Abstract

In this study, a square cavity is modeled using Computational Fluid Dynamics (CFD) as well as artificial intelligence (AI) approach. In the square cavity, copper (Cu) nanoparticle is the nanofluid and the flow velocity characteristics in the x-direction and y-direction, and the fluid temperature inside the cavity at different times are considered as CFD outputs. CFD outputs have been assessed using one of the artificial intelligence algorithms, such as a combination of neural network and fuzzy logic (ANFIS). As in the ANFIS method, we have a non-dimension procedure in the learning step, and there is no issue in combining other characteristics of the flow and thermal distribution beside the x and y coordinates, we combine two coordinate parameters and one flow parameter. This ability of method can be considered as a meshless learning step that there is no instability of the numerical method or limitation of boundary conditions. The data were classified using the grid partition method and the MF (membership function) type was dsigmf (difference between two sigmoidal membership functions). By achieving the appropriate intelligence in the ANFIS method, output prediction was performed at the points of cavity which were not included in the learning process and were compared to the existing data (the results of the CFD method) and were validated by them. This new combination of CFD and the ANFIS method enables us to learn flow and temperature distribution throughout the domain thoroughly, and eventually predict the flow characteristics in short computational time. The results from AI in the ANFIS method were compared to the ant colony and fuzzy logic methods. The data from CFD results were inserted into the ant colony system for the training process, and we predicted the data in the fuzzy logic system. Then, we compare the data with the ANFIS method. The results indicate that the ANFIS method has a high potentiality compared to the ant colony method because the amount of R in the ANIFS system is higher than R in the ant colony method. In the ANFIS method, R is equal to 0.99, and in the ant colony method, R is equal to 0.91. This shows that the ant colony needs more time for both the prediction and training of the system. Also, comparing the pattern recognition in the two systems, we can obviously see that by using the ANFIS method, the predictions completely match the target points. But the other method cannot match the flow pattern and velocity distribution with the CFD method.

Similar content being viewed by others

Introduction

Natural convection heat transfer of a heated enclosure has widespread application in industries dealing with fluids. Its application includes solar collectors, thermal storage systems, building thermal design, aviation thermal management, heat dissipation from electronic devices, air conditioning, heaters, chemical processing tools, lubrication, and drying technologies1,2,3. To improve the heat transmission features inactively, utilizing fluid with high thermal conductivity is usual. Furthermore, rich heat dissipation properties can be achieved by using material that has a higher surface area4,5,6. There are also several research studies focusing on the effect of physical parameters on the nanofluid system and the thermal distribution of nanofluid in physical problems7,8,9,10.

In thermal engineering uses, the nano-sized additives are utilized in the base fluid with a lower thermal conductivity11. Better thermal conductivity characteristics of base fluid are obtained through the higher thermal conductivity of nanoparticles, even for the small quantity of metallic or nonmetallic additive particles, including Al2O3, Cu, Ag, Au, CuO, SiO2, TiO2 with an average particle size less than 100 nm12,13,14,15,16.

Investigating thermal structures employing experimental physics involves some drawbacks as well as limitations, although it is constantly a useful and important trend17,18. The challenging determination of the role of different physical phenomena to the system effectiveness is one of the disadvantages. Furthermore, high-cost tests regularly make an obstruction for performing comprehensive experimental investigations19,20,21,22. Simulation and modeling the optimal system progressively provide an appropriate substitute for the tests. Cubic Interpolation Particle (CIP) among all numerical methods has been currently developed for modeling the nanoparticles. In addition to this numerical model, machine learning techniques have been mixed with numerical or experimental data for predicting the multiphase flow. In about one decade, some researchers23,24 have combined the CFD method with machine learning algorithms to predict the fluid flow, particularly multiphase flow and heat transfer problems25,26. They examined different tuning parameters to achieve the best accuracy of the model in predicting the flow27,28,29.

For predicting the process of engineering, numerous machine learning techniques exist30,31,32,33. Intelligent methods and soft numerical algorithms such as neural networks34,35,36,37 and support vector machines35,36,37 are frequently used in the prediction of process engineering in industries or physics in real-life applications. The combination of neural cells and fuzzy structure called ANFIS is usually recommended for the prediction process38, and it is capable of directing complex associations. A smart approach is provided by this model to estimate the complex mechanisms in engineering39. Regulating the robotic movements in hazardous circumstances is an appropriate instance that can be mentioned here. Consequently, such techniques are appropriate to control the robots ant time that hazardous reactions can harm people40. Combination of machine learning and experimental or numerical outputs enables us to accelerate the optimization of process engineering, particularly when we require to run many CFD simulations to optimize the process41,42,43.

As far as the numerical method for solving of the CFD could take much time from researchers and engineers, and understanding of the big datasets is difficult, the machine learning method can be combined with CFD. Therefore, the results from CFD data could be used for the prediction of the process in CFD form. The results also could use the CFD datasets for a better understanding of the engineers. On the other hand, the conventional methods are weak for learning and understanding of the CFD data. Furthermore, they do not have the ability to train the matrices with different dimensions in order to provide a good understanding of the dataset for the engineers. AI has the ability to create mathematical correlations between the inputs and outputs, which could be beneficial in the training of a process. In previous studies, different processes have been studied in AI and CFD methods. The combination of the mentioned methods was used in different processes, including bubbly flow in the bubble column reactors, and nanofluid characteristics. In the current study, we used the ANFIS method and different membership functions to have the accuracy of the ANFIS method for creating the best prediction in our system. After the prediction in the ANFIS method, we also used the ACO method to complete the training process with this method, and the prediction completed by using the fuzzy logic system. After the prediction, ANFIS and ACO methods were compared with each other to study the accuracy of the ANFIS with other machine learning methods.

In this study, the liquid flow pattern and temperature distribution in a square cavity are calculated based on the CFD method. Different fluid parameters are obtained as the output of the CFD method. The flow characteristics include the flow pattern in different spaces, and the fluid temperature inside the cavity. In particular, grid partition with dsigmf as the membership function type was used for data classification, and by altering the structure of membership for neural cells, the influence of this parameter on the ANFIS intelligence was evaluated.

CFD method

A square surrounded area along with its physical specifications is shown in Fig. 1. The temperatures in upright left and right solid sections of the empty space are maintained constant (see Fig. 1), and their particular dimensionless values are equivalent to one. The right-hand side wall is colder than the left. The adiabatic assumption (no heat transfer) is implemented to the bottom and top walls of the simulation geometry. The nanofluid comprises of Cu particles suspended in water. Cubic-Interpolated Pseudo-particle (CIP)17 has been used to simulate the flow pattern and temperature distribution in the square shape cavity.

Representation of the square space and its boundary conditions17.

To start the model development, vorticity equation may be expressed as17:

Also, the energy equation17:

The thermal diffusivity is calculated as17:

The density of a fluid in the square shape domain that has floating particles is calculated using17:

In which, the parameters \(\phi\), \(\rho_{f}\), and \(\rho_{s}\) are the volumetric fraction of the floating particles, density of the particles, and the density of the pure fluid, successively17.

The formulation for effective stagnant thermal conductivity of fluid mixture was primarily suggested by Wasp44 and also used in17:

The CIP model is implemented to derive the advection term in order to calculate vorticity. Additional details concerning the numerical calculations are given in17.

The Nusselt number is calculated for a mixture of Nanoparticles in the fluid, and it is controlled by some thermal parameters. The local Nusselt number for the nanofluid is given by17:

The Nusselt number of the nanofluids is a function of thermal characteristics, such as thermal conductivity and heat capacitance of both liquid and particles (nanomaterials). We have measured the Nusselt number numerically through the cavity domain. More specifically, the average Nusselt is calculated based on the integral over all computing nodes in x-direction and y-direction, and the average Nusselt number is derived from23:

The nanofluid is created by using water, and the water includes Cu with uniform volume fraction, and we use a square shape domain to simplify the solving. The fluid in the cavity is incompressible and Newtonian. Moreover, there is no viscosity dissipation, and the flow regime is laminar. The current study is two-dimensional, and the CIP method is used for minimizing the numerical diffusion for high order Naiver Stokes equation. The characteristics of the nanofluids used in the fluid is sphere shape particles of Cu in the water.

The characteristics of the nanoparticles are according to the following features:

The density of Cu is 8,933 kg/m3, Specific heat at constant pressure (CP) for Cu is 385 (j/kg K), thermal conductivity is 401 (w/m k) and Electrical conductivity is 5.96 × 107.

ANFIS method

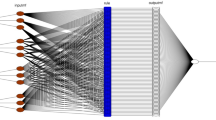

ANFIS is considered as a fuzzy extrapolation system to forecast the behavior of the nonlinear and complex system precisely45,46. Various kinds of fuzzy reasoning exist implementing the If–Then rules suggested by Takagi and Sugeno in ANFIS systems47. The scheme of the utilized ANFIS technique to predict the hydrodynamic properties is provided in Fig. 2 in the cavity. In this work, the location of CFD elements (x and y coordinate), as well as temperature distribution in the cavity, are considered as input parameters of the learning method. However, for the output parameter, the flow characteristics such as velocity distribution is used in the training method. Detailed descriotion of ANFIS method can be found in our previous publications23,24,27,28,29,46,48,49,50.

Results and discussion

It has been recognized that addition of nanoparticles inside the liquid leads to the increase of heat transfer and improvement of the efficiency of a system. As previous studies have shown, increasing the actions of the nanoparticles in a heating system could change the heating potentiality and increase the heat transfer of the system. In this research, we study that AI has the potentiality to predict the data relating to nanofluid. To do so, we added the nanofluid in the CFD, and after the training of the CFD dataset, we introduce the data set in the intelligence algorithm to see whether AI could predict CFD data when systems included nanoparticles.

In this study, the temperature distribution, as well as flow field in a square shape cavity, are calculated using the CFD method. Different fluid characteristics are obtained as the output of the CFD method, such as flow pattern in the x-direction and y-direction, and the thermal fluid distribution inside the cavity. In the present study, three inputs were used in the learning process of the ANFIS method, including the coordinates in the x-direction as the first input and coordinates in the y-direction as the second input and the temperature of the fluid inside the cavity as the third input. Also, the fluid velocity in the x-direction (u) was considered as the output. In the learning stage, the maximum iteration was considered to be 800, P = 65% (P represents the percentage of the total data which has been included in the training process). In the training process, 65% of the data was involved in the testing stage, and 100% of the data were considered for validation of the training stage. The Grashof number (Gr), which is a dimensionless number in fluid dynamics and heat transfer, was considered to be 11,000, and φ = 5% (φ represents the percentage of nanoparticles in the fluid showing the volume of nanoparticles in the liquid). Also, the Grid partition method was used in this study to classify the data and dsigmf (Difference between two sigmoidal membership functions) was considered as the type of membership function (MF).

With the aforementioned assumptions and by considering an input in the ANFIS method learning process (x-direction coordinates) and an output (fluid velocity in the x-direction (u)), the learning process, which includes the training and testing stages, was separately performed for a number of MFs (MF = 2, 3, 4). As shown in Fig. 3, the value of Regression (R) in all of the learning processes equals zero. Changing the number of MFs had no impact on the increase of ANFIS intelligence.

Afterward, to promote the model, the No. of inputs was increased, and the coordinates in x-direction and y-direction were considered as the inputs of ANFIS, while the fluid velocity in the x-direction (u) was considered as output. Training/testing procedures were performed for two MFs. As shown in Fig. 4, a good improvement in the intelligence of the system was achieved and the value of R increased to 0.86. The number of MFs was changed to evaluate the increase in the system intelligence; the No. was increased to 3, and the learning process was carried out. The value of R was increased to 0.95, which indicates the positive effect of this change; hence the number of MFs was increased to 4, resulting in an R-value of 0.98.

Subsequently, the number of inputs was increased from 2 to 3, the x-direction and y-direction coordinates and the fluid temperature were considered as the inputs of the learning process and the fluid velocity in the x-direction (u) was considered as output. The training/testing stages were carried out for a number of MFs; the obtained value of 0.93 for R is indicative of a 7% increase in the system intelligence compared to the similar conditions in which two inputs participated in the learning stage. After that, the number of MFs was increased to 3 and the learning process was performed once more. According to Fig. 5, the increase of the R value to 0.99 indicates achieving high intelligence for the ANFIS method.

By increasing the number of MFs to 4 and performing the learning process, we observe a value of 0.999 for R, showing that the system reached complete intelligence. Using this suitable intelligence, we can predict nodes that are not present in the training stage, which shows the functionality and practicality of using the ANFIS method23. In Fig. 6, the schematic view of the ANFIS system is observed, which illustrates the creation of 4 rules for each individual input and 64 rules for output.

By using ANFIS intelligence, we can obtain more information. According to Fig. 7, the comparison of the CFD and ANFIS results validates the ANFIS predictions and CFD data. The combination of ANFIS and CFD creates the ability to predict points that are not present in the learning process, as well as predictable points that are not created by CFD, which is a very useful feature for combining the ANFIS and CFD methods. The results indicate a positive effect of using dsigmf as a membership function and selecting the grid partition as a clustering type to achieve the full ANFIS intelligence.

(a) Validation of ANFIS (inputs 1 and 2), Max Iteration = 800, type of MFs = dsigmf, number of inputs MFs = (4). (b) Validation of ANFIS (inputs 1 and 3), Max Iteration = 800, type of MFs = dsigmf, number of inputs MFs = (4). (c) Validation of ANFIS (inputs 2 and 3), Max Iteration = 800, type of MFs = dsigmf, number of inputs MFs = (4).

In the current research paper, we study the comparison of results between the ANFIS and ant colony methods. In our study, the ant colony method was used for the training of the system, and the fuzzy structure system was used for the prediction of our dataset.

As shown in Fig. 8, the ANFIS method has high potentiality for the flow prediction in the square shape domain. The R criterion for this method is equal to 0.99, and the criteria for the ant colony is equal to 0.92. This shows that ANFIS has high accuracy in prediction, meaning that neural networks have high potentiality for the training of the data compared to the ACO method. For a better comparison of predictability of the methods, we study the methods in pattern recognition comparison. We compare the CFD and velocity distribution patterns for ANFIS and ACO methods, and the two methods were compared to CFD data to see which method can predict the patterns in the domain.

As shown in Fig. 9, ANFIS has high potentiality for predicting the flow pattern. However, ACO cannot predict the pattern well, and the predicted data does not match the CFD data meaning the data differs significantly with the CFD method. Due to the comparison of the methods by using R criteria, the ANFIS method has a lower error. The two methods can show us the flow inside the cavity. They also show the flow streamline in the middle of the domain, indicating zero velocity distribution in the middle of the square shape, and by moving further from the middle of the domain, the fluid velocity could increase.

Conclusions

In this study, nanofluid was simulated in a cavity by using CFD, and the fluid characteristics were studied by combining one of the methods of artificial intelligence (ANFIS) with CFD. In this study, one of the data clustering methods called Grid partition was used, and the number of MFs was considered as one of the grid partition variables. The changes in the number of MFs and the number of inputs were considered as the most important parameters influencing the ANFIS intelligence enhancement, which had an appropriate impact on the enhancement of ANFIS intelligence. The use of dsigmf as one of the varieties of MFs in this study has been effective in producing high-level intelligence that results in high accuracy of prediction.

One of the huge applications of the current research study is that repetitive solving of the CFD method, we could delete them and use AI instead. The AI method is a substitution for CFD to optimize the process, and it can avoid repetitive solving in the optimization process. On the other hand, one of the best applications that this method could create with itself is that the AI method has the ability to create mathematical correlations that can examine the physical phenomena partially. Mathematical correlations could run as solvers in the methods and software packages to decrease the role of CFD in solving the mechanical and chemical processes. When AI methods complete the training in different dimensions of the data, the methods could create a good understanding of the data. They can also create good relationships between the inputs and output, which are very difficult to be understood by conventional methods. If we want to understand only the CFD data, it will be very time-consuming. But the AI methods help us to study the effect of each input and output parameters on each other. So we can have a better understanding of the process. The current study shows us that AI could have the ability of prediction for thermal and flow characteristics in a square shape domain. When the nanofluid is used in the domain, we used AI for two different methods, which are ANFIS and ACO methods plus the fuzzy logic system.

Comparing two methods for the prediction and flow characteristics, the ANFIS method has a high ability in the prediction of the data, and the flow characteristics in the domain. Nevertheless, the other method, could not predict some local points in the domain, while it can complete the prediction to some extent. So the prediction ability of ACO is lower than the ANFIS method. The two methods can show us the flow in the domain. Also, they can show the flow streamline in the domain, and in the middle of the domain, a zero velocity distribution is seen. By moving further from the middle of the domain, the velocity of points in the domain increases. For future studies for the purpose of prediction of nanofluid in a domain, we can use a variety of methods to compare their abilities with each other. For instance, we can use deep learning to see how the prediction happens via this method. We can also consider different operation conditions to increase the ability of training in machine learning, and therefore, the system can consider different conditions for the prediction.

Abbreviations

- cp :

-

Specific heat capacity of the system

- g :

-

Gravity

- H :

-

Height of domain

- K :

-

Thermal conductivity in the cavity

- Nu :

-

Nondimensional Nusselt number

- t :

-

Time

- T :

-

Temperature in the domain

- u, v :

-

Velocity in different directions

- U,V :

-

Dimensionless velocity

- x, y :

-

Coordinates

- X, Y :

-

Dimensionless coordinates

- α :

-

Thermal diffusivity in the domain

- ϕ :

-

Solid volume fraction

- ν :

-

Kinematic viscosity

- ω :

-

Vorticity of the fluid flow

- ρ :

-

Density of fluid

- μ :

-

Dynamic viscosity

- f :

-

Fluid in the cavity

- nf :

-

Nanofluid

References

Ahmed, A. et al. Development of surface treated nanosilica for wettability alteration and interfacial tension reduction. J. Dispers. Sci. Technol. 39(10), 1469–1475 (2018).

Nakhjiri, A. T. et al. Experimental investigation and mathematical modeling of CO2 sequestration from CO2/CH4 gaseous mixture using MEA and TEA aqueous absorbents through polypropylene hollow fiber membrane contactor. J. Membr. Sci. 565, 1–13 (2018).

Nakhjiri, A. T. et al. The effect of membrane pores wettability on CO2 removal from CO2/CH4 gaseous mixture using NaOH, MEA and TEA liquid absorbents in hollow fiber membrane contactor. Chin. J. Chem. Eng. 26(9), 1845–1861 (2018).

Choi, S. U. & Eastman, J. A. Enhancing thermal conductivity of fluids with nanoparticles (Argonne National Lab, Lemont, 1995).

Das, S. K., Choi, S. U. & Patel, H. E. Heat transfer in nanofluids—a review. Heat Transf. Eng. 27(10), 3–19 (2006).

Dashti, A., Harami, H. R. & Rezakazemi, M. Accurate prediction of solubility of gases within H2-selective nanocomposite membranes using committee machine intelligent system. Int. J. Hydrog. Energy 43(13), 6614–6624 (2018).

Acharya, N. Active-passive controls of liquid di-hydrogen mono-oxide based nanofluidic transport over a bended surface. Int. J. Hydrog. Energy 44(50), 27600–27614 (2019).

Acharya, N. On the flow patterns and thermal behaviour of hybrid nanofluid flow inside a microchannel in presence of radiative solar energy. J. Therm. Anal. Calorim. 141, 1425–1442 (2019).

Acharya, N. Framing the impacts of highly oscillating magnetic field on the ferrofluid flow over a spinning disk considering nanoparticle diameter and solid liquid interfacial layer. J. Heat Transf. 142, 102503 (2020).

Acharya, N., Das, K. & Kundu, P. K. Effects of aggregation kinetics on nanoscale colloidal solution inside a rotating channel. J. Therm. Anal. Calorim. 138(1), 461–477 (2019).

Keblinski, P., Eastman, J. A. & Cahill, D. G. Nanofluids for thermal transport. Mater. Today 8(6), 36–44 (2005).

Kinloch, I. A., Roberts, S. A. & Windle, A. H. A rheological study of concentrated aqueous nanotube dispersions. Polymer 43(26), 7483–7491 (2002).

Krishnamurthy, S. et al. Enhanced mass transport in nanofluids. Nano Lett. 6(3), 419–423 (2006).

Wang, X.-Q. & Mujumdar, A. S. Heat transfer characteristics of nanofluids: a review. Int. J. Therm. Sci. 46(1), 1–19 (2007).

Wasan, D. T. & Nikolov, A. D. Spreading of nanofluids on solids. Nature 423(6936), 156 (2003).

Zhang, L. et al. Investigation into the antibacterial behaviour of suspensions of ZnO nanoparticles (ZnO nanofluids). J. Nanopart. Res. 9(3), 479–489 (2007).

Safdari, A., Dabir, H. & Kim, K. C. Cubic-interpolated pseudo-particle model to predict thermal behavior of a nanofluid. Comput. Fluids 164, 102–113 (2018).

Tohver, V. et al. Nanoparticle engineering of complex fluid behavior. Langmuir 17(26), 8414–8421 (2001).

Liu, G. et al. Ultrathin two-dimensional MXene membrane for pervaporation desalination. J. Membr. Sci. 548, 548–558 (2018).

Mohebbi, R. et al. Lattice Boltzmann method based study of the heat transfer augmentation associated with Cu/water nanofluid in a channel with surface mounted blocks. Int. J. Heat Mass Transf. 117, 425–435 (2018).

Mohebbi, R. et al. Forced convection of nanofluids in an extended surfaces channel using lattice Boltzmann method. Int. J. Heat Mass Transf. 117, 1291–1303 (2018).

Olle, B. et al. Enhancement of oxygen mass transfer using functionalized magnetic nanoparticles. Indus. Eng. Chem. Res. 45(12), 4355–4363 (2006).

Nabipour, N. et al. Prediction of nanofluid temperature inside the cavity by integration of grid partition clustering categorization of a learning structure with the fuzzy system. ACS Omega 5(7), 3571–3578 (2020).

Xu, P. et al. Flow visualization and analysis of thermal distribution for the nanofluid by the integration of fuzzy c-means clustering ANFIS structure and CFD methods. J. Vis. 23, 97–110 (2019).

Azwadi, C. S. N. et al. Adaptive-network-based fuzzy inference system analysis to predict the temperature and flow fields in a lid-driven cavity. Numer. Heat Transf. A Appl. 63(12), 906–920 (2013).

Rezakazemi, M. & Shirazian, S. Development of a 3D hybrid intelligent-mechanistic model for simulation of multiphase chemical reactors. Chem. Eng. Technol. 41(10), 1982–1993 (2018).

Tian, E. et al. Simulation of a bubble-column reactor by three-dimensional CFD: multidimension-and function-adaptive network-based fuzzy inference system. Int. J. Fuzzy Syst. 22, 477–490 (2019).

Cao, Y. et al. Prediction of fluid pattern in a shear flow on intelligent neural nodes using ANFIS and LBM. Neural Comput. Appl. 32, 13313–13321 (2019).

Babanezhad, M. et al. Liquid-phase chemical reactors: Development of 3D hybrid model based on CFD-adaptive network-based fuzzy inference system. Can. J. Chem. Eng. 97, 1676–1684 (2019).

Yilmaz, I. & Kaynar, O. Multiple regression, ANN (RBF, MLP) and ANFIS models for prediction of swell potential of clayey soils. Expert Syst. Appl. 38(5), 5958–5966 (2011).

Yun, Z. et al. RBF neural network and ANFIS-based short-term load forecasting approach in real-time price environment. IEEE Trans. Power Syst. 23(3), 853–858 (2008).

Zeinali, M. et al. Influence of piston and magnetic coils on the field-dependent damping performance of a mixed-mode magnetorheological damper. Smart Mater. Struct. 25(5), 055010 (2016).

Nakhjiri, A. T. & Heydarinasab, A. Computational simulation and theoretical modeling of CO2 separation using EDA, PZEA and PS absorbents inside the hollow fiber membrane contactor. J. Ind. Eng. Chem. 78, 106–115 (2019).

Edincliler, A. et al. Triaxial compression behavior of sand and tire wastes using neural networks. Neural Comput. Appl. 21(3), 441–452 (2012).

Mahmoud, M. A. & Ben-Nakhi, A. E. Neural networks analysis of free laminar convection heat transfer in a partitioned enclosure. Commun. Nonlinear Sci. Numer. Simul. 12(7), 1265–1276 (2007).

Ozsunar, A., Arcaklıoglu, E. & Dur, F. N. The prediction of maximum temperature for single chips’ cooling using artificial neural networks. Heat Mass Transf. 45(4), 443–450 (2009).

Sudhakar, T., Balaji, C. & Venkateshan, S. Optimal configuration of discrete heat sources in a vertical duct under conjugate mixed convection using artificial neural networks. Int. J. Therm. Sci. 48(5), 881–890 (2009).

Avila, G. & Pacheco-Vega, A. Fuzzy-C-means-based classification of thermodynamic-property data: a critical assessment. Numer. Heat Transf. A Appl. 56(11), 880–896 (2009).

Lei, Y. et al. Fault diagnosis of rotating machinery based on multiple ANFIS combination with GAs. Mech. Syst. Signal Process. 21(5), 2280–2294 (2007).

Ryoo, J., Dragojlovic, Z. & Kaminski, D. A. Control of convergence in a computational fluid dynamics simulation using ANFIS. IEEE Trans. Fuzzy Syst. 13(1), 42–47 (2005).

Ben-Nakhi, A., Mahmoud, M. A. & Mahmoud, A. M. Inter-model comparison of CFD and neural network analysis of natural convection heat transfer in a partitioned enclosure. Appl. Math. Model. 32(9), 1834–1847 (2008).

Boyacioglu, M. A. & Avci, D. An adaptive network-based fuzzy inference system (ANFIS) for the prediction of stock market return: the case of the Istanbul stock exchange. Expert Syst. Appl. 37(12), 7908–7912 (2010).

Yan, Y., Safdari, A. & Kim, K. C. Visualization of nanofluid flow field by adaptive-network-based fuzzy inference system (ANFIS) with cubic interpolation particle approach. J. Vis. 23(2), 259–267 (2020).

Wasp, F.J., Solid-liquid slurry pipeline transportation. Trans. Tech. Berlin (1977)

Soroush, E. et al. ANFIS modeling for prediction of CO2 solubility in potassium and sodium based amino acid salt solutions. J. Environ. Chem. Eng. 7(1), 102925 (2019).

Rezakazemi, M., Mosavi, A. & Shirazian, S. ANFIS pattern for molecular membranes separation optimization. J. Mol. Liq. 274, 470–476 (2019).

Takagi, T. & Sugeno, M. Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man Cybern. 15(1), 116–132 (1985).

Babanezhad, M., Nakhjiri, A. T. & Shirazian, S. Changes in the number of membership functions for predicting the gas volume fraction in two-phase flow using grid partition clustering of the ANFIS method. ACS Omega 5, 16284–16291 (2020).

Babanezhad, M. et al. Liquid-phase chemical reactors: development of 3D hybrid model based on CFD-adaptive network-based fuzzy inference system. Can. J. Chem. Eng. 97, 1676–1684 (2019).

Nguyen, Q. et al. Fluid velocity prediction inside bubble column reactor using ANFIS algorithm based on CFD input data. Arab. J. Sci. Eng. https://doi.org/10.1007/s13369-020-04611-6 (2020).

Author information

Authors and Affiliations

Contributions

M.P., M.B., and A.T.N. performed the simulations and analysis. M.R. validated the simulation results. A.M. edited the manuscript, and provided supervision. S.S. provided research supervision and funding. M.P. and M.B. wrote the main text of manuscript. S.S. improved the text and writing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pishnamazi, M., Babanezhad, M., Nakhjiri, A.T. et al. ANFIS grid partition framework with difference between two sigmoidal membership functions structure for validation of nanofluid flow. Sci Rep 10, 15395 (2020). https://doi.org/10.1038/s41598-020-72182-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-72182-5

This article is cited by

-

Application of Bio Coagulation–Flocculation and Soft Computing Aids for the Removal of Organic Pollutants in Aquaculture Effluent Discharge

Chemistry Africa (2024)

-

An equilibrium analysis of the impact of real estate price volatility on macroeconomics based on ant colony algorithm

Journal of Combinatorial Optimization (2023)

-

Exploration of the effects of Coriolis force and thermal radiation on water-based hybrid nanofluid flow over an exponentially stretching plate

Scientific Reports (2022)

-

Neural-based modeling adsorption capacity of metal organic framework materials with application in wastewater treatment

Scientific Reports (2022)

-

Intensification of CO2 absorption using MDEA-based nanofluid in a hollow fibre membrane contactor

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.