Abstract

Phase-change memory (PCM) has been considered a promising candidate for solving von Neumann bottlenecks owing to its low latency, non-volatile memory property and high integration density1,2. However, PCMs usually require a large current for the reset process by melting the phase-change material into an amorphous phase, which deteriorates the energy efficiency2,3,4,5. Various studies have been conducted to reduce the operation current by minimizing the device dimensions, but this increases the fabrication cost while the reduction of the reset current is limited6,7. Here we show a device for reducing the reset current of a PCM by forming a phase-changeable SiTex nano-filament. Without sacrificing the fabrication cost, the developed nano-filament PCM achieves an ultra-low reset current (approximately 10 μA), which is about one to two orders of magnitude smaller than that of highly scaled conventional PCMs. The device maintains favourable memory characteristics such as a large on/off ratio, fast speed, small variations and multilevel memory properties. Our finding is an important step towards developing novel computing paradigms for neuromorphic computing systems, edge processors, in-memory computing systems and even for conventional memory applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data required for assessing the conclusions can be accessed publicly at https://doi.org/10.5281/zenodo.10663106 (ref. 44).

Code availability

The original code used for the electrothermal simulation is publicly available in ref. 43.

References

Ambrogio, S. et al. Equivalent-accuracy accelerated neural-network training using analogue memory. Nature 558, 60–67 (2018).

Ding, K. et al. Phase-change heterostructure enables ultralow noise and drift for memory operation. Science 366, 210–215 (2019).

Khan, A. I. et al. Ultralow-switching current density multilevel phase-change memory on a flexible substrate. Science 373, 1243–1247 (2021).

Raoux, S., Xiong, F., Wuttig, M. & Pop, E. Phase change materials and phase change memory. MRS Bull. 39, 703–710 (2014).

Ahn, C. et al. Energy-efficient phase-change memory with graphene as a thermal barrier. Nano Lett. 15, 6809–6814 (2015).

Im, D. H. et al. A unified 7.5 nm dash-type confined cell for high performance PRAM device. In IEEE International Electron Devices Meeting 1–4 (IEEE, 2008).

Kang, M. J. et al. PRAM cell technology and characterization in 20 nm node size. In IEEE International Electron Devices Meeting 3.1.1–3.1.4 (IEEE, 2011).

Mehonic, A. & Kenyon, A. J. Brain-inspired computing needs a master plan. Nature 604, 255–260 (2022).

Roy, K., Jaiswal, A. & Panda, P. Towards spike-based machine intelligence with neuromorphic computing. Nature 575, 607–617 (2019).

Xia, Q. & Yang, J. J. Memristive crossbar arrays for brain-inspired computing. Nat. Mater. 18, 309–323 (2019).

Ielmini, D. & Ambrogio, S. Emerging neuromorphic devices. Nanotechnology 31, 092001 (2020).

Hong, S. et al. Extremely high performance, high density 20 nm self-selecting cross-point memory for Compute Express Link. In 2022 IEEE International Electron Devices Meeting 18.6.1–18.6.4 (IEEE, 2022).

Ielmini, D. & Wong, H. S. P. In-memory computing with resistive switching devices. Nat. Electron. 1, 333–343 (2018).

Kim, T. & Lee, S. Evolution of phase-change memory for the storage-class memory and beyond. IEEE Trans. Electron Dev. 67, 1394–1406 (2020).

Choi, S. et al. SiGe epitaxial memory for neuromorphic computing with reproducible high performance based on engineered dislocations. Nat. Mater. 17, 335–340 (2018).

Yao, P. et al. Fully hardware-implemented memristor convolutional neural network. Nature 577, 641–646 (2020).

Park, S. O., Jeong, H., Park, J., Bae, J. & Choi, S. Experimental demonstration of highly reliable dynamic memristor for artificial neuron and neuromorphic computing. Nat. Commun. 13, 2888 (2022).

Goh, Y. et al. High performance and self-rectifying hafnia-based ferroelectric tunnel junction for neuromorphic computing and TCAM applications. In IEEE International Electron Devices Meeting 17.2.1–17.2.4 (IEEE, 2021).

Jung, S. et al. A crossbar array of magnetoresistive memory devices for in-memory computing. Nature 601, 211–216 (2022).

Koelmans, W. W. et al. Projected phase-change memory devices. Nat. Commun. 6, 8181 (2015).

Salinga, M. et al. Monatomic phase change memory. Nat. Mater. 17, 681–685 (2018).

Hong, S. M. et al. Relaxation oscillation effect of the ovonic threshold switch on the SET characteristics of phase-change memory in cross-point structure. IEEE Electron Device Lett. 42, 1759–1761 (2021).

Shukla, K. D., Saxena, N., Durai, S. & Manivannan, A. Redefining the speed limit of phase change memory revealed by time-resolved steep threshold-switching dynamics of AgInSbTe devices. Sci. Rep. 6, 37868 (2016).

Peng, C. et al. Performance improvement of Sb2Te3 phase change material by Al doping. Appl. Surf. Sci. 257, 10667–10670 (2011).

Hu, J. et al. Cr-doped Sb2Te materials promising for high performance phase-change random access memory. J. Alloys Compd. 908, 164593 (2022).

Tong, L. et al. Improved phase-change characteristics of Si doped GeSbTe thin films used for phase change memory. J. Non-Cryst. Solids 358, 2402–2404 (2012).

Li, T. et al. Carbon doping induced Ge local structure change in as-deposited Ge2Sb2Te5 film by EXAFS and Raman spectrum. AIP Adv. 8, 025201 (2018).

Yang, W., Hur, N., Lim, D. H., Jeong, H. & Suh, J. Heterogeneously structured phase-change materials and memory. J. Appl. Phys. 129, 050903 (2021).

Lama, G. et al. Multilayered Sb-rich GeSbTe phase-change memory for best endurance and reduced variability. IEEE Trans. Electron Devices 69, 4248–4253 (2022).

Xiong, F. et al. Low-power switching of phase-change materials with carbon nanotube electrodes. Science 332, 568–570 (2011).

Liang, J., Jeyasingh, R. G. D., Chen, H. Y. & Wong, H. S. P. An ultra-low reset current cross-point phase change memory with carbon nanotube electrodes. IEEE Trans. Electron Devices 59, 1155–1163 (2012).

Choi, B. J. et al. Phase change memory cell using Ge2Sb2Te5 and softly broken-down TiO2 films for multilevel operation. Appl. Phys. Lett. 97, 132107 (2010).

You, B. K., Byun, M., Kim, S. & Lee, K. J. Self-structured conductive filament nanoheater for chalcogenide phase transition. ACS Nano 9, 6587–6594 (2015).

Gallo, M., le, Kaes, M., Sebastian, A. & Krebs, D. Subthreshold electrical transport in amorphous phase-change materials. New J. Phys. 17, 093035 (2015).

Ielmini, D. & Zhang, Y. Evidence for trap-limited transport in the subthreshold conduction regime of chalcogenide glasses. Appl. Phys. Lett. 90, 192102 (2007).

Gunti, S. R., Ayiriveetil, A. & Sundarrajan, A. Thermodynamic, kinetic and electrical switching studies on Si15Te85-xInx glasses: observation of boolchand intermediate phase. J. Solid State Chem. 184, 3345–3352 (2011).

Roy, D., Tanujit, B., Jagannatha, K. B., Asokan, S. & Das, C. Influence of Cu doping in Si-Te-based chalcogenide glasses and thin films: electrical switching, morphological and raman studies. IEEE Trans. Electron Devices 68, 1196–1201 (2021).

Saito, Y., Sutou, Y. & Koike, J. Crystallization behavior and resistance change in eutectic Si15Te85 amorphous films. Thin Solid Films 520, 2128–2131 (2012).

Petersen, K. E., Birkholz, U. & Adler, D. Properties of crystalline and amorphous silicon telluride. Phys. Rev. B 8, 1453 (1973).

Redaelli, A. Phase Change Memory: Device Physics, Reliability and Applications (Springer International Publishing, 2017).

Raoux, S. & Wuttig, M. Phase Change Materials: Science and Applications (Springer New York, 2008).

Khan, A. I. et al. Unveiling the effect of superlattice interfaces and intermixing on phase change memory performance. Nano Lett. 22, 6285–6291 (2022).

Niraula, D. & Karpov, V. Numerical modeling of resistive switching in RRAM device. In COMSOL Conference 1–7 (COMSOL, 2017).

Park, S.-O. et al. Phase-change memory via a phase-changeable self-confined nano-filament_Source-Data. Zenodo https://doi.org/10.5281/zenodo.10663106 (2024).

Ielmini, D. Threshold switching mechanism by high-field energy gain in the hopping transport of chalcogenide glasses. Phys. Rev. B 78, 035308 (2008).

Hwang, T. Y. et al. Rice-like tellurium thin films deposited by a galvanic displacement reaction and ultra-high sensing response to hydrogen sulfide (H2S) gas at room temperature. Sens. Actuat. B 282, 756–764 (2019).

Karthik, R. et al. Highly sensitive pyroelectric detector using atomically thin nanoscale silicon ditelluride. ACS Appl. Nano Mater. 6, 10168–10177 (2023).

Park, W. I. et al. Self-assembled incorporation of modulated block copolymer nanostructures in phase-change memory for switching power reduction. ACS Nano 7, 2651–2658 (2013).

Neumann, C. M. et al. Engineering thermal and electrical interface properties of phase change memory with monolayer MoS2. Appl. Phys. Lett. 114, 082103 (2019).

Acknowledgements

This work was supported by the National R&D Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2022M3I7A2078273, 2022M3F3A2A01072851 and 2020R1C1C1007464) and the Nanomedical Devices Development Project of NNFC.

Author information

Authors and Affiliations

Contributions

S.-O.P. and S.H. contributed equally to this work, and S.C. directed the team. S.-O.P. designed the basic concept of the device. S.-O.P., S.H. and S.C. designed the experiments. S.-O.P., S.H., S.-J.S. and D.K. fabricated the device and performed electrical measurements. S.-O.P., S.H., S.-J.S., S.S., H.J., T.P. and S.C. designed and carried out the TEM, EDS and FFT studies. S.-O.P., S.H., S.-J.S., S.S., H.J., T.P., W.J.C., J.K. and S.C. conducted the device analysis and discussed the overall work. S.-O.P., S.H. and S.C. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

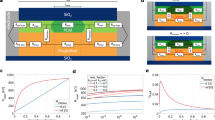

Extended Data Fig. 1 Cross-sectional transmission electron microscopy (TEM) bright field (BF) and high-angle annular dark-field (HAADF) images of the NFPCM in the set state.

a. An illustration of the NFPCM with the normal forming condition. b. The TEM BF image of the NFPCM, formed with the normal forming condition. c. The TEM HAADF image exhibiting a highly confined filament is formed in the a-Si layer with approximately 5.5 nm of diameter. d. An illustration of the NFPCM with the aggressive forming condition to form a thick filament. e. The TEM BF image of the NFPCM, formed with the aggressive forming condition. f. The TEM HAADF image of a thick filament in the a-Si layer. Since heavier Te atoms appear brighter than lighter Si atoms in the HAADF image, c and f indicate that the Te atoms are inserted into the a-Si layer and form a SiTex filament. Detailed explanations about forming strategies are provided in the Methods section.

Extended Data Fig. 2 TEM image of the SiTex filament in the set state.

High-resolution TEM image of the set state device with the aggressive forming process. The image shows lattice fringes in the filament while showing amorphous (no lattice fringes) in the a-Si region. The high-resolution TEM image indicates the formation of poly-crystalline SiTex filament in the set state.

Extended Data Fig. 3 Energy-dispersive spectroscopy (EDS) mapping results of the aggressively formed NFPCM.

a. Cross-sectional TEM HAADF image of the NFPCM with the aggressive forming (see Methods). b. EDS mapping results showing the Te atoms are injected into the a-Si layer, forming the SiTex filament.

Extended Data Fig. 4 EDS line scan results showing the stoichiometry of the filament.

a. The TEM HAADF image showing the direction of the EDS line scan (yellow arrow). b. Results of the EDS line scan demonstrating the overall stoichiometry of the filament is approximately 25.1% Si and 74.9% Te (~SiTe3), while the non-filamentary region is composed of about 100% Si.

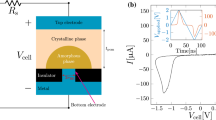

Extended Data Fig. 5 Different switching characteristics of SiTex film devices with three different stoichiometries on the 40 nm BEC.

Si-Te film-based devices with three different stoichiometries (95% Te (a), 75% Te (b), 50% Te (c)) are fabricated by co-sputtering Si and Te targets on the 40 nm BEC followed by sputtered W top electrode deposition to compare the electrical characteristics of various SiTex stoichiometries. Considering the bottom electrode contact area, the thickness of Si-Te films was selected as 35 nm to observe the clear transition between the selector and phase-change memory for various stoichiometries of Si-Te films45. a. The 95% Te device, which has a higher Te atomic ratio compared to the SiTe3, shows a threshold switching property with a large off-state resistance (a few tens of MΩ at 1 V), similar to chalcogenide-based selector devices. b. The 75% Te (SiTe3) device shows reversible non-volatile phase-change memory behavior similar to the NFPCM. c. The 50% Te device, which has a lower Te atomic ratio compared to the SiTe3, shows a threshold switching with a small on/off ratio and low off-state resistance (100 kΩ at 1 V). The results agree with the stoichiometry analysis from EDS analysis, where the SiTex filament is composed of 25% Si and 75% Te and exhibits non-volatile phase-change behaviors.

Extended Data Fig. 6 Diffraction pattern analysis of the poly-crystalline SiTex filament by fast-Fourier transformation (FFT).

a. TEM image of the SiTex filament in set state. b-d. High-resolution TEM images of the grains in the filament, showing clear lattice fringes. e-g. FFT analyses conducted on the high-resolution TEM image in (b-d). h-j. The inverse-FFT results obtained from FFT results to measure the interatomic distance of each crystal. For the grains marked in the green (b and e) and pink (d and g) boxes, hexagonal diffraction patterns of the trigonal Te crystal (0 0 1) plane were obtained. The two nearest spots to the diffraction center (marked as yellow circles) represent (\(\bar{1}20\)) and (\(2\bar{1}0\)) planes of the Te crystal (e and g). The measured interatomic distances through inverse FFT on the FFT result were close to 0.22 nm, consistent with the interatomic distance of the trigonal Te crystal46 (h and j). On the other hand, the grain marked in the blue box exhibited a diffraction pattern of the trigonal SiTe2 crystal (0 0 1) plane with a 0.38 nm interatomic distance (f and i), indicating the grain is composed of trigonal SiTe2 crystal47. The two nearest spots to the diffraction center represent (0 1 0) and (1 0 0) planes and the second closest spot represents (\(\bar{1}20\)) plane of the SiTe2 crystal. The diffraction patterns and interatomic distances indicate the formation of Te and SiTe2 crystals in the poly-crystalline SiTex filament.

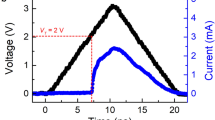

Extended Data Fig. 7 The set and reset switching speeds of the 5 μm NFPCM with various pulse widths.

a. The set speed of the NFPCM measured by applying set pulses (3.5 V) with various widths from 100 to 5,000 ns to the device in a high resistance state (HRS), showing a fast set speed of ~150 ns. b. The reset speed of the NFPCM measured by applying reset pulses (7 V) with various widths from 20 to 1,000 ns to the device in a low resistance state (LRS), showing a fast reset speed of less than 20 ns. It is noted that the switching speed, especially the set (crystallization) speed, is affected by several factors, such as the distance that atoms should travel to form crystals and the existence of crystal seeds promoting the nucleation speed. Therefore, modification of the switching speed could be possible through material variations.

Extended Data Fig. 8 Device resistance versus temperature curves with and without the NB process.

a. The device resistance versus temperature curve for the NFPCM without NB process, showing 439 K of a glass transition temperature (Tg) which corresponds to Si ~25% and Te ~75% alloy39. b. The device resistance versus temperature curve for the NFPCM with the NB process, showing increased Tg of 470 K, which corresponds to the Si ~29% and Te ~71% alloy. Because the Tg of the Si-Te system increases as the atomic percentage of the Te decreases, the results reveal that the NB process generates the Te-deficient SiTex filament (29% of Si and 71% of Te) compared to the filament without the NB process (25% of Si and 75% of Te).

Extended Data Fig. 9 The set and reset switching speeds of the NFPCM fabricated on the 40 nm BEC.

To analyze the switching speeds of the NFPCM with a scaled device size, the device is fabricated on the BEC having 40 nm of diameter (W/Te/a-Si/BEC). a. The set speed of the 40 nm NFPCM measured by applying set pulses (3.5 V) with various widths from 100 to 5,000 ns, showing a fast set speed of ~150 ns. b. The reset speed of the NFPCM measured by applying reset pulses (6.5 V) with various widths from 20 to 1,000 ns, showing a fast reset speed of less than 20 ns. The results show that the switching speed of the 40 nm device is similar to the 5 μm device. Since the forming process is barely affected by the device size, the device characteristics can also be independent of the device size.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, SO., Hong, S., Sung, SJ. et al. Phase-change memory via a phase-changeable self-confined nano-filament. Nature 628, 293–298 (2024). https://doi.org/10.1038/s41586-024-07230-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-024-07230-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.