Abstract

Monolayer transition metal dichalcogenides MX2 (M = Mo, W; X = S) exhibit remarkable electronic and optical properties, making them candidates for application within flexible nano-optoelectronics. The ability to achieve a high optical signal, while quantitatively monitoring strain in real-time is the key requirement for applications in flexible sensing and photonics devices. Surface-enhanced Raman scattering (SERS) allows us to achieve both simultaneously. However, the SERS depends crucially on the size and shape of the metallic nanoparticles (NPs), which have a large impact on its detection sensitivity. Here, we investigated the SERS of monolayer MX2, with particular attention paid to the effect of the distribution of the metallic NPs. We show that the SERS depends crucially on the distribution of the metallic NPs and also the phonon mode of the MX2. Moreover, strong coupling between MX2 and metallic NPs, through surface plasmon excitation, results in splitting of the  and

and  modes and an additional peak becomes apparent. For a WS2-Ag system the intensity of the additional peak increases exponentially with local strain, which opens another interesting window to quantitatively measure the local strain using SERS. Our experimental study may be useful for the application of monolayer MX2 in flexible nano-optoelectronics.

modes and an additional peak becomes apparent. For a WS2-Ag system the intensity of the additional peak increases exponentially with local strain, which opens another interesting window to quantitatively measure the local strain using SERS. Our experimental study may be useful for the application of monolayer MX2 in flexible nano-optoelectronics.

Similar content being viewed by others

Introduction

Two dimensional (2D) transition metal dichalcogenides (TMDs) have attracted much attention recently due to their outstanding electronic and optical attributes1,2,3,4,5,6,7,8,9,10. In contrast with graphene TMDs usually have energy bandgaps, ranging from 1 to 2 eV and typically display a transition from an indirect to direct-bandgap when the thickness is reduced to a monolayer2,3,11,12 For example, monolayer WS2 has a direct bandgap of 2.1 eV and its bulk state has an indirect bandgap of 1.3 eV12. The lack of inversion symmetry of TMDs together with strong spin–orbit coupling may lead to many as yet unforeseen applications13,14,15 Recent experimental studies suggest that monolayer WS2 and monolayer MoS2 have carrier mobilities of ∼140 cm2/(V·s) at low temperatures and a high on/off current ratio of 106 16,17,18. In particular, intense photoluminescence (PL) has been found in monolayer WS219. These properties suggest that monolayer MX2 has the potential to be candidate within flexible 2D nano-optoelectronics. Mechanical strain is an important parameter in determining the performance of flexible devices20,21,22,23,24,25,26,27. It can strongly modify electronic structure and optical properties of 2D semiconductors. For example, a tensile strain exceeding 1% can cause a direct-to-indirect transition of the optical bandgap of monolayer MoS225,26,27. Thus, to utilize monolayer MX2 within flexible 2D nano-optoelectronics, it is important to find a method to achieve a high optical signal, while quantitatively monitoring strain in real-time. Surface-enhanced Raman scattering (SERS) allows us to achieve both simultaneously. Raman spectroscopy is nondestructive and is widely used to measure the number of atomic layers, and the mechanical and thermal properties of graphene and various inorganic layered materials28. Moreover, the optical properties of monolayers such as graphene can be enhanced by surface resonances29,30,31,32,33, and similarly metals (e.g., Ag and Au) on the surface monolayer MX2 are known to produce enhancements through surface plasmon resonances34,35,36. However, the SERS depends crucially on the size and shape of metallic nanoparticles (NPs), which have a large impact on its detection sensitivity.

In this paper, we investigated the SERS of monolayer MX2, with particular attention paid to the effect of the distribution of the metallic NPs. We found that the SERS depends crucially on the distribution of the metallic NPs and also the phonon mode of the MX2. Strong coupling between the MX2 and metallic NPs, through surface plasmon excitation, results in splitting of the  and

and  modes and an additional peak becomes apparent. For the WS2-Ag system, the intensity of the additional peak increases exponentially with local strain. Our experimental study may be useful for the application of monolayer MX2 in flexible nano-optoelectronics.

modes and an additional peak becomes apparent. For the WS2-Ag system, the intensity of the additional peak increases exponentially with local strain. Our experimental study may be useful for the application of monolayer MX2 in flexible nano-optoelectronics.

Results

Sample preparation and characterization

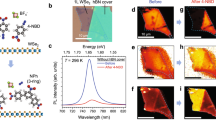

Monolayer MX2 (M = Mo, W; X = S) can be obtained by the top-down methods, such as mechanical exfoliation2,37, and chemical exfoliation38,39,40,41, or by bottom up methods, such as transition metal sulfurization or metal oxide sulfurization42,43,44,45,46,47,48,49,50,51,52,53, and the decomposition of thiomolybdates54. In this work, to achieve large-scale continuous monolayer WS2 films, a monolayer WO3 film was first deposited on single crystal sapphire substrate using an e-beam heated WO3 source in a MBE system (DCA). Figure 1a shows a representative reflection high electron diffraction pattern (RHEED) of an α-Al2O3 (0001) substrate after annealing with an oxygen partial pressure of 1 × 10−5 Torr for 2 hours. The observed diffraction pattern of the [0110] crystallographic direction of the α-Al2O3 surface shows vertical lattice rods and sharp Kikuchi lines indicating a flat and well-ordered surface. The monolayer WO3 layer was deposited at a substrate temperature of 400 °C. After growth, the monolayer of WO3 was annealed at 650 °C with an oxygen partial pressure of 5 × 10−6 Torr for 30 minutes. Figure 1b is the RHEED pattern of a WO3 monolayer grown on the α-Al2O3 substrate after annealing. The sharp lines and diffraction spots originate from monoclinic WO3 (110) plane. One can see that WO3 can be epitaxially grown on a sapphire substrate which allows us to precisely control the thickness of WS2. The chemical composition of the WO3 was investigated by X-Ray photoelectron spectroscopy (XPS). Figure 1c shows that the W 4f7/2 and W 4f5/2 peaks are located at 35.1 eV and 37.2 eV indicating W6+ oxidation states. To form WS2, the sample was removed from the MBE chamber and sulfurized at 700 °C for 15 min in a furnace using 10% H2 in Argon gas as the carrier. Figure 1d,e show the XPS compositional analysis of monolayer WS2 grown on a sapphire substrate for the S and W peaks respectively. The peak positions for W4+ 4f7/2, W4+ 4f7/2, S 2p3/2, and S 2p1/2 are 32.7 eV, 34.7 eV, 162.3 eV, and 163.5 eV respectively. From Fig. 1d,e, we can also estimate that the atomic ratio of W: S is approximately 1: 2. PL spectra were used to further evaluate the thickness of the WS2 layer (Fig. 1f). A bandgap of ∼2 eV was observed indicating the grown WS2 was monolayer in nature19. To produce MoS2, a procedure similar to that for WS2 was used. After the growth of monolayer MoO3 by MBE, the sample was removed from the MBE chamber and sulfurized at 700 °C for 1 min to 2 min in a furnace. The chemical composition of the MoS2 layer was investigated by XPS (Figures S1a). The Mo 3d5/2, Mo 3d3/2, and S 2s peaks have been consistently energy shifted in order to position the peak in the C 1s region at a binding energy (BE) of 284.7 eV. The peak positions for the Mo 3d5/2, Mo 3d3/2, and S 2s are 229 eV, 232 eV, and 226 eV respectively, which are consistent with the values for bulk MoS2. From Figure S1a, we can also estimate that the atomic ratio of Mo: S is approximately 1: 2. Raman spectroscopy was used to further evaluate the quality of the MoS2 layer. Figure S1b shows high resolution transmission electron microscopy (HRTEM) of a MoS2 layer. The XPS and HRTEM results indicate the good quality and layered structure of the MoS2. As the area of the monolayer MX2 is determined by that of the initial MO3 monolayer, we developed a convenient technique to produce large-scale monolayer MX2. The overlaying Ag NPs of different sizes was achieved using E-beam evaporation. The size and the morphology of Ag NPs were characterized by SEM.

(a) RHEED patterns of a sapphire substrate after annealing with oxygen for 2 hours. (b) RHEED pattern of monolayer WO3 grown on a sapphire substrate. (c) X-ray photoemission spectroscopy compositional analysis of monolayer WO3 grown on a sapphire substrate. X-ray photoemission spectroscopy compositional analysis for the S (d) and W (e) peaks of monolayer WS2 grown on a sapphire substrate. (f) PL spectrum of monolayer WS2 grown on sapphire substrate.

SERS at room temperature

Figure 2a shows a schematic of the experimental set-up. Raman measurements were performed using a Renishaw RM1000 spectrometer with an excitation wavelength of 532 nm. Figure 2b displays the Raman spectra of the monolayer WS2 without and with Ag NPs on top. Raman modes were assigned by fitting the spectra using a multi-peak Lorentzian approach as displayed in Figure S2. The Raman spectrum of monolayer WS2 displays an in-plane active mode  at 356 cm−1 and an out-of-plane mode

at 356 cm−1 and an out-of-plane mode  at 417 cm−1. The

at 417 cm−1. The  mode is located at 353 cm−1. Compared with bulk WS255, the frequency of the out-of-plane mode

mode is located at 353 cm−1. Compared with bulk WS255, the frequency of the out-of-plane mode  is red-shifted from 421 to 417 cm−1. The softening of the

is red-shifted from 421 to 417 cm−1. The softening of the  mode is due to the absence of Van der Waals interactions between the layers. By growing Ag NPs on the top of monolayer WS2, an increase in the intensity of the Raman active modes is observed, as shown in Fig. 2b. The intensity of the

mode is due to the absence of Van der Waals interactions between the layers. By growing Ag NPs on the top of monolayer WS2, an increase in the intensity of the Raman active modes is observed, as shown in Fig. 2b. The intensity of the  mode is enhanced by a factor of 3. Note, due to the non-uniform distribution of the Ag NPs, the enhancement factor has a variation of approximately 10%. Interestingly, for the out-of-plane

mode is enhanced by a factor of 3. Note, due to the non-uniform distribution of the Ag NPs, the enhancement factor has a variation of approximately 10%. Interestingly, for the out-of-plane  modes, additional peaks show up (marked with an arrow in Fig. 2b). In the vicinity of the metallic NPs, the electric field will be enhanced due to the collective oscillations of the conduction electrons inside the structure, thus the scattering process is enhanced by a factor of (Elocal/E0)4, where E0 is the strength of the incident E-field and Elocal is the strength of the local electric field in the presence of the metallic NPs or at the plasmonic hotspots34,35,36. Moreover, the strength of the localized electric field depends on the size, shape and interactions between the isolated NPs. It is also reported that such an enhancement could be maximized if the excitation wavelength was tuned to be close to the surface plasmon resonance wavelength of the metal particles56,57,58. To understand how Ag NPs enhance the Raman signal of our monolayer WS2, the electric field amplitude cartography was simulated using a Finite Difference Time Domain (FDTD) approach. Figure S3a shows a schematic drawing of the structure used for the simulation. The position and shape of the silver NPs were extracted from SEM images by performing a simple filtering and thresholding processes (Figures S3b and S3c). All the simulations were performed using a mesh size of 0.2 nm in the x, y, and z-directions. Figure 2d shows the simulated electrical field distribution of the real surface with an excitation wavelength of 532 nm. At first glance, the electric field is localized at the Ag NP−WS2 boundary, indicating the enhanced Raman scattering at the Ag NP−WS2 boundary dominates the overall SERS signal which is consistent with other reports36. The amplitude of the normalized electric field intensity (|Elocal|2/|E0|2) varies from 3 up to 100, which corresponds to a local enhancement of the Raman scattering of 9 up to 104. This heterogeneity is mainly due to the wide range of Ag NP sizes and shapes. Indeed, in the case of a Ag NP with an arbitrary shape, the polarizability of the NP is proportional to

modes, additional peaks show up (marked with an arrow in Fig. 2b). In the vicinity of the metallic NPs, the electric field will be enhanced due to the collective oscillations of the conduction electrons inside the structure, thus the scattering process is enhanced by a factor of (Elocal/E0)4, where E0 is the strength of the incident E-field and Elocal is the strength of the local electric field in the presence of the metallic NPs or at the plasmonic hotspots34,35,36. Moreover, the strength of the localized electric field depends on the size, shape and interactions between the isolated NPs. It is also reported that such an enhancement could be maximized if the excitation wavelength was tuned to be close to the surface plasmon resonance wavelength of the metal particles56,57,58. To understand how Ag NPs enhance the Raman signal of our monolayer WS2, the electric field amplitude cartography was simulated using a Finite Difference Time Domain (FDTD) approach. Figure S3a shows a schematic drawing of the structure used for the simulation. The position and shape of the silver NPs were extracted from SEM images by performing a simple filtering and thresholding processes (Figures S3b and S3c). All the simulations were performed using a mesh size of 0.2 nm in the x, y, and z-directions. Figure 2d shows the simulated electrical field distribution of the real surface with an excitation wavelength of 532 nm. At first glance, the electric field is localized at the Ag NP−WS2 boundary, indicating the enhanced Raman scattering at the Ag NP−WS2 boundary dominates the overall SERS signal which is consistent with other reports36. The amplitude of the normalized electric field intensity (|Elocal|2/|E0|2) varies from 3 up to 100, which corresponds to a local enhancement of the Raman scattering of 9 up to 104. This heterogeneity is mainly due to the wide range of Ag NP sizes and shapes. Indeed, in the case of a Ag NP with an arbitrary shape, the polarizability of the NP is proportional to  which is different from the resonance of an ideal sphere

which is different from the resonance of an ideal sphere  , where

, where  and

and  are the dielectric functions of the Ag NP and WS2 respectively.

are the dielectric functions of the Ag NP and WS2 respectively.  is the depolarization factor of the NPs in the x, y, and z-directions and

is the depolarization factor of the NPs in the x, y, and z-directions and  for an arbitrary shape. Moreover, when the distance between the nanostructures is decreased, strong electromagnetic coupling between the Ag NPs will occur which can further strengthen the electric field at the vicinity of interacting Ag NPs.

for an arbitrary shape. Moreover, when the distance between the nanostructures is decreased, strong electromagnetic coupling between the Ag NPs will occur which can further strengthen the electric field at the vicinity of interacting Ag NPs.

(a) Schematic drawing of the experimental setup for the SERS measurements of WS2. (b) Raman spectra of monolayer WS2 with (Red) and without (Black) 5 nm nominally thick Ag NPs on top. Arrow indicates the splitting of the  mode. (c) SEM image of 5 nm nominally thick Ag NPs on monolayer WS2. (d) Simulated electric field cartography at the surface of the area marked in Fig. 2c with an excitation wavelength of 532 nm.

mode. (c) SEM image of 5 nm nominally thick Ag NPs on monolayer WS2. (d) Simulated electric field cartography at the surface of the area marked in Fig. 2c with an excitation wavelength of 532 nm.

We observed similar effect in the Ag NP-MoS2 system. Figure 3a displays the Raman spectra of monolayer MoS2 without and with Ag NPs on top. By growing Ag NPs on the top of monolayer MoS2, an increase in the intensity of the Raman active modes is also observed. To clearly demonstrate the SERS effect, Fig. 3c shows the Raman intensity mapping of MoS2 with and without Ag NPs on top. Although a decrease in the intensity can be observed from top to bottom, due to absorbates or contaminants on the surface, the 2D Raman intensity mapping does correlate with the contrast seen in the rectangle in Fig. 3b. Thus, it gives another indication that the enhanced Raman signal is due to the SERS. Moreover, the intensity at the boundary of the bare MoS2 and MoS2/Ag is smaller than that of the MoS2/Ag but larger than that of bare MoS2, thus suggesting observation of the propagation of surface plasmons into the bare monolayer MoS2. Similar to WS2, the  , and

, and  modes are split. Clear splitting of the

modes are split. Clear splitting of the  mode was not observed in Fig. 2b for WS2. The reason being that the

mode was not observed in Fig. 2b for WS2. The reason being that the  and 2LA(M) modes for WS2 are very close. Moreover, the in-plane mode E1g is activated, which is normally forbidden in the backscattering Raman process.

and 2LA(M) modes for WS2 are very close. Moreover, the in-plane mode E1g is activated, which is normally forbidden in the backscattering Raman process.

Thickness dependent SERS

To further investigate the impact of Ag NP distribution on the SERS signal, Fig. 4a shows Raman spectra of monolayer WS2 with different nominal thicknesses of Ag NPs on top. The Raman intensity does depend on the nominal thickness of the Ag NPs and the distribution of the Ag NPs. When the nominal thickness is increased from 1 nm to 10 nm, the morphology of Ag NPs is modified (Figure S4). For a thickness of 1 nm, well separated Ag NPs are present. When the thickness is increased to 5 nm, Ag NPs are separated but elongated and Ag NPs with multiple axes emerge. While for a thickness of 10 nm, it is more like a 10 nm thick non-continuous film on the surface. We define the enhancement factor as the ratio between the Raman intensity (frequency-integrated area under each peak) of a monolayer WS2 covered with Ag NPs and that without Ag NPs. Interestingly, SERS also depends on the phonon mode of the monolayer WS2. The enhancement factors of the  ,

,  , and

, and  modes were 2.6, 3, and 1.5, respectively, for a 5 nm nominal thickness of Ag NPs (Fig. 4b). By increasing the nominal thickness of the Ag NPs from 1 to 5 nm, a clear enhancement of the Raman signal for the

modes were 2.6, 3, and 1.5, respectively, for a 5 nm nominal thickness of Ag NPs (Fig. 4b). By increasing the nominal thickness of the Ag NPs from 1 to 5 nm, a clear enhancement of the Raman signal for the  and

and  modes is observed, which is followed by a decrease in the enhancement factor when the thickness is increased to 10 nm. An explanation for the decrease in the enhancement factor for 10 nm nominally thick Ag NPs can be understood from the Ag morphology. The boundary density for the 10 nm non-continuous film is much less than that for 1 nm or 5 nm Ag NPs which decreases the overall SERS. The enhancement process is also accompanied by a red-shift of the Raman active modes, as shown in Fig. 4a. Interestingly, for out-of-plane

modes is observed, which is followed by a decrease in the enhancement factor when the thickness is increased to 10 nm. An explanation for the decrease in the enhancement factor for 10 nm nominally thick Ag NPs can be understood from the Ag morphology. The boundary density for the 10 nm non-continuous film is much less than that for 1 nm or 5 nm Ag NPs which decreases the overall SERS. The enhancement process is also accompanied by a red-shift of the Raman active modes, as shown in Fig. 4a. Interestingly, for out-of-plane  modes, the enhancement factor is less sensitive to the nominal thickness of the Ag NPs (Fig. 4b) and additional peaks show up at 405 and 432 cm−1 (Fig. 4c). It was shown by Wang et al. that due to strong surface plasmon excitation, the Raman signal at the boundary of metal-WS2 is dominated by local strain and the out-of-plane

modes, the enhancement factor is less sensitive to the nominal thickness of the Ag NPs (Fig. 4b) and additional peaks show up at 405 and 432 cm−1 (Fig. 4c). It was shown by Wang et al. that due to strong surface plasmon excitation, the Raman signal at the boundary of metal-WS2 is dominated by local strain and the out-of-plane mode is split36. Similar effects can be expected in our Ag NP-WS2 system as the SERS signal is also dominated by the Raman scattering at the Ag NP-WS2 boundary. Moreover, the intensity of the split mode (P1 marked in Fig. 3c) increases linearly with the Ag NP nominal thickness (Figure S5). As the absolute intensity values depend on the laser power, we use IP1/IP0 where IP1 and IP0 are the intensities of modes P1 and P0 respectively. The intensity ratio has an error of 8% due to the Lorenztian fittings. To demonstrate it can be used to quantitatively measure the local strain, we plot the intensity of the split peak (P1) as a function of the local strain, where the local strain is quantitated by the relative shift of P0 (Table 1 in supporting information)59. In addition, from the error of the relative shift (±0.1 cm−1), the error for the calculated values of the local strain is approximately ± 0.3%. It is found that the intensity of the split peak increases exponentially with the local strain. Interestingly, the intensity of P2 also follows a similar strain dependence. In our Ag NP-WS2 system, strain is produced by the Ag NP deposition (Fig. 4d). The exponential dependence of the Raman intensity on the local strain opens another interesting window to quantitatively measure the local strain using SERS. It can also explain why the enhancement factor of the

mode is split36. Similar effects can be expected in our Ag NP-WS2 system as the SERS signal is also dominated by the Raman scattering at the Ag NP-WS2 boundary. Moreover, the intensity of the split mode (P1 marked in Fig. 3c) increases linearly with the Ag NP nominal thickness (Figure S5). As the absolute intensity values depend on the laser power, we use IP1/IP0 where IP1 and IP0 are the intensities of modes P1 and P0 respectively. The intensity ratio has an error of 8% due to the Lorenztian fittings. To demonstrate it can be used to quantitatively measure the local strain, we plot the intensity of the split peak (P1) as a function of the local strain, where the local strain is quantitated by the relative shift of P0 (Table 1 in supporting information)59. In addition, from the error of the relative shift (±0.1 cm−1), the error for the calculated values of the local strain is approximately ± 0.3%. It is found that the intensity of the split peak increases exponentially with the local strain. Interestingly, the intensity of P2 also follows a similar strain dependence. In our Ag NP-WS2 system, strain is produced by the Ag NP deposition (Fig. 4d). The exponential dependence of the Raman intensity on the local strain opens another interesting window to quantitatively measure the local strain using SERS. It can also explain why the enhancement factor of the  mode is less than that of the

mode is less than that of the  mode.

mode.

mode at room temperature.

mode at room temperature.In conclusion, we investigated SERS for monolayer MX2, paying particular attention to the effect of the distribution of the metallic NPs. We show that the SERS depends crucially on the distribution of the Ag NPs and also the phonon modes of the MX2. Moreover, strong coupling between the MX2 and the Ag NPs through surface plasmon excitation results in splitting of the  mode and additional peaks are manifested. The intensity of the additional peak increases exponentially with local strain, which opens another interesting window into quantitatively measuring the local strain through SERS.

mode and additional peaks are manifested. The intensity of the additional peak increases exponentially with local strain, which opens another interesting window into quantitatively measuring the local strain through SERS.

Methods

Monolayer MX2 growth and characterization

To achieve large-scale continuous monolayer MX2 films, a monolayer MO3 film was first deposited on single crystal sapphire substrate using an e-beam heated MO3 source in a MBE system (DCA). Reflection high electron diffraction (RHEED) was used to monitor and establish growth mode. After growth, the monolayer of MO3 was annealed with an oxygen partial pressure of 5 × 10−6 Torr for 30 minutes. To form MX2, the sample was removed from the MBE chamber and sulfurized in a furnace using 10% H2 in Argon gas as the carrier. The quality of the sample was investigated by X-ray photoemission spectroscopy (XPS), Raman spectroscopy, high resolution transmission electron microscopy (HRTEM), and PL spectroscopy indicating the high quality of the monolayer MX2.

Additional Information

How to cite this article: Zhang, D. et al. Surface enhanced Raman scattering of monolayer MX2 with metallic nano particles. Sci. Rep. 6, 30320; doi: 10.1038/srep30320 (2016).

References

Wang, Q., Kalantar-Zadeh, K., Kis, A., Coleman, J. & Strano, M. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotech. 7, 699–712 (2012).

Mak, K., Lee, C., Hone, J., Shan, J. & Heinz, T. Atomically Thin MoS2: A New Direct-Gap Semiconductor. Phys. Rev. Lett. 105, 136805 (2010).

Sobhani, A. et al. Enhancing the photocurrent and photoluminescence of single crystal monolayer MoS2 with resonant plasmonic nanoshells. Appl. Phys. Lett. 104, 031112 (2014).

Radisavljevic, B., Radenovic, A., Brivio, J., Giacometti, V. & Kis, A. Single-layer MoS2 transistors. Nat. Nanotech. 6, 147–150 (2011).

Xiao, D., Liu, G., Feng, W., Xu, X. & Yao, W. Coupled Spin and Valley Physics in Monolayers of MoS2 and Other Group-VI Dichalcogenides. Phys. Rev. Lett. 108, 196802 (2012).

Jones, A. et al. Optical generation of excitonic valley coherence in monolayer WSe2 . Nat. Nanotech. 8, 634–638 (2013).

Cao, T. et al. Valley-selective circular dichroism of monolayer molybdenum disulphide. Nat. Commun. 3, 887 (2012).

Mak, K., He, K., Shan, J. & Heinz, T. Control of valley polarization in monolayer MoS2 by optical helicity. Nat. Nanotech. 7, 494–498 (2012).

Mak, K., McGill, K., Park, J. & McEuen, P. The valley Hall effect in MoS2 transistors. Science 344, 1489–1492 (2014).

Zhang, Y., Oka, T., Suzuki, R., Ye, J. & Iwasa, Y. Electrically Switchable Chiral Light-Emitting Transistor. Science 344, 725–728 (2014).

Zhao, W. et al. Evolution of Electronic Structure in Atomically Thin Sheets of WS2 and WSe2 . ACS Nano 7, 791–797 (2013).

Kuc, A., Zibouche, N. & Heine, T. Influence of quantum confinement on the electronic structure of the transition metal sulfide TS2 . Phys. Rev. B 83, 245213 (2011).

Xiao, D., Liu, G., Feng, W., Xu, X. & Yao, W. Coupled Spin and Valley Physics in Monolayers of MoS2 and Other Group-VI Dichalcogenides. Phys. Rev. Lett. 108, 196802 (2012).

Rycerz, A., Tworzydło, J. & Beenakker, C. Valley filter and valley valve in graphene. Nat. Phys. 3, 172–175 (2007).

Xiao, D., Yao, W. & Niu, Q. Valley-Contrasting Physics in Graphene: Magnetic Moment and Topological Transport. Phys. Rev. Lett. 99, 236809 (2007).

Withers, F., Bointon, T., Hudson, D., Craciun, M. & Russo, S. Electron transport of WS2 transistors in a hexagonal boron nitride dielectric environment. Sci. Rep. 4, 4967 (2014).

Liu, X. et al. High Performance Field-Effect Transistor Based on Multilayer Tungsten Disulfide. ACS Nano 8, 10396–10402 (2014).

Ovchinnikov, D., Allain, A., Huang, Y. S., Dumcenco, D. & Kis, A. Electrical Transport Properties of Single-Layer WS2 . ACS Nano 8, 8174–8181 (2014).

Peimyoo, N. et al. Nonblinking, Intense Two-Dimensional Light Emitter: Monolayer WS2 Triangles. ACS Nano 7, 10985–10994 (2013).

Conley, H. et al. Bandgap Engineering of Strained Monolayer and Bilayer MoS2 . Nano Lett. 13, 3626–3630 (2013).

Zhu, C. et al. Strain tuning of optical emission energy and polarization in monolayer and bilayer MoS2 . Phys. Rev. B 88, 121301 (2013).

Pu, J. et al. Highly Flexible MoS2 Thin-Film Transistors with Ion Gel Dielectrics. Nano Lett. 12, 4013–4017 (2012).

Chang, H. et al. High-Performance, Highly Bendable MoS2 Transistors with High-K Dielectrics for Flexible Low-Power Systems. ACS Nano 7, 5446–5452 (2013).

Yoon, J. et al. Flexible Electronics: Highly Flexible and Transparent Multilayer MoS2 Transistors with Graphene Electrodes. Small 9, 3185–3185 (2013).

Lu, P., Wu, X., Guo, W. & Zeng, X. Strain-dependent electronic and magnetic properties of MoS2 monolayer, bilayer, nanoribbons and nanotubes. Phys. Chem. Chem. Phys. 14, 13035 (2012).

Pan, H. & Zhang, Y. Tuning the Electronic and Magnetic Properties of MoS2 Nanoribbons by Strain Engineering. J. Phys. Chem. C 116, 11752–11757 (2012).

Shi, H., Pan, H., Zhang, Y. & Yakobson, B. Quasiparticle band structures and optical properties of strained monolayer MoS2 and WS2 . Phys. Rev. B 87, 155304 (2013).

Calizo, I., Balandin, A., Bao, W., Miao, F. & Lau, C. Temperature Dependence of the Raman Spectra of Graphene and Graphene Multilayers. Nano Lett. 7, 2645–2649 (2007).

Kim, N., Oh, M. K., Park, S., Kim, S. K. & Hong, B. H. Effect of Gold Substrates on the Raman Spectra of Graphene. Bull. Korean Chem. Soc. 31, 999–1003 (2010).

Sidorov, A. N., Sławiński, G. W., Jayatissa, A. H. & Zamborini, F. P. Sumanasekera G.U. A surface-enhanced Raman spectroscopy study of thin graphene sheets functionalized with gold and silver nanostructures by seed-mediated growth. Carbon 50, 699 (2012).

Wang, P. et al. Giant Optical Response from Graphene–Plasmonic System. Acs Nano 6, 6244 (2012).

Khorasaninejad, M. et al. Highly Enhanced Raman Scattering of Graphene using Plasmonic Nano-Structure. Sci. Rep. 3, 2936, 2013

Kalbac, M., Vales, V. & Vejpravova, J. The effect of a thin gold layer on graphene: a Raman spectroscopy study. RSC Adv. 4, 60929–60935 (2014).

Xu, H., Aizpurua, J., Käll, M. & Apell, P. Electromagnetic contributions to single-molecule sensitivity in surface-enhanced Raman scattering. Phys. Rev. E 62, 4318–4324 (2000).

Le Ru, E. & Etchegoin, P. Quantifying SERS enhancements. MRS Bull. 38, 631–640 (2013).

Sun, Y. et al. Probing Local Strain at MX2 –Metal Boundaries with Surface Plasmon-Enhanced Raman Scattering. Nano Lett. 14, 5329–5334 (2014).

Novoselov, K. Electric Field Effect in Atomically Thin Carbon Films. Science 306, 666–669 (2004).

Coleman, J. et al. Two-Dimensional Nanosheets Produced by Liquid Exfoliation of Layered Materials. Science 331, 568–571 (2011).

Paton, K. et al. Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids. Nat. Mater. 13, 624–630 (2014).

Joensen, P., Frindt, R. & Morrison, S. Single-layer MoS2. Mater. Res. Bull. 21, 457–461 (1986).

Eda, G. et al. Photoluminescence from Chemically Exfoliated MoS2 . Nano Lett. 11, 5111–5116 (2011).

Lee, K., Gatensby, R., McEvoy, N., Hallam, T. & Duesberg, G. High-Performance Sensors Based on Molybdenum Disulfide Thin Films. Adv. Mater. 25, 6699–6702 (2013).

Zhan, Y., Liu, Z., Najmaei, S., Ajayan, P. & Lou, J. Large-Area Vapor-Phase Growth and Characterization of MoS2 Atomic Layers on a SiO2 Substrate. Small 8, 966–971 (2012).

Kong, D. et al. Synthesis of MoS2 and MoSe2 Films with Vertically Aligned Layers. Nano Lett. 13, 1341–1347 (2013).

Gatensby, R. et al. Controlled synthesis of transition metal dichalcogenide thin films for electronic applications. Appl. Surf. Sci. 297, 139–146 (2014).

Gutiérrez, H. et al. Extraordinary Room-Temperature Photoluminescence in Triangular WS2 Monolayers. Nano Lett. 13, 3447–3454 (2013).

Song, J. et al. Layer-Controlled, Wafer-Scale, and Conformal Synthesis of Tungsten Disulfide Nanosheets Using Atomic Layer Deposition. ACS Nano 7, 11333–11340 (2013).

Orofeo, C., Suzuki, S., Sekine, Y. & Hibino, H. Scalable synthesis of layer-controlled WS2 and MoS2 sheets by sulfurization of thin metal films. Appl. Phys. Lett. 105, 083112 (2014).

Elías, A. et al. Controlled Synthesis and Transfer of Large-Area WS2 Sheets: From Single Layer to Few Layers. ACS Nano 7, 5235–5242 (2013).

Jung, Y. et al. Metal Seed Layer Thickness-induced transition from vertical to horizontal growth of MoS2 and WS2 . Nano Lett. 14, 6842–6849 (2014).

Morrish, R., Haak, T. & Wolden, C. Low-Temperature Synthesis of n -Type WS2 Thin Films via H2S Plasma Sulfurization of WO3 . Chem. Mater. 26, 3986–3992 (2014).

Yun, S. et al. Synthesis of Centimeter-Scale Monolayer Tungsten Disulfide Film on Gold Foils. ACS Nano 9, 5510–5519 (2015).

O’Brien, M. et al. Plasma assisted synthesis of WS2 for gas sensing applications. Chem. Phys. Lett. 615, 6–10 (2014).

Kang, K. et al. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 520, 656–660 (2015).

Zhang, X. et al. Phonon and Raman scattering of two-dimensional transition metal dichalcogenides from monolayer, multilayer to bulk material. Chem. Soc. Rev. 44, 2757–2785 (2015).

Niu, J. et al. Study of electromagnetic enhancement for surface enhanced Raman spectroscopy of SiC graphene. Appl. Phys Lett. 100, 191601 (2012).

Singha, S. S., Nandi, D. & Singha, A. Tuning the photoluminescence and ultrasensitive trace detection properties of few-layer MoS2 by decoration with gold nanoparticles. RSC Adv. 5, 24188, (2015).

Ling, X. et al. Raman Enhancement Effect on Two-Dimensional Layered Materials: Graphene, h-BN and MoS2 . Nano Lett. 14, 6 3033 (2014).

Wang, Y. et al. Strain-induced direct–indirect bandgap transition and phonon modulation in monolayer WS2 . Nano Resear. 8, 2562–2572 (2015).

Acknowledgements

This work was supported by the Beijing Institute of Technology Research Fund Program for Young Scholars and National Plan for Science and technology (Nos NPST 2472-02 and NPST 2529-02) of King Abdulaziz City for Science and Technology. H.C.W., MOH.A. and MOU.A. thank Saudi Aramco for the financial support (project No. 6600028398). We would like to thank R. Gatensby for the sulfurization.

Author information

Authors and Affiliations

Contributions

H.-C.W. supervised the project and led the overall effort. D.Z., Y.-C.W., M.Y. and X.L. carried out the Raman measurements. C.Ó.C., M.A. and I.S. grew the sample. B.S.C. performed TEM characterization. M.A. performed the FDTD simulation. D.Z., Y.-C.W., J.-J.W., H.X., H.L. and H.-C.W. analyzed the data. H.-C.W. wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhang, D., Wu, YC., Yang, M. et al. Surface enhanced Raman scattering of monolayer MX2 with metallic nano particles. Sci Rep 6, 30320 (2016). https://doi.org/10.1038/srep30320

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep30320

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

and

and  modes. (b) Optical image of MoS2 with and without Ag NPs on top. (c) 2D distribution of Raman intensity corresponding to the rectangle in Fig. 3b.

modes. (b) Optical image of MoS2 with and without Ag NPs on top. (c) 2D distribution of Raman intensity corresponding to the rectangle in Fig. 3b.

mode with different thickness Ag NPs on top of it. (d) IP1/IP0 and IP2/IP0 as a function of the Ag NP thickness induced strain.

mode with different thickness Ag NPs on top of it. (d) IP1/IP0 and IP2/IP0 as a function of the Ag NP thickness induced strain.