Abstract

A systematic study is currently demonstrated approach for approving the superior role of silver and palladium metallic particles in acting the role of mordant with acquiring the dyed cotton fabrics excellence in color fastness with additional functions of antimicrobial potentiality and UV-protection action. Whereas, samples were dyed with extract of red peanuts skin as natural textile colorant (RPN dye). The represented data revealed that, in absence of mordant, the samples treated with metal precursors prior to dyeing were exhibited with the excellent color strength, color fastness, antimicrobial action and UV-protection action. Color fastness (washing, rubbing and light fastness) was estimated to be in the range of very good–excellent. Sample pretreated with silver salt and dyed in the absence of mordant was graded with excellent UV-protection action (UPF 31.5, UVB T% 2.6% and UVB blocking percent 97.4%). Antimicrobial potency against E. coli, S. aureus and Candida albicans through inhibition zone and the reduction percent was approved to be in the range of excellence (93.01–99.51%) for the samples dyed in absence of mordant and pretreated with either silver or palladium precursors.

Similar content being viewed by others

Introduction

Natural dyes are superiorly exhibited with biocompatibility and wide applicability in various pharmacological purposes. Compared to their synthetic equivalents, they are less harmful in terms of environmental safety and health. Annatto, turmeric, and saffron are examples of natural dyes that are widely applicable as food additives. However, metallic mordants are mainly required as they are disadvantageous with poor fastness, due to they are weakly bonded to the textile materials1,2.

On the other hand, protective textiles could be identified as clothing materials that could successively protect the customer body from any of external threating agents such as biological agents, bullet and chemical agent, firing, coldness, and heating. The protective textile materials could cover at least thirty percent of the whole body that could be exploited in sporting, military, and industrial purposes3,4,5,6,7,8.

Cotton fabrics were widely applied in different purposes attributing to their outstanding characters such as, absorptivity, biodegradability, smoothness, and breathability. However, it is disadvantageously characterized with poor ultraviolet shielding, and high flammability and prone, meaning it could be attacked with different microbial strains specially the bacterial strains9,10,11. Numerous researches were reported different investigative techniques for acquiring different textile materials additional functions, like ultraviolet shielding12,13,14,15, microbicide activities15,16, coloration17,18, optical activity19, insect repellency20,21 and self-cleaning19,22,23. Moreover, the protective masking and air-filtering textile materials were prepared for protection from chemical warfare gas24.

For manufacturing of functional textile materials, numerous researching approaches were considered with the successive application of different organic reagents, like, Triclosan (for bactericidal potency), Benzophenones (for ultraviolet resistance), Dimethylol-dihydroxy-ethylene urea (for wrinkle resistance), Fluorocarbons (for hydrophobic character), long-chain hydrocarbons and Polydimethylsiloxanes (for softening and flexibility)25,26. Butane tetra-carboxylic acid, Citric acid and Maleic acid27,28,29 were also applied for preparing cotton fabrics with wrinkle resistance affinity.

In the represented approach, the point of novelty is the demonstration of a systematic study for validation the superior role of silver and palladium particles in enhancing the color fastness and acquiring the dyed cotton fabrics excellent color fastness, antimicrobial potentiality and UV-protective affinity. Whereas, the prepared cotton samples were dyed with extract of red peanuts skin as an example of natural textile colorant30,31,32. Regulative uploading of palladium and silver was proceeded via immobilization within the polymeric matrix of cotton fabrics dyed with the extract of red peanuts skin, whereas, the effect of reaction conditions and reaction sequencing were systematically studied.

Experimental

Materials and chemicals

Silver nitrate (AgNO3, ≥ 99.0%, Sigma-Aldrich), palladium chloride (PdCl2, 99.0%, Sigma-Aldrich), aluminium sulphate (Al2(SO4)3, Alum, 99.99%, Sigma-Aldrich) and sodium carbonate (Na2CO3, > 99.5%, Sigma-Aldrich) were exploited as received. Red peanuts were supported from the local market in Egypt. Bleached 100% cotton fabrics (160 g/m2) were provided by El-Mahalla Company for Spinning and Weaving, El-Mahalla El-Kubra – Egypt. For cleaning the prepared fabric samples, fabrics (1/50 material: liquor ratio) were washing using 2 g/L nonionic detergent (Hospatal CV – Clariant) at 50 °C for 30 min. Fabrics were rinsed with tap water at room temperature and dried in the atmospheric air.

Procedure

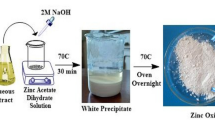

In the current approach, successive immobilization of silver and palladium particles within dyed cotton fabrics, in order to contribute in fabric coloration and functionalization, was performed. The experimental work could be clarified (Table 1) in the following points;

-

a-

Dyeing with red peanuts in the presence of mordant (sample A): cotton fabrics were dyed with solution of natural dye extracted from red peanuts (5g dispersed in 100 ml of distilled water were boiled for 1 h) at 80 °C, pH 9.5, L: R 1:40 for 1 h. Then for mordanting, the sample was soaked in a solution containing 1.8 g/L of (Alum), pH 7, L: R 1:40, at 80 °C for 30 min.

-

b-

Treatment process (samples B1, B2, C1 & C2): cotton fabrics were treated only with metal precursors, whereas, the fabrics were immersed within solution containing 100 ppm of AgNO3 or PdCl2 at 80 °C or 60 °C for 30 min, respectively.

-

c-

Post-treatment process (D1 & D2): all the samples were dyed with natural dye then treated with metal precursors.

-

d-

Pre-treatment process (samples E1 & E2): cotton fabrics were immersed within solution containing 100 ppm of AgNO3 or PdCl2 at 60 °C for 30 min then let the sample dry to be sequentially dyed with natural dye.

-

e-

Pre-treatment in the presence of mordant (F1 & F2): samples were treated with metal precursors then dyed with natural dye to be sequentially treated with mordant (Alum)

-

f-

Simultaneous treatment (G1 & G2): samples were concurrently dyed and treated with metal precursors.

Analysis and characterization

Native and the currently prepared functional fabrics were both analyzed in order to give information about the change in the topography after fabric treatment with high resolution scanning electron microscopy (SEM Quanta FEG 250 with field emission gun, FEI Company – Netherlands). The chemical characterization of fabrics surface was identified with energy dispersive X-ray spectroscopic (EDX) analysis unit (EDAX AMETEK analyzer) connected to the electron microscopy. X-ray diffraction data for both of pristine and treated cotton fabrics at room temperature with diffractometer (X’Pert MPP with a type PW 3050⁄10 goniometer), whereas, the diffraction angle (2θ) was estimated in range of 10°–80° using monochromatized software of PROFIT (Mo Kα X-radiation at 40 kV, 50 mA and λ = 0.70930 Å) with step size of 0.03°.

Infrared spectral data were detected for cotton fabrics before and after treatment using attenuated total reflection–Fourier Transformation infrared spectroscope (ATR-FTIR). Fabrics were analysed with high resolution JASCO FT/IR–4700 spectroscopy (JASCO Analytical Instruments, Easton, USA) attached to deuterated triglycine sulfate (TGS) detector and conducted with ATR in the infrared range. Spectral data were estimated in wavenumber range of 4000–500 cm–1 (using transmission mode (T%), resolution of 4 cm–1 with 2 mm/sec scanning speed and 1.0 cm–1 interval scanning using 64 repetitious scans average). X-ray photoelectron spectroscopic (XPS) analysis were performed for the samples prepared via pre-treatment process (E1 & E2), using X-Ray–FG ON (400 µm). Whereas, these conditions were concerned; samples were neutralized via low energy electrons (0.1 eV), with hybrid mode (with electrostatic and magnetic lenses), 10–22 scanning and CAE 50 were used and the excitation of photoelectrons by monochromatic Alpha irradiation.

Color coordinates (L, a*, b*) of cotton fabrics before and after treatment were evaluated with colorimeter with (UltraScan Pro, Hunter Lab, USA), pulsed xenon lamps as light source, 10° observer (with D65 illuminant, d/2 viewing geometry and measurement area of 2 mm). L is referring to lightness (0–100) from black to white and a* (+ /–) is for a red/ green ratio, whereas, b* (+ /–) is corresponding to yellow/blue ratio33. Moreover, color strength (K/S) was estimated at wavelength of 535 nm and absorption was detected in the range of 350–650 nm. All estimated values were detected for two times and the mean average was taken in account. Colour fastness were examined for the treated fabrics according to the method reported in literature34. Washing and rubbing fastness were all tested in accordance to ISO 105-C02, ISO 105-X12 and ISO 105-E0435, respectively. While the light fastness was determined using ISO 105-B02 via Blue-scale36.

Antimicrobial potency of the treated fabrics against (Staphylococcus aureus), gram-negative bacteria species (Escherichia coli) and fungal species (Candida albicans) was tested via the qualitative methodology of inhibition zone (disk diffusion test)37. In this method, the different tested microbial strains were allowed to grow in media for preparing the microbial suspension. 100 μL of microbial colloidal solution was dispersed on agar plates for broth in which it was maintained. The treated fabrics (0.5 cm) were added in the middle of plate to be incubated at 37 °C for one day. The diameter of inhibition zone was estimated in millimeters with slipping calipers in accordance to NCCLS, 199737. After incubating, colony forming units (CFU) were counted for each prepared plate37,38.

Results and discussion

Production of protective textiles becomes more extensively considered for specialized work environments in which there is a risk of exposing to ultraviolet light, fires, chemicals and pathogens, such like in hospitals, police stations, fire departments and battlefields. In the represented approach, a systematic study is demonstrated for approving the superior role of silver and palladium metallic particles in acquiring the dyed cotton fabrics excellent color fastness, microbicidal potentiality and UV-protective affinity. Whereas, the prepared cotton samples were dyed with extract of red peanuts skin (RPN dye) as an example of natural textile colorants.

According to Fig. 1 that represents a suggestive mechanism for the interaction between cotton fabric, RPN dye and metal precursors, so as it could be declared that, RPN dye is well known as a water-soluble colorant with cationic quaternary ammonium group39,40,41, could interact with the hydroxyl groups in the cellulosic backbone of fabric. Whereas, addition of mordant results in formation of a coordinative complex between RPN macromolecules and Alum particles, in order to enhance the color fastness of the treated fabrics. In the current approach, silver or palladium salt precursors were exploited instead of mordant, as it could form a chemically stable complex with the phenolic groups of RPN dye moieties for concurrent improvement the color fastness and acquire the treated fabric the superior characteristics of either silver or palladium particles for antimicrobial & UV-blocking actions.

SEM & EDX images

SEM & EDX characterizations were performed for both of untreated and treated cotton fabrics to show their morphological and geometrical features and to observe the topographical changes of the examined fabrics after treatment. SEM micrographs were represented in Fig. 2. Figure 2a shows that, untreated cotton fabric was shown with a clear and smooth surface, whereas, Fig. 2b views a well dispersion of RPN dye macromolecules on the surface of dyed fabric (sample A). Figure 2c and d shows that, metal particles were visibly shown on the surface of the treated fabric, this could affirm the successive immobilization of metal particles within fabric matrix.

Figure 2e and f represents that, sequential dyeing of silver-treated fabric resulted in observing more of dispersed particles on the surface of fabric, attributing to the higher affinity of RPN moieties in coordinative bonding with higher amounts of metal particles. These could give an information about the role of RPN dye moieties in regular implantation of well-assembled metal particles. However, lesser amounts of palladium particles were observed by comparing to silver, that, could be attributed to the masking effect of RPN dye macromolecules42. Further improvement for successive implantation of metal particles within the undyed and dyed cotton fabrics was achieved via analyzing EDX data, where, Ag & Pd signals were precisely estimated for the treated fabrics (Fig. 2c–f).

FTIR

FTIR spectra of untreated and treated samples were shown in Fig. 3. Pristine cotton was displayed with three characteristic peaks at 1635 cm–1, 2882 cm–1 and 3304 cm–1, corresponding to C=O, C–H asymmetric stretching and O–H stretching, respectively43,44,45. Transmission peaks of C–O stretching were detected at 1021 and 1152 cm−1. Three bands at 1312–1362 cm−1 are corresponding to vibrations of C–H and C–C. all of the previously referred peaks are characteristic for cellulosic backbone of cotton fabric. After treatment with either silver or palladium salt precursors, and after dyeing, no significant changing in the estimated characteristic bands of cotton was observed, meaning that, neither dyeing nor implantation of metal particles were affected on the chemical composition of cotton fabrics. However, one new band characteristic for O–M (871 cm−1) was visibly noted in the spectral data of all the prepared samples with either silver or palladium. This could declare that, the reducible functional groups for either cellulosic skeleton (for the undyed fabrics) or the phenolic groups of RPN dye moieties (for the dyed fabrics) were successively shared in chemical bonding and stabilization of metal particles.

XRD analysis

Figure 4 shows XRD data for pristine cotton, dyed cotton (A), undyed (B1 & B2) and dyed fabrics after treatment with silver and palladium precursors (D1 & D2). From the plotted data it could be declared that, untreated cotton fabric exhibited with characteristic diffraction peaks at (2θ°) = 15.1°, 16.9°, 23.2° & 34.2°, referring to the crystalline structure of cellulose in the untreated cotton fabric. Neither dyeing nor successive implantation of nanosilver and nanopalladium particles were affected on the fabric crystallinity, as the as-mentioned characteristic diffraction peaks of cotton were similarly detected for the treated fabrics. After treatment with silver precursor in both of B1 & D1 fabrics, characteristic peak of silver was estimated at (2θ°) = 38.1°, typical for (111) of face center crystalline (FCC) structure for silver (JCPDS data number 04–0783 card46,47. Moreover, the fabrics treated with palladium salt precursor were assigned at 2θ = 45.5°, which is corresponded to (200) of face centered crystalline (FCC) structures for Pd (JCPDS data number 89–4897 card)48,49.

XPS analysis

XPS spectral mapping data for samples prepared via pre-treatment process (E1 & E2) in Fig. 5 could provide further confirmation about the chemical composition and ionic state for both silver and palladium moieties and its successive immobilization within dyed fabric matrix. The survey spectrum (Fig. 5a and e) could show that, binding energies of C1s, O1s and Ag3d, were located at 281–291, 529–535, and 364–376 eV50. C1s bands were estimated at binding energies of 284.1, 285.6 and 288.2 eV that were referred to C–C, C–H and C–O, respectively (Fig. 5b and f)51. For O1s, binding energies peaks at 531.3 and 532.1 eV, were corresponding to C–O and C–O–O, respectively (Fig. 5c and g). In case of Ag3d, the bands detected at 367.0 and 373.2/373.6 eV were assigned to 3d3/2 and 3d5/2 of the metallic form of Ag (Ag0) which clearly approved the successive anchoring of silver within fabric matrix (Fig. 5d). Whereas, in case of Pd3d, energy bands detected at 335.5, and 340.8/343.1 eV were referred to 3d3/2 and 3d5/2 of palladium (Pd0) which also affirmed the immobilization of Pd within dyed fabric matrix (Fig. 5h)52,53,54,55. In Accordance to literature55,56,57, the peaks at 367.7 eV & 337.9 eV were corresponded to the 3d5/2 of Ag–O & Pd–O to affirm the coordinative bonding between the immobilized metals and the phenolic groups of RPN dye moieties uploaded within the matrix of the tested fabrics.

Absorbance spectral mapping

For investigation the effect of metal implantation and the process sequencing on the optical properties of the dyed fabrics, all of the as-prepared samples were analyzed with UV–Visible spectroscopy, and the estimated spectral mapping data were plotted in Fig. 6. From the displayed UV- Visible spectra, the examined samples could be ordered according to the estimated values of intensity as follows; F1 > > A > E1 ~ E2 ~ D2 ~ F2 ~ G2 > > C1 ~ G1 ~ D1 ~ B1 ~ B2 ~ C2. This could be explained in the following points, (i) compared to all of the prepared samples, implantation of silver particles within fabric prior to dyeing in the presence of mordant resulted in obtaining a sample with the highest intense color to reflect the role of silver particles for enhancement of fabric coloration, (ii) both of silver and palladium particles could act the role of mordant when the samples were treated with metal precursors prior to dyeing (E1 &E2), (iii) in the presence of dye and regardless to the reaction sequencing, treatment of samples with palladium precursor resulted in obtaining samples with higher intensity values rather than that treated with silver, owing to the higher reactivity of palladium in the presence of dye moieties, however, (iv) in the absence of either dye or mordant, sample treated with silver precursor at 60 °C (sample C1) exhibited with color intensity close to that of dyed sample (A) rather than that treated with palladium, attributing to that, palladium required higher temperature to be more accessible for interacting with fabric backbone.

Color measurements

In order to approve the effect of metal incorporation on fabric coloration; color coordinates (L*, a* and b*) and color strength (K/S) were evaluated for all of the prepared samples and the data were tabulated in Table 2. From the presented data, it could be recognized that; metal incorporation into the dyed fabric, resulted in significant increment for both of a* and b* positive values, meaning the color changed to the reddish-yellow, attributing to the successive coordination and stabilization of metals58,59,60,61,62,63. Figure 7 also showed the effect of process sequencing on the color strength (K/S) to affirm that, samples prepared via pre-treatment process in the absence of mordant (E1 & E2) were observed with color strength values closer to the that of the dyed sample with mordanting (A). Additionally, sample prepared with silver via pre-treatment process in the presence of mordant is exhibited with significantly higher color strength (F1) compared to the dyed cotton (A).

Moreover, from the tabulated data in Table 2, it could be declared that, regardless to the reaction conditions, treatment of cotton fabrics with silver precursor resulted in significant increment of reddish color (a*), whereas, yellowness (b*) is shown to visibly higher for samples treated with palladium precursor. Samples that where prepared via pre-treatment process without mordant (E1 & E2) is shown with much higher redness and yellowness compared to the dyed cotton (A). Insignificant differences in the values of a* and b* could be observed, by comparing between the samples prepared via pre-treatment process in the absence (E1 &E2) and in the presence of mordant (F1 &F2). Comparing between the samples prepared via pre-treatment, post treatment and simultaneous processes, the highest values of a* & b* were estimated for samples of prepared via pre-treatment process in the absence of mordant, to signify the accessibility of silver and palladium in playing the role of mordant in fabric coloration. These findings are in harmony with the previously illustrated data.

Fastness properties

Table 3 represented the estimated values for following up the effect of reaction sequencing and coordinative clustering and stabilization of metals on the fastness properties of the currently-prepared fabrics. Data revealed that, regardless to the reaction sequencing, the successive coordination of metals either silver or palladium resulted in significant enhancement in the fastness properties. From the estimated data it could depict that, successive immobilization of metal precursors using the currently demonstrated techniques did not affect on rubbing and washing fastness and significantly enhanced the light fastness. Samples that prepared via the pre-treatment process in absence of mordant (E1 & E2) were shown good rubbing and excellent washing fastness, while, light fastness was graded as outstanding. So, in summarization, either silver or palladium particles were successfully played the role of mordant for chemical stabilization of dye moieties within the fabric matrix.

UV-blocking potentiality

Cotton textiles were ascribed as one of the highly applicable textile materials in various purposes, attributing to their biocompatibility, smoothness, and breathability, however, it could exhibit some of disadvantages such as prone to high flammability, biological attacking, and low ultraviolet resistance9,10,11. Additionally, protective textile materials must be characterized with high UV ray reflecting and/or absorption affinity so as it could prevent UV irradiation from threatening the human body.

Therefore, recent reports were considered with preparation of UV-protective textiles. Numerous systematic studies were performed for exploiting some of metallic oxides (like, titanium dioxide, silicon dioxide, zirconium dioxide, magnesium dioxide and zinc oxide), and some of organic polymers were successively applied for treatment of cotton-based textiles to acquire the prepared textiles special properties64,65,66. In the current study, an innovative approach was demonstrated for acquirement the treated cotton fabric with UV-protective potency via successive immobilizing of silver and palladium within cotton dyed with RPN dye.

Transmission percent (T%, Fig. 8) and Ultraviolet Protection Factor (UPF, Table 4) could be described as key parameters for evaluating the ultraviolet blocking affinity for all of the currently prepared samples. According to the tabulated data, it could be revealed that, the blocking percent of treated samples showed that UV-B blocking percent is significantly higher than that for UV-A for all samples. Ultraviolet blocking potency was analyzed in a wavelength range of 280−400 nm, as shown in Fig. 8, for all of the prepared samples. T% of cotton fabric was estimated to be ca. 58.2% and 99.8% for both of UV-A and UV-B, respectively. As demonstrated in Fig. 8, the protection percentage for all of the prepared fabrics indicated with minor UV transmittance compared to dyed sample, i.e., T% of all the prepared samples was observably diminished after immobilization of metal particles within dyed samples.

Moreover, the presented data in Table 4 show that, regardless to the reaction sequencing, samples that were dyed using either silver or palladium instead of mordant were exhibited with higher UPF, UVA blocking and UVB blocking values compared to that dyed with mordanting (A). However, samples that were prepared with palladium salt were exhibited with significantly higher values of UPF rather than that estimated for samples prepared with silver precursor. In the absence of mordant, samples prepared with post-treatment process (D2, UPF 28.6, UVB T% 3.1%, UVB blocking percent 96.9%) exhibited with higher UV-resistance rather than that prepared with pre-treatment process (E2, UPF 12.0, UVB T% 8.0%, UVB blocking percent 92.0%). However, the sample prepared with simultaneous process showed with the highest UV-blocking action (G2, UPF 31.5, UVB T% 2.6%, UVB blocking percent 97.4%). However, it could be decided that, whatever the applied process for sample treatment, exploitation of either silver or palladium instead of mordant acquired the dyed samples excellent UV-blocking potentiality.

Antimicrobial action

Investigative approaches concerned in biotechnology spurs extensive consideration for manufacturing of multi-functional textiles16,18,19,67,68,69. According to literature18,62,70 silver precursors were exploited in manufacturing of biologically active textiles, whereas, no previous reports were studied the antimicrobial activities of dyed cotton immobilized with the as-applied metal precursors. In the current approach, the leadership role of the immobilized metals for dyeing and functionalization of the treated fabrics to be efficiently applicable in medical purpose is approved. Herein, the antimicrobial potency for the treated fabrics was evaluated against E. coli (G –ve bacteria), S. aureus (G + ve bacteria) and Candida albicans through inhibition zone and the reduction percent was estimated to be tabulated in Table 5. The estimated data revealed that, against E. coli, S. aureus and Candida albicans, respectively, comparing to the dyed sample with mordanting (A, 65.52%, 74.90% & 58.00%), only treatment of samples with either silver (B1, 84.04%, 89.21% & 85.96%) or palladium (B2, 80.89%, 86.21% & 79.58%) acquired the samples very good antimicrobial activities. However, the samples prepared via pre-treatment process in absence of mordant showed excellent antimicrobial action by exploiting either silver (E1, 89.56%, 96.71% & 93.01%) or palladium (E2, 92.17%,89.51% & 92.87C%). So, it could be eventually decided that, successive implantation of either silver or palladium showed to act the role of mordant with higher color fastness, in addition to acquire the treated fabrics excellence in UV-protection and antimicrobial actions.

Conclusions

In the represented approach, a systematic study is demonstrated for approving the superior role of silver and palladium metallic particles to act the role of mordant, with enhancing the color fastness and acquiring the dyed (with extract of red peanuts skin) cotton fabrics excellent antimicrobial potentiality and UV-protective affinity. From the represented data it could be declared that, the samples treated with metal precursors prior to dyeing were exhibited with the highest color strength, very good–excellent color fastness, very good UV blocking (UVB blocking percent was 97.4), and excellence biocidal potency (microbial reduction percent was ranged in 93.01–99.51%).

Data availability

The all data generated or analyzed during the current study are included in this manuscript.

Change history

25 October 2023

A Correction to this paper has been published: https://doi.org/10.1038/s41598-023-44959-x

01 May 2024

A Correction to this paper has been published: https://doi.org/10.1038/s41598-024-60771-7

References

Bhat, S. V., Nagasampagi, B. A. & Sivakumar, M. Chemistry of Natural Products (Alpha Science Int’l Ltd, 2005).

Kadolph, S. Natural dyes: A traditional craft experiencing new attention. Delta Kappa Gamma Bull. 75(1), 14 (2008).

Gorji, M., Bagherzadeh, R. & Fashandi, H. Electrospun Nanofibers in Protective Clothing 571–598 (Elsevier, 2017).

Hassabo, A. G., El-Naggar, M. E., Mohamed, A. L. & Hebeish, A. A. Development of multifunctional modified cotton fabric with tri-component nanoparticles of silver, copper and zinc oxide. Carbohyd. Polym. 210, 144–156 (2019).

Zhang, H. et al. Facile synthesis of SiO2 @ TiO2 hybrid NPs with improved photocatalytic performance. Micro Nano Lett. 13(5), 666–668 (2018).

P. Baglioni, L. Dei, L. Fratoni, P.L. Nosotro, M. Moroni, Process for the preparation of nano-and micro-particles of group II and transition metals oxides and hydroxides, the nano-and micro-particles thus obtained and their use in the ceramic, textile and paper industries, Google Patents (2005).

Subash, A. A., Chandramouli, K. V., Ramachandran, T., Rajendran, R. & Muthusamy, M. Preparation, characterization, and functional analysis of zinc oxide nanoparticle-coated cotton fabric for antibacterial efficacy. J. Text. Inst. 103(3), 298–303 (2012).

Wong, Y., Yuen, C., Leung, M., Ku, S. & Lam, H. Selected applications of nanotechnology in textiles. AUTEX Res. J. 6(1), 1–8 (2006).

Goncalves, G., Marques, P. A., Pinto, R. J., Trindade, T. & Neto, C. P. Surface modification of cellulosic fibres for multi-purpose TiO2 based nanocomposites. Compos. Sci. Technol. 69(7–8), 1051–1056 (2009).

Li, Q., Chen, S. L. & Jiang, W. C. Durability of nano ZnO antibacterial cotton fabric to sweat. J. Appl. Polym. Sci. 103(1), 412–416 (2007).

Li, Y., Wu, D.-X., Hu, J.-Y. & Wang, S.-X. Novel infrared radiation properties of cotton fabric coated with nano Zn/ZnO particles. Colloids Surf. A 300(1–2), 140–144 (2007).

Khan, M. Z. et al. In situ deposition of TiO2 nanoparticles on polyester fabric and study of its functional properties. Fibers Polym. 16(5), 1092–1097 (2015).

Nazari, A., Montazer, M., Mirjalili, M. & Nazari, S. Polyester with durable UV protection properties through using nano TiO2 and polysiloxane softener optimized by RSM. J. Text. Inst. 104(5), 511–520 (2013).

Ates, E. S. & Unalan, H. E. Zinc oxide nanowire enhanced multifunctional coatings for cotton fabrics. Thin Solid Films 520(14), 4658–4661 (2012).

Emam, H. E., Darwesh, O. M. & Abdelhameed, R. M. Protective cotton textiles via amalgamation of cross-linked zeolitic imidazole framework. Ind. Eng. Chem. Res. 59, 10931–10944 (2020).

Ahmed, H. B., El-Hawary, N. S. & Emam, H. E. Self-assembled AuNPs for ingrain pigmentation of silk fabrics with antibacterial potency. Int. J. Biol. Macromol. 105, 720–729 (2017).

Emam, H. E. & Abdelhameed, R. M. Anti-UV radiation textiles designed by embracing with nano-MIL (Ti, In)–metal organic framework. ACS Appl. Mater. Interfaces 9(33), 28034–28045 (2017).

Ahmed, H. B., Emam, H. E., Mashaly, H. M. & Rehan, M. Nanosilver leverage on reactive dyeing of cellulose fibers: Color shading, color fastness and biocidal potentials. Carbohyd. Polym. 186, 310–320 (2018).

Emam, H. E., Abdelhamid, H. N. & Abdelhameed, R. M. Self-cleaned photoluminescent viscose fabric incorporated lanthanide-organic framework (Ln-MOF). Dyes Pigments 159, 491–498 (2018).

Abdel-Mohdy, F., Fouda, M. M., Rehan, M. & Aly, A. Repellency of controlled-release treated cotton fabrics based on cypermethrin and prallethrin. Carbohyd. Polym. 73(1), 92–97 (2008).

Abdelhameed, R. M., Kamel, O. M., Amr, A., Rocha, J. O. & Silva, A. M. Antimosquito activity of a titanium–organic framework supported on fabrics. ACS Appl. Mater. Interfaces 9(27), 22112–22120 (2017).

Rehan, M., Hartwig, A., Ott, M., Gätjen, L. & Wilken, R. Enhancement of photocatalytic self-cleaning activity and antimicrobial properties of poly (ethylene terephthalate) fabrics. Surf. Coat. Technol. 219, 50–58 (2013).

Emam, H. E., Ahmed, H. B., Gomaa, E., Helal, M. H. & Abdelhameed, R. M. Recyclable photocatalyst composites based on Ag3VO4 and Ag2WO4 @ MOF@ cotton for effective discoloration of dye in visible light. Cellulose 27, 1–17 (2020).

Li, X. et al. Facile synthesis and flame retardant performance of NaAl (OH) 2CO3 whiskers. Powder Technol. 206(3), 358–361 (2011).

Almeida, L.d. Functionalisation of textiles: Future perspectives (2006).

Hewson, M. Formaldehyde in textiles. J. Soc. Dyers Colour. 110(4), 140–142 (1994).

Yang, C. Q., Xu, L., Li, S. & Jiang, Y. Nonformaldehyde durable press finishing of cotton fabrics by combining citric acid with polymers of maleic acid. Text. Res. J. 68(6), 457–464 (1998).

Welch, C. M. Tetracarboxylic acids as formaldehyde-free durable press finishing agents: Part I: Catalyst, additive, and durability studies. Text. Res. J. 58(8), 480–486 (1988).

Yang, C. Q., Chen, D., Guan, J. & He, Q. Cross-linking cotton cellulose by the combination of maleic acid and sodium hypophosphite. 1. Fabric wrinkle resistance. Ind. Eng. Chem. Res. 49(18), 8325–8332 (2010).

Chukwumah, Y., Walker, L. T. & Verghese, M. Peanut skin color: A biomarker for total polyphenolic content and antioxidative capacities of peanut cultivars. Int. J. Mol. Sci. 10(11), 4941–4952 (2009).

Yu, J., Ahmedna, M. & Goktepe, I. Effects of processing methods and extraction solvents on concentration and antioxidant activity of peanut skin phenolics. Food Chem. 90(1–2), 199–206 (2005).

Van Ha, H., PokornÝ, J. & Sakurai, H. Peanut skin antioxidants. J. Food Lipids 14(3), 298–314 (2007).

Gulrajani, M. L. Colour Measurment, Principles, Advances and Industerials Applications (Woodhead Publishing, 2010).

Chrysler, L. Methods of Test for Color Fastness of Textiles and Leather (Bradford, 1990).

B. STANDARD, B. ISO, Textiles—Tests for colour fastness—Part E04: Colour fastness to perspiration. ISO (1996) 105-E04.

N. ISO, Textiles—Tests for Colour Fastness—Part B02: Colour Fastness to Artificial Light: Xenon Arc Fading Lamp Test, International Organization for Standardization Geneva (1988).

CLSI, Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically; Approved Standard—Ninth Edition, Vol. 32 No. 2, M07-A9 Clinical and Laboratory Standards Institute USA (2012).

Emam, H. E., Zahran, M. & Ahmed, H. B. Generation of biocompatible nanogold using H2O2–starch and their catalytic/antimicrobial activities. Eur. Polym. J. 90, 354–367 (2017).

Kuang, Q., Yu, Y., Attree, R. & Xu, B. A comparative study on anthocyanin, saponin, and oil profiles of black and red seed coat peanut (Arachis hypogacea) grown in China. Int. J. food Prop. 20(sup1), S131–S140 (2017).

Zhao, Z. et al. Characterization and purification of anthocyanins from black peanut (Arachis hypogaea L.) skin by combined column chromatography. J. Chromatogr. A 1519, 74–82 (2017).

Attree, R., Du, B. & Xu, B. Distribution of phenolic compounds in seed coat and cotyledon, and their contribution to antioxidant capacities of red and black seed coat peanuts (Arachis hypogaea L.). Ind. Crops Prod. 67, 448–456 (2015).

Mouxiou, E., Eleftheriadis, I., Nikolaidis, N. & Tsatsaroni, E. Reactive dyeing of cellulosic fibers: Use of cationic surfactants and their interaction with reactive dyes. J. Appl. Polym. Sci. 108(2), 1209–1215 (2008).

Emam, H. E., Ahmed, H. B. & Bechtold, T. In-situ deposition of Cu2O micro-needles for biologically active textiles and their release properties. Carbohydr. Polym. 165, 255–265 (2017).

Emam, H. E., El-Hawary, N. S. & Ahmed, H. B. Green technology for durable finishing of viscose fibers via self-formation of AuNPs. Int. J. Biol. Macromol. 96, 697–705 (2017).

Emam, H. E., El-Zawahry, M. M. & Ahmed, H. B. One-pot fabrication of AgNPs, AuNPs and Ag-Au nano-alloy using cellulosic solid support for catalytic reduction application. Carbohydr. Polym. 166, 1–13 (2017).

Yang, L., Shang, L. & Nienhaus, G. U. Mechanistic aspects of fluorescent gold nanocluster internalization by live HeLa cells. Nanoscale 5(4), 1537–1543 (2013).

Huang, J. et al. Ag dendrite-based Au/Ag bimetallic nanostructures with strongly enhanced catalytic activity. Langmuir 25(19), 11890–11896 (2009).

Sekiguchi, Y., Hayashi, Y. & Takizawa, H. Synthesis of palladium nanoparticles and palladium/spherical carbon composite particles in the solid–liquid system of palladium oxide–alcohol by microwave irradiation. Mater. Trans. 52(5), 1048–1052 (2011).

Ngnie, G., Dedzo, G. K. & Detellier, C. Synthesis and catalytic application of palladium nanoparticles supported on kaolinite-based nanohybrid materials. Dalton Trans. 45(22), 9065–9072 (2016).

Mutharani, B., Ranganathan, P., Chen, S.-M. & Karuppiah, C. Enzyme-free electrochemical detection of nanomolar levels of the organophosphorus pesticide paraoxon-ethyl by using a poly (N-isopropyl acrylamide)-chitosan microgel decorated with palladium nanoparticles. Microchim. Acta 186(3), 1–11 (2019).

Rehan, M., Mashaly, H. M., Mowafi, S., Abou El-Kheir, A. & Emam, H. E. Multi-functional textile design using in-situ Ag NPs incorporation into natural fabric matrix. Dyes Pigments 118, 9–17 (2015).

Zhang, L. et al. Palladium nanoparticles as catalysts for reduction of Cr (VI) and Suzuki coupling reaction. J. Nanopart. Res. 19(4), 150 (2017).

Fu, G. et al. Polyallylamine functionalized palladium icosahedra: One-pot water-based synthesis and their superior electrocatalytic activity and ethanol tolerant ability in alkaline media. Langmuir 29(13), 4413–4420 (2013).

Lee, A. F., Ellis, P. J., Fairlamb, I. J. & Wilson, K. Surface catalysed Suzuki-Miyaura cross-coupling by Pd nanoparticles: An operando XAS study. Dalton Trans. 39(43), 10473–10482 (2010).

Tang, B. et al. Palladium nanoparticle colored cotton fabric as a highly efficient catalyst for colorimetric sensing of H2O2. Cellulose 27(13), 7791–7803 (2020).

Moglianetti, M. et al. Intracellular antioxidant activity of biocompatible citrate-capped palladium nanozymes. Nanomaterials 10(1), 99 (2020).

Peuckert, M. XPS study on surface and bulk palladium oxide, its thermal stability, and a comparison with other noble metal oxides. J. Phys. Chem. 89(12), 2481–2486 (1985).

Emam, H. E., Mowafi, S., Mashaly, H. M. & Rehan, M. Production of antibacterial colored viscose fibers using in situ prepared spherical Ag nanoparticles. Carbohydr. Polym. 110, 148–155 (2014).

Emam, H. E., Rehan, M., Mashaly, H. M. & Ahmed, H. B. Large scaled strategy for natural/synthetic fabrics functionalization via immediate assembly of AgNPs. Dyes Pigments 133, 173–183 (2016).

Emam, H. E., Saleh, N., Nagy, K. S. & Zahran, M. Functionalization of medical cotton by direct incorporation of silver nanoparticles. Int. J. Biol. Macromol. 78, 249–256 (2015).

Emam, H. E., Saleh, N., Nagy, K. S. & Zahran, M. Instantly AgNPs deposition through facile solventless technique for poly-functional cotton fabrics. Int. J. Biol. Macromol. 84, 308–318 (2016).

Mowafi, S., Rehan, M., Mashaly, H. M., Abou El-Kheir, A. & Emam, H. E. Influence of silver nanoparticles on the fabrics functions prepared by in-situ technique. J. Text. Inst. 108, 1–12 (2017).

Rehan, M., Mashaly, H. M., Mowafi, S., El-Kheir, A. A. & Emam, H. E. Multi-functional textile design using in-situ Ag NPs incorporation into natural fabric matrix. Dyes Pigments 118, 9–17 (2015).

Hojjati, B., Sui, R. & Charpentier, P. A. Synthesis of TiO2/PAA nanocomposite by RAFT polymerization. Polymer 48(20), 5850–5858 (2007).

Gandhi, S. et al. Ultrasound assisted one pot synthesis of nano-sized CuO and its nanocomposite with poly (vinyl alcohol). J. Mater. Sci. 45(6), 1688–1694 (2010).

Charpentier, P. et al. Nano-TiO2/polyurethane composites for antibacterial and self-cleaning coatings. Nanotechnology 23(42), 425606 (2012).

Ahmed, H. B. et al. Technical textiles modified with immobilized carbon dots synthesized with infrared assistance. J. Colloid Interface Sci. 604, 15–29 (2021).

Emam, H. E., Darwesh, O. M. & Abdelhameed, R. M. Protective cotton textiles via amalgamation of cross-linked zeolitic imidazole framework. Ind. Eng. Chem. Res. 59(23), 10931–10944 (2020).

Emam, H. E., El-Shahat, M., Hasanin, M. S. & Ahmed, H. B. Potential military cotton textiles composed of carbon quantum dots clustered from 4–(2, 4–dichlorophenyl)–6–oxo–2–thioxohexahydropyrimidine–5–carbonitrile. Cellulose 28(15), 9991–10011 (2021).

Emam, H. E. Arabic gum as bio-synthesizer for Ag–Au bimetallic nanocomposite using seed-mediated growth technique and its biological efficacy. J. Polym. Environ. 27(1), 210–223 (2019).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors conceived of the presented idea. N.E.-H., H.M. and H.A. carried out the experimental work and performed the analytic part. H.E. and H.A. figured out the data, discussed the results and presented the data. H.A. and H.E. supervised the findings of the work and wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: In the original version of this Article Hossam E. Emam was incorrectly affiliated with ‘Chemistry Department, Faculty of Science, Helwan University, Ain-Helwan, Cairo, 11795, Egypt’. Their correct affiliation is listed in the correction notice.

The original online version of this Article was revised: In the original version of this Article Hanan B. Ahmed was incorrectly affiliated with ‘Dyeing, Printing and Auxiliaries Department, Textile Research and Technology Institute, National Research Centre, 33 EL Buhouth St., Dokki, Giza, 12311, Egypt’. The correct affiliation is listed here: Chemistry Department, Faculty of Science, Helwan University, Ain-Helwan, Cairo 11795, Egypt.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Emam, H.E., El-Hawary, N.S., Mashaly, H.M. et al. Involvement of silver and palladium with red peanuts skin extract for cotton functionalization. Sci Rep 13, 16131 (2023). https://doi.org/10.1038/s41598-023-43267-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-43267-8

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.