Abstract

Ionic liquids (ILs) are more widely used within the industry than ever before, and accurate models of their physicochemical characteristics are becoming increasingly important during the process optimization. It is especially challenging to simulate the viscosity of ILs since there is no widely agreed explanation of how viscosity is determined in liquids. In this research, genetic programming (GP) and group method of data handling (GMDH) models were used as white-box machine learning approaches to predict the viscosity of pure ILs. These methods were developed based on a large open literature database of 2813 experimental viscosity values from 45 various ILs at different pressures (0.06–298.9 MPa) and temperatures (253.15–573 K). The models were developed based on five, six, and seven inputs, and it was found that all the models with seven inputs provided more accurate results, while the models with five and six inputs had acceptable accuracy and simpler formulas. Based on GMDH and GP proposed approaches, the suggested GMDH model with seven inputs gave the most exact results with an average absolute relative deviation (AARD) of 8.14% and a coefficient of determination (R2) of 0.98. The proposed techniques were compared with theoretical and empirical models available in the literature, and it was displayed that the GMDH model with seven inputs strongly outperforms the existing approaches. The leverage statistical analysis revealed that most of the experimental data were located within the applicability domains of both GMDH and GP models and were of high quality. Trend analysis also illustrated that the GMDH and GP models could follow the expected trends of viscosity with variations in pressure and temperature. In addition, the relevancy factor portrayed that the temperature had the greatest impact on the ILs viscosity. The findings of this study illustrated that the proposed models represented strong alternatives to time-consuming and costly experimental methods of ILs viscosity measurement.

Similar content being viewed by others

Introduction

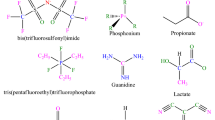

Ionic Liquids (ILs) are novel, highly tunable, and unique compounds that emerged in response to interest in green chemical technologies1. In the last few decades, an enormous amount of research has gone into developing ILs for a wide range of uses, from industrial to molecular, such as gas absorption, energy storage, biotechnology, electrochemistry, separation, and fluid flow in porous media2,3,4,5. ILs are materials composed only of ions and having a melting point of less than 100 °C. They are created chemically when organic cations (such pyridinium, phosphonium, imidazolium, and ammonium) combine with organic and inorganic anions (like phosphates, halides, and sulfates)5,6. When Paul Walden originally described the IL (ethylammonium nitrate ([NHHH2] [NO3]) back in 1914, he had no idea that nearly a century later the field of ILs would become very significant6. Since 1996, the number of scientific papers on ILs has skyrocketed from just a few to over 8000 by 2020, far outpacing the growth rates of other well-known scientific fields7.

The type and arrangement of cations and anions, as well as the quantity of branching chains inside the molecules, are strongly linked to the characteristics of ILs8. ILs have several noteworthy characteristics, such as strong ion conductivity, remarkable permittivity, outstanding electrical properties, nonflammability, high heat capacity, and thermal and chemical durability8,9. Decades of research have led to the development of novel ionic liquids that can be synthesized to customize their physical and chemical characteristics for specific applications. As more ion combinations were developed, it became essential to describe their physical and chemical characteristics10,11. The addition of even small quantities of chemical precursors, for instance halides or water, might cause ILs to become very sensitive. Therefore, studying their physicochemical properties is vital. Density, electrical/thermal conductivity, sound speed, surface and interface properties, refractive index, and viscosity are necessary variables that require precise prediction and optimization. Viscosity is one of the key physicochemical characteristics that assist in assessing the purity, fluid dynamics, and intermolecular forces of ILs11,12. ILs have complex thermodynamic and physicochemical properties, therefore, modeling approaches and large datasets are needed to predict their viscosity. ILs have a viscosity range of between 10 and 10,000 mPa s, and their viscosity is much higher than conventional solvents (0.1–100 mPa s), which may be a big issue for applications requiring mass or charge transfer13. In this regard, accurate models of ILs viscosity are required for process modeling, which allow to minimize costs/energy and predict physicochemical properties of ILs14,15,16. Several computational methods, including group contribution methods (GCM), intelligent approaches (IA), and quantitative structure-property relationships (QSPR), can be used to determine the viscosity of ILs15,17,18. For example, Gardas and Coutinho used GCM to estimate the viscosity of ILs across a large temperature range (293–393 K) utilizing 500 data points from 29 distinct ILs (based on imidazolium, pyrrolidinium, and pyridinium). According to the results, 7.7% was the absolute average relative deviation (AARD) for determining the viscosity of ILs19. Other research was conducted by Gharagheizi et al. In this study, the viscosity of the IL was estimated using a GCM method. The model was based on 443 distinct ILs (1672 data points) with the temperature range from 253.15 to 433.15 K, and the result was an AARD of 6.3%20. Lazzús et al., in turn, developed a GCM-based linear model to predict ILs viscosity at temperatures ranging from 253 to 395 K, with an AARD of approximately 4.5%21. At the same time, AARD was about 11.4% in the study of Paduszynski et al. This work detailed the use of feed-forward neural network (FF-NN) based GCM using 13,000 data points (1484 ILs) with temperature and pressure ranges of 253–573 K and 0.06–350 MPa, respectively22. Finally, AARD for linear and nonlinear models were 10.68% and 6.58%, accordingly, as was suggested by the QSPR model of Zhao et al.23. This paper was based on a databank consisting of 1502 experimental points (89 ILs) across a broad range of temperatures (253.15–395.2 K) and pressures (0.1–300 MPa).

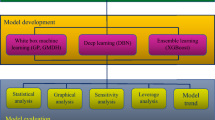

The nodes and layers of an artificial neural network (ANN) are controlled by a vast collection of equations. Aside from that, the number of nodes and levels in the network are decided either manually or at random24,25. The use of machine learning methods to model complicated systems has gained popularity recently25,26,27,28,29,30,31. Machine learning methods fall into two categories: black and white-box methods. Black-box models such as neural networks or gradient boosting may be quite accurate26. Black-box models (e.g., support vector regression (SVR) and decision tree) rely on a complicated computer-aided process, whereas white-box models (e.g., gene expression programming (GEP) and group method of data handling (GMDH)) clearly provide a simple and explainable approach26,32,33,34. Because white-box models provide a model that is more like to human language, they are often understandable to experts in practical applications. White-box models are based on patterns, rules, or decision trees32,35. The GMDH methodology, a self-organizing neural network, can not only describe the system's genome using simple polynomials, but it can also employ standard minimization procedures to determine the optimal configuration24. In our previous research, we used several black-box machine learning approaches for modeling the viscosity of ILs. Also, we developed a simple correlation using a trial-and-error procedure. However, the proposed correlation was not accurate enough and could predict the data with an AARD of 28%, which is high for engineering practices25. Thus, developing a more accurate correlation with high accuracy using advanced correlative approaches such as GMDH and GP appears to be a preferable research direction.

This work models a vast set of 2813 experimental viscosity values from 45 distinct IL using GP and GMDH models with diverse inputs. Additionally, empirical and theoretical methods—such as Eyring's theory (ET)—are used to estimate the viscosity of pure ILs. To determine which approach is the most correct, the dependability of the models that are provided is assessed using both graphical and statistical criteria. The sensitivity analysis is also used to determine how different input factors affect viscosity in relation to one another. Lastly, the quality of the experimental data is assessed and the application domain of the suggested models is determined using the leverage technique.

Data collection

A model can be more accurate and widely applicable the more data points it contains. In order to do this, 2813 experimental viscosity data from 45 ILs were gathered from open literature sources at varying pressures (0.06–298.9 MPa), temperatures (253.15–573 K), and viscosities (1.13–9667.6 MPa.s)36,37,38,39,40,41,42,43,44,45,46,47,48.

Recognizing the potential risks associated with open literature data, a thorough screening method was implemented. This process evaluates the quality and consistency of experimental data based on specific criteria. Rigorous analysis was applied to any data points that raised questions, with verification achieved through direct contact with the original authors or alternative sources. This scrupulous approach enhances the robustness of the analytical data, fortifying the conclusions drawn. Strict standards for experimental data from open literature sources significantly contribute to the reliability of the results, highlighting the commitment to data dependability.

The dataset was randomly split into training (80%) and test (20%) subsets, ensuring that the test set remains undisclosed during parameter adjustments for independence. The application of k-fold cross-validation to the training subset played a pivotal role in this investigation. This approach ensures that each observation in the dataset is included in both the training and validation sets. The deliberate use of 6 k-folds for all models was strategic, with the choice depending on the data size—striking a balance between avoiding excessive or insufficient fold sizes. The train data underwent random partitioning into 6 folds, where the model fitting involved K-1 folds (i.e., 5 folds), and validation was conducted using the remaining fold.

Model development

Using Eyring’s Theory (ET) to calculate Pure Viscosity

Kirkwood et al. have come up with a strong theory regarding how monatomic liquids transport49. This idea itself, however, does not provide immediate results. The absolute rate idea was suggested by Eyring et al.50,51. The individual molecules are always moving in a pure liquid at rest. But because the molecules are closely packed inside a "cage," the motion is mostly limited to the vibrations that each molecule generates in response to its nearest neighbors. The height-energy barrier \(\frac{\Delta \widehat{{G}_{0}^{+}}}{{{\text{N}}}_{{\text{A}}}}\)is this "cage" where \({{\text{N}}}_{{\text{A}}}\)stands for the Avogadro number (molecules/g-mol). Additionally, in order to "escape" from the stationary fluid cage, \({\Delta{G+0}}\)ˆ, or a molar-free activation energy, is required. (Fig. 1)25,51.

Illustration of a liquid flow's escape mechanism. Molecule 1 has to go through a "bottleneck" in order to get to the vacant position.25.

Following Eyring’s theory (ET), a molecule escapes its “cage” into a resting liquid's “hole”25. As a result, every molecule moves in the length of “\(\dot{\alpha }\)” at a frequency “\(f\)”. The frequency is set by the rate expression:

where \(K\), \(P\), and \(R\) are stand for the Boltzmann (J/K), the Planck constant, and the gas constant (J/mole·k), respectively. \(T\) and \(\Delta \widehat{{G}_{0}^{+}}\) represent the molar activation energy and absolute temperature (K) of the fluid at rest. Additionally, a fluid traveling in the x-direction with a gradient of velocity \(\left(\frac{d{V}_{x}}{dy}\right)\)experiences molecular reconfigurations more often. The potential energy barrier, deformed by the applied stress \({\tau }_{yx}\) is seen in Fig. 1 and will be expressed using the subsequent equation:

where an estimate of how much work was performed on the molecules is shown by \(\pm (\gamma /\dot{\alpha })\left(\frac{{\tau }_{yx}\widetilde{Q}}{2}\right)\). This is the mole liquid volume denoted by \(\widetilde{Q}\). Equations (2) and (3) are then merged as follows:

The net velocity (Fig. 1) shows the separation between molecules in layer "A" and layer "B." The computation involves multiplying the net frequency of advancing jumps (\({f}_{+}-{f}_{-}\)) by the distance travel in each jump (\({\dot{\alpha}}\)). The frequency of forward and backward leaps are denotedby "\({f}_{+}\)" and "\({f}_{-}\)". The following equation is used:

Over a fairly small distance “\(\dot{\alpha }\)” between the two layers, a linear velocity profile may be observed, allowing:

To sum up, Eqs. (4) and (6) are combined to form the following equation:

If \(\frac{\gamma {\tau }_{yx}\widetilde{Q}}{2\dot{\alpha }TR}\ll 1\), the Taylor series can also be applied. Finally, the viscosity is derived using the following equation:

The unity factor, \(\frac{\gamma }{\dot{\alpha }}\), makes the equation without compromising accuracy, since \(\widehat{\Delta {G}_{0}^{+}}\) is acquired empirically to ensure that the equation’s values match the experimental results. However, it is demonstrated that, for a given fluid, the estimated \(\widehat{\Delta {G}_{0}^{+}}\) (free activation energies) are almost constant when fitting Eq. (8) to experimental viscosity values. This translates to the boiling point internal energy of vaporization \(\left(\Delta {\widehat{U}}_{vap}=\Delta {H}_{{\text{vap}}}-\mathrm{RT\Delta }{Z}_{{\text{vap}}}\right)\), which is given by Eq. (9) as follows63:

By using this empiricism and setting \(\frac{\dot{\alpha }}{\gamma }=1\), Eq. (8) becomes as follows when empiricism is set at \(\frac{\dot{\alpha }}{\gamma }=1\):

The following is an accurate estimate of the vaporization energy provided by the Trouton's rule at the typical boiling point:

Equation (10), when approximated, reads as follows:

where \(\eta\) indicates the expected viscosity (mPa·s) of pure ILs. \({{\text{N}}}_{A}\) and \(p\), respectively, are the Avogadro number (mole−1) and the Plank constant (J·s). The \(\overline{Q }\) represents the volume of a mole of liquid (m3 mole−1), \({T}_{b}\) and \(T\) stands for the boiling temperature (K) and temperature (K), respectively. To promote the performance of Eq. (12), a “\(\lambda\)” term was added to Eq. (12) in Excel program for each IL in this study. This term is not constant; rather, it varies depending on ionic liquid. Empiricism \(\eta =A{\text{exp}}(B/T)\)is compatible with eqs. (10) and (12) and appears to be a popular and useful approach. Viscosity decreases with temperature, according to the theory.

Group method of data handling (GMDH)

Ivakhnenko's data-management approach for groups matches Darwin's natural choice concept52. By merging two independent variables, the system chooses the optimal polynomial terms. The approach generates a generic multinomial term at each stage. The vast relationship multinomial Volterra–Kolmogorov–Gabor (VKG) analyzes the entire network52:

In the above equation, the count of independent variables in the experiment is denoted by \({N}_{v}\). From a set of measured data with N data points, a matrix can be generated. The measured results \(\overrightarrow{{V}_{y}}=\left({y}_{1},{y}_{2},\dots ,{y}_{n}\right)\) are represented on the left-hand side of the matrix, while the independent variables \(\overrightarrow{{V}_{n}}=\left({x}_{1},{x}_{2},\dots ,{x}_{n}\right)\) are represented on the right-hand side of the matrix. Both sides of the matrix are produced from the same set of data. When two independent variables are coupled, a quadratic polynomial \(\left(\begin{array}{c}{N}_{v}\\ 2\end{array}\right)\) can be used to estimate the actual data. Using \({N}_{v}\) parameters, here is a formula for \(\left(\begin{array}{c}{N}_{v}\\ 2\end{array}\right):\)

The matrix of independent variables can here be built using the vector of new variables \(\overrightarrow{{V}_{z}}=\left({z}_{1},{z}_{2},\dots ,{z}_{n}\right)\). To modify the parameters of equations, the least squares method is utilized (15). The objective is to maintain the square of the deviation from the actual data as small as possible in each column:

In the above equation, \({N}_{t}\) denotes the count of datasets used. The measured data is used to construct training and testing subsets. The proportion of training and testing subsets is chosen at random. Equations are derived using the training set of data (15). The ideal set of parameters \(\left({z}_{i}\right)\). Variations from planned results must fulfill the following criteria, based on the predefined requirement:

here, \(\varepsilon\) is an optional/random value. Just the z columns that meet the criteria are kept, whereas the ones that do not are deleted. The entire variation is preserved after each repetition and compared to the prior repetitions to check if the least variation has been achieved.

Genetic programming (GP)

GP is a breakthrough in optimization computing that combines traditional genetic methods with symbolic improvement53,54,55. It is predicated on an approach called "tree representation." This form is incredibly flexible since trees may represent full models of industrial systems, mathematical formulae, or computer programs. Creating model structures like differential equations, kinetic ordering, and steady-state models is best accomplished with this approach56,57. To achieve great variation, GP first creates an initial population, which consists of randomly selected individuals (trees). A new generation is finally formed by the software, which evaluates the individuals, selects individuals for reproduction, creates new individuals by mutation, crossover, and direct reproduction57. Unlike other optimization techniques, symbolic improvement uses the architectural arrangement of many symbols to convey workable solutions (that is, vectors of real values).

Model assessment

Statistical criteria

The models' validity was tested using the determination coefficient (R2), standard deviation (SD), average absolute relative deviation (AARD%), average relative deviation percent (ARD%), and root mean square error (RMSE). Below are the statistical parameters:

Determination Coefficient (R2): R2 is a regression coefficient that shows the model’s accuracy. The model fits the data better if it is close to 1. R2s mathematical formula is as follows:

Average Relative Deviation (ARD%): The relative deviation of the anticipated outcomes from the experimental data is determined using the ARD%:

Positive and negative ARD (%) represents a model’s underestimate and overestimate, respectively.

Standard Deviation (SD): SD is a metric used to quantify the degree of dispersion of data around the central point. This has the following definition:

Average Absolute Relative Deviation (AARD%): The relative absolute deviation is used to quantify the difference between the actual or real data and the projected or represented data. It is shown by the equation that follows:

Root Mean Square Error (RMSE): The RMSE is a frequently used statistical analysis approach for estimating the discrepancies between experimental and expected values. It goes by the name:

When calculating the average IL viscosity using experimental/real data,the experimental/real viscosity (η) and the number of data points \({N}_{P}\) are represented by the variables “est”, and “exp”, respectively.

Graphical assessment of the models

Several graphical plots were used in this research to further evaluate the suggested models and measure their predicted performances. Among the visualization plots are diagrams showing the cumulative frequency and error distribution. In order to measure the distribution of error around the zero line and to indicate whether the model has a tendency to make mistakes, the percentage of relative deviation is displayed against target/real values in the error distribution. The cross-plot displays the estimated/represented value of the model in relation to the experimental data. After that, a slope line with a 45° unit is constructed to connect the experimental and represented/predicted values. A more accurate model is indicated by more data points that are shown along this line. The bulk of approximations will be inside a standard error range if the cumulative frequency is calculated from the absolute relative error.

Results and discussion

Development of models

Using 2813 points of data (45 ionic liquids) collected from the literature, models were developed. Table 2‘s “Total” refers to the whole set of data (2813 data points) that were used for analysis and modeling in the current research. The database was split into training sets (which made up 80% of the overall dataset) and test sets (20% of the total dataset) at random. The 563 data points in the "testing" set were used to track over-fitting errors and the reliability of the built models. The "training" subset (2250 data sets) caused changes to the model's structure and tuning parameters. T, P, Mw, Vc, Tb, Tc, Pc and w were the input parameters, and IL viscosity was the output (Table 1).

To begin with, the GMDH method was used to build a new empirical correlation. The viscosity of ILs with 5, 6, and 7 inputs was found to be:

5 Inputs:

The 6 Inputs:

7 Inputs:

Furthermore, the equations below proposed for 5, 6, and 7 inputs in GP model:

5 Input:

6 Input:

\({c}_{0}=0.26945 ;{c}_{1}=15.569 ;{c}_{2}=0.7941 ;{c}_{3}=0.5728 ;{c}_{4}=-12.046;{c}_{5}=14.544 ;{c}_{6}=0.2556 ;{c}_{7}= 0.3401 ;{c}_{8}=1.3188 ;{c}_{9}=0.26945 ;{c}_{10}=-0.043257 ;{c}_{11}=15270 ;{c}_{12}= -1.1226\).

7 Input:

\({c}_{0}=14.019 ;{c}_{1}=2.0204 ;{c}_{2}=0.25903 ;{c}_{3}=2.8184 ;{c}_{4}=0.88752;{c}_{5}=1.5553 ;{c}_{6}=0.46073 ;{c}_{7}= 1.2408 ;{c}_{8}=2.0204 ;{c}_{9}=0.25903 ;{c}_{10}=2.8184 ;{c}_{11}=0.88752 ;{c}_{12}= 0.91528 ;{c}_{13}=2.02;{c}_{14}=1.8657 ;{c}_{15}=-3.4975;{c}_{16}=1.0567 ;{c}_{17}=1.3443 ;{c}_{18}=-3.4975 ;{c}_{19}=1.553;{c}_{20}=11.329;{c}_{21}=2.3349;{c}_{22}=1213.7;{c}_{23}=-3.6512\).

The critical temperature and pressure values of the IL are denoted Tc and Pc, respectively. There is also an acentric factor (w), temperature (T), and pressure (P), as well as IL molecular weight (Mw), critical volume (Vc), and IL boiling temperature (Tb). The other parameters are the adjustable correlation coefficients (Table 2).

The RMSE, SD, R2, and AARPE% for the proposed correlation are calculated for the GP and GMDH models in Table 2.

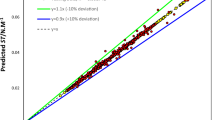

The cross-plots on the results of the experimental viscosity data and the predicted data for the given correlation are displayed in Fig. 2. Around the unit-slope line, this figure shows a medium-uniform distribution of forecasts. The viscosity of the ILs that were taken from the database was estimated using temperature (T) and boiling temperature (Tb), in accordance with Eyring's theory (Eq. 13). AARD stands for 21.86%. The expected vs experimental IL viscosity is also plotted in a logarithmic cross-plot in Fig. 2. The data points were somewhat near the diagonal line, indicating moderate conformity. But data indicates that Arrhenius reliance does not match the experimental transport characteristics of ILs, which is why Eyring's theory does not hold up. In fact, ILs viscosity decreased as temperature rose, and this feature has to be changed by new model improvements. In order to define the thermal characteristics of ILs, the Vogel–Tamman–Fulcher (VTF) development is frequently used. This provides the basis for a complex energy landscape with several local potential energy minimums and a broad variety of energy barriers58,59.

The white-box machine learning models were carried out using GP and GMDH and compared to ET and Mousavi's model25. "White-box" models in machine learning are those that are easy for experts in the application area to understand. These models, in general, provide a fair mix between explainability and accuracy. The numerical assessment of the created methods is presented in Table 3. With the use of a GMDH optimizer, it was shown that the usage of seven inputs was the best design for forecasting the viscosity of ILs since it can anticipate the whole data collection with more accuracy than other approaches (AARD% = 8.14).

Statistical evaluation

To illustrate the error margin, many statistical metrics were computed for both created models with different inputs, including ARD, AARD, RMSE, SD, and R2. As more input data was provided, the AARD, ARD, SD, and RMSE values for the test and training datasets decreased, as seen in Table 3 for the GP and GMDH models. . The following is a breakdown of the models based on how accurate they are: Mousavi et al. correlation < Eyring theory < GP < GMDH. As a result, the GMDH model may produce more reliable estimates than the other established models.

Graphical error analysis

A number of graphical error evaluations developed from the GP and GMDH models were examined in order to offer a more lucid evaluation of the models' efficacy. To evaluate the models, the predicted viscosity measurements were compared to the experimental measurements shown in Fig. 3(a–c). For the GP and GMDH models, there is a high formation of points around the unit slope in both the test and training datasets. The observed viscosity values are shown to be more accurate by the GMDH correlations than by the GP and Mousavi et al. correlations (Fig. 3c). As indicated in Fig. 3, the data distribution for GMDH correlation with 7 inputs is more on the slop line than the GMDH data with 5 and 6 inputs. The GMDH decreases overall relative deviation, resulting in the smallest error margin.

The AARE% of the white-box machine learning models is shown against the number of input parameters in Fig. 4. Comparing the GP model with experimental data indicated that it was less accurate, less flexible, and less well-suited than the GMDH model. Furthermore, the GMDH model with 7 inputs showed higher accuracy with experimental viscosity data in comparison to the GMDH trained on 5 and 6 inputs.

To show the models' level of competence, comparative graphs are used, such as cumulative frequency plots. The GMDH has the maximum cumulative frequency for a given absolute relative deviation, as seen in Fig. 5. To put it another way, the GMDH model predicted almost 70% of the data points as we got closer to the ARD of less than 4%, but the corresponding values for the GP models were 9%, 11%, and 10%, respectively.

Figure 6 presents a comparison of the created models with respect to their relative deviations. The model's ability to precisely predict the viscosity of ILs is demonstrated by the dense cluster of dots surrounding the zero line. As can be seen, the GMDH model with 5, 6, and 7 inputs estimated viscosity better than GP, Eyring theory, and Mousavi et al. correlations.

Error distribution plots of the developed correlations compared to the Eyring modified and Mousavi’s models. Fig 6(a) with 7 inputs (6a-1: GMDH, 6a-2: GP), Fig 6(b) with 6 inputs (6b-1: GMDH, 6b-2: GP), Fig 6(c) with 5 inputs (5c-1: GMDH, 5c-2: GP), and Fig 6(d) (6d-1: modified Eyring model, 6d-2: modified Mousavi model).

Figure 7 compares the acentric factor, molecular weight, boiling temperature, critical temperature / pressure, temperature, and pressure impacts (7 inputs) on AARD (%) for the GMDH and GP models under investigation. According to our findings, the GP model is more sensitive to changes, which leads to greater parameter values than the GMDH model, which was shown to be less susceptible. The GP model, for instance, is very temperature-sensitive (Fig. 7a). Thus, the GMDH model may be applied in a wide range of temperatures with a lower relative error of ARE <15%, whereas the GP model can only be utilized in a narrow range of temperatures (381-445 K) with a minimum relative error of 14.6%.

AARD values of 8.14% and 25.76% for the 7 inputs are displayed in Table 3 and are thus retained for future analyses since they are among the best responses for the GMDH and GP models. Based on the GMDH and GP correlations, Fig. 8 shows how temperature and pressure affect 1-ethyl-3-methylimidazolium hexafluorophosphate. The anticipated viscosity of ILs using both models is consistent with the experimental dataset, as expected. Viscosity assessments for ILs using GP correlations are, in turn, inconsistent, as seen in Fig. 8, and come with large error margins. As can be observed in Fig. 8b, there is a physical link between the temperature and the GMDH model; but, as the pressure increases, neither model can adequately represent the experimental data.

Identifying outliers in experimental data, GMDH, and GP models

Finding data that significantly differs from the bulk of the data in a database is the aim of outlier (or aberrant) identification60,61. Leverage is a well-known approach for doing this60,62. Standardized residuals (R) and the Hat matrix (H) are used62. The R value for each data point can be found using the below equation:

\(MSE\) stands for mean square error (MSE), while the \({i}_{th}\) data point's error and \({ii}_{th}\) Hat indices (Leverage) are represented by \({z}_{i}\) and \({H}_{ii}\)63. In addition, the following formula may be used to calculate Hat index (or Leverage):64

here, X represents a two-dimensional q × w matrix (where “q” shows the number of data and “w” is the count of input variables). Also, Xt is transpose of matrix. The outliers were investigated using the Williams plot after the R and H values were measured. In addition, the Leverage limit (H*), a parameter defined as 3a/b, where b stands for the count of data points and a is the number of model parameters plus one, is applied in this approach.

The calculated R values must be within [− 3, + 3] standard deviations in order to encompass 99.7% of the normally distributed data17,62. The model is statistically valid if a significant proportion of data points are in the range of \({H}^{*}\ge H\ge 0\) and \(3\ge R\ge -3\)17. Since they are highly expected yet outside of the application domain, data points in the range of \(-3\le R\le 3\) and \({H}^{*}\le H\) are referred to as "Good High Leverage" points. Conversely, data points with R values larger than or less than -3 are referred to as "Bad High Leverage" data points. These regions are beyond the applicability range of the model and have significant levels of uncertainty. It is clear that reliable data significantly affect the GMDH (7 inputs) model's performance, making it the best model used in this study. The H* value, as per the suggested model, was 0.0085. The GMDH model's Williams plot is shown in Fig. 9 into the statistically significant range of \(0\le H\le 0.0085\) and \(-3\le R\le 3\), all data points appear to fit into the established GMDH model. Less residual value normalization leads to an increase in reliability. However, However, 24 suspicious data points, or fewer than 1% of the total data in Fig. 9, either \(R\) < − 3 or \(R\) > 3, making them outliers with considerable uncertainty. Furthermore, 77 data points, or 3% of all data had H > 0.0085. These points are all in the range of \(-3\le R\le 3\), which indicates that they are all Good High Leverage regardless of their Hat (Leverage) values.

Variables' relative importance

When taking the GMDH model, all input variables were tested to see how much of an influence they had on the viscosity of ILs. The relative significance of the inputs with respect to one another is shown in Fig. 10. One measure used to evaluate each input parameter's impact on the pure viscosity of ILs as a model output is the relevance factor (r). Negative values indicate an inverse correlation between the input and output parameters, and vice versa. Relevance Factor (\(r\)) values are analyzed in accordance with the following equation65:

where \(n\) represents the number of datasets. Also, the j-th value, and the mean of the I-th input are respectively represented by the variables,\({I}_{i,j}\), and \({\overline{I} }_{i}\). Whereas \(\overline{\eta }\) denotes the average value of the predicted ILs viscosity, while \({\eta }_{j}\) represnts the j-th value of the represented/expected viscosity. Based on the GMDH (as the output), Fig. 10 displays the relative effects of each parameter on the pure viscosity of ILs. It is demonstrated that temperature and the acentric factor significantly affect the model's output.

Viscosity increases with an increase in pressure or acentric factor in pure ionic liquids. As Fig. 10 illustrates, increasing \(T,{M}_{w},{V}_{c},{T}_{b},{T}_{c}\), and \({P}_{c}\) parameters will result in a decrease in the viscosity of ILs, since they have negative relevance factors. Moreover, the temperature has the most significant effect on the viscosity of ILs compared to other inputs.

We compared our models to a nonlinear artificial neural network (ANN) model using a dataset of 8,523 IL-water mixture viscosity data points16. The assessment included critical performance indicators such as mean absolute error (MAE) and R-squared (R2). The results show that the GP and GMDH models have equivalent, if not greater, prediction accuracy, with benefits in simplicity and interpretability. This comparative research not only supports our models' effectiveness but also highlights their potential as reliable methods for forecasting IL viscosity. Our target in this research was in line with the goal of obtaining better predictions about the physical features of ILs15. The main concern, though, is making accurate predictions regarding the viscosity of pure IL. We used the genetic programming (GP) and group method of data handling (GMDH) techniques to do this. In particular, our study adds custom models with clear benefits, focusing on accuracy and ease of use in determining the viscosity of pure ILs.

Conclusions

The GMDH model was obtained by modeling 2813 experimental findings from 45 ILs based on temperature, pressure, molecular weight, critical volume, and acentric factor. Furthermore, IL viscosity was calculated using temperature and boiling temperature in accordance with Eyring's hypothesis. There were statistical and graphical comparisons between GMDH and experimental data in order to evaluate the model's efficacy. AARD, ARD, RMSE, and R2 parameters indicated that the GMDH model performed rather well. Using the relevance factor, the impact of input characteristics on the model's target parameter was also investigated. The relevance factor illustrated that the temperature is the most important parameter affecting ILs viscosity. Finally, the employed dataset's reliability and validity were assessed using the leverage statistics. In our case, Williams' plot was applied to study the established paradigm's applicability domain and data collection. Only a small number of data points were found to be outside the realm of applicability. In light of all the above, the developed GMDH model is able to accurately forecast IL viscosity and obtain IL physicochemical parameters in different chemical engineering processes.

Data availability

All data have been gathered from the literature. All references used for extracting the required data have been cited in the text. However, the data will be available from the corresponding author upon reasonable request.

References

Salgado, J. et al. Density and viscosity of three (2, 2, 2-trifluoroethanol+ 1-butyl-3-methylimidazolium) ionic liquid binary systems. J. Chem. Thermodyn. 70, 101–110 (2014).

Wu, T.-Y., Chen, B.-K., Hao, L., Kuo, C.-W. & Sun, I.-W. Thermophysical properties of binary mixtures {1-methyl-3-pentylimidazolium tetrafluoroborate+ polyethylene glycol methyl ether}. J. Taiwan Inst. Chem. Eng. 43(2), 313–321 (2012).

Canongia Lopes, J. et al. Polarity, viscosity, and ionic conductivity of liquid mixtures containing [C4C1im][Ntf2] and a molecular component. J. Phys. Chem. B 115(19), 6088–6099 (2011).

Hezave, A. Z., Dorostkar, S., Ayatollahi, S., Nabipour, M. & Hemmateenejad, B. Dynamic interfacial tension behavior between heavy crude oil and ionic liquid solution (1-dodecyl-3-methylimidazolium chloride ([C12mim][Cl]+ distilled or saline water/heavy crude oil)) as a new surfactant. J. Mol. Liq. 187, 83–89 (2013).

Atashrouz, S., Zarghampour, M., Abdolrahimi, S., Pazuki, G. & Nasernejad, B. Estimation of the viscosity of ionic liquids containing binary mixtures based on the Eyring’s theory and a modified Gibbs energy model. J. Chem. Eng. Data 59(11), 3691–3704 (2014).

Zafarani-Moattar, M. T. & Majdan-Cegincara R. Viscosity, density, speed of sound, and refractive index of binary mixtures of organic solvent+ ionic liquid, 1-butyl-3-methylimidazolium hexafluorophosphate at 298.15 K. J. Chem. Eng. Data 52(6), 2359–2364 (2007).

Welton, T. Ionic liquids: A brief history. Biophys. Rev. 10(3), 691–706 (2018).

Freemantle, M. An Introduction to Ionic Liquids (Royal Society of Chemistry, 2010).

Schmidt, H. et al. Experimental study of the density and viscosity of 1-ethyl-3-methylimidazolium ethyl sulfate. J. Chem. Thermodyn. 47, 68–75 (2012).

Torrecilla, J. S., Tortuero, C., Cancilla, J. C. & Díaz-Rodríguez, P. Neural networks to estimate the water content of imidazolium-based ionic liquids using their refractive indices. Talanta 116, 122–126 (2013).

Torrecilla, J. S., Tortuero, C., Cancilla, J. C. & Díaz-Rodríguez, P. Estimation with neural networks of the water content in imidazolium-based ionic liquids using their experimental density and viscosity values. Talanta 113, 93–98 (2013).

Zhu, A., Wang, J. & Liu, R. A volumetric and viscosity study for the binary mixtures of 1-hexyl-3-methylimidazolium tetrafluoroborate with some molecular solvents. J. Chem. Thermodyn. 43(5), 796–799 (2011).

Yu, G., Zhao, D., Wen, L., Yang, S. & Chen, X. Viscosity of ionic liquids: Database, observation, and quantitative structure-property relationship analysis. AIChE J. 58(9), 2885–2899 (2012).

Burrell, G. L., Burgar, I. M., Separovic, F. & Dunlop, N. F. Preparation of protic ionic liquids with minimal water content and 15N NMR study of proton transfer. Phys. Chem. Chem. Phys. 12(7), 1571–1577 (2010).

Duong, D. V. et al. Machine learning investigation of viscosity and ionic conductivity of protic ionic liquids in water mixtures. J. Chem. Phys. 156(15), 85592 (2022).

Chen, Y., Peng, B., Kontogeorgis, G. M. & Liang, X. Machine learning for the prediction of viscosity of ionic liquid–water mixtures. J. Mol. Liq. 350, 118546 (2022).

Hosseinzadeh, M. & Hemmati-Sarapardeh, A. Toward a predictive model for estimating viscosity of ternary mixtures containing ionic liquids. J. Mol. Liq. 200, 340–348 (2014).

Barycki, M. et al. Temperature-dependent structure-property modeling of viscosity for ionic liquids. Fluid Phase Equilibria 427, 9–17 (2016).

Gardas, R. L. & Coutinho, J. A. A group contribution method for viscosity estimation of ionic liquids. Fluid Phase Equilibria 266(1–2), 195–201 (2008).

Gharagheizi, F., Ilani-Kashkouli, P., Mohammadi, A. H., Ramjugernath, D. & Richon, D. Development of a group contribution method for determination of viscosity of ionic liquids at atmospheric pressure. Chem. Eng. Sci. 80, 326–333 (2012).

Lazzús, J. A. & Pulgar-Villarroel, G. A group contribution method to estimate the viscosity of ionic liquids at different temperatures. J. Mol. Liq. 209, 161–168 (2015).

Paduszynski, K. & Domanska, U. Viscosity of ionic liquids: An extensive database and a new group contribution model based on a feed-forward artificial neural network. J. Chem. Inf. Model. 54(5), 1311–1324 (2014).

Zhao, Y., Huang, Y., Zhang, X. & Zhang, S. A quantitative prediction of the viscosity of ionic liquids using S σ-profile molecular descriptors. Phys. Chem. Chem. Phys. 17(5), 3761–3767 (2015).

Atashrouz, S., Pazuki, G. & Alimoradi, Y. Estimation of the viscosity of nine nanofluids using a hybrid GMDH-type neural network system. Fluid Phase Equilibria 372, 43–48 (2014).

Mousavi, S. P. et al. Viscosity of ionic liquids: Application of the Eyring’s theory and a committee machine intelligent system. Molecules 26(1), 156 (2021).

Loyola-Gonzalez, O. Black-box vs. white-box: Understanding their advantages and weaknesses from a practical point of view. IEEE Access 7, 154096–154113 (2019).

Menad, N. A. & Noureddine, Z. An efficient methodology for multi-objective optimization of water alternating CO2 EOR process. J. Taiwan Inst. Chem. Eng. 99, 154–165 (2019).

Kang, D., Wang, X., Zheng, X. & Zhao, Y.-P. Predicting the components and types of kerogen in shale by combining machine learning with NMR spectra. Fuel 290, 120006 (2021).

Mohammadi, M.-R. et al. Modeling the solubility of light hydrocarbon gases and their mixture in brine with machine learning and equations of state. Sci. Rep. 12(1), 14943 (2022).

Ma, J., Kang, D., Wang, X. & Zhao, Y.-P. Defining kerogen maturity from orbital hybridization by machine learning. Fuel 310, 122250 (2022).

Lv, Q. et al. Modelling CO2 diffusion coefficient in heavy crude oils and bitumen using extreme gradient boosting and Gaussian process regression. Energy 275, 127396 (2023).

Dong, G. Exploiting the power of group differences: Using patterns to solve data analysis problems. Synth. Lect. Data Min. Knowl. Discov. 11(1), 1–146 (2019).

Rudin, C. Please stop explaining black box models for high stakes decisions. Statistics 1050, 26 (2018).

Rudin, C. Stop explaining black box machine learning models for high stakes decisions and use interpretable models instead. Nat. Mach. Intell. 1(5), 206–215 (2019).

Loyola-González, O. et al. PBC4cip: A new contrast pattern-based classifier for class imbalance problems. Knowl.-Based Syst. 115, 100–109 (2017).

Gaciño, F. M., Paredes, X., Comuñas, M. J. & Fernández, J. Effect of the pressure on the viscosities of ionic liquids: Experimental values for 1-ethyl-3-methylimidazolium ethylsulfate and two bis (trifluoromethyl-sulfonyl) imide salts. J. Chem. Thermodyn. 54, 302–309 (2012).

Gaciño, F. M., Paredes, X., Comuñas, M. J. & Fernández, J. Pressure dependence on the viscosities of 1-butyl-2, 3-dimethylimidazolium bis (trifluoromethylsulfonyl) imide and two tris (pentafluoroethyl) trifluorophosphate based ionic liquids: New measurements and modelling. J. Chem. Thermodyn. 62, 162–169 (2013).

Xu, Y., Chen, B., Qian, W. & Li, H. Properties of pure n-butylammonium nitrate ionic liquid and its binary mixtures of with alcohols at T=(293.15 to 313.15) K. J. Chem. Thermodyn. 58, 449–459 (2013).

Yu, Z., Gao, H., Wang, H. & Chen, L. Densities, viscosities, and refractive properties of the binary mixtures of the amino acid Ionic Liquid [bmim][Ala] with methanol or benzylalcohol at T=(298.15 to 313.15) K. J. Chem. Eng. Data 56(6), 2877–2883 (2011).

Domańska, U., Zawadzki, M. & Lewandrowska, A. Effect of temperature and composition on the density, viscosity, surface tension, and thermodynamic properties of binary mixtures of N-octylisoquinolinium bis (trifluoromethyl) sulfonyl imide with alcohols. J. Chem. Thermodyn. 48, 101–111 (2012).

Fendt, S., Padmanabhan, S., Blanch, H. W. & Prausnitz, J. M. Viscosities of acetate or chloride-based ionic liquids and some of their mixtures with water or other common solvents. J. Chem. Eng. Data 56(1), 31–34 (2011).

Domańska, U., Skiba, K., Zawadzki, M., Paduszyński, K. & Królikowski, M. Synthesis, physical, and thermodynamic properties of 1-alkyl-cyanopyridinium bis (trifluoromethyl) sulfonyl imide ionic liquids. J. Chem. Thermodyn. 56, 153–161 (2013).

Rocha, M. A., Ribeiro, F. M., Ferreira, A. I. L., Coutinho, J. A. & Santos, L. M. Thermophysical properties of [CN− 1C1im][PF6] ionic liquids. J. Mol. Liq. 188, 196–202 (2013).

Diogo, J. C., Caetano, F. J., Fareleira, J. M. & Wakeham, W. A. Viscosity measurements of three ionic liquids using the vibrating wire technique. Fluid Phase Equilibria 353, 76–86 (2013).

Liu, X., Afzal, W. & Prausnitz, J. M. Unusual trend of viscosities and densities for four ionic liquids containing a tetraalkyl phosphonium cation and the anion bis (2, 4, 4-trimethylpentyl) phosphinate. J. Chem. Thermodyn. 70, 122–126 (2014).

Qian, W., Xu, Y., Zhu, H. & Yu, C. Properties of pure 1-methylimidazolium acetate ionic liquid and its binary mixtures with alcohols. J. Chem. Thermodyn. 49, 87–94 (2012).

Ochędzan-Siodłak, W., Dziubek, K. & Siodłak, D. Densities and viscosities of imidazolium and pyridinium chloroaluminate ionic liquids. J. Mol. Liq. 177, 85–93 (2013).

Yan, F. et al. Prediction of ionic liquids viscosity at variable temperatures and pressures. Chem. Eng. Sci. 184, 134–140 (2018).

Kirkwood, J. G., Buff, F. P. & Green, M. S. The statistical mechanical theory of transport processes. III. The coefficients of shear and bulk viscosity of liquids. J. Chem. Phys. 17(10), 988–994 (1949).

Eyring, H. Viscosity, plasticity, and diffusion as examples of absolute reaction rates. The Journal of chemical physics 4(4), 283–291 (1936).

Plawsky, J. L. Transport Phenomena Fundamentals (CRC Press, 2009).

Ivakhnenko, A. G. Polynomial theory of complex systems. IEEE Trans. Syst. Man Cybern. 4, 364–378 (1971).

Shokir, E. E. M., Emera, M., Eid, S. & Wally, A. A new optimization model for 3D well design. Oil Gas Sci. Technol. 59(3), 255–266 (2004).

McKay, B., Willis, M. & Barton, G. Steady-state modelling of chemical process systems using genetic programming. Comput. Chem. Eng. 21(9), 981–996 (1997).

Koza, J. R. & Koza, J. R. Genetic Programming: on the Programming of Computers by Means of Natural Selection (MIT Press, 1992).

Madar, J., Abonyi, J. & Szeifert, F. Genetic programming for system identification. Intelligent Systems Design and Applications (ISDA 2004) Conference, Budapest, Hungary (2004).

Shokir, E. M. E-M. & Dmour, H. N. Genetic programming (GP)-based model for the viscosity of pure and hydrocarbon gas mixtures. Energy Fuels 23(7), 3632–3636 (2009).

García-Garabal, S. et al. Transport properties for 1-ethyl-3-methylimidazolium n-alkyl sulfates: Possible evidence of grotthuss mechanism. Electrochim. Acta 231, 94–102 (2017).

Tammann, G. & Hesse, W. Die Abhängigkeit der Viscosität von der Temperatur bie unterkühlten Flüssigkeiten. Z. Anorganische Allgemeine Chemie 156(1), 245–257 (1926).

Shateri, M., Ghorbani, S., Hemmati-Sarapardeh, A. & Mohammadi, A. H. Application of Wilcoxon generalized radial basis function network for prediction of natural gas compressibility factor. J. Taiwan Inst. Chem. Eng. 50, 131–141 (2015).

Atashrouz, S., Mirshekar, H. & Hemmati-Sarapardeh, A. A soft-computing technique for prediction of water activity in PEG solutions. Colloid Polym. Sci. 295(3), 421–432 (2017).

Hemmati-Sarapardeh, A., Aminshahidy, B., Pajouhandeh, A., Yousefi, S. H. & Hosseini-Kaldozakh, S. A. A soft computing approach for the determination of crude oil viscosity: Light and intermediate crude oil systems. J. Taiwan Inst. Chem. Eng. 59, 1–10 (2016).

Atashrouz, S., Mirshekar, H. & Mohaddespour, A. A robust modeling approach to predict the surface tension of ionic liquids. J. Mol. Liq. 236, 344–357 (2017).

Rousseeuw, P. J. & Leroy, A. M. Robust Regression and Outlier Detection. Syria Studies vol. 7 (Wiley, 1987).

Mousavi, S.-P. et al. Modeling surface tension of ionic liquids by chemical structure-intelligence based models. J. Mol. Liq. 342, 116961 (2021).

Acknowledgements

The study was funded by the Foreign Young Talent Program (Grant No: DL2022011001L) from the Ministry of Science and Technology of China.

Author information

Authors and Affiliations

Contributions

S.K.: Investigation, Visualization, Writing-Original Draft, F.H.: Conceptualization, Validation, Modeling, S.A.: Writing-Review & Editing, Methodology, Data curation, Supervision, D.N.: Writing-Review & Editing, Validation, A.H-S.: Methodology, Validation, Supervision, Writing-Review & Editing. A.M.: Writing-Review & Editing, Validation, Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kiani, S., Hadavimoghaddam, F., Atashrouz, S. et al. Modeling of ionic liquids viscosity via advanced white-box machine learning. Sci Rep 14, 8666 (2024). https://doi.org/10.1038/s41598-024-55147-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-55147-w

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.