Abstract

(2S,3S)-2,3-Butanediol ((2S,3S)-2,3-BD) is a potentially valuable liquid fuel and an excellent building block in asymmetric synthesis. In this study, cofactor engineering was applied to improve the efficiency of (2S,3S)-2,3-BD production and simplify the product purification. Two NADH regeneration enzymes, glucose dehydrogenase and formate dehydrogenase (FDH), were introduced into Escherichia coli with 2,3-BD dehydrogenase, respectively. Introduction of FDH resulted in higher (2S,3S)-2,3-BD concentration, productivity and yield from diacetyl and large increase in the intracellular NADH concentration. In fed-batch bioconversion, the final titer, productivity and yield of (2S,3S)-2,3-BD on diacetyl reached 31.7 g/L, 2.3 g/(L·h) and 89.8%, the highest level of (2S,3S)-2,3-BD production thus far. Moreover, cosubstrate formate was almost totally converted to carbon dioxide and no organic acids were produced. The biocatalytic process presented should be a promising route for biotechnological production of NADH-dependent microbial metabolites.

Similar content being viewed by others

Introduction

2,3-Butanediol (2,3-BD) is a promising bulk chemical with extensive industry applications1,2,3. The heating value of 2,3-BD (27,200 J/g) is comparable with that of other liquid fuels e.g. methanol (22,100 J/g) and ethanol (29,100 J/g), making 2,3-BD a potentially valuable fuel or a fuel additive4. Dehydration of 2,3-BD yields methyl ethyl ketone that is a high quality aviation fuel3,5. There are three isomeric forms of 2,3-BD: (2R,3R)- and (2S,3S)- forms that are optically active, as well as an optically inactive meso-form5. Optically pure 2,3-BD can act as an excellent building block in asymmetric synthesis of chiral compounds that contain 2 vicinal stereocenters6. Thus, it is desirable to develop a practical technique for the production of optically pure 2,3-BD7. Since native microorganisms generally produce a mixture of two isomers (meso- and (2S,3S)- or meso- and (2R,3R)-), metabolic engineering and synthetic biology have been applied to improve the productivity and purity of optically pure 2,3-BD5,8,9,10,11. Researchers reported previously that (2S,3S)-2,3-BD could be produced from diacetyl (DA) by engineered Escherichia coli strains expressing 2,3-butanediol dehydrogenase (2,3-BDH)9,11. Glucose was used for the internal cofactor regeneration. However, two problems need to be solved for economical industrial production: (1) the yield of (2S,3S)-2,3-BD was not satisfactory due to the accumulation of intermediate product acetoin (AC); (2) organic acids excreted during the glucose metabolism would make the purification difficult.

The transformation between 2,3-BD and AC was reversible and coupled with the NADH/NAD+ conversion. Through manipulating the level of intracellular cofactors, production of 2,3-BD or AC can be improved12,13. The accumulation of AC can be ascribed to the unbalance between NADH consumption and regeneration. Goldberg et al. also reported that the internal cofactor regeneration is usually not fast or efficient enough due to the high heterogeneous enzyme concentration in recombinant biocatalysts14. In addition, glucose was metabolized to organic acids such as acetic acid and lactic acid when it was used for the internal cofactor regeneration. Organic acids will cause high energy consumption and loss of the aim product in downstream purification processes15. It has been reported that regeneration of the cofactor makes the production process economically and industrially feasible by driving the reaction to completion, preventing the accumulation of by-products and simplifying the reaction work-up16. Therefore, a potential strategy to solve the aforementioned two problems is to introduce efficient cofactor regeneration system instead of merely using the internal one.

Glucose dehydrogenase (GDH) and formate dehydrogenase (FDH) are widely-used for cofactor regeneration17,18,19,20,21,22. GDH oxidizes the cosubstrate glucose with the regeneration of NAD(P)H. It was rather inexpensive, highly active and stable. Because of the hydrolysis of the coproduct gluconolactone to gluconic acid, the reaction is nearly irreversible, providing a strong driving force for NADH regeneration18. In the case of FDH, NADH is formed when formate is converted to carbon dioxide by FDH. The advantages of FDH involve the use of formate as a cheap and innocuous substrate and ready removal of the coproduct carbon dioxide, thereby a favorable thermodynamic equilibrium18,23.

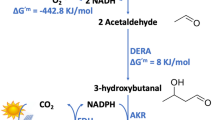

In the present study, FDH or GDH was co-expressed with 2,3-BDH in E. coli, respectively, as shown in Figure 1. The performance of the two resulting recombinant strains, E. coli BL21 (DE3) (pETDuet-bdhgdh) and E. coli BL21 (DE3) (pETDuet-bdhfdh) was evaluated in terms of enzymatic activities, (2S,3S)-2,3-BD production and intracellular NADH/NAD+ level. Our intention is to develop an efficient biocatalytic process for the production of (2S,3S)-2,3-BD by cofactor engineering.

Results

Cloning and expression of bdh, gdh and fdh

To investigate co-expression of 2,3-BDH with GDH or FDH, gdh gene from Bacillus subtilis 168 and fdh gene from Candida boidinii NCYC 1513 were cloned and different engineered E. coli strains were constructed. The resulting recombinant strains, E. coli BL21 (DE3) (pETDuet-bdhgdh) and E. coli BL21 (DE3) (pETDuet-bdhfdh) were characterized for their enzymatic activities and the results were shown in Table 1.

Crude extract of induced E. coli BL21 (DE3) (pETDuet-bdhgdh) showed a 2,3-BDH activity of 39.1 U/mg and a GDH activity of 17.6 U/mg. Meanwhile, a 2,3-BDH activity of 38.9 U/mg and an FDH activity of 0.3 U/mg were detected in crude extract of induced E. coli BL21 (DE3) (pETDuet-bdhfdh). SDS-PAGE analyses of the recombinant proteins were shown in Figure 2. 2,3-BDH and GDH have similar molecular weights, 26.8 kDa for 2,3-BDH and 28.1 kDa for GDH, respectively. These two enzymes were poorly resolved by SDS-PAGE analysis. However, the results of enzyme activity assay and SDS-PAGE indicated that gdh and fdh were successfully co-expressed with bdh, respectively.

Bioconversion with different cofactor regeneration systems

In order to evaluate the potential of the recombinants with different cofactor regeneration systems for the (2S,3S)-2,3-BD production from DA, batch bioconversion was carried out under the same conditions as presented by Li et al.11. Whole cells of recombinants were used as biocatalysts because they were convenient to prepare and suitable for the reactions that require cofactor regenerations14,24. Glucose and formate were added as the cosubstrates for GDH and FDH, respectively, to produce reducing equivalent.

As shown in Table 2, 16.8 g/L of (2S,3S)-2,3-BD (purity > 99%) was obtained after 6 h with a productivity of 2.8 g/(L·h) by E. coli BL21 (DE3) (pETDuet-bdhgdh). The conversion yield of (2S,3S)-2,3-BD on DA was 85.4%. Gluconic acid, acetic acid and lactic acid were the main byproducts. Using E. coli BL21 (DE3) (pETDuet-bdhfdh) as biocatalyst resulted in higher (2S,3S)-2,3-BD concentration, productivity and yield. After 5 h of reaction, 17.8 g/L of (2S,3S)-2,3-BD (purity > 99.0%) was accumulated with a productivity of 3.6 g/(L·h) and a conversion yield of 91.8% by E. coli BL21 (DE3) (pETDuet-bdhfdh). The pH changes during the batch bioconversion were also monitored. Concerning E. coli BL21 (DE3) (pETDuet-bdhgdh), pH was decreased, for the formation of acetic acid, lactic acid and gluconic acid from glucose. Therefore, 10 M NaOH was added periodically to control pH at 7.0. With respect to E. coli BL21 (DE3) (pETDuet-bdhfdh), the consumption of formate resulted in the increase of pH and HCl was added to maintain pH.

Effects of NADH regeneration system on intracellular NADH and NAD+

Heterogeneous expression of GDH or FDH in E. coli was expected to regenerate cofactors and increase the overall intracellular NADH pool, thereby improving the flux of NADH-dependent pathways22. The results of batch bioconversions showed that E. coli BL21 (DE3) (pETDuet-bdhfdh) achieved a higher concentration, productivity and yield of (2S,3S)-2,3-BD than the other two biocatalysts, possibly indicating more NADH was produced by FDH. To explain the phenomenon, intracellular concentrations of NADH and NAD+ were determined.

In all three recombinants, total concentrations of NADH and NAD+ remained constant. Compared with expression of 2,3-BDH alone, co-expression of GDH with 2,3-BDH didn't change the level of NADH remarkably (Figure 3 a and b). As we expect, E. coli BL21 (DE3) (pETDuet-bdhfdh) showed a relatively high level of NADH and a low one of NAD+. The ratio of NADH to NAD+ was also higher and increased continuously. During the bioconversion, DA was converted to (2S,3S)-2,3-BD with NADH consumption. The increased NADH level and ratio of NADH to NAD+ suggested that NADH was indeed regenerated in the engineered strain. After 5 h, the intracellular NADH concentration of E. coli BL21 (DE3) (pETDuet-bdhfdh) increased by 0.43 (0.74 to 1.17) μmol/g DCW, which was slightly lower than those of the other two recombinants (0.45 (0.33 to 0.78) for E. coli BL21 (DE3) (pETDuet-bdh) and 0.49 (0.35 to 0.84) for E. coli BL21 (DE3) (pETDuet-bdhgdh)).

Fed-batch bioconversion by biocatalyst containing 2,3-BDH and FDH

Efficient fed-batch strategies could enhance the concentrations of the aim products5,25,26. To obtain a higher concentration of (2S,3S)-2,3-BD, fed-batch bioconversion was carried out using E. coli BL21 (DE3) (pETDuet-bdhfdh), with an initial DA concentration of 20.0 g/L and adding 5.0 g/L of DA at 2, 4 and 6 h. Formate was used as the driving force for NADH regeneration and added at 0, 4 and 6 h. As shown in Figure 4a, after 14 h of reaction, 31.7 g/L of (2S,3S)-2,3-BD (purity > 99.0%) was produced from 35.3 g/L of DA with a productivity of 2.3 g/(L·h). Only 2.6 g/L of AC was accumulated, leading to a high yield of (2S,3S)-2,3-BD on DA (89.8%). Formate was almost used up at the end of the reaction (Figure 4b) and no organic acids were detected.

Discussion

As a predominant redox product of catabolism, NADH plays an important role in over 700 biochemical reactions, a number of which are synthetically practical enzymatic reactions16,27. Given the high cost of NADH, its stoichiometric use is not economically feasible. Instead, in situ regeneration of the cofactor is necessary16,23. (2S,3S)-2,3-BD is an important precursor of asymmetric synthesis and potentially valuable liquid fuel1,2,3. Engineered biocatalysts were constructed to achieve (2S,3S)-2,3-BD production9,10,11. However, the processes usually suffer from low yield and difficult purification. Here, the efficiency of (2S,3S)-2,3-BD production was improved and the downstream process was simplified by cofactor engineering. The gdh gene encoding GDH and fdh gene encoding FDH were co-expressed with bdh encoding 2,3-BDH in E. coli, respectively. The two resulting recombinants, E. coli BL21 (DE3) (pETDuet-bdhgdh) and E. coli BL21 (DE3) (pETDuet-bdhfdh), shared a similar 2,3-BDH activity, which was nearly half of that of E. coli BL21 (DE3) (pETDuet-bdh)11. The expression levels of 2,3-BDH were quantified using the Glyko BandScan 5.0 software (Glyko, USA). When 2,3-BDH was expressed individually and co-expressed with FDH, the amounts of the recombinant 2,3-BDH accounted for about 25.8% and 15.8% of the total protein in the crude extracts, respectively. It revealed that the 2,3-BDH expression level in co-expression system was about 61.2% of individual recombinant protein. The 2,3-BDH expression level in E. coli BL21 (DE3) (pETDuet-bdhgdh) was not quantified since 2,3-BDH and GDH were overlapped in the gel image. This suggests that the expression levels of the co-expression systems were relatively lower than those of the individual recombinant proteins. Similar results were obtained in other engineered E. coli strains when two genes were co-expressed20,28.

Batch bioconversion was carried out to evaluate the potential of (2S,3S)-2,3-BD production from DA by the recombinants. Compared with the results achieved previously by E. coli BL21 (DE3) (pETDuet-bdh), co-expressing 2,3-BDH with GDH slightly improved the production of (2S,3S)-2,3-BD11. Analysis of by-products indicated that only 5.2 g/L of gluconic acid was produced from glucose by GDH to regenerate NADH (Table 2). Rest of the consumed glucose was metabolized to acetic acid and lactic acid during glucolysis. While co-expressing 2,3-BDH with FDH benefited the production of (2S,3S)-2,3-BD markedly by improving the concentration, productivity and conversion yield. Only 1.1 g/L of AC was accumulated, which contributed to the high conversion yield of (2S, 3S)-2,3-BD on DA (91.8%). Moreover, no organic acids were detected in the bioconversion broth of E. coli BL21 (DE3) (pETDuet-bdhfdh). In the recovery process of alcohols such as 2,3-BD and 1,3-propanediol, vacuum evaporation is usually employed to concentrate the broth. The existence of organic acids will make the operating temperature rise and the on-off concentration ratio decrease, resulting in high energy consumption. Besides, parts of aim product will be lost during the concentration process15. Therefore, preventing the synthesis of organic acids is of great significance.

To investigate the effect of cofactor regeneration systems on intracellular NADH/NAD+ level, concentrations of NADH and NAD+ were determined. Introduction of FDH resulted in higher intracellular NADH/NAD+ level, indicating a high efficiency of NADH regeneration. The relatively lower increased amount of NADH concentration might be due to two reasons. Firstly, a high NADH level was achieved by E. coli BL21 (DE3) (pETDuet-bdhfdh), which might drive the production of (2S,3S)-2,3-BD and consumption of NADH. As shown in Table 2, the highest titer of (2S,3S)-2,3-BD was produced by E. coli BL21 (DE3) (pETDuet-bdhfdh). Therefore, the amount of increased NADH level of E. coli BL21 (DE3) (pETDuet-bdhfdh) might be lower. Secondly, there are systems in microbial cells for maintaining the NADH/NAD+ ratio, for the homeostasis of NADH/NAD+ is essential to sustain the metabolism27. As a result, the intracellular NADH concentration might be difficult to improve when it reach a high level.

As mentioned above, a high GDH activity (17.6 U/mg) was detected in crude extract of E. coli BL21 (DE3) (pETDuet-bdhgdh), but only part of glucose was metabolized to gluconic acid by GDH in the batch bioconversion (Table 2). The low efficiency of GDH in whole-cell biocatalysis might be due to permeation resistance of glucose. Glucose is mainly transported into cells by the active transporter of the phosphotransferase system (PTS) with phosphorylation, producing intracellular glucose-6-phosphate. Meanwhile, glucose can also enter in a non-phosphorylated form through permeation29. In crude extract, glucose acted as the substrate of GDH without permeation across the membrane, leading to a high GDH activity. While in the whole-cell biocatalysis, permeation resistance limited the amount of intracellular glucose. As a result, only part of NADH was produced by GDH, which did not improve the level of intracellular NADH significantly.

To improve the concentration of (2S,3S)-2,3-BD, fed-batch bioconversion was carried out using E. coli BL21 (DE3) (pETDuet-bdhfdh). In comparison with the results achieved by E. coli BL21 (DE3) (pETDuet-bdh) previously11, co-expressing FDH with 2,3-BDH improved the final (2S,3S)-2,3-BD titer from 26.8 g/L to 31.7 g/L and the productivity from 1.9 g/(L·h) to 2.3 g/(L·h). It is worth noting that the conversion yield was increased from 66.7% to 89.8%. In addition, the absence of glucose avoided the production of organic acids, which can make the product extraction easier. It has been reported that the cost of substrates accounted for more than about 30% of total production-cost of 2,3-BD30. Therefore, the cost analyses of substrates were performed to evaluate the fed-batch bioconversions of (2S,3S)-2,3-BD by E. coli BL21 (DE3) (pETDuet-bdh) and E. coli BL21 (DE3) (pETDuet-bdhfdh), without consideration of production process (see Supplementary Data 1 online). The formate cost of E. coli BL21 (DE3) (pETDuet-bdhfdh) was 0.5 US$/kg (2S,3S)-2,3-BD, which was decreased by over 60% than the glucose cost (1.3 US$/kg (2S,3S)-2,3-BD) of E. coli BL21 (DE3) (pETDuet-bdh). Due to the high yield of the recombinant with FDH, the DA cost was 24.5 US$/kg (2S,3S)-2,3-BD, which was decreased by over 25% than recombinant without FDH (33.0 US$/kg (2S,3S)-2,3-BD). Considering the easier purification, introduction of FDH would futher decrease the cost of (2S,3S)-2,3-BD production.

In summary, the introduction of NADH regeneration system may improve the efficiency of (2S,3S)-2,3-BD production and simplify the downstream process. Co-expression of FDH and 2,3-BDH can increase the availability of intracellular NADH and resulted in higher titer, productivity and yield than those of previous studies. Moreover, no organic acids were produced, which may make the product extraction easier. The method developed in this work suggests a useful approach to improve the production efficiency of similar biotechnological processes.

Methods

Enzymes and chemicals

The FastPfu DNA polymerase was acquired from TransGen Biotech (China). The restriction enzymes and T4 DNA ligase were purchased from New England Bio-Labs (Beverly, MA). meso-2,3-BD (98.0%), (2R,3R)-2,3-BD (98.0%) and (2S,3S)-2,3-BD (99.0%) were obtained from ACROS (The Kingdom of Belgium). Isopropyl-β-D-1-thiogalactopyranoside (IPTG), Dithiothreitol (DTT) and phenylmethanesulfonyl fluoride (PMSF) were purchased from Merck (Germany). Ampicillin, NADH and NAD+ were purchased from Amresco (USA). All other chemicals were of analytical grade and commercially available.

Bacterial strains and plasmids

The bacterial strains and plasmids used in this study are listed in Table 3. E. coli DH5α and BL21 (DE3) were used as cloning and expression host, respectively. The pEASY-Blunt cloning vector (TransGen Biotech, China) was used for gene cloning and pETDuet-1 with two T7 promoters was used for gene expression. Luria-Bertani (LB) medium was used for E. coli and B. subtilis 168 cultivations. C. boidinii NCYC 1513 was cultured in YPD medium (2.0% glucose, 2.0% peptone and 1.0% yeast extract). Ampicillin was used at a concentration of 100 μg/mL.

Cloning and expression of bdh, gdh and fdh

B. subtilis 168 and C. boidinii NCYC 1513 genomic DNAs were extracted with the Wizard Genomic DNA Purification Kit (Promega, Madison, WI, USA). The gdh gene was amplified by PCR using forward primer pg1 with a BglII restriction site insertion and reverse primer pg2 with an XhoI restriction site insertion. The PCR product was firstly ligated to the pEASY-Blunt vector and the resulting plasmid was designated pEASY-Blunt-gdh. The pEASY-Blunt-gdh was then sequenced (Sangon, Shanghai, China) to verify that no mutations were introduced by PCR. Next, to construct the recombinant plasmid pETDuet-bdhgdh under the control of the T7 promoter, pEASY-Blunt-gdh was digested with BglII and XhoI and the gel-purified gdh fragment was ligated to the pETDuet-bdh vector digested with the same restriction enzymes. The resulting plasmid was designated pETDuet-bdhgdh. The gdh gene fragment was also ligated to the pETDuet-1 vector with the same restriction sites to obtain the pETDuet-gdh. Using the same process that described above, the fdh gene fragment was obtained from the genome of C. boidinii NCYC 1513 using primers pf1 (with the NdeI restriction site) and pf2 (with the XhoI restriction site) and the pETDuet-bdhfdh was constructed.

Biocatalyst preparation and bioconversion conditions

The recombinant strains were grown in LB medium containing 100 μg/mL of ampicillin at 37°C on a rotary shaker (180 rpm). The cultures were induced with 1 mM IPTG at an OD620 nm of 0.6. 16°C was used for induction to avoid the formation of inactive inclusion bodies for about 10 h. The cells were harvested by centrifugation at 6,000 × g for 5 min at 4°C and then washed twice with 0.85% NaCl. The cell pellets were resuspended in 50 mM Tris-HCl buffer (pH 7.4) and maintained at 4°C for further study.

The bioconversion conditions were as same as that presented by Li et al.11. 10 mL of mixture was reacted at 30°C and 200 rpm in 100 mL flasks. The cell concentration in the reaction was 6.0 g dry cell weight (DCW)/L. pH was controlled at 7.0 by adding HCl or 10 M NaOH. (2S,3S)-2,3-BD production using E. coli BL21 (DE3) (pETDuet-bdhgdh) as the whole-cell biocatalyst was carried out using 20.0 g/L of DA as substrate and 40.0 g/L of glucose as the source of reducing equivalent (molar ratio of 1:1 (DA: glucose)) in 200 mM Tris–HCl buffer (pH 7.0). For (2S,3S)-2,3-BD production catalyzed by E. coli BL21 (DE3) (pETDuet-bdhfdh), 20.0 g/L of DA and 32.0 g/L of formate were required (molar ratio of 1:2 (DA: formate)).

Assays for 2,3-BDH, GDH and FDH activities

The harvested cells were resuspended in 20% glycerol, 0.1 mM PMSF and 1 mM DTT in 50 mM Tris-HCl buffer (pH 7.4) and disrupted by sonication in an ice bath. The homogenate was centrifuged at 18,000 × g for 30 min and the supernatant (crude extract) was recovered. The expressed enzyme was determined by SDS-PAGE. Enzyme activities were assayed spectrophotometrically by measuring the change in absorbance at 340 nm corresponding to the oxidation of NADH or the reduction of NAD+ (ε340 = 6220/M cm) at 30°C. One unit of 2,3-BDH activity was defined as the amount of enzyme that consumed 1 μmol of NADH per min. The reaction solution contained 5 mM of DA and 0.2 mM of NADH in 50 mM Tris-HCl buffer (pH 7.4). One unit of GDH and FDH activity was defined as the amount of enzyme that produced 1 μmol of NADH per min. The reaction solution contained 5 mM of glucose for GDH or formate for FDH and 0.2 mM of NAD+ in 50 mM Tris-HCl buffer (pH 7.4).

Determination of NADH and NAD+ concentrations

The intracellular concentrations of NADH and NAD+ were determined using the EnzyChrom NAD+/NADH Assay kit (E2ND-100) from BioAssay Systems (Hayward, CA, USA) according to the manufacturers' instructions. About 106 cells were required for each sample. The assay kit is based on a lactate dehydrogenase cycling reaction, in which the formed NADH reduces a formazan (MTT) reagent. The intensity of the reduced product color, measured at 565 nm, is proportionate to the NAD+/NADH concentration in the sample.

Analytical methods

The software Glyko BandScan 5.0 (Glyko, USA) was used for analyzing gel images of SDS-PAGE and quantifying the amount of cellular proteins. The concentrations of 2,3-BD and AC were determined by GC using the method described previously10. The purity of (2S,3S)-2,3-BD was defined as  , where [S], [M] and [R] represent the concentrations of (2S,3S)-2,3-BD, meso-2,3-BD and (2R,3R)-2,3-BD, respectively. Glucose was measured enzymatically by a bio-analyzer (SBA-40C, Shandong Academy of Sciences, China) after diluted to the appropriate concentration. The concentration of DA was measured using the colorimetric method31. Organic acids were determined by HPLC using the method described previously11. Gluconic acid was poorly resolved from glucose in this HPLC method and quantified by the gluconokinase/6-phosphogluconate dehydrogenase assay kit (product number 10 428 191 035; R-Biopharm AG, Darmstadt, Germany) after appropriate dilution of the sample.

, where [S], [M] and [R] represent the concentrations of (2S,3S)-2,3-BD, meso-2,3-BD and (2R,3R)-2,3-BD, respectively. Glucose was measured enzymatically by a bio-analyzer (SBA-40C, Shandong Academy of Sciences, China) after diluted to the appropriate concentration. The concentration of DA was measured using the colorimetric method31. Organic acids were determined by HPLC using the method described previously11. Gluconic acid was poorly resolved from glucose in this HPLC method and quantified by the gluconokinase/6-phosphogluconate dehydrogenase assay kit (product number 10 428 191 035; R-Biopharm AG, Darmstadt, Germany) after appropriate dilution of the sample.

References

Syu, M. J. Biological production of 2,3-butanediol. Appl. Microbiol. Biotechnol. 55, 10–18 (2001).

Celińska, E. & Grajek, W. Biotechnological production of 2,3-butanediol–current state and prospects. Biotechnol. Adv. 27, 715–725 (2009).

Oliver, J. W., Machado, I. M., Yoneda, H. & Atsumi, S. Cyanobacterial conversion of carbon dioxide to 2,3-butanediol. Proc. Natl. Acad. Sci. 110, 1249–1254 (2013).

Xiao, Z. et al. Thermophilic fermentation of acetoin and 2,3-butanediol by a novel Geobacillus strain. Biotechnol. Biofuels 5, 88 (2012).

Ji, X. J., Huang, H. & Ouyang, P. K. Microbial 2,3-butanediol production: a state-of-the-art review. Biotechnol. Adv. 29, 351–364 (2011).

Liu, R. & Högberg, H. E. Chemoenzymatic preparation of (2S,3S)- and (2R,3R)-2,3-butanediols and their esters from mixtures of d,l- and meso-diols. Tetrahedron: Asymmetry 12, 771–778 (2001).

Zeng, A. P. & Sabra, W. Microbial production of diols as platform chemicals: recent progresses. Curr. Opin. Biotechnol. 22, 1–9 (2011).

Yan, Y., Lee, C. C. & Liao, J. C. Enantioselective synthesis of pure (R,R)-2,3-butanediol in Escherichia coli with stereospecific secondary alcohol dehydrogenases. Org. Biomol. Chem. 7, 3914–3917 (2009).

Ui, S. et al. Production of l-2,3-butanediol by a new pathway constructed in Escherichia coli. Lett. Appl. Microbiol. 39, 533–537 (2004).

Xiao, Z. et al. A novel whole-cell biocatalyst with NAD+ regeneration for production of chiral chemicals. PLoS One 5, e8860 (2010).

Li, L. et al. Biocatalytic production of (2S,3S)-2,3-butanediol from diacetyl using whole cells of engineered Escherichia coli. Bioresour. Technol. 115, 111–116 (2012).

Gaspar, P., Neves, A. R., Gasson, M. J., Shearman, C. A. & Santos, H. High yields of 2,3-butanediol and mannitol in Lactococcus lactis through engineering of NAD+ cofactor recycling. Appl. Environ. Microbiol. 77, 6826–6835 (2011).

Ji, X. J. et al. Cofactor engineering through heterologous expression of an NADH oxidase and its impact on metabolic flux redistribution in Klebsiella pneumonia. Biotechnol. Biofuels 6, 7 (2013).

Goldberg, K., Schroer, K., Lütz, S. & Liese, A. Biocatalytic ketone reduction–a powerful tool for the production of chiral alcohols–part II: whole-cell reductions. Appl. Microbiol. Biotechnol. 76, 249–255 (2007).

Gong, Y., Tang, Y., Wang, X. L., Yu, L. X. & Liu, D. H. The possibility of the desalination of actual 1,3-propanediol fermentation broth by electrodialysis. Desalination 161, 169–l78 (2004).

Koeller, K. M. & Wong, C. H. Enzymes for chemical synthesis. Nature 409, 232–240 (2001).

Berríos-Rivera, S. J., Bennett, G. N. & San, K. Y. Metabolic engineering of Escherichia coli: increase of NADH availability by overexpressing an NAD+-dependent formate dehydrogenase. Metab. Eng. 4, 217–229 (2002).

Goldberg, K., Schroer, K., Lütz, S. & Liese, A. Biocatalytic ketone reduction–a powerful tool for the production of chiral alcohols–part I: processes with isolated enzymes. Appl. Microbiol. Biotechnol. 76, 237–248 (2007).

Shen, N. D. et al. Efficient synthesis of a chiral precursor for angiotensin-converting enzyme (ACE) inhibitors in high space-time yield by a new reductase without external cofactors. Org. Lett. 14, 1982–1985 (2012).

Kaup, B., Bringer-Meyer, S. & Sahm, H. Metabolic engineering of Escherichia coli: construction of an efficient biocatalyst for d-mannitol formation in a whole-cell biotransformation. Appl. Microbiol. Biotechnol. 64, 333–339 (2004).

Shaw, N. M., Robins, K. T. & Kiener, A. Lonza: 20 years of biotransformations. Adv. Synth. Catal. 345, 425–435 (2003).

Zhang, Y., Huang, Z., Du, C., Li, Y. & Cao, Z. Introduction of an NADH regeneration system into Klebsiella oxytoca leads to an enhanced oxidative and reductive metabolism of glycerol. Metab. Eng. 11, 101–106 (2009).

van der Donk, W. A. & Zhao, H. Recent developments in pyridine nucleotide regeneration. Curr. Opin. Biotechnol. 14, 421–426 (2003).

Schmid, A. et al. Industrial biocatalysis today and tomorrow. Nature 409, 258–268 (2001).

Nie, Z. K. et al. An effective and simplified fed-batch strategy for improved 2,3-butanediol production by Klebsiella oxytoca. Appl. Biochem. Biotechnol. 163, 946–953 (2011).

Qin, J. et al. Production of 2,3-butanediol by Klebsiella pneumoniae using glucose and ammonium phosphate. Chin. J. Chem. Eng. 14, 132–136 (2006).

Liu, L. M. & Chen, J. Cofactor engineering enhances the physiological function of an industrial strain. Progress in Molecular and Environmental Bioengineering–From Analysis and Modeling to Technology Applications. 427–444 (2011).

Rathnasingh, C., Raj, S. M., Jo, J. E. & Park, S. Development and evaluation of efficient recombinant Escherichia coli strains for the production of 3-hydroxypropionic acid from glycerol. Biotechnol. Bioeng. 104, 729–739 (2009).

Plumbridge, J. Expression of ptsG, the gene for the major glucose PTS transporter in Escherichia coli, is repressed by Mlc and induced by growth on glucose. Mol. Microbiol. 29, 1053–1063 (1998).

Wang, A. et al. Efficient 2,3-butanediol production from cassava powder by a crop-biomass-utilizer, Enterobacter cloacae subsp. dissolvens SDM. PLoS One 7, e40442 (2012).

Swindell, S. R. et al. Genetic manipulation of the pathway for diacetyl metabolism in Lactococcus lactis. Appl. Environ. Microbiol. 62, 2641–2643 (1996).

Acknowledgements

The authors acknowledge the National Basic Research Program of China (2011CBA00800) from Ministry of Science and Technology of China and the grant from National Natural Science Foundation of China (31121064). This work was partially supported by the Chinese National Program for High Technology Research and Development (2011AA02A207 and 2012AA022104).

Author information

Authors and Affiliations

Contributions

Y.W., C.M. and P.X. designed experiments. Y.W. and L.L. performed experiments. C.M. and C.G. and P.X. contributed reagents and materials. Y.W., L.L., F.T. and C.G. analyzed data. Y.W., P.X. and F.T. wrote the manuscript. All authors have read and approved the final manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Wang, Y., Li, L., Ma, C. et al. Engineering of cofactor regeneration enhances (2S,3S)-2,3-butanediol production from diacetyl. Sci Rep 3, 2643 (2013). https://doi.org/10.1038/srep02643

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02643

This article is cited by

-

Mechanism of microbial production of acetoin and 2,3-butanediol optical isomers and substrate specificity of butanediol dehydrogenase

Microbial Cell Factories (2023)

-

Highly efficient biosynthesis of spermidine from L-homoserine and putrescine using an engineered Escherichia coli with NADPH self-sufficient system

Applied Microbiology and Biotechnology (2022)

-

Purification and Characterization of (2R,3R)-2,3-Butanediol Dehydrogenase of the Human Pathogen Neisseria gonorrhoeae FA1090 Produced in Escherichia coli

Molecular Biotechnology (2021)

-

Efficient bioproduction of 5-aminolevulinic acid, a promising biostimulant and nutrient, from renewable bioresources by engineered Corynebacterium glutamicum

Biotechnology for Biofuels (2020)

-

Synthetic engineering of Corynebacterium crenatum to selectively produce acetoin or 2,3-butanediol by one step bioconversion method

Microbial Cell Factories (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

) E. coli BL21 (DE3) (pETDuet-bdh), (

) E. coli BL21 (DE3) (pETDuet-bdh), ( ) E. coli BL21 (DE3) (pETDuet-bdhgdh), (

) E. coli BL21 (DE3) (pETDuet-bdhgdh), ( ) E. coli BL21 (DE3) (pETDuet-bdhfdh). Error bars indicate s.d. (n = 3).

) E. coli BL21 (DE3) (pETDuet-bdhfdh). Error bars indicate s.d. (n = 3).

) (2S,3S)-2,3-BD, (

) (2S,3S)-2,3-BD, ( ) AC, (

) AC, ( ) DA and (

) DA and ( ) formate. Error bars indicate s.d. (n = 3).

) formate. Error bars indicate s.d. (n = 3).