Abstract

Water pollution deteriorates ecosystems and has a great threaten to the environment. The environmental benefits of wastewater treatment are extremely important to minimize pollutants. Here, the biochar purchased from the related industry was used to treat the wastewater which contained high concentration of vanadium (V). The concentration of vanadium was measured by the IC-OES and the results showed that 96.1% vanadium (V) was reduced at selected reaction conditions: the mass ratio of biochar to vanadium of 5.4, reaction temperature of 90 °C, reaction time at 60 min and concentration of H2SO4 of 10 g/L, respectively. Response surface methodology confirmed that all the experimental parameters had positive effect on the reduction of vanadium (V), which could improve the reduction efficiency of vanadium (V) as increased. The influence of each parameter on the reduction process followed the order: A (Concentration of H2SO4) > C (mass ratio of biochar to vanadium) > B (mass ratio of biochar to vanadium). Especially, the mass ratio of biochar to vanadium and concentration of H2SO4 had the greatest influence on the reduction process. This paper provides a versatile strategy for the treatment of wastewater containing vanadium (V) and shows a bright tomorrow for wastewater treatment.

Similar content being viewed by others

Introduction

Vanadium, as one of the transition metals, is existed in multiple valences including II, III, IV, and V in the environment, among which, vanadium in IV, and V are stable and common1,2,3,4. Vanadium's low concentration is beneficial for healthy cell proliferation, while high concentration increases the risk of functional lesions in spleen, bones, liver, kidneys and nervous system by food chain5,6,7,8. Vanadium is belonged to the list of environmentally hazardous elements commented by the United Nations Environment Program (UNEP) and the limit level is set as below 0.2 μg/L and below 0.05 μg/L in China (Standard of China GB 5749-2006)9,10,11,12. Compared with other heavy metals, vanadium is more toxic due to its strong oxidative damage to the cells. Thus, it should be removed before wastewater discharge.

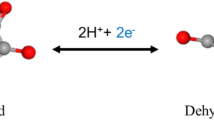

Many methods like biological remediation, adsorption and reduction had been developed for vanadium removal. Biological remediation gained attentions due to its low cost and potential applications for in-situ remediation13,14,15,16, but knowledge is limited on their interaction during the process as well as their biogeochemical cycling in groundwater. Another low cost and easy-operation technology is adsorption, which has been widely applied in treatment of heavy metal containing wastewater17,18,19. And many materials are evaluated, such as zeolite, chitosan, biochar, and orange peel20,21,22. However, adsorption is limited to the large scale and industrial application, also the low concentration of vanadium in the vanadium-containing water streams. Commonly reduction of vanadium (V) to vanadium (IV) is recognized as a feasible method to detoxify them in groundwater as the vanadium (IV) had less toxic and mobile23. Biochar derived from municipal solid waste, straw, wood, manure, sludge, and shell waste is a typical material used in the pollution control because of its low-cost and abundant feed stock availability24,25,26,27. In addition, the large surface area, high mineral content, and rich oxygen-containing functional groups of biochar were favorable for adsorption of wastewater contaminants such as antibiotics, dyes, and heavy metals. However, in our recent studies, biochar had been proved to be an efficient reductant for high valence heavy metal control18,19,28,29. Thus, biochar was applied to treat vanadium-containing wastewater in this paper. The experimental parameters including the mass ratio of biochar to vanadium (m(C)/m(V)), reaction temperature, reaction time and concentration of H2SO4 on the reduction process were investigated. In order to optimize the reaction conditions, the response surface methodology was also investigated.

Materials and methods

Materials

Sodium vanadate, sulfuric acid and biochar were of analytical grade and purchased from Kelong Co., Ltd, Chengdu, China. All solutions were prepared with deionized water with a resistivity greater than 18 MΩ/cm (HMC-WS10).

Experimental procedure

The detailed experimental procedure could be seen in our previous works30,31,32,33,34. For the batch experiments, 0.05 M sodium vanadate solution (prepared by dissolving amount of sodium vanadate in the distilled water) was added into the 300 mL beaker placed in a water bath, the initial pH of the vanadium solution was adjusted by adding sulfuric acid. After the temperature was heated to the determined, the biochar was added and then stirred at 500 rpm. During the reaction process, the samples were collected every 5 min and the concentration of vanadium (V) were measured by Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES, Optima 5300DV)31,32,34, and the reduction efficiency (η) of vanadium (V) was calculated by following Eq. (1):

where Ct, Ct − 1, are the concentration of vanadium (V) at reaction time of t and the last time, mg/L.

Response surface methodology

The response surface methodology (RSM) was applied to optimize the experimental process and order the significance of experimental parameters as the single factor ignore the interactions between the parameters (seen in the supporting information)25,32,35,36,37. The whole design was conducted in the software Design Expert 8.0. The experimental parameters were set as A (Concentration of H2SO4), B (Reaction Temperature) and C (m(C)/m(V)), reduction efficiency was set as the response. The actual values for them were confirmed through the single factor experimental results and displayed in Table 1.

Results and discussion

Thermodynamics analysis

Figure 1a summarized the mole distribution of vanadium species in the aqueous solution at [V] = 0.05 mol/L, the results indicated that the vanadium (V) existed in the form of VO2+, HVO42−, H2VO4−, V2O74−, HV2O73−, H2V2O72−, V4O124−, V4O136−, HV4O135−, V5O155−, V6O186−, V10O286−, HV10O285−, H2V10O284−, H3V10O283−18,31,38. The main reactions during the reduction process were likely reacted as Eqs. (2), (3), (4) and (5). The standard Gibbs energy (\(\Delta {\text{G}}_{{\text{T}}}^{\uptheta }\)) of these reaction equations at selected reaction temperatures could be calculated with \(\Delta_{{\text{f}}} {\text{H}}_{{{298}}}^{\uptheta }\), \({\text{S}}_{{{298}}}^{\uptheta }\) and \({\text{C}}_{{\text{p}}}\) following Eqs. (6), (7) and (8)39,40.

Equation (9) was obtained by merging Eqs. (6), (7) and (8).

And \(\Delta {\text{Cp}}\) was calculated as Eq. (10).

Then \(\Delta {\text{G}}_{{\text{T}}}^{\uptheta }\) was calculated as Eq. (11).

Integrate.

The \(\Delta_{{\text{f}}} {\text{H}}_{{{298}}}^{\uptheta }\), \(\Delta {\text{S}}_{{\text{T}}}^{\uptheta }\), a, b, c and d in Eq. (12) could be obtained from the handbook.

The results showed in Fig. 1b displayed that the ΔG of the Eqs. (2)–(5) which occurred during the reduction process were all negative at selective reaction temperatures. It was concluded that the reduction process was easy to occur in thermodynamics. The E-pH diagram of vanadium and biochar measured by HSC Chemistry 6.0 was shown in Fig. 1c, it was clear that vanadium (V) was above than biochar, which meant that the oxidation–reduction potential of vanadium (V) was higher than biochar, thus, the biochar could be used as a reductant to reduce vanadium (V) into vanadium (IV) in theory.

Reduction process

In this paper, the effect of parameters including the mass ratio of biochar to vanadium (m(C)/m(V)), reaction temperature, reaction time and concentration of H2SO4 on the reduction process were investigated, the results were displayed in Fig. 2.

The mass ratio of biochar to vanadium had a significant effect on the reduction of vanadium (V) as it was the main reaction reagent. A series of experiments were conducted to investigate the effect of the mass ratio of biochar to vanadium (m(C)/m(V)) on the reduction process. The m(C)/m(V) was set as m(C)/m(V) = 0.9, 1.8, 2.7, 3.6, 4.5 and 5.4, respectively. The results showed that the reduce efficiency of vanadium was increased with the increase of m(C)/m(V) at selected reaction temperatures. High dosage was beneficial for the reduction process as the biochar was the direct reaction reagent. The reduction efficiency of vanadium was just 5.2% at m(C)/m(V) = 0.9, concentration of H2SO4 was 0 g/L and reaction temperature of 30 °C, it was improved to 12.1% at the m(C)/m(V) = 0.9 while other conditions were kept. It was just increased 7 percentages. While at concentration of H2SO4 was 10 g/L, the reduction efficiency was increased from 58.8% to 85.1% as mass ratio of biochar to vanadium increased from m(C)/m(V) = 0.9 to m(C)/m(V) = 5.4. The large improvement indicated that the mass ratio of biochar to vanadium had significant effect on the reduction process.

Usually, reaction temperature played an important role in a standard chemical reaction. In this paper, reaction temperature was set as 30, 50, 70, and 90 °C, respectively. Compared the experimental results at selected temperatures, the reduction efficiency was increased with the increasing of reaction temperature, and the increasing trend of reduction efficiency was similar with mass ratio of biochar to vanadium, which indicated that both mass ratio of biochar to vanadium and reaction temperature had significant effect on the reduction process. Higher temperature could intensify the activity of biochar molecule and vanadium (V) ion, promote the extent of the reduction reaction and enforce the reduction of vanadium (V). The maximum reduction efficiency of vanadium at reaction temperature of 30 °C was 85.1% at m(C)/m(V) = 5.4 with 10 g/L H2SO4, while at the reaction temperature of 90 °C, the reduction efficiency was 90.2% just at m(C)/m(V) = 0.9 and increased to 96.1% at at m(C)/m(V) = 5.4. The results indicated that the higher reaction temperature could enhance the reduction process significantly.

The results showed in Fig. 2 indicated that the concentration of H2SO4 had different effect on the reduction efficiency with mass ratio of biochar to vanadium and reaction temperature. When the concentration of H2SO4 was 0 g/L, the vanadium was existed as HVO42− and VO43− owing to the high alkaline solution, the reaction was not significant and little vanadium was reduced. With the increase of concentration of H2SO4, the existence of vanadium was changed, the maximum reduction efficiency was achieved at 10 g/L and then decreased follow the increase of concentration of H2SO4. The reduction reaction was simple while the experimental results were special and the detailed reaction mechanism between biochar with polymeric vanadium ions was not clear and needed further study in our future works. At concentration of H2SO4 was 0 g/L, the maximum reduction efficiency of vanadium was just 15.6% at m(C)/m(V) = 0.9 and reaction temperature of 90 °C, it was improved to 96.1% at concentration of H2SO4 was 10 g/L and decreased to 73.5% at concentration of H2SO4 was 30 g/L as other conditions kept.

As discussed above, the experimental parameters all had significant effect on the reduction process, in order to optimize the reaction conditions, response surface methodology was introduced.

Response surface methodology

Response surface methodology was an efficient method which offered a large amount of information from a relative small number of experiments, allowing the observation of both the effect of the independent variables on the response as well as their possible interactions. And it had been extensively applied for optimization study of test parameters and obtained response surfaces25,32,35,36,37. From the results analyzed above, the parameters including the mass ratio of biochar to vanadium (m(C)/m(V)), reaction temperature, reaction time and concentration of H2SO4 all had influences on the reduction process, but was hard to distinguish the important for all. Thus, the response surface methodology was applied.

Model fitting

The squares root was used to express the simulated results and it was presented in Eq. (13):

\({\text{sqrt }}\left(\upeta \right) = {8}.{77} + {2}.{21}*{\text{A}} + 0.{3}0*{\text{B}} + 0.{63}*{\text{C}} + 0.0{82}*{\text{AB}} - 0.0{39}*{\text{AC}} - 0.{13}*{\text{BC}} - {3}.{1}0*{\text{A}}^{{2}} - 0.{14}*{\text{B}}^{{2}} - 0.{24}*{\text{C}}^{{2}}\) (13)

The influence of each parameter on the reduction efficiency of vanadium (V) could be seen from the coefficients before them in the Eq. (13). The coefficients of them were 2.21, 0.30 and 0.63, respectively, which confirmed that all the parameters had positive effects on the reduction efficiency. The results displayed in Fig. 3 indicated that the influence of each parameter on the reduction efficiency followed the order: A > C > B, which was consistent with the results described in Eq. (13). Above all, the mass ratio of biochar to vanadium and concentration of H2SO4 had the greatest influence on the reduction process.

Response surface analysis

The reduction process of vanadium using biochar through various variables could be investigated through these model equations. Different parameters R2, P-values, F-values and adjusted R2 values were measured as standard that were helpful to determine the accuracy of every coefficient in order to appraise the significance of predicated model35,36,37,41,42. The ANOVA results (seen in Table 2) confirmed that model F-values of 148.66 showed that predicated model was substantial. There was only 0.01% chance that an F-values, which could occur owing to noise. The model P-values (< 0.0001) less than 0.050 indicted model terms were significant. In this optimization case, several model terms such as A, B, C and A2 were in significant form due to their less P-value. The values larger than 0.10 means insignificant model terms. In this case, AB, AC, BC, and B2 were insignificant model terms. The R2-value exhibited a measure of how much variability in the observed response values could be expressed by the experimental factors as well as their interactions by establishing a relationship between predicated and experimental consequences. R2 close to one revealed good fitting of experimental data into predicated model equation. The regression model produced higher R2 up to 0.9948 signifying excellent fitting between model as well as experimental data values. The Rredicated-R2 up to 0.9167 was in reasonable agreement with the Adjusted-R2 of 0.9881. The Adequate-precision was helpful to evaluate the signal-to-noise ratio. A ratio greater than 4 was desirable. Here, higher Adequate-precision of 34.441 revealed an adequate signal. This regression model could be applied to navigate the design space.

The possible inspiration of variables over maximum reduction efficiency for vanadium using biochar was explained through response surface plots. These response surface plots were helpful for the determination of cooperative association between specific parameter and response for the maximum reduction efficiency. Figure 4 described the 2-D counter plots of combined influence of four experimental parameters over the reduction efficiency for vanadium using biochar. The counter plots were providing the mutual interactions among the independent parameters. It could be analyzed that all selected parameters had direct effect over the reduction of vanadium. These response surface plots confirmed the perfect and strong interactions among the selected independent experimental parameters. Higher reaction temperature and higher mass ratio of biochar to vanadium were beneficial for the reduction process, the results were consistent with our previous studies28,34.

Response surface plots for factors. (a) X1 = A: [H2SO4], X2 = B: Temperature C: m(C)/m(V) = 0.90, 1.80, 2.70, 3.60, 4.50, 5.40. (b) X1 = A: [H2SO4], X2 = C: m(C)/m(V) B: Temperature = 30°C, 50°C, 70°C, 90°C. (c) X1 = B: Temperature, X2 = C: m(C)/m(V) A: [H2SO4] = 0 g/L, 5 g/L, 10 g/L, 15 g/L, 20 g/L, 30 g/L.

Conclusions

A highly efficient reduction process of vanadium (V) with biochar was investigated and the following conclusions could be obtained:

-

1.

The vanadium (V) was easily being reduced by biochar at high reaction temperature with high mass ratio of biochar to vanadium in acidic medium. Nearly 96.1% vanadium (V) was reduced at selected reaction conditions: the mass ratio of biochar to vanadium at m (C)/m(V) = 5.4, reaction temperature of 90 °C, reaction time at 60 min and concentration of H2SO4 of 10 g/L, respectively.

-

2.

Response surface methodology confirmed that all the experimental parameters had positive effect on the reduction of vanadium (V). The influence of each parameter on the reduction process followed the order: A (concentration of H2SO4) > C (mass ratio of biochar to vanadium) < B (m (C)/m(V). Especially, the mass ratio of biochar to vanadium and concentration of H2SO4 had the greatest influence on the reduction process.

Data availability

All data generated or analyzed during this study are included in this published article and supporting information.

References

Mangini, L. F. K., Valt, R. B. G., Ponte, M. J. J. D. S. & Ponte, H. D. A. Vanadium removal from spent catalyst used in the manufacture of sulfuric acid by electrical potential application. Sep. Purif. Technol. 246, 116854 (2020).

Li, H., Wang, C., Lin, M., Guo, Y. & Xie, B. Green one-step roasting method for efficient extraction of vanadium and chromium from vanadium-chromium slag. Powder Technol. 360, 503–508 (2020).

Huang, X. et al. Removal of V(V) from solution using a silica-supported primary amine resin: batch studies. Exp. Anal. Math. Model. Mol. 25, 1448 (2020).

Yu, Y.-Q. & Yang, J.-Y. Oral bioaccessibility and health risk assessment of vanadium (IV) and vanadium (V) in a vanadium titanomagnetite mining region by a whole digestive system in-vitro method (WDSM). Chemosphere 215, 294–304 (2019).

Li, Y., Low, G. K. C., Scott, J. A. & Amal, R. Microbial reduction of hexavalent chromium by landfill leachate. J. Hazard Mater. 142, 153–159 (2007).

Xu, X., Xia, S., Zhou, L., Zhang, Z. & Rittmann, B. E. Bioreduction of vanadium (V) in groundwater by autohydrogentrophic bacteria: Mechanisms and microorganisms. J. Environ. Sci. 30, 122–128 (2015).

Chen, D., Xiao, Z., Wang, H. & Yang, K. Toxic effects of vanadium (V) on a combined autotrophic denitrification system using sulfur and hydrogen as electron donors. Bioresour. Technol. 264, 319–326 (2018).

Liu, H. et al. Microbial reduction of vanadium (V) in groundwater: Interactions with coexisting common electron acceptors and analysis of microbial community. Environ. Pollut. 231, 1362–1369 (2017).

Lin, H., Liu, J., Dong, Y. & He, Y. The effect of substrates on the removal of low-level vanadium, chromium and cadmium from polluted river water by ecological floating beds. Ecotoxicol. Environ. Saf. 169, 856–862 (2019).

Zhang, J., Dong, H., Zhao, L., McCarrick, R. & Agrawal, A. Microbial reduction and precipitation of vanadium by mesophilic and thermophilic methanogens. Chem. Geol. 370, 29–39 (2014).

Wang, S. et al. Enhancement of synchronous bio-reductions of vanadium (V) and chromium (VI) by mixed anaerobic culture. Environ. Pollut. 242, 249–256 (2018).

Zhang, B., Feng, C., Ni, J., Zhang, J. & Huang, W. Simultaneous reduction of vanadium (V) and chromium (VI) with enhanced energy recovery based on microbial fuel cell technology. J. Power Sources 204, 34–39 (2012).

Reijonen, I., Metzler, M. & Hartikainen, H. Impact of soil pH and organic matter on the chemical bioavailability of vanadium species: The underlying basis for risk assessment. Environ. Pollut. 210, 371–379 (2016).

Nayak, S., Saarmi, R. & Kale, B. P. P. A review of chromite mining in Sukinda Valley of India: Impact and potential remediation measures. Int. J. Phytoremed. 22, 804–818 (2020).

Shaheen, S. M., Rinklebe, J., Frohne, T., White, J. R. & DeLaune, R. D. Redox effects on release kinetics of arsenic, cadmium, cobalt, and vanadium in Wax Lake Deltaic freshwater marsh soils. Chemosphere 150, 740–748 (2016).

Fang, D., Zhang, X., Dong, M. & Xue, X. A novel method to remove chromium, vanadium and ammonium from vanadium industrial wastewater using a byproduct of magnesium-based wet flue gas desulfurization. J. Hazard Mater. 336, 8–20 (2017).

Taweekarn, T., Wongniramaikul, W. & Choodum, A. Removal and recovery of phosphate using a novel calcium silicate hydrate composite starch cryogel. J. Environ. Manag. 301, 113923 (2022).

Peng, H. et al. Removal and recovery of vanadium from waste by chemical precipitation, adsorption, solvent extraction, remediation, photo-catalyst reduction and membrane filtration. A review. Environ. Chem. Lett. 20, 1763–1776 (2022).

Peng, H. & Guo, J. Removal of chromium from wastewater by membrane filtration, chemical precipitation, ion exchange, adsorption electrocoagulation, electrochemical reduction, electrodialysis, electrodeionization, photocatalysis and nanotechnology: A review. Environ. Chem. Lett. 18, 2055–2068 (2020).

Leiviskä, T., Matusik, J., Muir, B. & Tanskanen, J. Vanadium removal by organo-zeolites and iron-based products from contaminated natural water. J. Clean. Prod. 167, 589–600 (2017).

Jiang, Y. et al. Synchronous microbial vanadium (V) reduction and denitrification in groundwater using hydrogen as the sole electron donor. Water Res. 141, 289–296 (2018).

Mohamed, A. K. & Mahmoud, M. E. Nanoscale Pisum sativum pods biochar encapsulated starch hydrogel: A novel nanosorbent for efficient chromium (VI) ions and naproxen drug removal. Bioresour. Technol. 308, 123263 (2020).

Chen, G. & Liu, H. Understanding the reduction kinetics of aqueous vanadium(V) and transformation products using rotating ring-disk electrodes. Environ. Sci. Technol. 51, 11643–11651 (2017).

Peng, H. et al. Efficient adsorption-photocatalytic removal of tetracycline hydrochloride over La2S3-modified biochar with S,N-codoping. J. Water Process Eng. 49, 103038 (2022).

Peng, H. et al. Efficient removal of Cr (VI) with biochar and optimized parameters by response surface methodology. Processes 9, 889 (2021).

Wang, B. et al. Phosphogypsum as a novel modifier for distillers grains biochar removal of phosphate from water. Chemosphere 238, 124684 (2020).

Shakoor, M. B. et al. A review of biochar-based sorbents for separation of heavy metals from water. Int. J. Phytoremediat. 22, 111–126 (2020).

Peng, H., Guo, J., Qiu, H., Wang, C., Zhang, C., Hao, Z., Rao, Y., & Gong, Y. Efficient removal of Cr (VI) with biochar and optimized parameters by response surface methodology. In Processes (2021).

Bashir, A. et al. Removal of heavy metal ions from aqueous system by ion-exchange and biosorption methods. Environ. Chem. Lett. 17, 729–754 (2019).

Peng, H., Leng, Y. & Guo, J. Electrochemical removal of chromium (VI) from wastewater. Appl. Sci. 9, 1156 (2019).

Peng, H. et al. A clean method for vanadium (V) reduction with oxalic acid. Metals 12, 557 (2022).

Peng, H. et al. Thermodynamic and kinetic studies on adsorption of vanadium with glutamic acid. ACS Omega 6, 21563–21570 (2021).

Peng, H., Guo, J. & Wang, B. Adsorption behavior of Fe (III) in aqueous solution on melamine. Water Sci. Technol. 82, 1848–1857 (2020).

Peng, H. & Guo, J. Reduction behavior of chromium(VI) with oxalic acid in aqueous solution. Sci. Rep. 10, 17732 (2020).

Bao, S., Chen, Q., Zhang, Y. & Tian, X. Optimization of preparation conditions of composite electrodes for selective adsorption of vanadium in CDI by response surface methodology. Chem. Eng. Res. Des. 168, 37–45 (2021).

Peng, H., Wang, F., Li, G., Guo, J. & Li, B. Highly efficient recovery of vanadium and chromium: Optimized by response surface methodology. ACS Omega 4, 904–910 (2019).

Anfar, Z. et al. Recent trends on numerical investigations of response surface methodology for pollutants adsorption onto activated carbon materials: A review. Crit. Rev. Environ. Sci. Technol. 50, 1043–1084 (2019).

Peng, H. et al. Vanadium recovery by glycine precipitation. Environ. Chem. Lett. 20, 1569–1575 (2022).

Banwen, S. & Yuji, L. Inorganic Chemistry Series (Science Press, 1998).

Peng, H., Guo, J., Liu, Z. & Tao, C. Direct advanced oxidation process for chromium(III) with sulfate free radicals. SN Appl. Sci. 1, 828 (2018).

Zbair, M., Anfar, Z. & Ahsaine, H. A. Reusable bentonite clay: modelling and optimization of hazardous lead and p-nitrophenol adsorption using a response surface methodology approach. RSC Adv. 9, 5756 (2019).

Olmez, T. The optimization of Cr(VI) reduction and removal by electrocoagulation using response surface methodology. J. Hazard Mater. 162, 1371–1378 (2009).

Funding

This work was supported by the key development projects of the Liangshan Prefecture (Nos. 23ZDYF0169 and 23ZDYF0173), the National Natural Science Foundation of China (No. U1960101) and Key research and development plan of Anhui Province (No. 2022l07020037).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Yuting Wu, Jing Guo, The first draft of the manuscript was written by Hao Peng and Bing Li. Laixin Wang and Yinhe Lin commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Peng, H., Wang, L., Guo, J. et al. Efficient reduction of vanadium (V) with biochar and experimental parameters optimized by response surface methodology. Sci Rep 14, 8118 (2024). https://doi.org/10.1038/s41598-024-58880-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-58880-4

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.