Abstract

Glasses and gels, common amorphous solids with diverse applications, share intriguing similarities, including rigidity without translational order and dynamic slowing during ageing. However, their various underlying differences have not yet been explained. Here, through simulations, we elucidate distinct elastic properties related to temperature, observation times and ageing in glasses and gels, uncovering the underlying mechanisms. Configurational constraints, characterized by vibrational mean-squared displacements, similarly impact shear and bulk moduli in gels, but uniquely affect the shear modulus in glasses. As glasses age, a persistent trend of stiffening emerges, in contrast to gels, which initially stiffen and subsequently soften. We attribute these differences to mechanisms minimizing free energy: structural ordering in glasses and interface reduction in gels. Our findings not only reveal distinct behaviours but also shed light on the origin and evolution of elasticity in non-equilibrium disordered solids, with implications for amorphous material application and design.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Code availability

The codes used in this study are available from the corresponding author upon reasonable request.

References

Berthier, L. & Biroli, G. Theoretical perspective on the glass transition and amorphous materials. Rev. Mod. Phys. 83, 587–645 (2011).

Wang, W. H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 57, 487–656 (2012).

Zaccarelli, E. Colloidal gels: equilibrium and non-equilibrium routes. J. Phys. Condens. Matter 19, 323101 (2007).

Royall, C. P., Faers, M. A., Fussell, S. L. & Hallett, J. E. Real space analysis of colloidal gels: triumphs, challenges and future directions. J. Phys. Condens. Matter 33, 453002 (2021).

Baus, M. Statistical mechanical theories of freezing: an overview. J. Stat. Phys. 48, 1129–1146 (1987).

Tanaka, H., Tong, H., Shi, R. & Russo, J. Revealing key structural features hidden in liquids and glasses. Nat. Rev. Phys. 1, 333–348 (2019).

Bonn, D., Denn, M. M., Berthier, L., Divoux, T. & Manneville, S. Yield stress materials in soft condensed matter. Rev. Mod. Phys. 89, 035005 (2017).

Lu, P. J. et al. Gelation of particles with short-range attraction. Nature 453, 499–503 (2008).

Zia, R. N., Landrum, B. J. & Russel, W. B. A micro-mechanical study of coarsening and rheology of colloidal gels: cage building, cage hopping, and Smoluchowski’s ratchet. J. Rheol. 58, 1121–1157 (2014).

Testard, V., Berthier, L. & Kob, W. Influence of the glass transition on the liquid-gas spinodal decomposition. Phys. Rev. Lett. 106, 125702 (2011).

Testard, V., Berthier, L. & Kob, W. Intermittent dynamics and logarithmic domain growth during the spinodal decomposition of a glass-forming liquid. J. Chem. Phys. 140, 164502 (2014).

Whitaker, K. A. et al. Colloidal gel elasticity arises from the packing of locally glassy clusters. Nat. Commun. 10, 2237 (2019).

Tsurusawa, H., Leocmach, M., Russo, J. & Tanaka, H. Direct link between mechanical stability in gels and percolation of isostatic particles. Sci. Adv. 5, eaav6090 (2019).

Hsiao Lilian, C., Newman Richmond, S., Glotzer Sharon, C. & Solomon Michael, J. Role of isostaticity and load-bearing microstructure in the elasticity of yielded colloidal gels. Proc. Natl Acad. Sci. USA 109, 16029–16034 (2012).

Patrick Royall, C., Williams, S. R., Ohtsuka, T. & Tanaka, H. Direct observation of a local structural mechanism for dynamic arrest. Nat. Mater. 7, 556–561 (2008).

Zhang, S. et al. Correlated rigidity percolation and colloidal gels. Phys. Rev. Lett. 123, 058001 (2019).

Tsurusawa, H. & Tanaka, H. Hierarchical amorphous ordering in colloidal gelation. Nat. Phys. 19, 1171–1177 (2023).

Joshi, Y. M. Dynamics of colloidal glasses and gels. Annu. Rev. Chem. Biomol. Eng. 5, 181–202 (2014).

Ruzicka, B. & Zaccarelli, E. A fresh look at the Laponite phase diagram. Soft Matter 7, 1268–1286 (2011).

Alexander, S. Amorphous solids: their structure, lattice dynamics and elasticity. Phys. Rep. 296, 65–236 (1998).

DeGiuli, E. Field theory for amorphous solids. Phys. Rev. Lett. 121, 118001 (2018).

Lemaître, A. Stress correlations in glasses. J. Chem. Phys. 149, 104107 (2018).

Nampoothiri, J. N. et al. Emergent elasticity in amorphous solids. Phys. Rev. Lett. 125, 118002 (2020).

Wang, Y., Wang, Y. & Zhang, J. Connecting shear localization with the long-range correlated polarized stress fields in granular materials. Nat. Commun. 11, 4349 (2020).

Yoshino, H. & Mézard, M. Emergence of rigidity at the structural glass transition: a first-principles computation. Phys. Rev. Lett. 105, 015504 (2010).

Yoshino, H. & Zamponi, F. Shear modulus of glasses: results from the full replica-symmetry-breaking solution. Phys. Rev. E 90, 022302 (2014).

Szamel, G. & Flenner, E. Emergence of long-range correlations and rigidity at the dynamic glass transition. Phys. Rev. Lett. 107, 105505 (2011).

Parisi, G. & Zamponi, F. Mean-field theory of hard sphere glasses and jamming. Rev. Mod. Phys. 82, 789–845 (2010).

Yanagishima, T., Russo, J. & Tanaka, H. Common mechanism of thermodynamic and mechanical origin for ageing and crystallization of glasses. Nat. Commun. 8, 15954 (2017).

Tong, H., Sengupta, S. & Tanaka, H. Emergent solidity of amorphous materials as a consequence of mechanical self-organisation. Nat. Commun. 11, 4863 (2020).

Ding, J. et al. Universal structural parameter to quantitatively predict metallic glass properties. Nat. Commun. 7, 13733 (2016).

Saw, S. & Harrowell, P. Rigidity in condensed matter and its origin in configurational constraint. Phys. Rev. Lett. 116, 137801 (2016).

Greinert, N., Wood, T. & Bartlett, P. Measurement of effective temperatures in an aging colloidal glass. Phys. Rev. Lett. 97, 265702 (2006).

C. K. Poon, W. et al. Delayed sedimentation of transient gels in colloid-polymer mixtures: dark-field observation, rheology and dynamic light scattering studies. Faraday Discuss. 112, 143–154 (1999).

Teece, L. J. et al. Gels under stress: The origins of delayed collapse. Colloids Surf. A 458, 126–133 (2014).

Bartlett, P., Teece, L. J. & Faers, M. A. Sudden collapse of a colloidal gel. Phys.Rev. E 85, 021404 (2012).

Kamp, S. W. & Kilfoil, M. L. Universal behaviour in the mechanical properties of weakly aggregated colloidal particles. Soft Matter 5, 2438–2447 (2009).

Clarke, A. Gel breakdown in a formulated product via accumulated strain. Soft Matter 17, 7893–7902 (2021).

Fenton, S. M. et al. Minimal conditions for solidification and thermal processing of colloidal gels. Proc. Natl Acad. Sci. USA 120, e2215922120 (2023).

Bouzid, M. et al. Computing the linear viscoelastic properties of soft gels using an optimally windowed chirp protocol. J. Rheol. 62, 1037–1050 (2018).

Bantawa, M. et al. The hidden hierarchical nature of soft particulate gels. Nat. Phys. 19, 1178–1184 (2023).

Griffiths, S., Turci, F. & Royall, C. P. Local structure of percolating gels at very low volume fractions. J. Chem. Phys. 146, 014905 (2017).

Yunker, P., Zhang, Z., Aptowicz, K. B. & Yodh, A. G. Irreversible rearrangements, correlated domains, and local structure in aging glasses. Phys. Rev. Lett. 103, 115701 (2009).

Tateno, M., Yanagishima, T. & Tanaka, H. Microscopic structural origin behind slowing down of colloidal phase separation approaching gelation. J. Chem. Phys. 156, 084904 (2022).

Tanaka, H., Nishikawa, Y. & Koyama, T. Network-forming phase separation of colloidal suspensions. J. Phys. Condens. Matter 17, L143 (2005).

Kawasaki, T. & Tanaka, H. Structural evolution in the aging process of supercooled colloidal liquids. Phys. Rev. E 89, 062315 (2014).

Widmer-Cooper, A. & Harrowell, P. Free volume cannot explain the spatial heterogeneity of Debye–Waller factors in a glass-forming binary alloy. J. Non Cryst. Solids 352, 5098–5102 (2006).

Widmer-Cooper, A. & Harrowell, P. Predicting the long-time dynamic heterogeneity in a supercooled liquid on the basis of short-time heterogeneities. Phys. Rev. Lett. 96, 185701 (2006).

Mizuno, H. & Ikeda, A. in Low-Temperature Thermal and Vibrational Properties of Disordered Solids (ed. Ramos, M.) Ch. 10 (World Scientific, 2022).

Kriuchevskyi, I., Wittmer, J. P., Meyer, H. & Baschnagel, J. Shear modulus and shear-stress fluctuations in polymer glasses. Phys. Rev. Lett. 119, 147802 (2017).

Lemaître, A. & Maloney, C. Sum rules for the quasi-static and visco-elastic response of disordered solids at zero temperature. J. Stat. Phys. 123, 415 (2006).

Furukawa, A. & Tanaka, H. Direct evidence of heterogeneous mechanical relaxation in supercooled liquids. Phys. Rev. E 84, 061503 (2011).

Rocklin, D. Z., Hsiao, L., Szakasits, M., Solomon, M. J. & Mao, X. Elasticity of colloidal gels: structural heterogeneity, floppy modes, and rigidity. Soft Matter 17, 6929–6934 (2021).

Bonacci, F. et al. Contact and macroscopic ageing in colloidal suspensions. Nat. Mater. 19, 775–780 (2020).

Tong, H. & Tanaka, H. Revealing hidden structural order controlling both fast and slow glassy dynamics in supercooled liquids. Phys. Rev. X 8, 011041 (2018).

Tong, H. & Tanaka, H. Structural order as a genuine control parameter of dynamics in simple glass formers. Nat. Commun. 10, 5596 (2019).

Zhang, H., Zhang, Q., Liu, F. & Han, Y. Anisotropic-isotropic transition of cages at the glass transition. Phys. Rev. Lett. 132, 078201 (2024).

Cheng, Y. Q. & Ma, E. Configurational dependence of elastic modulus of metallic glass. Phys. Rev. B 80, 064104 (2009).

Jabbari-Farouji, S., Tanaka, H., Wegdam, G. H. & Bonn, D. Multiple nonergodic disordered states in Laponite suspensions: a phase diagram. Phys. Rev. E 78, 061405 (2008).

Goodrich, C. P., Liu, A. J. & Nagel, S. R. The principle of independent bond-level response: tuning by pruning to exploit disorder for global behavior. Phys. Rev. Lett. 114, 225501 (2015).

Shen, X. et al. Achieving adjustable elasticity with non-affine to affine transition. Nat. Mater. 20, 1635–1642 (2021).

Tateno, M. & Tanaka, H. Numerical prediction of colloidal phase separation by direct computation of Navier–Stokes equation. npj Comput. Mater. 5, 40 (2019).

Wang, X., Ramírez-Hinestrosa, S., Dobnikar, J. & Frenkel, D. The Lennard–Jones potential: when (not) to use it. Phys. Chem. Chem. Phys. 22, 10624–10633 (2020).

Schröder-Turk, G. E. et al. Disordered spherical bead packs are anisotropic. Europhys. Lett. 90, 34001 (2010).

Acknowledgements

H.T. acknowledges the support by the Grant-in-Aid for Specially Promoted Research (JSPS KAKENHI Grant No. JP20H05619) from the Japan Society for the Promotion of Science (JSPS). M.T. acknowledges the support from JSPS KAKENHI (Grant No. JP20K14424). Y.W. acknowledges the support from Shanghai Jiao Tong University via the scholarship for outstanding PhD graduates. We thank the Supercomputer Center, the Institute for Solid State Physics, the University of Tokyo, for the use of the facilities.

Author information

Authors and Affiliations

Contributions

H.T. designed and supervised the project. Y.W. performed research. Y.W. and M.T. analysed data. All authors discussed the results and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Physics thanks Raffaele Pastore, Lei Xu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Snapshots of the gelation process.

Particles are colour-coded to differentiate those in the foreground from those in the background.

Extended Data Fig. 2 Self-intermediate scattering functions of glasses and gels.

a, Self-intermediate scattering function Fs(k, Δt, tw) for glasses at different ages (tw/τB = 9.6 × 101, 9.6 × 102, 9.6 × 103, 9.6 × 104, 9.6 × 105), depicted from left to right. Here, k is the peak wavenumber of the structural factor. b, Fs(k, Δt, tw) of all particles (dashed lines) and only isostatic particles (solid lines) for gels at different ages (tw/τB = 102, 103, 104, 105, 106), shown from left to right. The vertical dashed lines in a and b indicate the period of oscillatory deformation used in measuring the moduli of glasses and gels, respectively.

Extended Data Fig. 3 Ageing dynamics and observation-time-dependent elasticity in glasses with the Lennard-Jones potential (LJ glasses) and gels with the Wang-Frenkel potential (WF gels).

a, Illustration of the typical structure of an LJ glass. Particles are colour-coded based on their sizes. b, MSD \({\langle {\Delta} r^2 \rangle}\) versus observation time Δt for LJ glasses at different ageing time, tw. Here, the time unit is scaled by the Brownian time, τB. c, Observation-time-dependent shear modulus G and bulk modulus K of LJ glasses. Short bars indicate the affine moduli, GA and KA. d, Illustration of the typical structure of a WF gel. Particles are colour-coded based on their sizes. e, MSD of all particles \(\langle \Delta r^2 \rangle\) (dashed curves) and only isostatic particles \({\langle \Delta r^2 \rangle}_{\rm{iso}}\) (solid curves) versus Δt for WF gels at various tw. f, Observation-time-dependent shear modulus G and bulk modulus K of WF gels. Inset: the same data as the main panel with the vertical axis zoomed out to show the affine moduli GA and KA, as indicated by the short bars. The same plot as the Fig. 1 in the main text.

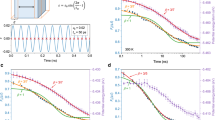

Extended Data Fig. 4 Amplitude and frequency sweep moduli in gels.

a, Shear stress σxy versus time t/Δt under oscillatory shear strain ϵxy (solid blue curve), where Δt is the period time. The black points represent individual σxy, and the red curve represents the fitting results using \({\sigma }_{xy}={\sigma }_{0}\sin (\omega t+\delta )\). b, Strain amplitude γ sweep of storage shear modulus \({G}^{{\prime} }\) and loss shear modulus G″. c, Frequency ω = 2π/(Δt/τB) sweep of \({G}^{{\prime} }\) and G″. d, Pressure p and volumetric strain ϵb versus t/Δt under oscillatory uniform compression ϵb (blue solid curve). The red curve represents the fitting results using \(p={p}_{0}\sin (\omega t+\delta )+{p}_{{{{\rm{c}}}}}\), where pc is the initial pressure of the system. e, Volume strain amplitude γb sweep of storage bulk modulus \({K}^{{\prime} }\) and loss bulk modulus K″. f, Frequency ω = 2π/(Δt/τB) sweep of \({K}^{{\prime} }\) and K″. The vertical dashed lines mark the amplitude and frequency used to measure the moduli in Fig. 2d–f. In this work, G and K refer specifically to the storage moduli \({G}^{{\prime} }\) and \({K}^{{\prime} }\).

Extended Data Fig. 5 Schematic representation of the observation-time (Δt) or frequency (ω)-dependent shear modulus.

The levels of affine (GA) and plateau shear moduli (Gp) are indicated on the left axis.

Extended Data Fig. 6 Age-dependent elasticity in LJ glasses and WF gels.

The age-dependent thermal elasticity G (a,d), K (b,e), modulus ratio G/K and Poisson ratio ν (c,f) (red circles) and corresponding inherent elasticity at zero temperature (blue squares) in LJ glasses (a–c) and WF gels (d–f). The observation time Δt used to measure these moduli are marked by the vertical dashed lines in Extended Data Fig. 3. The same plot as the Fig. 2 in the main text.

Extended Data Fig. 7 Scaled moduli versus mean-squared displacement (MSD) in glasses and gels.

a, Shear modulus G scaled by the affine modulus GA (infinite-frequency modulus) versus the inverse of MSD \({\langle \Delta {r}^{2}\rangle }^{-1}\) in glasses. b, Shear modulus G scaled by GA versus the inverse of isostatic MSD \({\langle \Delta {r}^{2}\rangle }_{{{{\rm{iso}}}}}^{-1}\) in gels. c, Scaled shear modulus G/GIS versus MSD \({\langle \Delta {r}^{2}\rangle }_{{{{\rm{rel}}}}}^{-1}\) in glasses. d, Scaled shear modulus G/GIS and bulk modulus K/KIS versus MSD of isostatic particles \({\langle \Delta {r}^{2}\rangle }_{{{{\rm{iso}}}},{{{\rm{rel}}}}}^{-1}\) in gels. e, Scaled shear modulus G/GIS and bulk modulus K/KIS versus original MSD of all particles \({\langle \Delta {r}^{2}\rangle }^{-1}\) in gels.

Extended Data Fig. 8 Role of inherent elasticity and MSD on thermal elasticity in the LJ glasses and WF gels.

a, Inverse MSD \(\langle \Delta r^2\rangle^{-1}\) of LJ glasses at different observation times Δt plotted against scaled waiting time tw/τB. b, Ratios between thermal elasticity and inherent elasticity M/MIS of LJ glasses versus tw/τB for different Δt. c, Scaled shear modulus G/GIS of LJ glasses versus \(\langle \Delta r^2\rangle^{-1}\) for different Δt. d, Inverse MSD of isostatic particles \((Z\geq6)\) \({\langle \Delta r^2\rangle}^{-1}_{\rm{iso}}\) of WF gels versus tw/τB for different Δt. e,f, G/GIS and K/KIS of WF gels versus tw/τB (e) and \({\langle \Delta r^2\rangle}^{-1}_{\rm{iso}}\) (f) for different Δt. The same plot as the Fig. 3 in the main text.

Extended Data Fig. 9 Age-dependent structure of glasses in inherent states.

a, Orientational order parameter Ω and cage anisotropy parameter η. b, Pressure p. Note that the scales of all vertical axes are the same as those shown for the corresponding structural parameters in Fig. 4 in the main text.

Extended Data Fig. 10 Age-dependent potential energy and structure in the LJ glasses and WF gels.

a, Age-dependent potential energy per particle (red open circles), E, and per contact (blue open squares), 2E/Z, in LJ glasses. b, Age-dependent orientational order parameter and Ω anisotropy parameter η of Voronoi cells in LJ glasses, where Ω = 0 indicates perfect order and η = 1 indicates isotropic cells. c, Age-dependent pressure p in LJ glasses. d, The same as in a, for WF gels. e, Age-dependent contact number Z in WF gels. f, Age-dependent loop number Nloop in WF gels. The same plot as the Fig. 4 in the main text.

Supplementary information

Supplementary Information

Supplementary Figs. 1–4.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Tateno, M. & Tanaka, H. Distinct elastic properties and their origins in glasses and gels. Nat. Phys. (2024). https://doi.org/10.1038/s41567-024-02456-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41567-024-02456-6