Abstract

The plastic deformation behavior of single crystals of two transition-metal diborides, ZrB2 and TiB2 with the AlB2 structure has been investigated at room temperature as a function of crystal orientation and specimen size by micropillar compression tests. Although plastic flow is not observed at all for their bulk single crystals at room temperature, plastic flow is successfully observed at room temperature by the operation of slip on {1\({\bar{1}}\)00}<11\({\bar{2}}\)3> in ZrB2 and by the operation of slip on {1\({\bar{1}}\)00}<0001> and {1\({\bar{1}}\)00}<11\({\bar{2}}\)0> in TiB2. Critical resolve shear stress values at room temperature are very high, exceeding 1 GPa for all observed slip systems; 3.01 GPa for {1\({\bar{1}}\)00}<11\({\bar{2}}\)3> slip in ZrB2 and 1.72 GPa and 5.17 GPa, respectively for {1\({\bar{1}}\)00}<0001> and {1\({\bar{1}}\)00}<11\({\bar{2}}\)0> slip in TiB2. The identified operative slip systems and their CRSS values are discussed in comparison with those identified in the corresponding bulk single crystals at high temperatures and those inferred from micro-hardness anisotropy in the early studies.

Similar content being viewed by others

Introduction

Transition-metal diborides, ZrB2 and TiB2 with the hexagonal AlB2 structure (Pearson symbol: hP3, space group: P6/mmm) are important members of ultra-high temperature ceramics (UHTC)1,2,3,4,5,6,7, because of their numerous unique and advantageous physical and chemical properties required for ultra-high temperature applications8,9,10. Many transition-metal diborides including the above diborides have been considered to be promising candidate materials for a number of applications such as cutting tool11,12, armor11,12, diffusion barrier for preventing electromigration13, electrodes14, refractory structural materials for hypersonic vehicles15,16,17, control rod for nuclear reactors11 and so on8,9,10. Owing to the technological importance, mechanical properties of transition-metal diborides have been investigated for a several decades18,19,20,21,22,23,24. Many of studies in the early days utilized micro-hardness anisotropy to infer operative slip systems at room temperature, although only slip along <11\(\bar{2}\)0> directions (a slip) on either basal or prism plane was considered18,19,20. However, the operative slip systems at room temperature thus inferred for transition-metal diborides are somewhat controversial. For example, in ZrB2 single crystals, the operation of {1\(\bar{1}\)00}<11\(\bar{2}\)0> (prism a) slip was inferred by Haggerty et al.20, while Nakano et al.19 inferred the operation of (0001)<11\(\bar{2}\)0> (basal a) slip. Similarly, in TiB2 single crystals, the operation of both {1\(\bar{1}\)00}<11\(\bar{2}\)0> and (0001)<11\(\bar{2}\)0> slip was inferred by Mersol et al.18, whereas Nakano et al.19 inferred the operation of only {1\(\bar{1}\)00}<11\(\bar{2}\)0> slip. Later, slip involving the c-axis component has been claimed to participate in deformation of transition-metal diborides at room temperature21,22. Ghosh et al.21 identified the operation of {1\(\bar{1}\)00}[0001] (prism c) slip by transmission electron microscopy (TEM) in scratch-induced groove by nano-indentation on a ZrB2-SiC composite. Csanadi et al.22 then inferred the operation of {1\(\bar{1}\)00}[0001] and {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip at room temperature in ZrB2 from slip patterns around cube corner of nano-indent. In contrast to the intensive studies with indentation methods to infer operative slip systems at room temperature, the number of studies to investigate the macroscopic flow behavior of transition-metal diborides with compression/tensile tests of bulk single crystals is very much limited20,23,24. Haggerty et al.20 observed plastic flow of ZrB2 single crystals occurring only above 2050 °C in compression by the operation of (0001)<11\(\bar{2}\)0> slip, while Ramberg et al.23 observed plastic flow in TiB2 polycrystals occurring only above 1700 °C in compression without identifying the operative slip systems. However, these studies are far from systematic to understand the macroscopic flow behavior of transition-metal diborides since orientation- and temperature-dependent operative slip systems and their critical resolved shear stress (CRSS) values are not elucidated at all. Recently, we have made a first systematic study of the plastic deformation behavior of single crystals of TiB2 and ZrB2 in compression as a function of crystal orientation and temperature in a wide range from room temperature to 1500 °C25. In ZrB2, plastic flow is observed above 700 °C by the operation of slip on {1\(\bar{1}\)00}<11\(\bar{2}\)3> (prism a + c) and above 800 °C by the operation of slip on (0001)<11\(\bar{2}\)0> (basal a), whereas any appreciable plastic flow is not observed in TiB2 below 1500 °C. The absence of plastic flow below 1500 °C in TiB2 is considered to be closely associated with the existence of high density of grown-in stacking faults on prism planes. Of particular importance to notice is that plastic flow is not observed at room temperature in bulk single crystals of both transition-metal diborides. This clearly indicates that plastic flow observed at room temperature in the vicinity of micro-hardness indents in transition-metal diborides in the early studies18,19,20,21,22 is due to small-scale plasticity that does not occur in bulk but often occurs in small volume of brittle material even at temperatures well below the brittle-ductile transition temperature26,27,28,29,30,31. Micropillar compression testing that utilizes specimen of micrometer size32,33,34 has increasingly been known in recent years to offer one of the best ways to investigate such small-scale plasticity of brittle materials with many accumulated examples35,36,37,38,39,40,41,42,43. Indeed, Csanadi et al.44 recently utilized micropillar compression testing and confirmed plastic flow occurring by the operation of {1\(\bar{1}\)00}<11\(\bar{2}\)3> (prism a + c) slip in ZrB2 at room temperature. Interestingly, the slip system they identified in micropillar testing at room temperature is completely different from those ({1\(\bar{1}\)00}<11\(\bar{2}\)0>20 and (0001)<11\(\bar{2}\)0>19) inferred from micro-hardness anisotropy but coincides with one of the two slip systems we identified to operate in bulk single crystals above 700 °C25. However, since crystal orientations they tested in micropillar compression (two orientations near [0001] and [1\(\bar{1}\)00]) are not favored to activate slip systems other than {1\(\bar{1}\)00}<11\(\bar{2}\)3> (prism a + c) slip, whether or not another slip system ((0001)< 11\(\bar{2}\)0>) we identified to operate in bulk ZrB2 single crystals at high temperatures can operate at room temperature is not clear. On top of that, whether or not TiB2 also exhibits plastic flow at room temperature in micropillar compression and if so, which slip systems are activated in TiB2 are not clear at all yet.

In the present study, we investigate the plastic deformation behavior of single crystals of TiB2 and ZrB2 at room temperature as a function of crystal orientation and specimen size by micropillar compression testing, in order to see if plastic flow occurs in these transition-metal diborides and to identify the operative slip systems and their CRSS values. We also pay attention to the different c/a axial ratios for ZrB2 (1.123) and TiB2 (1.066) to see if the c/a axial ratio affects the operative slip systems. We discuss the identified operative slip systems and their CRSS values in comparison with those identified in the corresponding bulk single crystals at high temperatures25 and with those inferred from micro-hardness anisotropy in the early studies18,19,20.

Results

Stress–strain behavior and size-dependent strength

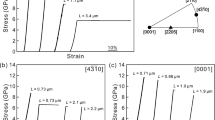

Selected stress–strain curves for single-crystal micropillar specimens of ZrB2 with the [11\(\bar{2}\)6], [11\(\bar{2}\)0], [01\(\bar{1}\)0] and [0001] orientations are shown in Fig. 1a–d, respectively. The specimen sizes (edge length L) tested are indicated for each of stress–strain curves. Compression tests were usually intended to interrupt before failure occurs for the ease of slip trace observations. However, failure occurred often prematurely or immediately after yielding for many cases of [11\(\bar{2}\)6], [11\(\bar{2}\)0] and [01\(\bar{1}\)0] orientations. Stress–strain curves shown in Fig. 1a–c correspond thus to only those specimens in which yielding was successfully observed. On the other hand, premature failure always occurred at the stress level exceeding 20 GPa without exhibiting any appreciable plastic strain prior to failure for micropillars with the [0001] orientation (see the inset figure of specimen after premature failure in Fig. 1d). The occurrence of premature failure at a very high stress level exceeding 20 GPa for the [0001] orientation of ZrB2 is consistent with the result of micropillar compression by Csanadi et al.44. For the other three orientations, yielding is defined either as the elastic limit at which the stress–strain behavior deviates from the linear relationship or as the stress at which the first strain burst occurs, as indicated by arrows in Fig. 1a–c. The magnitude of strain (flat portions of stress–strain curves) for each burst as well as the occurrence of strain burst itself depends on individual specimen without any definite trend in terms of specimen size and stress level for all the three orientations of Fig. 1a–c. The magnitude of strain for each burst in ZrB2 seems to be rather small when compared to many other brittle materials such as SiC39 and Mo5SiB237. The yield stress thus defined for all the three orientations ([11\(\bar{2}\)6], [11\(\bar{2}\)0] and [01\(\bar{1}\)0]) of ZrB2 seems not to depend much on the specimen size (edge length L), although the experimental scatter is very large to safely conclude.

Selected stress–strain curves obtained for micropillar specimens of ZrB2 with (a) [11\(\bar{2}\)6], (b) [11\(\bar{2}\)0], (c) [01\(\bar{1}\)0] and (d) [0001] orientations. Yield stresses are defined either as the elastic limit at which the stress–strain behavior deviates from the linear relationship or as the stress at which the first strain burst occurs, as indicated by arrows. The inset figure of (d) corresponds to the [0001]-oriented specimen with L = 2.7 μm.

Selected stress–strain curves for single-crystal micropillar specimens of TiB2 with the [11\(\bar{2}\)6], and [11\(\bar{2}\)0] are shown in Fig. 2a,b, respectively. The stress–strain behaviors of all these specimens are very similar to those observed for micropillar specimens of ZrB2 with the [11\(\bar{2}\)6], [11\(\bar{2}\)0] and [01\(\bar{1}\)0] orientations; failure occurred often prematurely or immediately after yielding. As in the case of ZrB2, the yield stress is defined either as the elastic limit or as the first strain burst stress, as indicated by arrows in Fig. 2a,b and it is seen not to depend much on the specimen size (edge length L), although the experimental scatter is again very large to safely conclude. Of significance to note is the occurrence of room-temperature plastic flow in TiB2, in which any appreciable plastic flow was not observed at all for bulk single crystals below 1500 °C in our previous study25.

Selected stress–strain curves obtained for micropillar specimens of TiB2 with (a) [11\(\bar{2}\)6] and (b) [11\(\bar{2}\)0] orientations. Yield stresses are defined either as the elastic limit at which the stress–strain behavior deviates from the linear relationship or as the stress at which the first strain burst occurs, as indicated by arrows.

The variation of yield stresses with specimen size (edge length L) is plotted in Fig. 3a–c, respectively for [11\(\bar{2}\)6], [11\(\bar{2}\)0] and [01\(\bar{1}\)0] orientations of ZrB2 and in Fig. 3d,e, respectively for [11\(\bar{2}\)6] and [11\(\bar{2}\)0] orientations of TiB2. Although the experimental scatter is again very large to safely conclude, the yield stress seems not to depend much on the specimen size for all cases of Fig. 3a–e. The yield stresses obtained for all three orientations of ZrB2 are very high, being distributed around 10 GPa. Although this is also the case for the [11\(\bar{2}\)0] orientation of TiB2, the yield stresses for the [11\(\bar{2}\)6] orientation of TiB2 are a bit smaller, being distributed in the range of 3–7 GPa. Of interest to note in Fig. 3 is that while TiB2 is exceptionally brittle in bulk as any plastic flow is not observed at all below 1500 °C25, the magnitude of the yield stress at room temperature for TiB2 is in the same range (for the [11\(\bar{2}\)0] orientation) or a bit smaller (for the [11\(\bar{2}\)6] orientation) than those for ZrB2.

SEM deformation structures (slip system identification)

Figure 4a–c show SEM secondary electron images of deformation structures observed for micropillar specimens of ZrB2 with the [11\(\bar{2}\)6], [11\(\bar{2}\)0] and [01\(\bar{1}\)0] orientations, respectively. The observations were made along the direction inclined by 30° from the loading axis. For the [11\(\bar{2}\)6] orientation (Fig. 4a), straight slip traces are clearly observed on the (1\(\bar{1}\)00) surface, while slip traces observed on the (\(\bar{1}\)\(\bar{1}\)21) surface are fairly faint. Slip trace analysis on the two orthogonal surfaces indicates the occurrence of slip on (01\(\bar{1}\)0) and (10\(\bar{1}\)0). The faint slip lines on the (11\(\bar{2}\)\(\bar{1}\)) surface indicates that the slip vector is contained in the (11\(\bar{2}\)\(\bar{1}\)) plane. Stereographic analysis has revealed that the slip directions are parallel to [\(\bar{2}\)11\(\bar{3}\)] and [1\(\bar{2}\)1\(\bar{3}\)] on (01\(\bar{1}\)0) and (10\(\bar{1}\)0), respectively. The slip system thus identified to operate in the micropillar with the [11\(\bar{2}\)6] orientation are (01\(\bar{1}\)0)[\(\bar{2}\)11\(\bar{3}\)] and (10\(\bar{1}\)0)[1\(\bar{2}\)1\(\bar{3}\)] (prism a + c). Although the slip system identified to operate in bulk single crystals of ZrB2 with the same orientation at high temperatures above 800 °C is basal a slip25, this is replaced by prism a + c slip at room temperature.

For the [11\(\bar{2}\)0] orientation (Fig. 4b), straight slip traces corresponding slip on (10\(\bar{1}\)0) are clearly observed on both the (1\(\bar{1}\)00) and (0001) surfaces. Since there is no resolved shear stress for prism c slip and basal a slip, either prism a slip or prism a + c slip should operate for this orientation. The intense slip traces observed on the (0001) surface, on which the a slip directions are contained, clearly denies the operation of prism a slip, indicating the operation of prism a + c ((10\(\bar{1}\)0)[1\(\bar{2}\)13] and (10\(\bar{1}\)0)[1\(\bar{2}\)1\(\bar{3}\)]) slip for the [11\(\bar{2}\)0] orientation. This slip system coincides with that observed to operate in bulk single crystals of ZrB2 with the same orientation at high temperatures above 700 °C25. The operative slip system for the [01\(\bar{1}\)0] orientation is similarly determined to be prism a + c ((1\(\bar{1}\)00)[11\(\bar{2}\)3], (1\(\bar{1}\)00)[11\(\bar{2}\)\(\bar{3}\)], (10\(\bar{1}\)0)[1\(\bar{2}\)13] and (10\(\bar{1}\)0)[1\(\bar{2}\)1\(\bar{3}\)]) slip from the slip trace analysis of Fig. 4c that straight slip traces corresponding slip on (1\(\bar{1}\)00) and (10\(\bar{1}\)0) are clearly observed on both the (\(\bar{2}\)110) and (0001) surfaces. The operation of prism a + c slip for the [01\(\bar{1}\)0] orientation of ZrB2 is consistent with the result of micropillar compression by Csanadi et al.44. The operative slip system (prism a + c slip) identified for each orientation does not vary with specimen size.

Figure 4d,e show SEM secondary electron images of deformation structures observed for micropillar specimens of TiB2 with the [11\(\bar{2}\)6] and [11\(\bar{2}\)0] orientations, respectively. The slip system operative for the [11\(\bar{2}\)6] orientation is determined to be (01\(\bar{1}\)0)[0001] (prism c) from the fact that the intense and faint slip traces corresponding to slip on (01\(\bar{1}\)0) are observed respectively for the (\(\bar{1}\)\(\bar{1}\)21) and (\(\bar{1}\)100) surfaces (Fig. 4d). For the [11\(\bar{2}\)0] orientation (Fig. 4e), straight slip traces corresponding slip on (01\(\bar{1}\)0) are clearly observed on the (1\(\bar{1}\)00) surface while they are only faint on the (0001) surface. As described above, the possible slip systems to operate for this orientation are either prism a slip or prism a + c slip. Since the a slip directions are contained on the (0001) surface on which slip traces are only faintly observed, the operative slip system for this orientation is determined to be prism a ((01\(\bar{1}\)0)[2\(\bar{1}\)\(\bar{1}\)0]). Although prism a slip was inferred to operate in TiB2 from micro-hardness anisotropy18,19, this slip system was not identified to operate in bulk single crystals of any of ZrB2, TiB2 and CrB2 in our previous study25.

Specimen size-dependent CRSS

The slip systems identified to operate are slip on {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip in ZrB2 and slip on {1\(\bar{1}\)00}<0001> and {1\(\bar{1}\)00}<11\(\bar{2}\)0> in TiB2. CRSS values for these slip systems calculated with the yield stress and the corresponding Schmid factor of the relevant slip system (Table 1) are plotted in Fig. 5a,b as a function of specimen size for ZrB2 and TiB2. The CRSS values for all these slip systems do not much depend on specimen size, although an inverse power-law scaling (i.e., CRSS ∝ L−n) is established for many conventional metal and alloys32,33,34,45,46,47,48,49. If the average value is taken, the CRSS values are estimated to be 3.01 GPa for {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip in ZrB2 and 1.72 GPa and 5.17 GPa, respectively for {1\(\bar{1}\)00}<0001> and {1\(\bar{1}\)00}<11\(\bar{2}\)0> slip in TiB2.

Discussion

Operative slip systems and CRSS

In ZrB2, {1\(\bar{1}\)00}<11\(\bar{2}\)3> (prism a + c slip) slip, which was identified as the primary slip system at high temperatures in bulk single crystals, is only the operative slip system at room temperature. In TiB2, on the other hand, {1\(\bar{1}\)00}<0001> (prism c slip) and {1\(\bar{1}\)00}<11\(\bar{2}\)0> (prism a slip) slip are observed to operate at room temperature.

In early studies of micro-hardness anisotropy, basal a slip and prism a slip are inferred to be the primary slip system in transition-metal diborides, although the argument usually considered the possibility of only these two slip systems ignoring the possibility of any other slip systems containing the c-axis component18,19,20. Basal a slip was claimed to be the primary system in ZrB2 by Nakano et al.19 while prism a slip was claimed so in ZrB2 by Haggerty et al.20 and in TiB2 by Nakano et al.19. The argument seems only partly consistent with the present results of micropillar compression tests of TiB2, in which prism a slip is observed to operate at room temperature. However, in view of the fact that the CRSS value is much lower for prism c slip than for prism a slip in TiB2, the argument of the early studies as to which of the two, prism a slip and basal a slip, is the primary slip system in transition-metal diborides seems not to make sense at all. The results of micropillar compression tests of ZrB2 is also not consistent with the argument of the early studies, since prism a + c slip is proved to be only the operative slip system at room temperature. The operation of prism a + c slip was also indeed observed in micropillar compression tests of ZrB2 by Csanadi et al.44. Csanadi et al.22 inferred the co-operation of {1\(\bar{1}\)00}[0001] and {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip at room temperature in ZrB2 from slip patterns around a cube corner of a nano-indent. Slip on {1\(\bar{1}\)00}<0001> (prism c slip) was claimed to operate by Ghosh et al.21 for the first time in scratch-induced groove by nano-indentation on a ZrB2-SiC composite. However, the operation of {1\(\bar{1}\)00}[0001] slip was not observed at all in the present micropillar compression tests.

The CRSS values at room temperature are deduced to be 3.01 GPa for {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip in ZrB2 and 1.72 GPa and 5.17 GPa, respectively for {1\(\bar{1}\)00}<0001> and {1\(\bar{1}\)00}<11\(\bar{2}\)0> slip in TiB2. Slip systems expected to operate at room temperature depending on crystal orientation are plotted in Fig. 6a,b, respectively for ZrB2 and TiB2 with the use of the above CRSS values for the relevant slip systems. Since there is no slip system to operate near the [0001] orientation (Fig. 2d), the approximate corresponding area is left blank to indicate no operative slip system.

The CRSS value determined for {1\(\bar{1}\)00} < 11\(\bar{2}\)3 > slip at room temperature with micropillar specimens are compared with those obtained at high temperatures with bulk single crystals in Fig. 7 for ZrB2. Of interest to note in Fig. 7 is that the CRSS value at room temperature coincides well with the extension of the bulk CRSS-temperature relation for prism a + c slip in ZrB2, indicating the identical deformation mechanism operates at both room temperature and high temperatures. In contrast, the CRSS value for basal a slip at room temperature might be more than 20 GPa if it is on the extension of the bulk CRSS-temperature relation for basal a slip in ZrB2 (Fig. 7). The expected CRSS value may be too high for basal a slip to actually operate in ZrB2.

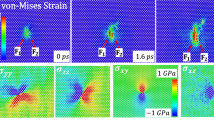

Selection of slip systems and dislocation dissociation modes

We now discuss some possible reasons about how the operative slip system is selected in micropillar single-crystal specimens at room temperature depending crystal orientation in ZrB2 and TiB2. In our previous study25, we calculated generalized stacking faults (GSF) energies on prism planes of ZrB2 and TiB2. Figure 8a,c show GSF energies on the prism plane in ZrB2 and TiB2, respectively. The energy maximum is located at the midpoint along the a- and c-axes, respectively, indicating that the dislocation with the Burgers vector (b) of 1/3[11\(\bar{2}\)0] and [0001] on prism plane may move as a perfect dislocation without dissociation into partial dislocations. On the other hand, an energy minimum is observed to exist at the midpoint along the a + c direction, indicating the dislocation with the b = 1/3[11\(\bar{2}\)3] on prism plane moves as an extended dislocation with two collinear identical partials separated by a stacking fault, as indicated below.

We indeed observed this dissociation scheme for the a + c dislocation on prism plane in ZrB2 by TEM in our previous study25. The results of our previous GSF calculations are shown in Fig. 8b,d a bit differently from Fig. 14 of our previous paper25 to indicate the energy landscape along the Burgers vectors of anticipated perfect dislocations for ZrB2 and TiB2, respectively. The maximum gradients of the GSF energy curve along the slip direction corresponding to the CRSS values for dislocation motion are tabulated in Table 2. The ease of the operation of slip systems can be evaluated with these values of the maximum gradients of the GSF energy curve (see also for Table 2), as follows.

The relative ease for the operation of the slip systems observed for micropillar specimens is correctly predicted with the DFT calculations for ZrB2 in that prism a + c slip is the easiest slip system but not completely for TiB2 in that the predicted easiest slip system (prism a + c slip) is not actually observed, although the relative ease is correctly predicted for prism c slip (the easiest system) and prism a slip. We tried to solve the question as to why prism a + c slip is predicted to operate more easily than prism c slip and prism a slip in TiB2 from the dislocation self-energy view point, since nucleation of mobile dislocations is mandatory for plastic flow to occur for micropillar specimen of brittle material. We calculated the energy factors of anticipated perfect (for prism a, prism c and basal a slip) and dissociated (b = 1/2(a + c) for prism a + c slip) dislocation for ZrB2 and TiB2 with the use of elastic constants determined at room temperature50,51, and the maximum energy for each dislocation is tabulated in Table 2. However, the above question could not be solved with the order of the magnitude of maximum energy in Table 2.

As described in our previous paper25, single crystals of ZrB2 and TiB2 used in the present study contain some growth faults with varying nature of the growth faults and their density depending on transition-metal diboride. There exists a possibility that these growth faults play a role making the prediction of operative slip systems difficult. More sophisticated work, such as that using growth fault-free single crystals, is definitely needed to answer this question.

Methods

Single crystals of the two transition-metal diborides, ZrB2 and TiB2 were grown as previously described in our previous paper25,52,53. In brief, single crystals of TiB2 and ZrB2 were grown with a radio-frequency heated floating-zone furnace from ingots with the stoichiometric compositions, measuring about 1 cm in diameter and 10 cm in length. Single crystals of these transition-metal diborides contain some grown-in defects of varying nature and density depending on diborides (Zr precipitates parallel to basal planes in ZrB2 and stacking faults on prism planes in TiB2) as detailed in our previous paper25. Orientations of single crystals were determined by the X-ray Laue back-reflection method. Four different loading-axis orientations, [0001], [11\(\bar{2}\)0], [01\(\bar{1}\)0] and [11\(\bar{2}\)6], were selected as the compression-axis orientations for ZrB2, while two loading-axis orientations, [11\(\bar{2}\)0] and [11\(\bar{2}\)6], were selected for TiB2. The highest Schmid factors for some possible slip systems ever reported (prism a, prism c, prism a + c and basal a) are listed in Table 1 for each orientation. After mechanical polishing with diamond paste to mirror finish, micropillar specimens with a square cross-section having an edge length L ranging from 1.0 to 8.0 μm and an aspect ratio of approximately 1:2.5 were machined from the single crystal with a JEOL JIB-4000 focused ion beam (FIB) apparatus at an operating voltage of 30 kV. A square cross-section was employed to facilitate the identification of slip planes and slip directions. Special care was taken to put one of the possible slip directions (either a, c or a + c) on one of the two orthogonal side faces, so that the slip direction is easily determined from the specimen shape change after deformation.

Compression tests were conducted with these micropillar specimens at a nominal strain rate of 1 × 10−4 s−1 at room temperature using Agilent nanoindenter G200 equipped with a flat punch diamond tip under the displacement-rate-controlled mode. Micropillar specimens were observed before and after deformation by scanning electron microscopy (SEM) with a JEOL JSM-7001FA electron microscope to identify the activated slip plane and slip direction.

Conclusions

-

1.

Plastic flow is successfully observed in compression at room temperature for both ZrB2 and TiB2 when tested with small specimens of the micron-meter-size, in spite of the high onset temperatures (700 °C) for plastic flow for bulk single crystals of ZrB2 and the absence of plastic flow below 1500 °C for TiB2.

-

2.

The operative slip systems identified at room temperature for micropillar specimens are completely different from those identified to operate at high temperatures in the corresponding bulk single crystals for both ZrB2 and TiB2. {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip, which was identified as the primary slip system at high temperatures in bulk single crystals, is only the operative slip system at room temperature in ZrB2. While any appreciable plastic flow is not observed in bulk single crystal of TiB2 below 1500 °C, {1\(\bar{1}\)00}<0001> and {1\(\bar{1}\)00}<11\(\bar{2}\)0> slip are observed to operate at room temperature in TiB2.

-

3.

The CRSS values for all slip systems identified to operate at room temperature in ZrB2 and TiB2 do not much depend on specimen size (side length, L), indicating the high Peierls (frictional) stress for the dislocation motion as often observed in many brittle materials. The bulk CRSS values at room temperature estimated as the value averaged over specimen size are 3.01 GPa for {1\(\bar{1}\)00}<11\(\bar{2}\)3> slip in ZrB2 and 1.72 GPa and 5.17 GPa, respectively for {1\(\bar{1}\)00}<0001> and {1\(\bar{1}\)00}<11\(\bar{2}\)0> slip in TiB2.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Fahrenholtz, W. G. & Hilmas, G. E. Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc. 90, 1347–1364 (2007).

Tang, S. F. & Hu, C. L. Design, preparation and properties of carbon fiber reinforced ultra-high temperature ceramic composites for aerospace. J. Mater. Sci. Technol. 33, 117–130 (2017).

Araia, Y., Inoue, R., Goto, K. & Kogo, K. Carbon fiber reinforced ultra-high temperature ceramic matrix composites: A review. Ceram. Int. 45, 14481–14489 (2019).

Golla, B. R., Mukhopadhyay, A., Basu, B. & Thimmappa, S. K. Review on ultra-high temperature boride ceramics. Prog. Mater. Sci. 111, 100651 (2020).

Al-Jothery, H. K. M., Albarody, T. M. B., Yusoff, P. S. M., Abdullah, M. A. & Hussein, A. R. A review of ultra-high temperature materials for thermal protection. IOP Conf. Ser. Mater. Sci. Eng. 863, 012003 (2020).

Rueschhoff, L. M., Carney, C. M., Apostolov, Z. D. & Cinibulk, M. K. Processing of fiber-reinforced ultra-high temperature ceramic composites: A review. Int. J. Ceram. Eng. Sci. 2, 22–37 (2020).

Binner, J. et al. Selection, processing, properties and applications of ultra-high temperature ceramic matrix. Int. Mater. Rev. 65, 389–444 (2020).

Goldschmidt, H. J. Interstitial Alloys (Buttrworths, 1967).

Matkovich, V. I. Boron and Refractory Borides (Springer, 1977).

Thompson, R. The chemistry of metal borides and related compounds. In Progress in Boron Chemistry, vol. 2 (eds. Brotherton R.J. & Steinberg, H.) 173–230 (Pergamon, 1970).

Telle, R., Sigl, L. S., & Takagi, S. Boride-based hard materials. In Handbook of Ceramic Hard Materials (ed. Riedel, R.) 802–945 (Wiley-VCH, 2000).

Munro, R. G. Material properties of titanium diboride. J. Res. Natl. Inst. Stand. Technol. 105, 709–720 (2000).

Sung, J., Goedde, D. M., Girolami, G. S. & Abelson, J. R. Remote-plasma chemical vapor deposition of conformal ZrB2 films at low temperature: A promising diffusion barrier for ultralarge scale integrated electronics. J. Appl. Phys. 91, 3904–3911 (2002).

Jin, Z. J., Zhang, M., Guo, D. M. & Kang, R. K. Electroforming of copper/ZrB2 coating and its performance as electro-discharge machining electrodes. Key Eng. Mater. 291–292, 537–542 (2005).

Opra, M. M., Talmy, I. G. & Zaykoski, J. A. Oxidation-based materials selection for 2000 °C+ hypersonic aerosurfaces: Theoretical considerations and historical experience. J. Mater. Sci. 39, 5887–5904 (2004).

Monteverde, F. & Savino, R. ZrB2-SiC sharp leading edges in high enthalpy supersonic flow. J. Am. Ceram. Soc. 95, 2282–2289 (2012).

Tan, W., Petorak, C. A. & Trice, R. W. Rare-earth modified zirconium diboride high emissivity coatings for hypersonic applications. J. Eur. Ceram. Soc. 34, 1–11 (2014).

Mersol, S. A., Lynch, C. T. & Vahldiek, F. W. Defect structure of single-crystal titanium diboride. In Anisotropy in Single-Crystal Refractory Compounds, vol. 2 (eds. Vahldiek, F. W. & Mersol, S. A.) 41–94 (Plenum Press, 1968).

Nakano, K., Imura, T. & Takeuchi, S. Hardness anisotropy of single crystals of IVa-diborides. Jpn. J. Appl. Phys. 12, 186–189 (1973).

Haggerty, J. S. & Lee, D. W. Deformation anisotropy of ZrB2 single crystals. J. Am. Ceram. Soc. 54, 572–576 (1971).

Ghosh, D., Subhash, G. & Orlovskaya, N. Slip-line spacing in ZrB2-based ultra high-temperature ceramics. Scripta Mater. 62, 839–842 (2010).

Csanadi, T., Kovalcikova, A., Dusza, J. & Fahrenholtz, W. G. Slip acitivation controlled nanohardeness anisotropy of ZrB2 ceramic grains. Acta Mater. 140, 452–464 (2017).

Ramberg, J. R. & Williams, W. S. High temperature deformation of titanium diboride. J. Mater. Sci. 22, 1815–1826 (1987).

Okamoto, N. L. et al. Mechanical and thermal properties of single crystals of ZrB2. MRS Symp. Proc. 753, 83–88 (2003).

Paul, B. et al. Plastic deformation of single crystals of CrB2, TiB2 and ZrB2 with the hexagonal AlB2 structure. Acta Mater. 211, 116857 (2021).

Gerberich, W. W. et al. Scale effects for strength, ductility, and toughness in “brittle” materials. J. Mater. Res. 24, 898–906 (2009).

Sung, T. H., Huang, J. C., Hsu, J. H. & Jian, S. R. Mechanical response of GaN film and micropillar under nanoindentation and microcompression. Appl. Phys. Lett. 97, 171904-1–3 (2010).

Östlund, F. et al. Ductile-brittle transition in micropillar compression of GaAs at room temperature. Philos. Mag. 91, 1190–1199 (2011).

Korte, S. & Clegg, W. J. Discussion of the dependence of the effect of size on the yield stress in hard materials studied by microcompression of MgO. Philos. Mag. 91, 1150–1162 (2011).

Kiani, S. et al. Dislocation glide-controlled room-temperature plasticity in 6H-SiC single crystals. Acta Mater. 80, 400–406 (2014).

Kwon, G. et al. Room-temperature yield and fracture strength of single crystalline 6H silicon carbide. J. Mater. Sci. 50, 8104–8110 (2015).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Dimiduk, D. M., Uchic, M. D. & Parthasarathy, T. A. Size-affected single-slip behavior of pure nickel microcrystals. Acta Mater. 53, 4065–4077 (2005).

Uchic, M. D., Shade, P. A. & Dimiduk, D. M. Plasticity of micrometer-scale single crystals in compression. Annu. Rev. Mater. Res. 39, 161–186 (2009).

Okamoto, N. L. et al. Compression deformability of Γ and ζ Fe–Zn intermetallics to mitigate detachment of brittle intermetallic coating of galvannealed steels. Scripta Mater. 69, 307–310 (2013).

Okamoto, N. L., Inomoto, M., Adachi, H., Takebayashi, H. & Inui, H. Micropillar compression deformation of single crystals of the intermetallic compound ζ-FeZn13. Acta Mater. 65, 229–239 (2014).

Kishida, K., Maruyama, T., Matsunoshita, H., Fukuyama, T. & Inui, H. Micropillar compression deformation of single crystals of Mo5SiB2 with the tetragonal D8l structure. Acta Mater. 159, 416–428 (2018).

Higashi, M., Momono, S., Kishida, K., Okamoto, N. L. & Inui, H. Anisotropic plastic deformation of single crystals of the MAX phase compound Ti3SiC2 investigated by micropillar compression. Acta Mater. 161, 161–170 (2018).

Kishida, K., Shinkai, Y. & Inui, H. Room temperature deformation of 6H-SiC single crystals investigated by micropillar compression. Acta Mater. 187, 19–28 (2020).

Hashizume, Y., Inomoto, M., Takebayashi, H., Okamoto, N. L. & Inui, H. Micropillar compression deformation of single crystals of the intermetallic compound ζ-Fe4Zn9. Acta Mater. 199, 514–522 (2020).

Kishida, K., Fukuyama, T., Maruyama, T. & Inui, H. Room temperature deformation of single crystals of Ti5Si3 with the hexagonal D88 structure investigated by micropillar compression tests. Sci. Rep. 10, 17983 (2020).

Hashizume, Y., Inomoto, M., Okamoto, N. L. & Inui, H. Plastic deformation of single crystals of the δ1p and δ1k intermetallic compounds in the Fe–Zn System by micropillar compression. Int. J. Plast. 136, 102889 (2021).

Kishida, K., Maruyama, T., Fukuyama, T. & Inui, H. Micropillar compression deformation of single crystals of α-Nb5Si3 with the D8l structure. Sci. Technol. Adv. Mater. 21, 805–816 (2021).

Csanadi, T. et al. Plasticity in ZrB2 micropillar induced by anomalous slip activation. J. Eur. Ceram. Soc. 36, 389–394 (2016).

Ng, K. S. & Ngan, A. H. W. Breakdown of Schmid’s law in micropillars. Scripta Mater. 59, 796–799 (2008).

Schneider, A. S. et al. Correlation between critical temperature and strength of small-scale bcc pillars. Phys. Rev. Lett. 103, 105501 (2009).

Lee, S. W. & Nix, W. D. Size dependence of the yield strength of fcc and bcc metallic micropillars with diameters of a few micrometers. Philos. Mag. 92, 1238–1260 (2012).

Parthasarathy, T. A., Rao, S. I., Dimiduk, D. M., Uchic, M. D. & Trinkle, D. R. Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples. Scripta Mater. 56, 313–316 (2007).

Bei, H., Shim, S., Pharr, G. M. & George, E. P. Effects of pre-strain on the compressive stress-strain response of Mo-alloy single crystal micropillars. Acta Mater. 56, 4762–4770 (2008).

Okamoto, N. L. et al. Temperature dependence of thermal expansion and elastic constants of single crystals of ZrB2 and the suitability ZrB2 of as a substrate for GaN growth. J. Appl. Phys. 93, 88–93 (2003).

Okamoto, N. L., Kusakari, M., Tanaka, K., Inui, H. & Otanai, S. Anisotropy in elasticity and thermal expansion of single crystals of CrB2, TiB2 and ZrB2. Acta Mater. 58, 76–84 (2010).

Otani, S. & Ishizawa, Y. Preparation of ZrB2 single crystals by the floating zone method. J. Cryst. Growth 165, 319–322 (1996).

Otani, S., Korsukova, M. M. & Mitsuhashi, T. Preparation of HfB2 and ZrB2 single crystals by the floating zone method. J. Cryst. Growth 186, 582–586 (1998).

Acknowledgements

This work was supported by Grant-in-Aids for Scientific Research on innovative Areas on High Entropy Alloys through the grant number JP18H05450 and JP18H05451, and in part by JSPS KAKENHI grant numbers JP18H01735, JP18H05478, JP19H00824, JP19K22053, JP20K21084, the Elements Strategy Initiative for Structural Materials (ESISM) from the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan (Grant number JPMXP0112101000) and JST CREST (Grant number JPMJCR1994).

Author information

Authors and Affiliations

Contributions

H.I. conceived the study. B.P. and Z.C. prepared the specimens, performed the micropillar compression and SEM experiments. K.K., B.P., S.M. and Z.C. performed the analysis of experimental data, prepared all of the figures and tables. S.O. prepared the bulk single crystals. N.L.O. performed the first-principles DFT calculations. B.P. and H.I. wrote the paper and all authors reviewed and commented on the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, Z., Paul, B., Majumdar, S. et al. Room-temperature deformation of single crystals of ZrB2 and TiB2 with the hexagonal AlB2 structure investigated by micropillar compression. Sci Rep 11, 14265 (2021). https://doi.org/10.1038/s41598-021-93693-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-93693-9

This article is cited by

-

Machine-learning potentials for nanoscale simulations of tensile deformation and fracture in ceramics

npj Computational Materials (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.