Abstract

The introduction of low detection limit ion selective electrodes (ISEs) may well pave the way for the determination of trace targets of cationic compounds. This research focuses on the detection of titanium (III) cation using a new PVC-membrane sensor based on synthesized tris(2pyridyl) methylamine (tpm) ionophore. The application and validation of the proposed sensor was done using potentiometric titration, inductively coupled plasma atomic emission spectrometry (ICP-AES) and atomic absorption spectrometry (AAS). The membrane sensor exhibited a Nernstian response to the titanium (III) cation over a concentration range of 1.0 × 10−6–1.0 × 10−2 M and pH range from 1–2.5. The Nernstian slope, the lower of detection (LOD) and the response time (t95%) of the proposed sensor were 29.17 ± 0.24 mV/dec, 7.9 × 10−7 M and 20 s, respectively. The direct determination of 4–39 μg/ml of titanium (III) standard solution showed an average recovery of 94.60 and a mean relative standard deviation of 1.8 at 100.0 μg/ml. Finally, the utilization of the electrodes as end-point indicators for potentiometric titration with EDTA solutions for titanium (III) sensor was successfully carried out.

Similar content being viewed by others

Introduction

Amongst the eight most hazardous chemicals (worst 10%), titanium chloride (TiCl4) is usually ranked as the worst. Among its side effect include burning effects in the eyes, skin, mucous layers, esophagus and stomach if ingested and might even cause lung damage or death if inhaled in high doses1.

There is a considerable effort to determine the titanium and titanium compounds in industrial applications and their corresponding hazardous effects to humans and the environment2,3,4,5. Several methods have been reported, such as gravimetric filter weight (G/FW)6 and inductively coupled argon plasma-atomic emission spectroscopy (ICP-AES)7,8,9. Although some of these methods are precise and selective for the determination of titanium in solution or biological and industrial samples, their applications are limited due to their large size, complex instruments, high cost and time consumption. In contrast, the method based on potentiometric ion-selective electrode are more advantageous, as they are more economical and less complicated to use, with excellent selectivity, fast response time and low detection limits10,11. Due to these merits, in this research, titanium selective electrode based on tris(2 pyridyl) methylamine (tpm) ionophore is introduced.

Among the many reported ion selective electrode for cations, this is the first report of titanium selective sensor based on a PVC matrix with specified features, such as low detection limit, good Nernstian response, fast response and wide concentration range that can be applied to measure titanium cations in real samples.

Experimental

In this experiment, for the fabrication of the membrane, tetrahydrofurane was used as the solvent and polyvinyl chloride powder (high molecular weight, PVC) was used as the matrix; both were purchased from Flucka. Dioctylphthalate (DOP) and dibutylphthalate (DBP) were procured from Merck, while 2-Nitrophenyl octyl ether (oNPOE) and nitrobenzene (NB) were procured from Flucka and benzyl acetate (BA) was purchased from Aldrich; all was utilized as sensor plasticizers. The following lipophilic anionic additives were also used: sodium tetraphenyl borate (NaTPB) purchased from Merck, while potassium tetrakis (4-chlorophenyl) borate (KTK), sodium tetrakis (4-fluorophenyl) borate (NaTFPB) and tetradodecylammonium tetrakis (4-chlorophenyl) borate (ETH 500) were purchased from the Flucka company. De-ionized water is used throughout the experiments.

A TiCl3 (Merck) Ethylenediaminetetraacetic acid disodium salt (EDTA) was used as a titrant (Sigma-Aldrich), while nitric acid (HNO3), hydrochloric acid (HCl) and sodium hydroxide (NaOH) (Merck) was used to adjust the pH of the solution. The cationics nitrate and chloride with the highest purity level were purchased from Merck, Fluka, Aldrich, BDH and HmbG companies and used after vacuum drying over P2O5.

Apparatus

A Mettler Toledo digital ion meter (Seven multi ion pH/mV/ORP) was used to measure the potentials. Two different reference electrodes (Mettler Toledo); calomel and silver/silver chloride (containing 3 molL−1 solution of KCl) were applied as internal and external reference electrodes, respectively. The pH-meter (DKK-TOA, HM-7J) was used for mountaineering the pH of the solutions. A Perkin-Elmer Lambda spectrophotometer 1650 pc (SHIMADZU) was used for parliamentary study of complex reactions between the tpm ionophore and titanium (III) cation.

The solution samples of the titanium target ions were measured for the purpose of comparing them to the fabricated cation selective electrodes using the Perkin-Elmer optical emission spectrometer (model Optima 2000 DV) as an inductively coupled plasma (ICP) with Ar and N2 high quality gases and the Thermo SCIENTIFIC atomic absorption spectrometer (AAs) (model S SEIES).

Synthesis of tpm ionophore

For the synthesis of the tpm ionophore, the n-Butyllithium was added dropwise to a solution of 2-aminomethylpyridine into dry tetrahydrofuran (THF) at −70°C under N2 gas. The solution was stirred after achieving its designated temperature to room temperature for 24 h. The resulting violet solution was stirred around 8 h after the addition of 2-Chloropyridine and water and was again stirred for 30 minutes. After the removal of volatile compounds via washing with water, the aqueous phase was separated with CH2Cl2 and the organic layer was dried on the vacuo over magnesium sulfate. The oily resulting solution was triturated using the Et2O–hexane binary mixture at a molar ratio of 1:1 and the resulting solid was recrystallized in water12.

Methodology

To prepare the membrane, PVC polymeric matrix, tris(2 pyridyl) methylamine (tpm), di-n-octyl phthalate (DOP) and potassium tetrakis (4-chlorophenyl) borate (KTK), with the composition of 33.0, 5.0, 61.0, 0.5 mg respectively, was dissolved in 3 ml of fresh THF. The dip-coating method was used to form the membrane. For this, a Pyrex tube (with a tip diameter of 3 mm o.d) was dipped for almost 10 s and then pulled out from the oily mixture, which induces slow evaporation; the oily mixture was kept at room temperature for 24 hours and the slow evaporation will eventually form a nontransparent membrane. The tube was filled with the 1.0 × 10−3 mol L−1 TiCl3 internal solution, while the electrode soaked in an equal concentration of titanium chloride solution overnight. The calomel reference electrode was placed in an internal solution and connected to a silver/silver chloride external reference electrode (containing 3 molL−1 solution of KCl), to the Mettler Toledo ion meter to measure the potential at 25.0 ± 0.1°C by setting up the following cell:

Hg2Cl2/Hg, KCl (satd.) | internal solution 1.0 × 10−3 mol L−1 of titanium chloride (III) || PVC membrane || test solution | Ag/AgCl, KCl (3 mol L−1).

For AAs and ICP studies, the sample solutions were prepared using the standard addition method by adding a known amount of the target ion into the blank sample (deionized water). Several standard solutions of the corresponding metal cations were prepared in order to determine their respective calibration curve.

Results and discussion

The main focus of this work is to design a noble tpm ionophore that possesses an effective binding complex with the titanium cation. Thus, the fabrication of PVC-based membrane of tpm and its utilization as a polymeric PVC sensor for the determination of titanium was investigated.

This membrane exhibits high selectivity toward Ti(OH)(OH2)52+ cation after being tested with various cations, which means that it can be used as a selective titanium (III) sensor.

The response of the sensor towards the titanium (III) cations is based on the formation of tpm-Ti(OH)(OH2)52+ complex, with a 1:1 mole ratio (Figure 1)13,14.

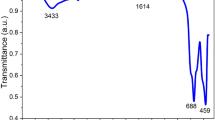

The parliamentary study of complex formation was studied using UV-Vis spectroscopy. For this study, three different solutions of TiCl3 (1.0 × 10−4 M), tpm (1.0 × 10−4 M) and a complex solution (mixture of tpm ionophore and TiCl3 solution 1:1 v/v) in dry acetonitrile was applied. As shown in S1, the addition of the ionophore solution with two maxima at 199 and 262 nm to the Ti(OH)(OH2)52+ equilibrium solution, with the maxima at 196 and 205 nm resulted in the decrease and increase in absorption and wavelength shifts and in the spectra of the complex, respectively. This observation revealed that tpm has a special affinity with the Ti(OH)(OH2)52+ cation.

Working concentration range and slope

The membrane potentials, based on the tpm ionophore as a function of Ti(OH)(OH2)52+ concentration in the range of 1 × 10−6 to 1 × 10−2 M was investigated. The effect of major component on the response of the electrodes for the membrane (with ionophore and without ionophore) was investigated as well. Figure 2 shows that the response of the sensors without the ionophore toward the titanium (III) cation was very weak. The addition of the tpm ionophore to the membrane elicited a linear response with a slope of 29.17 ± 0.24 over a working concentration range of 1 × 10−6 to 1 × 10−2 M for tpm-based membrane cation selective electrode.

Effect of membrane composition

According to the latest studies, the nature of ionophore is the key component to determine the sensitivity and selectivity parameters for the sensors. However, the roles of membrane composition and the properties of the solvents and additives cannot be ignored15,16,17,18. Therefore, the effects of the membrane composition, plasticizers and additives on the membranes' response based on tpm ionophore were investigated. As seen in Table 1, between four different plasticizers and four additives being used, the DOP and KTK for tpm-based titanium selective electrode resulted in the best responses. Table 1 shows that the optimum amount of ionophore is 5% and that the use of KTK as an anionic additive enhances the emf response of the polymeric sensor remarkably.

The significant plasticizer properties include lipophilicity, low vapor pressure, high molecular weight and also the high capacity to dissolve the component of membranes due to the enhanced sensitivity and selectivity of polymeric membrane sensors19,20. Hence, several membranes based on the PVC matrix with different plasticizers (DOP, DBP, oNPOE, BA and NB) were prepared. From Table 1, it is obvious that plasticizer DOP exhibited the best performance, with the widest linear concentration range and nearest Nernstian slope (membrane number 2).

It should be noted that the low-polarity plasticizer (DOP, ε = 5) yield suitable conditions to extract the titanium cation (Ti(OH)(OH2)52+) as opposed to high-polar plasticizer (NB, ε = 34.9), with high lipophilicity in the membrane. This behaviour is due to the influences of the DOP plasticizer on both the dielectric constant of the membrane and the mobility of the ionophore.

The performance of the membrane without plasticizers was also investigated. It generated no potential due to the unusable polymeric membrane with low mechanical resistance.

A series of polymeric membrane with different lipophilic anionic additives, such as NaTPB, NaTFPB, ETH 500 and KTK (Table 1) were employed to investigate the effect of lipophilic additives. As illustrated from Table 1, the proportion of 0.5% (w/w) KTK as an additive relative to the membrane composition for tpm-based membrane sensors demonstrated the best performance characteristics. This confirms that the existence of additive as a profit factor influences the enhancement of the performance of membrane sensors. These influences reduce the ohmic resistance and consequently ameliorate the membrane sensor's selectivity. In addition, the additives can be applied as a catalyst to enhance the kinetic exchange at the sample-membrane interface21,22. Therefore, KTK acts as a best counter-ion to facilitate the process of ion-charge transduction.

In addition, the results in Table 1 shows that membranes without tpm ionophore (Number 3) can somewhat respond to the target ion. Ion exchangers induces a selective response if little or no ionophore is present23,24.

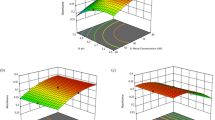

Artificial neural network analysis

The artificial neural network (ANN) modeling of the polymeric membrane composition was carried out by Neural Power software version 2.525. The ANN was made of 11 neurons as its input layer and a neuron in the output layer. The structure of the hidden layer was determined by examining a series of topologies with a varied node number from 1–10. The model training was carried out to test the data set and determine the minimum value of RMSE as an error function. The performance was repeated 10 times for each node in order to avoid random correlation due to the random initialization of the weight26. Among the repeated results, the minimum RMSE was selected as the best topology for the quick propagation algorithms. As illustrated in Figure 3a, the selected topology, 11-8-1 (input layer-hidden layer-output layer) was regarded as an efficient model training for the membrane composition to obtain the best Nernstian slope. As a result of ANN modeling and the importance of the effective variables on the slope was determined and plotted in Figure 3b. As observed, the tpm ionophore was the most effective variable that can act as the key factor to fabricate the optimized membrane sensor with other strands (DOP, KTK, PVC), which are of second-degree importance. The other variables are categorized into two identical importance groups, such as (BA, DBP and oNPOE) and (NaTFBP, NaTPB and ETH500). It means that one of the variables in each group can be selected as an input for the preparation of membrane sensors. The variety of input sensors could be of great advantage to the fabrication of sensors.

Calibration curve and statistical data

The detection limit of the electrode based on tpm was assessed by the recommendation of IUPAC27.

As shown in Figure 2, the emf response of the polymeric membrane based tpm indicates a Nernstian slope of 29.17 ± 0.24 mV per decade over a wide concentration ranges of the titanium cation, from 1 × 10−6 to 1 × 10−2 M. The detection limit of the titanium selective electrode was determined according to the cross-section of two extrapolated calibration plot (linear part) to the baseline potential being 7.9 × 10−7 M.

Repeatability and reproducibility

The repeatability and reproducibility of the proposed sensor based on tpm over concentration ranging from 1.0 × 10−6 to 1.0 × 10−2 M of TiCl3 solutions was done via three successive calibrations with the same membrane, on the same day on five different electrodes.

The repeatability of the proposed sensor was tested by five measurements over the working concentration ranges of the electrode. The standard deviation (SD) of the Nernstian slope of the three replicate measurements obtained was 0.24 mV for the electrode based on the tpm ionophore. As shown in S2, the value of the coefficient of variation (CV) was much lower than 5%, which indicates good repeatability of potential response.

The reproducibility of the ISE was studied using five different optimized membranes for the electrode. All membranes were prepared using similar methods and compositions. The results obtained for the standard deviations for the electrode based on tpm was 0.86 mV. The variation of results in this study compared to the repeatability study could be due to the different thicknesses of the five different membranes.

Effect of internal solution

The impression of the titanium chloride filling solution as an internal solution on the potential response of the proposed sensor for the Ti(OH)(OH2)52+ cation based on the tpm ionophore was studied. Three different concentrations of the titanium (III) cation (1.0 × 10−2, 1.0 × 10−3 and 1.0 × 10−4) were chosen and the sensor response was observed. As shown in S3, the concentration changes of the TiCl3 internal solution did not cause any considerable difference in the potential response of the membrane sensor. The best results in terms of slope and working concentration range for the proposed sensor case resulted in an internal solution of concentration 1.0 × 10−3 M. Consequently, the concentration of TiCl3 internal solution for the electrode based on tpm was kept at 1.0 × 10−3 M for all solutions.

Potential responses of fabricated electrode for other cations

In this experiment, we used the fabricated proposed sensor based on tpm ionophore for various common inorganic cations. The response of the sensor based on tpm was investigated for 20 cations. The potential responses are shown in S4. The membrane sensor displayed remarkable selectivity for Ti(OH)(OH2)52+ cations in contrast to other cations, while the slopes of the linear parts of potential responses of the fabricated electrode was negligible, the slope of the calibration curve for titanium(III) sensor based on tpm is much higher than other cations and demonstrated Nernstian behaviour. Note that the Nernstian slope is 59.20 mV/decade for the monovalent cation, 29.60 mV/decade for the divalent cation and 19.70 mV/decade for the trivalent cation18.

Effect of pH

The pH dependence of the optimized sensor based on tpm over the pH range from 0.2 to 5 in two fixed concentrations (1 × 10−5 M and 1 × 10−3 M) of the Ti(OH)(OH2)52+ cation were tested. All of the pH solutions were adjusted by either dilute hydrogen chloride or sodium hydroxide (0.1 M) solutions. The potential response of fabricated sensor based on tpm ionophore was measured as a function of pH; the obtained results are indicated in Figure 4.

As shown in Figure 4, the potential responses remained constant over the pH range of 1 to 3 for the fabricated electrode. The perceived shifts in the potential at lower and higher pH values could be due to the presence of hydrogen cations that acts as the interface cation, while the target cation is formed by the addition of titanium cation into the solution28. These behaviours shows that the response of the fabricated electrode based on tpm may be due to the Ti(OH)63+ and Ti2O(OH2)104+ cations29. In higher pH values (Ph > 5) and due to the formation of titanium oxide precipitation that moves out from the solution, the potential responses of electrodes were significantly altered.

Response time

The response time is a key factor in characterizing fabricated ion-selective electrodes. The critical response time of the ISE can be evaluated based on the recommendations of the IUPAC30. In this work, the practical response time was obtained for the tpm membrane-based ISE by changing the Ti(OH)(OH2)52+ concentration from 1.0 × 10−6 to 1.0 × 10−2 M. The measured potential versus time trace is illustrated in Figure 5 (a). As seen here, in whole concentrations (low-to-high), the tpm based membrane sensor reached equilibrium in 20 seconds. In order to appraise the reversibility of the sensor, a similar method in the opposite direction was pursued. The response time of the membrane sensor was measured by changing the sequence concentrations from the high-to-low Ti(OH)(OH2)52+ cation. As shown in Figure 5 (a), the response time in this case was longer than the low-to-high sample concentration (25 s). This might be due to the kinetic exchange of complexation–decomplextaion of the Ti(OH)(OH2)52+ cation with tpm ligand at the test solution-membrane interface11,31.

This assembly's polymeric sensor was also used in two different concentrations of the Ti(OH)(OH2)52+ cation (1.0 × 10−5 and 1.0 × 10−3 M) to investigate the stability time for the electrode potential resonance. As shown in Figure 5 (b), the potential response remained constant for almost 15 m.

Life time

The lifetime of the proposed sensor was investigated at different time periods; from 24 hours to 8 weeks. During these times, the optimized sensor was applied at least one hour per day and then stocked in 0.001 M Ti(OH)(OH2)52+ solution. Note that the electrode was equilibrated in 0.01 M Ti(OH)(OH2)52+ solution when any drift in the potential was observed. Table S5 presents the lifetime of the membrane sensor based on tpm, which was nearly two months. The Nernstian slope and detection limit of the sensor was only slightly altered. Therefore, this proposed sensor still provided a usable response during the period of two months. The slight increase or decrease in the slope and detection limit resulting from the ionophore and plasticizer is thought to have leached out from the membrane to the solution32.

Potentiometric selectivity of the sensors

Selectivity, as the significant factor of membrane sensor, is usually expressed for ion selective sensors in terms of potentiometric selectivity coefficients. It is defined by the relative response of the ion selective electrode to the target ion (primary ion) in the presence of other ions. In this work, the preference of the proposed electrode based on tpm for the 26 interfering cations relative to the Ti(OH)(OH2)52+ cation was evaluated by the separation solution method (SSM)33,34,35. The results of the potentiometric selectivity coefficient data for the membrane sensor based on tpm are summarized in Table 2. The perusal data clearly show that the electrode has more affinity towards Ti(OH)(OH2)52+ compared to other inorganic cations. Such remarkable selectivity over other common cations reflects its suitability when used as an ion carrier.

It is seen from Table 2 that the selectivity coefficient for the other cations are much smaller, proving that the sensor is sufficiently selective.

A typical selectivity pattern for a series of cations based on tpm is as follows:

Ti(OH)(OH2)52+ > Fe2+ > Pb2+ > Cd2+ > H+ > Ca2+ > Cu2+ > Zn2+ > Co2+ > Ni2+ > Mg2+ > Cr3+ > Mn2+, Nd3+ > Ce3+ > La3+ > Fe3+ > Ba2+ > Y3+ > Tb3+ > K+ > Rb+ > NH4+ > Na+ > Cs+ > Gd3+ > Li+.

Titration with EDTA

The proposed sensor was used as an indicator electrode in potentiometric titration of TiCl3 solution with EDTA. For this, a 25.0 ml solution of 1.0 × 10−4 M TiCl3 was titrated against a 1.0 × 10−2 M EDTA solution at a constant pH of 2.0. As indicated in Figure 6, the sharp inflection point shows the perfect titration, with the 1:1 stoichiometry of Ti-EDTA complex for both titrations. Thus, the sensors can be used to accurately determine the concentration of Ti(OH)(OH2)52+ cation under laboratory conditions.

The reaction equilibrium between titanium chloride, TiCl3 and EDTA at a constant pH of 2.0 can be written as:

Validation with AAs and ICP

Validation of the proposed sensor based on tpm was tested by comparing its inductively coupled plasma (ICP) and atomic absorption spectrometry (AAs). As depicted in Table 3, this sensor was used to determine the concentration of titanium in four different activity samples, with a pH of 2.0. The analyses were performed using the standard addition technique. Good recoveries were obtained in all samples and the results were in fair agreement with ICP and AAs.

Conclusion

The obtained results showed that the synthesized tpm could be used as a suitable ionophore for the determination of titanium (III) cation in polymeric cation selective sensor devices. The membrane with the optimized composition of 5.0:61.5:33.0:0.5 (mg) tpm:DOP:PVC:KTK was the best Nernstian response toward Ti(OH)(OH2)52+ cation species. The proposed sensor based on tpm ionophore exhibited a working concentration range of (1.0 × 10−6 to 1.0 × 10−2 M), low detection limit (8.0 × 10−7 M), long lifetime (2 month) and fast response time (20 s), with a Nernstian slope of (29.17 ± 0.24 mV/decade of activity). The selectivity coefficient of the membrane sensor for the titanium (III) cation was desirable compared to other investigated cations. Also, the fabricated sensor based on tpm was applied for the analysis of the titanium (II) cation in sample solutions as well as spectroscopy methods, such as AAs and ICP instruments.

References

Kapias, T. & Griffiths, R. Accidental releases of titanium tetrachloride (TiCl4) in the context of major hazards spill behaviour using REACTPOOL. J. Hazard. Mater. 119, 41–52 (2005).

Chen, X. Titanium Dioxide Nanomaterials and Their Energy Applications. Chinese. Journal. of Catalysis. 30, 839–851 (2009).

Warheit, D. B. et al. Development of a base set of toxicity tests using ultrafine TiO2 particles as a component of nanoparticle risk management. Toxicol. Lett. 171, 99–110 (2007).

Geiser, M. et al. Ultrafine particles cross cellular membranes by nonphagocytic mechanisms in lungs and in cultured cells. Environ. Health. Perspect. 113, 1555 (2005).

Tehrani, G. M. et al. Distribution of total petroleum hydrocarbons and polycyclic aromatic hydrocarbons in Musa bay sediments(northwest of the Persian Gulf). Environment Protection Engineering 39, 115–128 (2013).

Kapias, T. & Griffiths, R. F. Accidental releases of titanium tetrachloride (TiCl4) in the context of major hazards spill behaviour using REACTPOOL. J. Hazard. Mater. 119, 41–52 (2005).

Eller, P. M. & Cassinelli, M. E. NIOSH manual of analytical methods. (DIANE Publishing, (1994).

Tavakoly Sany, S. B. et al. Heavy metal contamination in water and sediment of the Port Klang coastal area, Selangor, Malaysia. Environ. Earth. Sci. 69, (2013).

Saadati, N. et al. Limit of detection and limit of quantification development procedures for organochlorine pesticides analysis in water and sediment matrices. Chem. Cen. J. 7, 1–10 (2013).

Bobacka, J., Ivaska, A. & Lewenstam, A. Potentiometric ion sensors. Chem. Rev. 108, 329–351 (2008).

Gholivand, M. B., Babakhanian, A. & Joshaghani, M. Zirconium ion selective electrode based on bis (diphenylphosphino) ferrocene incorporated in a poly (vinyl chloride) matrix. Anal. Chim. Acta. 584, 302–307 (2007).

Arnold, P. J. et al. Copper complexes of the functionalised tripodal ligand tris (2-pyridyl) methylamine and its derivatives. J. Chem. Soci. Dalton Trans. 2001, 736–746 (2001).

Rezayi, M., Kassim, A., Ahmadzadeh, S., Naji, A. & Ahangar, H. Conductometric determination of formation constants of tris (2-pyridyl) methylamine and titanium (III) in water-acetonitryl mixture. Int. J. Electrochem. Sci. 6, 4378–4387 (2011).

Rezayi, M., Heng, L. Y., Abdi, M. M., Noran, N. M. & Esmaeili, C. A Thermodynamic Study on the Complex Formation Between Tris (2-Pyridyl) Methylamine (tpm) with Fe2+, Fe3+, Cu2+ and Cr3+ Cations in Water–Acetonitrile Binary Solutions Using the Conductometric Method. Int. J. Electrochem. Sci 8, 6922–6932 (2013).

Shamsipur, M. et al. A schiff base complex of Zn (II) as a neutral carrier for highly selective PVC membrane sensors for the sulfate ion. Anal. Chem. 73, 2869–2874 (2001).

Farhadi, K. & Maleki, R. Clotrimazole-triiodide ion association as an ion exchanger for a triiodide ion-selective electrode. Anal. Sci. 18, 133–136 (2002).

Ganjali, M. R. et al. Novel triiodide ion-selective polymeric membrane sensor based on mercury-salen. Sensors and Actuators B: Chemical 105, 127–131 (2005).

Bakker, E., Buhlmann, P. & Pretsch, E. Carrier-based ion-selective electrodes and bulk optodes. Chem. Rev. 97, 3083–3132 (1997).

Eugster, R. et al. Plasticizers for liquid polymeric membranes of ion-selective chemical sensors. Anal. Chim. Acta. 289, 1–13 (1994).

Bakker, E., Bühlmann, P. & Pretsch, E. Polymer membrane ion-selective electrodes-what are the limits. Electroanalysis. 11, 915–933 (1999).

Ganjali, M. R., Norouzi, P., Shirvani-Arani, S. & Salavati-Niasari, M. Novel triiodide PVC-based membrane sensor based on a charge transfer complex of iodine and bis (2-hydroxyacetophenone) butane-2, 3-dihydrazon. Bulletin-Korean Chemical Society. 26, 1738 (2005).

Gupta, V. K., Hamdan, A. J. & Pal, M. K. Comparative study on 2-amino-1, 4-naphthoquinone derived ligands as indium (III) selective PVC-based sensors. Talanta. 82, 44–50 (2010).

Nieman, T. A. & Horvai, G. Neutral carrier potassium-selective electrodes with low resistances. Anal. Chim. Acta. 170, 359–363 (1985).

Ammann, D. et al. Lipophilic salts as membrane additives and their influence on the properties of macro-and micro-electrodes based on neutral carriers. Anal. Chim. Acta. 171, 119–129 (1985).

Abdollahi, Y. et al. Artificial neural network modeling of p-cresol photodegradation. Chem. Cent. J. 7, 1–7 (2013).

Kasiri, M., Aleboyeh, H. & Aleboyeh, A. Modeling and optimization of heterogeneous photo-fenton process with response surface methodology and artificial neural networks. Environ Sci. Technol. 42, 7970–7975 (2008).

IUPAC. Analytical Chemistry Division, Commission on Analytical Nomenclature, Recommended for nomenclature of ion-selective electrodes. Pure Appl. Chem. 48, 127–135 (1976).

Cassaignon, S., Koelsch, M. & Jolivet, J. P. From TiCl3 to TiO2 nanoparticles (anatase, brookite and rutile): Thermohydrolysis and oxidation in aqueous medium. J. Phys. Chem. Solids. 68, 695–700 (2007).

Rezayi, M. et al. Immobilization of tris (2 pyridyl) methylamine in PVC-membrane sensor and characterization of the membrane properties. Chem Cent J 6, 40 (2012).

Umezawa, Y., Umezawa, K. & Sato, H. Selectivity coefficients for ion-selective electrodes: recommended methods for reporting Kpota, B Values. Pure and applied chemistry. 67, 507–518 (1995).

Ganjali, M. R., Norouzi, P., Hatambeygi, N. & Salavati-Niasari, M. Anion recognition: fabrication of a highly selective and sensitive HPO42− PVC sensor based on a oxo-molybdenum methyl-salen. J. Braz. Chem. Soc. 17, 859–865 (2006).

Gupta, V. K., Goyal, R. N. & Sharma, R. A. Comparative studies of neodymium (III)-selective PVC membrane sensors. Analytica Chimica Acta 647, 66–71 (2009).

Umezawa, Y. et al. Potentiometric selectivity coefficients of ion-selective electrodes Part II. Inorganic anions. Pure Appl. Chem. 74, 923–994 (2002).

Bakker, E., Pretsch, E. & Bühlmann, P. Selectivity of potentiometric ion sensors. Anal. Chem. 72, 1127–1133 (2000).

Xiao, K. P., Bühlmann, P., Nishizawa, S., Amemiya, S. & Umezawa, Y. A chloride ion-selective solvent polymeric membrane electrode based on a hydrogen bond forming ionophore. Anal. Chem. 69, 1038–1044 (1997).

Acknowledgements

This work was supported by the University of Malaya, Kuala Lumpur, Malaysia by using the High Impact Research Grant UM-MOE UM.C/625/1/HIR/MOE/F00004-21001 from the Ministry of Higher Education Malaysia and PV 124-2012A and the department of chemistry, University Putra Malaysia, Serdang, Selangor, Malaysia.

Author information

Authors and Affiliations

Contributions

M.R., Y.A. and S.A. wrote the main manuscript text. Y.A., L.N. and S.B.T.S. contributed to Artificial Neural Network Analysis, preparing the figure and validation analysis, respectively. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

S1,S2, S3, S4, S5

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Rezayi, M., Karazhian, R., Abdollahi, Y. et al. Titanium (III) cation selective electrode based on synthesized tris(2pyridyl) methylamine ionophore and its application in water samples. Sci Rep 4, 4664 (2014). https://doi.org/10.1038/srep04664

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04664

This article is cited by

-

Burkholderia vietnamiensis G4 as a biological agent in bioremediation processes of polycyclic aromatic hydrocarbons in sludge farms

Environmental Monitoring and Assessment (2023)

-

Use of Efficient and Low-Cost Trimetallic Based on Zero-Valent Iron, Immobilized on Bentonite Surface to Remove Sunset Yellow and Tartrazine Dyes Using Response Surface Optimization Method

Water, Air, & Soil Pollution (2023)

-

Treatment of Leachate of Landfills Using Filters of Ceramic Waste and Scrap Rubber Waste

Water, Air, & Soil Pollution (2022)

-

Application of water quality indices for evaluating water quality and anthropogenic impact assessment

International Journal of Environmental Science and Technology (2019)

-

Removal of acetaminophen from hospital wastewater using electro-Fenton process

Environmental Earth Sciences (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.