Abstract

In the present work, a method based on solvent extraction and gas chromatography–mass spectrometry (GC-MS) has been validated for the determination of 1,4-dioxane in cosmetics. Various solvents including ethyl acetate, hexane, methanol, dichloromethane and acetone have been used for the extraction of 1,4-dioxane, among them the ethyl acetate was found to be the most efficient extracting solvent. This method has offered excellent quality parameters for instance linearity (R2 > 0.9991), limit of detection (LOD, 0.00065-0.00091 µg/mL), limit of quantification (LOQ, 0.00217–0.00304 µg/mL) and, precision intra-day (1.65–2.60%, n = 5) and inter-day (0.16–0.32%, n = 5) in terms of relative standard deviation (RSD%). A total of thirty-nine cosmetic samples of different brands and origin have been studied. Among them, the 1,4-dioxane was found in twenty-three samples (FB1-FB7, MC1-MC4, MC6-MC8, HS3, HS5, BL1-BL3, BL5 and PLD1-PLD3) at the levels between 0.15 µg/mL and 9.92 µg/mL, whereas in sixteen samples (MC5, HS1, HS2, SG1-SG5, BL4 and HP1- HP6) was found to be not detected. The recovery values were achieved between 93% and 99% in both low and high level of spiked samples. In comparison to the traditional analytical techniques, the proposed method was found to be very sensitive and cost-effective for the routine analysis of 1,4-dioxane at low concentration in cosmetics.

Similar content being viewed by others

Introduction

1,4-Dioxane is a synthetic compound mainly used as solvent in industrial based products for instance paints, waxes, polishes, inks and varnishes. It is also present in cosmetic formulations and personal care products as dispersants, lathering agents and emulsifiers1,2,3. In the meantime, the non-ionic surfactants have occupied an extensive proportion of global surfactant consumption, and are being used in cosmetics and associated products4,5. The non-ionic surfactants can be categorized into three groups with polyethylene oxide, polyhydric alcohol, and poly(ethylene/propylene) oxide. In the course of the ethoxylation reaction procedure, 1,4-dioxane can be produced as a by-product through the dimerization of ethylene oxide2,5,6. 1,4-dioxane has also been identified in various water samples7,8,9,10,11,12,13, and since 1978, the occurrence of 1,4-dioxane as a water pollutant is recognized in the United States8.

Based on sufficient toxicological information of 1,4-dioxane carcinogenicity in animals, the International Agency for Research on Cancer (IARC)14 and Integrated Risk Information System (IRIS)15 have classified 1,4-dioxane as a probable human carcinogen. Regarding to toxicity profile, the Environmental Protection Agency (EPA) has identified a chronic oral reference dose of 0.03 mg/kg/day based on the toxicity of kidney and liver in mice and rats15,16. The toxicity investigations have identified that the 1,4-dioxane is associated to the toxicity of internal organs and enhance the formation of tumors in such kinds of animals17,18. Because of all gathered 1,4-dioxane toxicological data, its presence in various matrices including cosmetics, food and environmental5,6,19,20, formerly many analytical procedures have been developed. Primarily the 1,4-dioxane has been identified in water samples using various analytical procedures for instance solid-phase extraction/gas chromatography-mass spectrometry (SPE-GC–MS)6,9,21, headspace solid-phase microextraction (headspace-SPME)-GC–MS22. Besides, the 1,4-dioxane has also been found in many cosmetics (shampoo2,5,23,24,25, conditioner5, cleanser5, dishwashing liquid5,23, liquid soap5,23,25, day cream5,24,25, after-shave emulsion24, moisturizing lotion5,24,25, sun cream24,25, baby lotion25, bath foam25, cleansing milk25, after-shave balm25 and hair lotion25) using different analytical techniques for instance SPE–GC–FID2, headspace–SPME–GC–MS5, headspace–gas chromatography–mass spectrometry (headspace–GC–MS)23, SPE–high-performance liquid chromatography–UV detector (HPLC–UV)24 and SPE–GC–MS26. In previous literatures, the 1,4-dioxane contamination in cosmetics was frequently identified and required additional considerations to end the use of it for health concerns. The developed methods, nevertheless, undergoes from various shortcomings for instance the necessity for extensive sample pretreatment including expensive and time taking. The sensitivity, recovery and precision were also low in these earlier techniques5,24,25,26,27. Therefore, a simple, precise and sensitive analytical procedure was required for the identification of 1,4-dioxane in cosmetics.

The objective of the present work was to develop an analytical method based on low-cost solvent extraction and GC–MS for the analysis of 1,4-dioxane in a broad range of commercially available cosmetics. The method has been demonstrated to be proficient of measuring 1,4-dioxane at trace level lower than the recommendations value28,29. The overall high throughput including sensitivity, recovery and precision presented by the proposed technique can be an advantage for this kind of investigation.

Results and discussion

Optimization of solvent extraction method

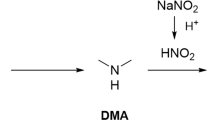

The assay of 1,4-dioxane in cosmetics was carried out by solvent extraction and GC–MS methods, respectively. Relating to the optimization of extracting solvents, initially, water was chosen as extracting solvent but 1,4-dioxane was found to have higher solubility due to the low octanol/water partition coefficient, and thus it was very challenging to extract 1,4-dioxane in aqueous medium using solvent extraction method. To sort out this problem, we have selected various pure extracting solvents for instance ethyl acetate, hexane, methanol, dichloromethane and acetone, and attempted to vary many parameters to extract 1,4-dioxane from cosmetics. The extraction procedures have been described as a sample extraction procedure section, the identical extraction procedures were applied for each extracting solvent. Among the tested extracting solvents, the ethyl acetate, hexane, methanol, dichloromethane and acetone have offered 1,4-dioxane recovery values of 99%, 47%, 70%, 89% and 35%, respectively. Among them, the ethyl acetate was found to be the most efficient extracting solvent where the 1,4-dioxane recovery value reaches up to 99%, nonetheless, the acetone offered the least 1,4-dioxane recovery value (35%). In previously reported study, the authors had applied combined liquid–liquid extraction (dichloromethane as extracting solvent) and GC–MS method30 for the identification of 1,4-dioxane in water samples, obtained excellent recovery up to 95%. Comparatively, the sample matrix was somewhat dissimilar but the recovery values were found to be in good agreement with the values obtained in current study. Nevertheless, the chlorinated solvents should be avoided to use as extracting solvent due to the environmental concern. Thus, the ethyl acetate was selected as an extracting solvent for the extraction of 1,4-dioxane in cosmetics. The enhancement, in the extraction of the target compound, can be because of the diverse composition of cosmetics. The effect of extracting solvents on recovery values has been demonstrated in Fig. 1. The Fig. 1 comprises a standard error bar of the mean which is the estimated values of the standard deviation (s) of means of analyzed samples, this is calculated using formula s/√(n), where n corresponds to the number of replicates (n = 5).

Method validation

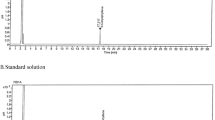

In order to assess the accurateness of the proposed solvent extraction-GC/MS procedure for the identification of 1,4-dioxane in cosmetics, the linearity, limits of detection (LOD, signal-to-noise ratio of 3:1) and limits of quantification (LOQ, signal-to-noise ratio of 10:1), precision (intra-day and inter-day) and accuracy were studied. The linearity of the method was investigated at six concentrations between 0.005 µg/mL and 50 µg/mL. This higher range was chosen due to 1,4-dioxane which is expected to be detected at low level (ng/L) to higher level µg/mL2. The linearity of the system was investigated by constructing calibration plot of the ratio of the peak area value of target compound 1,4-dioxane to the peak area value of cyclohexanone vs. ratio of the amounts of 1,4-dioxane and cyclohexanone. The linear range, slope, intercept and correlation coefficient (R2) of 1,4-dioxane have been illustrated in Fig. 2.

Sensitivity in terms of LOD and LOQ of the method was measured from cosmetic samples (MC5, HS1, HS2, HS4, SG1, SG2, SG3, SG4, SG5, BL4, HP1, HP2, HP3, HP4, HP5) free from 1,4-dioxane. These samples were spiked with low amounts (0.001 µg/mL) of 1,4-dioxane at the beginning of the extraction process. The achieved results have been illustrated in the Table 1. LOD of the solvent extraction-GC/MS in these cosmetic samples were achieved between 0.00065 µg/mL to 0.00091 µg/mL, whereas the LOQ obtained was between 0.00217 µg/mL and 0.00304 µg/mL (Table 1). The achieved outcomes show that the offered solvent extraction-GC/MS technique is appropriate for the determination of 1,4-dioxane in different kinds of cosmetic samples even at very low concentrations. The system precision was assessed by the intra-day and inter-day analysis. The intra-day analysis discusses to the determination of five samples injection in the same day whereas inter-day analysis discusses the determination of five samples injection over three consecutive days at low (0.3 µg/mL) and high (1.0 µg/mL) concentrations. The excellent intra-day (1.65–2.60%, n = 5) and inter-day (0.16–0.32%, n = 5) values in terms of RSD% were achieved. The precision of the system has been presented in Table 2.

The outcomes have revealed that the present method can be proposed for the routine analysis of 1,4-dioxane in cosmetic samples at very low concentrations. Until now, a few of literatures relating to the determination of 1,4-dioxane in cosmetics are available. In one of the study, the author has applied combined method based on headspace–GC–MS for the analysis of 1,4-dioxane in cosmetic products comprising polyethoxylated surfactants, found higher LOD value (0.3 µg/mL)27. Nevertheless, in another studies, the authors have applied combined headspace-SPME-GC–MS method for the analysis of 1,4-dioxane in nonionic surfactants and cosmetics, and SPE–GC–flame ionization detector (FID) detecting identification of 1,4-dioxane in cosmetic raw materials and finished cosmetic products, respectively, where the authors also detected higher LOD values ranged from 0.06 to 0.51 µg/mL5. Alternative method based on SPE-HPLC-UV detector using LiChrospher CH-8 reversed-phase column was also applied for the analysis of 1,4-dioxane in cosmetic samples, where the lowest measurable concentration was found to be 6.5 µg/g24. In comparison to the LOD value (0.00065 µg/mL) obtained in our work, the available traditional method offered lower sensitivity including solvent consumption, expensive materials and it was time consuming. As a result, the proposed method have offered advantages over sensitivity, rapidness, faster and inexpensive, and therefore the method could be applied as an advance technique for the routine analysis of 1,4-dioxane at trace level in cosmetics. Furthermore, there are other literatures available about 1,4-dioxane identification in water samples by means of numerous analytical methods for instance SPE-GC–MS6,10,21, and headspace–SPME-GC–MS22. Relatively, the outcomes achieved in the present work were also found in good agreement with the results obtained in water samples6,10,22, and thus the proposed method could also be applied for the analysis of 1,4-dioxane in water samples.

Application to cosmetic samples

The developed procedure in the present work was practically applied to examine the1,4-dioxane in commercially available cosmetic samples in Saudi Arabia. A total of thirty-nine cosmetic samples of different brand and origin have been investigated. The achieved results including concentrations and recovery values of 1,4-dioxane in cosmetic samples have been presented in Table 3. The 1,4-dioxane was found in most of the analyzed samples at levels between 0.15 to 9.92 µg/mL whereas in some samples (MC5, HS1, HS2, SG1-SG5, BL4 and HP1-HP6) the 1,4-dioxane found to be not detected. Recovery values were achieved from 93–98% at low level spiked concentrations and 95 to 99% at high level spiked concentrations. Relatively lower recovery values were obtained in low level spiked concentrations, the cause may be due to the samples complexity and higher loss during the sample extraction procedure. The amounts of 1,4-dioxane in facial and body scrub were obtained between 0.29 µg/mL and 9.92 µg/mL whereas in moisturizing cream (not detected-0.88 µg/mL), hair shampoo (not detected-0.23 µg/mL), shower gel (not detected), body lotion (not detected-0.16 µg/mL), hand soap (not detected) and powder laundry detergent (0.15 µg/mL and 0.21 µg/mL) were obtained. Among the analyzed samples, facial and body scrub, and powder laundry detergent produced 1,4-dioxane in all brand with highest concentration up to 9.92 µg/mL particularly in FB4 sample, however, the lowest concentration was obtained in PLD1, PLD2 and PLD5 samples up to 0.15 µg/mL. In shower gel and hand soap sample the 1,4-dioxane has not been identified in any brands. To demonstrate the outcomes, the GC-MS chromatogram of 1,4-dioxane (retention time (RT), 4.78) and cyclohexanone (RT, 6.03) of facial and body scrub (FB3, Perfect Cosmetics) sample have been displayed in Fig. 3.

It can be seen that the excellent resolution, symmetry and sensitivity was attained in the analysis, no tailing and interfering peaks were perceived at the same retention time of the studied analyte in cosmetic samples. Fuh and his coworkers have studied the presence of 1,4-dioxane in shampoo, liquid soap and dish washing detergent samples. The 1,4-dioxane was detected in shampoo samples at concentrations ranged from 11.5 to 41.1 µg/mL, whereas in liquid soap and dish washing detergent, the 1,4-dioxane was detected at concentrations ranged from 7.8 to 6.5 µg/mL5. These values were found in good agreements with the values obtained in the current study. In another work, Rastogi (1990) identified 1,4-dioxane in 82% of the studied cosmetic samples at amounts ranged from 0.3 to 96 µg/mL, and 85% of the dish washing samples contained 1,4-dioxane between 1.8 µg/mL and 65 µg/mL27. The variation in the concentrations was might be due to the different composition of the products, brand and origin. The results obtained from the current study are the substantial data source related to the presence of 1,4-dioxane in cosmetic samples of various brand and origin that are commercially available in the Saudi Arabian markets. The 1,4-dioxane could be primarily originated from the contaminations of nonionic surfactants through production. The cosmetic products are being worthy of further concerns, as they are extensively applied in our everyday existence. Table 4 displays the comparison of analyzed 1,4-dioxane in cosmetics from Saudi Arabia and with the earlier reported data. The LOD value in the present study was significantly enhanced as compared to those LOD values obtained in traditional extraction methods. Furthermore, the current method has also offered shorter analysis time, excellent precision and recovery values. According to the European Union directives on the safety of cosmetics31,32, 1,4-dioxane must not be applied in their preparations. Nevertheless, 1,4-dioxane was remains identified in cosmetic products in Saudi Arabia. Thus, the observing and reducing the amount of 1,4-dioxane in cosmetic products required additional concerns to encounter greater necessities of guidelines to protect user’s health.

Conclusions

A low cost, sensitive and reliable procedure based on solvent extraction and GC/MS has been developed for the determination of 1,4-dioxane in various cosmetic samples. Many solvents (methanol, hexane, dichloromethane and ethyl acetate) have been applied for the extraction of 1,4-dioxane, among them ethyl acetate was found to be the most efficient extracting solvent. A total of thirty-nine cosmetic samples of different brands and origin have been investigated, 1,4-dioxane was detected in most of the analyzed samples at concentrations ranged from 0.15 to 9.92 µg/mL, while in some samples (MC5, HS1, HS2, SG1- SG5, BL4 and HP1-HP6) 1,4-dioxane found to be not detected. The excellent quality parameters including recovery values (up to 99%) were achieved. The applied technique illustrates insignificant matrix effect and the lowest sample pretreatment needed deprived of losing target analyte. The inexpensive solvent extraction procedure implemented through the experimentation is a substantial benefit since during the sampling procedure it reduces the analysis period and the possibility of negligible losses of the studied compound and thus assists to offer enhanced method performance. The obtained results including excellent quality parameters and negligible matrix influences have made possible the applicability of the offered procedure as a new method for the routine examination 1,4-dioxane in cosmetic products.

Materials and Methods

Chemicals and reagents

The solvents and chemicals used in the current investigation were of analytical or liquid chromatography grade, obtained from Merck (Darmstadt, Germany). 1,4-dioxane and cyclohexanone were supplied from Sigma Aldrich (St. Louis, USA). Sodium sulfate anhydrous was purchased from Merck (Darmstadt, Germany). For sampling procedure, ultrapure water was produced using water filtration system (Milli–Q, Millipore Corporation, Bedford, USA). The stock standard solution of 1,4-dioxane was prepared in methanol at level 1000 µg/mL and applied for additional dilution methods. The IS solution was prepared in methanol at concentration 5 µg/mL and added to calibration solutions and samples during analysis. To verify the linearity (R2) of the procedure, 1,4-dioxane standard at various levels (0.005–50 µg/mL) were made using weight by weight. 1,4-dioxane standard solutions and cosmetics were filtered through syringe filter (0.22 μm) (PTFE, Macherey-Nagel GmbH, Düren, Germany) before being injected into the GC-MS system.

Sample extraction procedure

Cosmetic samples of various brands and origin were purchased from cosmetic and pharmacy shops located in Saudi Arabia. Cosmetic samples were refrigerated between 2–4 °C and investigated within one week to evade any microbial contamination. For the extraction of 1,4-dioxane from cosmetic samples, 1 g of cosmetic sample was accurately weighed in a 40 mL glass tube followed by the addition of 5 mL ethyl acetate. The sample solution was thoroughly mixed by means of vortex mixer (Jeio Tech, Seoul, South Korea) for 1 min. Afterward, the sample was moved to ultrasonic bath for sonication (10 min) at room temperature, sample centrifugation was carried out by HERMLE, model Z32 HK centrifuge system (Wehingen, Germany) at 6000 rpm for 8 min. The sample supernatant was taken out and moved to separating funnel followed by the addition of sodium sulfate to extract water contents. Finally, the sample was collected in a new glass tube and solvent was evaporated by means of nitrogen gas. Then, the extract of the sample was redissolved with 1 mL methanol (containing IS, 5 µg/mL) standard followed by mixing using vortex system. The 1 mL sample solution was filtered by means of PTFE syringe filter (0.22 μm) and injected into the GC-MS system. The sample injection volume was 1 µL to the splitless mode.

To evaluate the effectiveness of the extraction method and preventing the effect of matrix influences on retention time, peak intensity and shape, the quantification of 1,4-dioxane was carried out by a standard addition method comprising two non-spiked samples at zero levels and three spiked samples at 50% (0.1 µg/mL, values representing the increase of 1,4-dioxane in the sample after spiking), 100% (0.2 µg/mL) and 500% (1.0 µg/mL). The samples spiking was performed at the beginning of each extraction procedure. Samples were examined in triplicates, and the statistical analysis was carried out using ANOVA method.

The LOD and LOQ of the procedure were assessed in cosmetic samples (MC5, HS1, HS2, HS4, SG1, SG2, SG3, SG4, SG5, BL4, HP1, HP2, HP3, HP4, HP5) free from 1,4-dioxane. These samples were spiked with low amounts (0.001 µg/mL) of 1,4-dioxane before being analyzed by the optimized method. The recovery values of 1,4-dioxane were estimated at low and high concentrations in cosmetic samples, achieved from the added and found 1,4-dioxane concentrations. The quality control parameters of the system were also studied in each sample lot to confirm that the contamination of the samples did not come out and the sensitivity of the system was steady throughout the study.

Gas chromatography-mass spectrometric conditions

GC–MS analysis was carried out on a gas chromatograph (TRACETM 1310 GC) equipped with single quadrupole mass spectrometer (ISQLT) and auto-sampler unit model AI/AS1310 (Thermo Scientific, Waltham, USA). Separation of 1,4-dioxane was carried out on analytical Rxi-624Sil MS column with dimension 60 m, 0.53 mm I.D., 3.0 µm thickness (Restek, USA). The applied temperature program was started at 40 °C for 3 min, then rising to 240 °C at a rate of 50 °C/min (10 min). The flow-rate of helium (carrier gas) was controlled to get 100 kPa. The temperatures of injector, transfer line and ion source were adjusted to 250 °C. Ion source was established in electron ionization mode with 70 eV. The sample injection volume was 1 µL and operated to the splitless mode. The identification of the target analyte was performed using a mass spectrometer system. The data acquisition, data reporting, method setup and data processing were monitored using Xcalibur 3.1 software (Thermo Scientific, Waltham, USA).

To identify the target analytes, mass spectral database search methods was applied from National Institute of Standards and Technology (NIST, Gaithersburg, MD, USA). Gas chromatography-mass spectrometric analysis was carried out on a gas chromatograph (TRACETM 1310 GC) equipped with single quadrupole mass spectrometer (ISQLT) and auto-sampler unit model AI/AS1310 (Thermo Scientific, Waltham, USA). To identify the target analytes, mass spectral database search methods was applied from NIST. Prior to the analysis, the ionization mass spectra scan of 1,4-dioxane and cyclohexanone (IS) was carried out at concentration of 5 μg/mL. The electron ionization mass spectra scan was ranged from m/z, 20–300, and quantification was based on selected ion monitoring (SIM). The representing ions were m/z, 88 and 58 (1,4-dioxane) and m/z, 98 and 55 (cyclohexanone), respectively. The base peak of 1,4-dioxane and cyclohexanone was examined, and the particular qualifier ions were used as the established ions for further analysis. The obtained mass spectrum and fragmentation pattern of 1,4-dioxane (m/z, 88 and 58) and cyclohexanone (m/z, 98 and 55) have been displayed in Fig. 4.

References

Mohr, W. & Stickney, J. Environmental Investigation and Remediation: 1,4-Dioxane and other Solvent Stabilizers. CRC Press. Boca Raton, FL, pp 550 (2014).

Black, R. E., Hurley, F. J. & Havery, D. C. Occurrence of 1,4-Dioxane in cosmetic raw materials and finished cosmetic products. J. AOAC Int. 84, 666–670 (2001).

Environmental Protection Agency (EPA), Toxicological Review of 1,4-Dioxane (with Inhalation Update)., Washington, D.C. EPA/635/R-11/003F, 2013.

Martı́nez-Barrachina, S. et al. Determination of polyethoxylated non-ionic surfactants using potentiometric flow injection systems: Improvement of the detection limits employing an on-line pre-concentration stage. Anal. Chim. Acta 454, 217–227 (2002).

Fuh, C. B. et al. Impurity analysis of 1,4-dioxane in nonionic surfactants and cosmetics using headspace solid-phase microextraction coupled with gas chromatography and gas chromatography-mass spectrometry. J. Chromatogr. A 1071, 141–145 (2005).

Carrera, G. et al. Simultaneous determination of the potential carcinogen 1,4-dioxane and malodorous alkyl-1,3-dioxanes and alkyl-1,3-dioxolanes in environmental waters by solid-phase extraction and gas chromatography tandem mass spectrometry. J. Chromatogr. A 1487, 1–13 (2017).

Russeler, J., Kuhlicke, D. & Munte, T. F. Human error monitoring during implicit and explicit learning of a sensorimotor sequence. Neuroscience Res. 47, 233–240 (2003).

Kraybill, H. F. Carcinogenesis induced by trace contaminants in potable water. J. Urban Health 54, 413–427 (1978).

Isaacson, C. & Mohr, T. K. G. Quantitative Determination of 1,4-Dioxane and Tetrahydrofuran in Groundwater by Solid Phase Extraction GC/MS/MS. Environ. Sci. Technol. 40, 7305–7311 (2006).

Massey, S. S. et al. Probabilistic analysis of risks to us drinking water intakes from 1,4‐dioxane in domestic wastewater treatment plant effluents. Integr. Environ. Assess. Manag. 9, 554–559 (2013).

Adamson, D. T. et al. Evidence, of 1,4-Dioxane Attenuation at Groundwater Sites Contaminated with Chlorinated Solvents and 1,4-Dioxane. Environ. Sci. Technol. 49, 6510–6518 (2015).

European Commission (EC), Union Risk Assessment Report. https://echa.europa.eu/documents/10162/c44474a0-e926-451d-9efd-810b230008f4 (Accessed on 25/09/2018). 2001.

Manamsa, K. et al. A national-scale assessment of micro-organic contaminants in groundwater of England and Wales. Sci. Total Environ. 567, 712–726 (2016).

International Agency for Research on Cancer (IARC), Monographs on the Evaluation of Carcinogenic Risks to Humans. 71, 1597 http://monographs.iarc.fr/ENG/Monographs/vol83/mono83-1.pdf (Accessed on 20/10/2018). (1999).

Integrated Risk Information System (IRIS), Chemical Assessment Summary Environmental Protection Agency National Center for Environmental Assessment. 1–16 https://cfpub.epa.gov/ncea/iris2/chemicalLanding.cfm?substance_nmbr=326 (Accessed on 10/09/2018). (2012).

Agency for Toxic Substances and Disease Registry (ATSDR), Toxicological profile for 1,4-dioxane. 1–226 https://www.atsdr.cdc.gov/toxprofiles/tp187.pdf (Accessed on 02/10/2018). (2012).

Kasai, T. et al. Two-year inhalation study of carcinogenicity and chronic toxicity of 1,4-dioxane in male rats. Inhal. Toxicol. 21, 889–897 (2009).

Zhang, S., Gedalanga, P. B. & Mahendra, S. Advances in bioremediation of 1,4-dioxane-contaminated waters. J. Environ. Manag. 204, 765–774 (2017).

Guo, W. & Brodowsky, H. Determination of the trace 1,4-dioxane. Microchem. J. 64, 173–179 (2000).

Adams, C. D., Scanlan, P. A. & Secrist, N. D. Oxidation and Biodegradability Enhancement of 1,4-Dioxane Using Hydrogen Peroxide and Ozone. Environ. Sci. Technol. 28, 1812–1818 (1994).

Song, D. & Zhang, S. Rapid determination of 1,4-dioxane in water by solid-phase extraction and gas chromatography-mass spectrometry. J. Chromatogr. A 787, 283–287 (1997).

Nakamura, S. & Daishima, S. Simultaneous determination of 22 volatile organic compounds, methyl-tert-butyl ether, 1,4-dioxane, 2-methylisoborneol and geosmin in water by headspace solid phase microextraction-gas chromatography–mass spectrometry. Anal. Chim. Acta 548, 79–85 (2005).

Tahara, M., Obama, T. & Ikarashi, Y. Development of analytical method for determination of 1,4-dioxane in cleansing products. Int. J. Cosmetic Sci. 35, 575–580 (2013).

Scalia, S. Reversed-phase high-performance liquid chromatographic method for the assay of 1,4-dioxane in sulphated polyoxyethylene alcohol surfactants. J. Pharm. Biomed. Anal. 8, 867–870 (1990).

Scalia, S., Guarneri, M. & Menegatti, E. Determination of 1,4-dioxane in cosmetic products by high-performance liquid chromatography. Analyst 115, 929–931 (1990).

Black, D. B. et al. GC method for determining 1,4-dioxane in cosmetics. J. Assoc. Off. Ana.l Chem. 66, 180–183 (1983).

Rastogi, S. Headspace analysis of 1,4-dioxane in products containing polyethoxylated surfactants by GC-MS. Chromatographia 29, 441–445 (1990).

Food and Drug Administration (FDA), Considerations on Acceptable Trace Level of 1,4-Dioxane in Cosmetic Product. https://www.iccr-cosmetics.org/files/2414/8717/1555/ICCR_14-Dioxane_Final_2017.pdf (Accessed on 03/12/2018). 2017.

Scientific Committee on Consumer Safety (SCCS), The Report of the ICCR Working Group: Considerations on Acceptable Trace Level of 1,4-Dioxane in Cosmetic Products, https://ec.europa.eu/health/scientific_committees/consumer_safety/docs/sccs_o_194.pdf (Accessed on 04/12/2018). 2015.

Park, Y.-M. et al. Development of the analytical method for 1,4-dioxane in water by liquid–liquid extraction. Anal. Chim. Acta 548, 109–115 (2005).

Council Directive 76/768/EEC of 27 July 1976 on the approximation of the laws of the Member States relating to cosmetic products. OJEC L262 of 1976–09-27, pp. 169–200.

Commission Directive 2008/42/EC of 3 April 2008 amending Council Directive 76/768/EEC, concerning cosmetic products, for the purpose of adapting Annexes II and III thereto to technical progress. OJEC L93 of 2008-04-04, pp. 13–23.

Scalla, S. et al. Assay of 1,4-dioxane in cosmetic products by solid-phase extraction and GC-MS. J. Soc. Cosmet. Chem. 43, 207–213 (1992).

Zhou, W. The determination of 1,4-dioxane in cosmetic products by gas chromatography with tandem mass spectrometry. J. Chromatogr. A 1607, 460400 (2019).

Saraji, M. & Shirvani, N. Determination of residual 1,4-dioxane in surfactants and cleaning agents using headspace single-drop microextraction followed by gas chromatography–flame ionization detection. Int. J. Cosmetic Sci. 39, 36–41 (2017).

Acknowledgements

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for funding this work through the Research Group No. RG-1437-004.

Author information

Authors and Affiliations

Contributions

I.H.A., M.R.K. and H.M.A. performed data collection, statistical analysis, and manuscript writing. M.A. performed sample collection, and data interpretation. A.M.A. performed sample preparation and instrumental analysis. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alsohaimi, I.H., Khan, M.R., Ali, H.M. et al. Solvent extraction and gas chromatography–mass spectrometric determination of probable carcinogen 1,4-dioxane in cosmetic products. Sci Rep 10, 5214 (2020). https://doi.org/10.1038/s41598-020-62149-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-62149-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.