 and 2. α changes from 0.1458 to 0.047 as strip shape changes, which is also indicated by the line width of the magnetic spectrum. Figure 6 shows the variation of Hk and fr with the shape factor N. Hk increased from 2.2 Oe to 576 Oe and fr increased from 1 GHz to 10.6 GHz, the net frequency shift Δ fr is 9.6 GHz, which, to our best knowledge, might be the widest tuning range for the metal soft magnetic film. Hk and fr exhibit the same trend, which indicates that an increase in fr results mainly from shape anisotropy. Different Hk and fr were observed as d changes. For W fixed as 30 μm and L 5000 μm, the measured resonance frequencies are 5.56 GHz for d = 15 μm and 6.35 GHz for d = 30 μm. The main reason is that coupling between strips decreases with d, which will lead to the increase of Hk. The strip W and d can be controlled by photolithography process, thus we can fabricate strips of different sizes easily, which means that different shape anisotropies or Hk could be controlled. fr range from 1 and 10.6 GHz has been achieved and a wider range might be reached in combination with other anisotropies.

In summary, patterned FeNi strip films were produced by traditional magnetron sputtering and photolithograph. The IPUMA field up to 576 Oe and ferromagnetic fr from 1 to 10.6 GHz were obtained, which covers four microwave bands of L, S, C and X bands. The magnetic anisotropy strongly depends on the shape anisotropy determined by the W and gap d. It is a simple method to adjust the static anisotropy and dynamic high frequency properties of the soft magnetic films with or without strong magnetocrystalline or stress. Furthermore, a wider tunable range of the resonance frequency could be obtained if other anisotropies as magnetocrystalline anisotropy and stress anisotropy are included.

Methods

Sample preparation

Patterned Ta/FeNi/Ta film with strip arrays were produced by magnetron sputtering and photolithography method. Fe8Ni2 target were used during magnetron sputtering. A photoresist layer was spin coated onto a silicon substrate, then contact optical lithography was applied to fabricate strips with different W and d. The W and d varied from 2 to 500 μm and 2 to 30 μm, respectively. We first deposit Ta/FeNi/Ta films onto the Silicon substrates with patterned photoresist, then we do direct-current magnetron sputtering with a base pressure lower than 1 × 10−4 Pa and Ar processing pressure of 0.4 Pa. The thickness of the FeNi layer is 120 nm. The seed and the capping layer are Ta with the same thickness of 5 nm. Patterned FeNi strips are produced by removing photoresist with acetone.

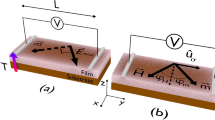

Measurement

Surface topographies were studied by SEM and AFM methods. The W, d and thickness of the patterned Ta/FeNi/Ta films were measured by a Dektak-XT step profiler. The thickness and roughness of the FeNi layer and Ta layer were measured by the Neutron reflectivity method at CMRR. A vibrating sample magnetometer (VSM, BKT-4500Z) was used to study the static magnetic properties of the FeNi films. Permeability spectra of the samples were measured in ranges between 100 MHz and 15 GHz, using the shorted micro-strip transmission-line perturbation method realized by a vector network analyzer (VNA, Agilent PNA8363B). All measurements were performed at room temperature.

Additional Information

How to cite this article: Ren, Y. et al. Patterned FeNi soft magnetic strips film with tunable resonance frequency from 1 to 10.6 GHz. Sci. Rep. 6, 31773; doi: 10.1038/srep31773 (2016).

References

Liu, Y., Chen, L., Tan, C. Y., Liu, H. J. & Ong, C. K. Broadband complex permeability characterization of magnetic thin films using shorted microstrip transmission-line perturbation. Review of Scientific Instruments 76, 063911 (2005).

Korenivski, V. & van Dover, R. B. Magnetic film inductors for radio frequency applications. Journal of Applied Physics 82, 5247–5254 (1997).

Seemann, K., Leiste, H. & Ziebert, C. Soft magnetic fecotan film cores for new high-frequency cmos compatible micro-inductors. Journal of Magnetism and Magnetic Materials 316, e879–e882 (2007).

Chai, G. et al. Adjust the resonance frequency of (co90nb10/ta)n multilayers from 1.4 to 6.5 ghz by controlling the thickness of ta interlayers. Applied Physics Letters 96, 012505 (2010).

Xue, D. S., Li, F. S., Fan, X. L. & Wen, F. S. Bianisotropy picture of higher permeability at higher frequencies. Chinese Physics Letters 25, 4120 (2008).

Han, X. M. et al. Tunable in-plane uniaxial anisotropy and the magnetization reversal mechanism of patterned high-frequency soft magnetic feta strips. Journal of Physics D-Applied Physics 46, 485004 (2013).

Li, S. et al. Driving ferromagnetic resonance frequency of fecob/pzn-pt multiferroic heterostructures to ku-band via two-step climbing: composition gradient sputtering and magnetoelectric coupling. Scientific Reports 4, 7393 (2014).

Li, C., Chai, G., Yang, C., Wang, W. & Xue, D. Tunable zero-field ferromagnetic resonance frequency from s to x band in oblique deposited cofeb thin films. Scientific Reports 5, 17023 (2015).

Yan, L. G. et al. Enhanced microwave absorption of fe nanoflakes after coating with sio2 nanoshell. Nanotechnology 21, 5 (2010).

Wang, Z. K. et al. Adjustable magnetic anisotropy and resonance frequency of patterned ferromagnetic films by laser etching. Journal of Alloys and Compounds 543, 197–199 (2012).

Fan, X. et al. In situ fabrication of co90nb10 soft magnetic thin films with adjustable resonance frequency from 1.3to4.9 ghz. Applied Physics Letters 92, 222505 (2008).

Ma, Y. G. & Ong, C. K. Soft magnetic properties and high frequency permeability in [coalo/oxide] multilayer films. Journal of Physics D: Applied Physics 40, 3286 (2007).

Shokrollahi, H. & Janghorban, K. Different annealing treatments for improvement of magnetic and electrical properties of soft magnetic composites. Journal of Magnetism and Magnetic Materials 317, 61–67 (2007).

Yu, Y. et al. Static and high frequency magnetic properties of fega thin films deposited on convex flexible substrates. Applied Physics Letters 106, 162405 (2015).

Ikeda, S., Nagae, T., Shimada, Y., Kim, K. H. & Yamaguchi, M. Micropatterned high permeability films with narrow bandwidth resonance loss for the band stop filter. Journal of Applied Physics 99, 08P507 (2006).

Perrin, G., Peuzin, J. C. & Acher, O. Control of the resonance frequency of soft ferromagnetic amorphous thin films by strip patterning. Journal of Applied Physics 81, 5166–5168 (1997).

Zhuang, Y., Vroubel, M., Rejaei, B., Burghartz, J. N. & Attenborough, K. Shape-induced ultrahigh magnetic anisotropy and ferromagnetic resonance frequency of micropatterned thin permalloy films. Journal of Applied Physics 99, 08C705 (2006).

Chen, X., Ma, Y. G. & Ong, C. K. Magnetic anisotropy and resonance frequency of patterned soft magnetic strips. Journal of Applied Physics 104, 013921 (2008).

Jamieson, B., O’Donnell, T., Kulkarni, S. & Roy, S. Shape-independent permeability model for uniaxially-anisotropic ferromagnetic thin films. Applied Physics Letters 96, 202509 (2010).

Fan, X. L. et al. Magnetic field-dependent shape anisotropy in small patterned films studied using rotating magnetoresistance. Scientific Reports 5, 9 (2015).

Gilbert, T. L. A phenomenological theory of damping in ferromagnetic materials. IEEE Trans. Magn 40, 3443–3449 (2004).

Acknowledgements

This work is supported by the NSF of China (Grant Nos 11304256 and 11505163), the Project of State Key Laboratory Cultivation Base for Non-metal Composites and Functional Materials (No. 14tdfk07), the Project of key laboratory of neutron physics, china academy of engineering physics (No. 2013BB04) and China Postdoctoral Science Foundation (No. 2016M592705).

Author information

Authors and Affiliations

Contributions

G.S. and S.P. designed the experiments, Y.R. performed the experiments, Y.R., X.L., Y.W., J.R., Y.Z., B.D. and H.Y. analyzed the results. All authors read and approved the final draft of the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Ren, Y., Li, X., Wang, Y. et al. Patterned FeNi soft magnetic strips film with tunable resonance frequency from 1 to 10.6 GHz. Sci Rep 6, 31773 (2016). https://doi.org/10.1038/srep31773

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep31773

This article is cited by

-

Improvement of high-frequency magnetic properties of CoFeB thin film using oblique deposition for spin wave electronic devices

Journal of Materials Science: Materials in Electronics (2024)

-

Magnetic properties study of spin pinned NiFe/FeMn/NiFe heterogeneous multilayer films with different NiFe thicknesses

Applied Physics A (2020)

-

Gap-dependent magnetic anisotropy and high-frequency property of micro-patterned NiFe film

Journal of Materials Science: Materials in Electronics (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.