Abstract

(Bi1−xLax)(Fe,Co)O3 multiferroic magnetic film were fabricated using pulsed DC (direct current) sputtering technique and demonstrated magnetization reversal by applied electric field. The fabricated (Bi0.41La0.59)(Fe0.75Co0.25)O3 films exhibited hysteresis curves of both ferromagnetic and ferroelectric behavior. The saturated magnetization (Ms) of the multiferroic film was about 70 emu/cm3. The squareness (S) (= remanent magnetization (Mr)/Ms) and coercivity (Hc) of perpendicular to film plane are 0.64 and 4.2 kOe which are larger compared with films in parallel to film plane of 0.5 and 2.5 kOe. The electric and magnetic domain structures of the (Bi0.41La0.59)(Fe0.75Co0.25)O3 film analyzed by electric force microscopy (EFM) and magnetic force microscopy (MFM) were clearly induced with submicron scale by applying a local electric field. This magnetization reversal indicates the future realization of high performance magnetic device with low power consumption.

Similar content being viewed by others

Introduction

Magnetic reversal using an electric field is a promising and future technology for multifunctional devices due to its lower power consumption. Multiferroic materials with magneto-electric effect, which simultaneously exhibit spontaneous polarization and magnetization, have been receiving greater attention for this system. BiFeO3 is a multiferroic material with a high ferroelectric Curie temperature (TC) of 1120 K and a high antiferromagnetic Neel temperature (TN) of 640 K. However, generally say, BiFeO3 films have a high leakage current density at room temperature1, so several methods such as substitution of atoms had been performed for reduction of the leakage current density and improvement of ferroelectric property of BiFeO3 films. For example, substitution of Er2, La3,4, or Sc5) for Bi, and substitution of Cr6,7, Mn8,9, or Ti10,11 for Fe. To apply magnetic devices of these BiFeO3 based films, improvement of their ferromagnetic property such as large saturation magnetization (Ms), large coercivity (Hc), and perpendicular magnetic anisotropy is more important. The substitution of atoms is also effective for the improvement of their ferromagnetic property. Suitable multiferroic materials with ferromagnetism with high Ms and ferroelectricity at room temperature, such as (Bi1−xBax)FeO3 powder12 have been reported. Multiferroic films with ferromagnetism and ferroelectricity at room temperature, such as (Bi1−xLax)FeO3 films13 and Bi(Fe,Co)O3 films14,15,16 also have been reported. However, the magnetic properties of the films were not sufficient for device application. As mentioned above, large Ms, large Hc, and perpendicular magnetic anisotropy are important. In our previous study, we succeeded to fabricate the highly qualified (Bi0.48Ba0.52)FeO3 films with ferromagnetism (Ms : 90 emu/cm3) and ferroelectricity17 by using a pulsed DC (direct current) reactive sputtering technique18. The Ms of this film was 1.5 times larger than that of (Bi0.46Ba0.54)FeO3 films fabricated by using an normal RF direct sputtering method19 and was similar to that of (Bi1−xBax)FeO3 powder12, this means that the quality of the (Bi1−xBax)FeO3 films fabricated by pulsed DC reactive sputtering technique with suitable sputtering condition is high. And also we have succeeded to demonstrate the magnetization reversal by local electric field application17. However, the Hc and the perpendicular magnetic anisotropy of the films were not sufficient for high performance magnetic device application. To change the intrinsic magnetic property, investigation of substitution materials against Bi (A site) and Fe (B site) should be suitable. For BiFeO3-based films, substitution of A-site with La13, substitution of B-site with Co14,15,16 were reported for the introduction of ferromagnetism. Therefore, substitution with both materials will have large effectiveness for introduction of ferromagnetism. In this study, to improve the magnetic properties of BiFeO3-based films, we aimed to produce highly qualified La and Co doped BiFeO3 films by using reactive pulsed DC sputtering method.

Results and discussion

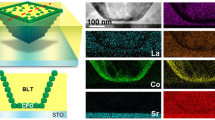

Figure 1 shows the X‐ray diffraction (XRD) profile of Bi–La–Fe–Co–O film on Ta/Pt layer fabricated by pulsed DC reactive sputtering. From previous study, crystallization of Bi–Ba–Fe–O films on Ta/Pt layer fabricated by pulsed DC reactive sputtering was accelerated compared with the case of Bi–Ba–Fe–O films fabricated by RF (radio frequency) direct sputtering17. Therefore, this indicates that the pulsed DC reactive sputtering is useful for fabrication of oxide films with high quality. The Pt underlayer was found to have a strong (111) orientation. The Bi–La–Fe–Co–O films were found to have (006) peak; this indicates that these films have a (001) orientation. Here, the peak at around 36° is from the substrate. With increasing La concentration, the (006) peak shifts to a lower angle. Here, the similar peak shifts were observed in the case of Bi–Ba–Fe–O films with increasing Ba concentration17,19. This indicates that the Bi atoms of the Bi(Fe,Co)O3 phase are replaced by La atoms.

Figure 2 shows the dependence of the Ms and Hc (in-plane and out-of-plane) measured by vibrating sample magnetometer (VSM) with the magnetic field of parallel and perpendicular to film plane on La concentration in the Bi–La–Fe–Co–O films fabricated by pulsed DC reactive sputtering. As mentioned before, the Ms in the (Bi0.48Ba0.52)FeO3 film fabricated by pulsed DC reactive sputtering is 1.5 times larger than that in the (Bi0.46Ba0.54)FeO3 film fabricated by normal RF direct sputtering method17,19. The reason of the large Ms in the Bi–Ba–Fe–O films fabricated by pulsed DC reactive sputtering was improvement of crystalline structure. With increasing La concentration up to around 0.6, Ms of the Bi–La–Fe–Co–O films increased up to 70 emu/cm3. The reason of the large Ms in this Bi–La–Fe–Co–O films fabricated by pulsed DC reactive sputtering is also crystalline structure with high quality. The reason of low Ms in the Bi–La–Fe–Co–O films with the La concentration of around 0.4 is due to the residual of BiFeO3 antiferromagnetic phase. With increasing La concentration more than 0.6, the Ms and Hc decreased. In the case of Bi–Ba–Fe–O films with the Ba concentration of more than 0.60, the Ms and Hc also decreased. Here, in the case of Bi–Ba–Fe–O films with the Ba concentration of more than 0.70, clear other phase was observed from XRD analysis17. Therefore, one of the reasons of the decrease in Ms and Hc (in-plane and out-of-plane) in the Bi–La–Fe–Co–O films with the La concentration of more than 0.65 is due to the inhibition of the formation of the (Bi1−xLax)(Fe0.75Co0.25)O3 ferrimagnetic phase and generation of other phase with paramagnetism.

Figure 3 shows the in-plane and out-of-plane magnetization (M–H) curves (a) measured by VSM with the magnetic field of parallel and perpendicular to film plane and ferroelectric (P–E) curves (b) measured by ferroelectric tester with the electric field perpendicular to film plane of the (Bi0.41La0.59)(Fe0.75Co0.25)O3 film fabricated by the pulsed DC reactive sputtering. A clear hysteresis loop in both magnetization and ferroelectric curves was observed. The Hc and squareness (S) (= remanent magnetization Mr/Ms) with the in-plane direction of the film were 2.7 kOe and 0.50, respectively. On the other hand, the Hc and S with the out-of-plane direction of the film were 4.2 kOe and 0.64, respectively. This indicates that this film has multiferroic property with ferromagnetism and ferroelectricity. Here, the relationship between the magnetic and ferroelectric properties will be discussed in a future study because only the minor loop of the electric property was measured here. To know the magnetic anisotropy of the (Bi1−xLax)(Fe0.75Co0.25)O3 film, various M-H curves were measured by VSM.

Figure 4 shows the dependence of the Hc (a) and S (b) on the VSM measuring angle between magnetic field and film plane of (Bi0.41La0.59)(Fe0.75Co0.25)O3 sample. The Hc and S measured with 0 degree indicates the in-plane Hc and S, and those with 90 degree indicates the out-of-plane Hc and S. The dependence of the Hc and S on the VSM measuring angle between magnetic field and film plane of (Bi0.48Ba0.52)FeO3 film17 are also shown in these figures. To recognize the magnetic anisotropy of these films, the dependence of the Hc and S of Stoner–Wohlfarth single-domain particle on the angle between magnetic field and easy or hard axis are also shown in these figures. With increasing the angle, the Hc and S decreased and lowest Hc and S were obtained at 90 degree for (Bi0.48Ba0.52)FeO3 film. This tendency is similar to the case of Stoner–Wohlfarth single-domain particle with the easy axis along 0 degree. On the other hand, with increasing the angle, the Hc and S increased and highest Hc and S were obtained at 90 degree for (Bi0.41La0.59)(Fe0.75Co0.25)O3 film. This tendency is also similar to the case of Stoner–Wohlfarth single-domain particle with the easy axis along 90 degree. This indicate that (Bi0.41La0.59)(Fe0.75Co0.25)O3 film has somewhat perpendicular magnetic anisotropy. These magnetic properties are suitable candidate for novel magnetic devices. Here, in our current data about dependence of Ms and Hc(out-of-plane)/Hc(in-plane) ratio for (Bi,La)(Fe,Co)O3 film on Co substitution against Fe, with increasing the Co substitution, both of the Ms and Hc ratio increase. However, in the case of (Bi,Ba)(Fe,Co)O3 film, both of the (high) Ms and (low) Hc ratio do not change against the Co substitution. Therefore, one of the causes of high magnetization and perpendicular magnetic anisotropy for (Bi0.41La0.59)(Fe0.75Co0.25)O3 film is both substitution of La and Co against Bi and Fe. The details about these mechanisms will be discussed in a forthcoming paper.

Figure 5 shows the temperature dependence of Ms and the magnetization curve obtained at a temperature of room temperature, 150 ℃, 250 ℃, and 350 ℃ for (Bi0.41La0.59)(Fe0.75Co0.25)O3 film. A clear hysteresis was observed and TC was approximately 420 ℃, which was estimated from dM/dT plot. This property is also useful for application to practical magnetic devices.

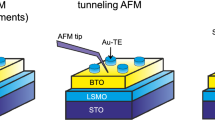

Figure 6 shows topographic (measured by atomic force microscope (AFM)), magnetic (measured by MFM), and electric (measured by EFM) images of (Bi0.41La0.59)(Fe0.75Co0.25)O3 film of before and after local electric field writing by conductive tip with − 10 V. The scan parameters for the writing process are “contact mode” with the scan speed of 5 µm/s and steps of every 10 nm. In previous study, the spatial resolution of our MFM measurement was around 10 nm22, which is sufficient for MFM measurement of magnetic domains with several hundred nano-meter width. The MFM image of (Bi0.41La0.59)(Fe0.75Co0.25)O3 film of before local electric field writing showed de-magnetized state. However, the MFM image of (Bi0.41La0.59)(Fe0.75Co0.25)O3 film after local electric field writing showed clear magnetic domain which magnetization direction is from down to up. This contrast pattern of MFM image is similar to EFM image. The reason of different of contrast color is that the applied low voltage to Co–Cr–Pt tip for EFM measurement was − 1 V. If we will choose the applied low voltage of + 1 V to tip for EFM measurement, the contrast color of EFM image is similar to the color of MFM image. We used low voltage of − 1 V to tip for EFM measurement to distinguish two images between MFM and EFM. This indicates that magnetization with the width of 500 nm is induced by the local electric field writing.

We examined how thin can be written in this (Bi0.41La0.59)(Fe0.75Co0.25)O3 film. The width of local electric field writing by conductive tip with − 10 V was varied from 500, 400, 300, 200, to 100 nm. The MFM (tip end: N), and EFM (tip end: –) images of (Bi0.41La0.59)(Fe0.75Co0.25)O3 film after applying DC voltage of − 10 V with various widths are shown in Fig. 7.

The line profiles of both images and full width at half maximum (FWHM) of each line profiles of induced domains with various widths are also shown. In the case of the line profile of MFM, peaks and valleys are reversed for easy comparing between line profiles of MFM and EFM. Down to the 300 nm width, the FWHM of each domains was similar to nominal value of electric field writing. However, less than 300 nm width, the FWHM of each domains was larger than nominal value of electric field writing. From these results, it is found that an electric field writing of down to 300 nm width, which is a level close to the width of the magnetization reversal region expected in magnetic device applications, is possible. Here, the reason of different FWHM between MFM image and EFM image should be discussed. The domain boundary of MFM image is not sharp compared with EFM image. This can be understood from line profile of especially narrow domains such as 100, 200 nm width. The slope of line profile from peak to valley and width of valley bottom in the case of MFM image are smaller than the case of EFM image. Generally, minimum domain width is several hundred nano-meter in ferromagnetic films and minimum domain width is several tens nano-meter in ferroelectric films. The reason is that the interaction between magnetic moments is very large compared with the case of electric moments. Therefore, this is reason about that the domain boundary of MFM image is not sharp compared with EFM image. On the other hand, minimum domain width of the (Bi,La)(Fe,Co)O3 film is around 100 nm, which is intermediate domain width between ferromagnetic and ferroelectric films. This indicates that the interaction between magnetic moment and electric moments exists. Based on the above, we have succeeded in demonstrating magnetization reversal on the submicron scale by applying a local electric field. This technique will be useful for realization of new magnetic devices.

Methods

Film fabrication

Multilayers of Ta (5 nm)/Pt (100 nm) / (Bi1−xLax)(Fe0.75Co0.25)O3 (300 nm) were deposited onto a thermally oxidized Si wafer using a UHV sputtering system (Eiko, ES-360-AK). The La concentration x was varied from 0.44 to 0.68. The Ta seedlayer, Pt underlayer, and (Bi1−xLax)(Fe0.75Co0.25)O3 layer were deposited at room temperature, 300 °C, and 570 °C, respectively. The film thickness and deposition temperature of the Ta seedlayer and Pt underlayer were optimized to obtain a strong (111) orientation of the Pt underlayer20. The very high frequency (VHF) (40.68 MHz) plasma irradiation21 during the reactive pulsed DC sputtering deposition of (Bi1−xLax)(Fe0.75Co0.25)O3 films was performed with an electric power of 5 W to obtain the crystal grain growth of (Bi1−xLax)(Fe0.75Co0.25)O3 thin films. The frequency of pulsed DC was fixed with 200 kHz. Here, the duty ratios between sputtering ON and OFF are 3 and 2, for example, the time of sputtering ON is 3 µs and that of OFF is 2 µs for this condition. The sputtering power of pulsed DC was fixed with 150 W. The details of pulsed DC sputtering source (ULVAC, DPG-P5) are described in the reference numbers 18 in the reference list. The details of fabrication of BiFeO3-based thin films by using a pulsed DC reactive sputtering method are described in the reference numbers 17 in the reference list.

Measurement

The composition of the fabricated (Bi1−xLax)(Fe0.75Co0.25)O3 films was analyzed by energy dispersive X-ray spectroscopy (EDS) (JEOL, JSM-5900LV). The crystallographic orientations and crystalline structures of the fabricated (Bi1−xLax)(Fe0.75Co0.25)O3 films were analyzed by X-ray diffraction (XRD) analysis (BRUKER, D8 ADVANCE). The magnetization curves of (Bi1−xLax)(Fe0.75Co0.25)O3 were measured using a vibrating sample magnetometer (VSM) (Toei, VSM-5S) with the application of a magnetic field of in-plane direction, out-of-plane direction, and various angle to the film surface. The ferroelectric hysteresis loops of the (Bi1−xLax)(Fe0.75Co0.25)O3 films were measured using a ferroelectric tester (TOYO, FCE-1E). The local electric field writing, and the electric and magnetic domain analyze were performed by scanning force microscopy (SPM) (SII, SPI-3800). The local electric field was applied to the (Bi1−xLax)(Fe0.75Co0.25)O3 film using an atomic force microscopy (AFM) of “contact mode” with a conductive, magnetic Co-Cr-Pt tip. The electric and magnetic domain structures of the (Bi1−xLax)(Fe0.75Co0.25)O3 film were analyzed by electric force microscopy (EFM) and magnetic force microscopy (MFM), respectively, with a conductive, magnetic Co-Cr-Pt tip (Manufacturer: Hitachi High-Tech Science Corporation, Model number: SI-MF40-Hc).

Conclusions

In summary, we fabricated high quality multiferroic (Bi1−xLax)(Fe,Co)O3 magnetic films using pulsed DC reactive sputtering technique. The magnetization (M–H) curve of out-of-plane and ferroelectric (P–E) curve of (Bi1−xLax)(Fe,Co)O3 shows clear hysteresis. The squareness (S) and coercivity (Hc) of perpendicular to film plane are 0.64 and 4.2 kOe which are larger compared with films in parallel to film plane 0.5 and 2.5 kOe. Curie temperature (TC) of (Bi1−xLax)(Fe,Co)O3 is 420 ℃, which is clearly higher than room temperature. The submicron-scale magnetization was introduced by applying a local electric field and that the directions of polarization and magnetization are parallel. This indicates the proposed multiferroic (Bi1−xLax)(Fe,Co)O3 films are expected to be useful in novel magnetic devices driven by electric field.

References

Naganuma, H., Inoue, Y. & Okamura, S. Dependence of ferroelectric and magnetic properties on measuring temperatures for polycrystalline BiFeO3 films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 55, 1046 (2008).

Xing, W. et al. Improved ferroelectric and leakage current properties of Er-doped BiFeO3 thin films derived from structural transformation. Smart Mater. Struct. 23, 085030 (2014).

Uchida, H., Ueno, R., Nakai, H., Funakubo, H. & Koda, S. Ion modification for improvement of insulating and ferroelectric properties of BiFeO3 thin films fabricated by chemical solution deposition. Jpn. J. Appl. Phys. Part 2, 44, L561 (2005).

Lee, Y.-H., Wu, J.-M. & Lai, C.-H. Influence of La doping in multiferroic properties of BiFeO3 thin films. Appl. Phys. Lett. 88, 042903 (2006).

Yasui, S. et al. Analysis for crystal structure of Bi(Fe,Sc)O3 thin films and their electrical properties. Appl. Phys. Lett. 91, 022906 (2007).

Kim, J. K., Kim, S. S., Kim, W.-J., Bhalla, A. S. & Guo, R. Enhanced ferroelectric properties of Cr-doped BiFeO3 thin films grown by chemical solution deposition. Appl. Phys. Lett. 88, 132901 (2006).

Singh, S. K., Sato, K., Maruyama, K. & Ishiwara, H. Cr-doping effects to electrical properties of BiFeO3 thin films formed by chemical solution deposition. Jpn. J. Appl. Phys. Part 2 45, L1087 (2006).

Chung, C.-F., Lin, J.-P. & Wu, J.-M. Influence of Mn and Nb dopants on electric properties of chemical-solution-deposited BiFeO3 films. Appl. Phys. Lett. 88, 242909 (2006).

Singha, S. K., Ishiwara, H. & Maruyama, K. Microstructure and frequency dependent electrical properties of Mn-substituted BiFeO3 thin films. Appl. Phys. Lett. 88, 262908 (2006).

Qi, X., Dho, J., Tomov, R., Blamire, M. G. & Driscoll, J. L. M. Greatly reduced leakage current and conduction mechanism in aliovalent-ion-doped. Appl. Phys. Lett. 86, 062903 (2005).

Wang, Y. & Nan, C.-W. Enhanced ferroelectricity in Ti doped multiferroic BiFeO3 thin films. Appl. Phys. Lett. 89, 052903 (2006).

Wang, D. H., Goh, W. C., Ning, M. & Ong, C. K. Effect of Ba doping on magnetic, ferroelectric, and magnetoelectric properties in mutiferroic BiFeO3 at room temperature. Appl. Phys. Lett. 88, 212907 (2006).

Yang, K. G., Yang, K. G., Zhang, Y. L., Yang, S. H. & Wang, B. Structural, electrical, and magnetic properties of multiferroic Bi1−xLaxFe1−yCoyO3 thin films. J. Appl. Phys. 107, 124109 (2010).

Naganuma, H., Miura, J. & Okamura, S. Ferroelectric, electrical and magnetic properties of Cr, Mn Co, Ni, Cu added polycrystalline BiFeO3 films. Appl. Phys. Lett. 93, 052901 (2008).

Barrionuevo, D. G., Singh, S. P., Katiyar, R. S. & Tomar, M. S. Ferroelectric and ferromagnetic properties of Co-doped BiFeO3 thin films. MRS Proc. 1256, 1256-N06-47 (2010).

Hojo, H., Oka, K., Shimizu, K., Yamamoto, H., Kawabe, R., & Azuma, M. Development of bismuth ferrite as a piezoelectric and multiferroic material by cobalt substitution. Adv. Mater. 30, 1705665 (2018).

Yoshimura, S., & Kuppan, M. Fabrication of high-qualified (Bi1−xBax)FeO3 multiferroic thin films by using a pulsed DC reactive sputtering method and demonstration of magnetization reversal by electric field. Jpn. J. Appl. Phys. 57, 0902B7 (2018).

Pelleymounter, D. R., Christie, D. J. & Fries, B. D. Pulsed DC power for magnetron sputtering: Strategies for maximizing quality and flexibility. In 57th Annual Technical Conference Proceedings Vol. 2014. 183–186 (2014).

Yoshimura, S., Sugawara, Y., Egawa, G., & Saito, H. Basic study of electric field induced magnetization reversal of multiferroic (Bi1−xBax)FeO3 thin films at room temperature for magnetic recording technology. J. Magn. Soc. Jpn. 42, 11 (2018).

Takeda, Y., Yoshimura, S., Takano, M., Asano, H. & Matsui, M. Effect of crystallographic orientation of Co2MnGe Heusler-alloy film on its surface roughness and ordered structure. J. Appl. Phys. 101, 09J514 (2007).

Yoshimura, S., Kobayashi, H., Egawa, G., Saito, H. & Ishida, S. Acceleration of ordering transformation of a new Fe2(Mn,Cr)Si Heusler-alloy film by very high frequency plasma irradiation process during radio frequency sputter deposition. J. Appl. Phys. 109, 07B751 (2011).

Yoshimura, S. et al. MFM analysis of magnetic inhomogeneity in recorded area for perpendicular magnetic recording media by simultaneous imaging of perpendicular and in-plane magnetic field gradient. J. Phys. Conf. Ser. 266, 012065 (2011).

Acknowledgements

This work was partially supported by the JST/PRESTO (No. JPMJPR152C, ID: 15655293). This work was also partially supported by the “JSPS KAKENHI Grant Number 17K06784”, and the “Hoso Bunka Foundation”.

Author information

Authors and Affiliations

Contributions

M.K., S.K., and S.Y. designed the research. M.K., D.Y., and G.E. fabricated and measured the films. The manuscript was written by M.K. and S.Y.. S.K. agreed to publish the work. All authors discussed the data and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuppan, M., Yamamoto, D., Egawa, G. et al. Magnetic properties of (Bi1−xLax)(Fe,Co)O3 films fabricated by a pulsed DC reactive sputtering and demonstration of magnetization reversal by electric field. Sci Rep 11, 11118 (2021). https://doi.org/10.1038/s41598-021-90547-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-90547-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.