Abstract

The atomic-scale structural rearrangement of glasses on applied stress is central to the understanding of their macroscopic mechanical properties and behaviour. However, experimentally resolving the atomic-scale structural changes of a deformed glass remains challenging due to the disordered nature of the glass structure. Conventional structural analyses such as X-ray diffraction are based on the assumption of structural isotropy and hence cannot discern the subtle atomic-scale structural rearrangement induced by deformation. Here we show that structural anisotropy correlates with non-affine atomic displacements—meaning those that do not preserve parallel lines in the atomic structure—in various types of glass. This serves as an approach for identifying the atomic-scale non-affine deformation in glasses. We also uncover the atomic-level mechanism responsible for plastic flow, which differs between metallic glasses and covalent glasses. The non-affine structural rearrangements in metallic glasses are mediated through the stretching or contraction of atomic bonds. The non-affinity of covalent glasses that occurs in a less localized manner is mediated through the rotation of atomic bonds or chains without changing the bond length. These findings provide key ingredients for exploring the atomic-scale process governing the macroscopic deformation of amorphous solids.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available via Figshare at https://doi.org/10.6084/m9.figshare.23515368. Source data are provided with this paper.

Code availability

Code data are available from the corresponding authors upon reasonable request.

References

Bourhis, E. L. Glass: Mechanics and Technology (John Wiley & Sons, 2014).

Ernsberger, F. M. Mechanical properties of glass. J. Non-Cryst. Solids 25, 293–321 (1977).

Morgan, R. J. & O’Neal, J. E. The mechanical properties of polymer glasses. Polym. Plast. Technol. 5, 173–197 (1975).

Schuh, C. A., Hufnagel, T. C. & Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067–4109 (2007).

Greer, A. L., Cheng, Y. Q. & Ma, E. Shear bands in metallic glasses. Mat. Sci. Eng. R 74, 71–132 (2013).

Yavari, A. R., Lewandowski, J. J. & Eckert, J. Mechanical properties of bulk metallic glasses. MRS Bull. 32, 635–638 (2011).

Wondraczek, L. Overcoming glass brittleness. Science 366, 804–805 (2019).

Hofmann, D. C. et al. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 451, 1085–1089 (2008).

Sarac, B. & Schroers, J. Designing tensile ductility in metallic glasses. Nat. Commun. 4, 2158 (2013).

Hirata, A. et al. Direct observation of local atomic order in a metallic glass. Nat. Mater. 10, 28–33 (2011).

Chen, D. Z. et al. Fractal atomic-level percolation in metallic glasses. Science 349, 1306–1310 (2015).

Yang, Y. et al. Determining the three-dimensional atomic structure of an amorphous solid. Nature 592, 60–64 (2021).

Falk, M. L. The flow of glass. Science 318, 1880–1881 (2007).

Cubuk, E. D. et al. Structure-property relationships from universal signatures of plasticity in disordered solids. Science 358, 1033–1037 (2017).

Wang, Z., Sun, B. A., Bai, H. Y. & Wang, W. H. Evolution of hidden localized flow during glass-to-liquid transition in metallic glass. Nat. Commun. 5, 5823 (2014).

Huang, P. Y. et al. Imaging atomic rearrangements in two-dimensional silica glass: watching silica’s dance. Science 342, 224–227 (2017).

Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 25, 407–415 (1976).

Argon, A. S. Plastic deformation in metallic glasses. Acta Metall. 27, 47–58 (1979).

Falk, M. L. & Langer, J. S. Dynamics of viscoplastic deformation in amorphous solids. Phys. Rev. E 57, 7192–7205 (1998).

Johnson, W. L. & Samwer, K. A universal criterion for plastic yielding of metallic glasses with a (T/Tg)2/3 temperature dependence. Phys. Rev. Lett. 95, 195501 (2005).

Liu, A. C. Y. et al. Local symmetry predictors of mechanical stability in glasses. Sci. Adv. 8, eabn0681 (2022).

Schall, P., Weitz, D. A. & Spaepen, F. Structural rearrangements that govern flow in colloidal glasses. Science 318, 1895–1899 (2007).

Laurati, M., Masshoff, P., Mutch, K. J., Egelhaaf, S. U. & Zaccone, A. Long-lived neighbors determine the rheological response of glasses. Phys. Rev. Lett. 118, 018002 (2017).

Kong, D. J., Chen, W. R., Zeng, K. Q., Porcar, L. & Wang, Z. Localized elasticity governs the nonlinear rheology of colloidal supercooled liquids. Phys. Rev. X 12, 041006 (2022).

Demkowicz, M. J. & Argon, A. S. High-density liquidlike component facilitates plastic flow in a model amorphous silicon system. Phys. Rev. Lett. 93, 025505 (2004).

Wang, Y. et al. Tension–compression asymmetry in amorphous silicon. Nat. Mater. 20, 1371–1377 (2021).

Zaccone, A. & Scossa-Romano, E. Approximate analytical description of the nonaffine response of amorphous solids. Phys. Rev. B 83, 184205 (2011).

Ganguly, S., Sengupta, S. & Sollich, P. Statistics of non-affine defect precursors: tailoring defect densities in colloidal crystals using external fields. Soft Matter 11, 4517–4526 (2015).

Ganguly, S., Sengupta, S., Sollich, P. & Rao, M. Nonaffine displacements in crystalline solids in the harmonic limit. Phys. Rev. E 87, 042801 (2013).

DiDonna, B. A. & Lubensky, T. C. Nonaffine correlations in random elastic media. Phys. Rev. E 72, 066619 (2005).

Popli, P., Kayal, S., Sollich, P. & Sengupta, S. Exploring the link between crystal defects and nonaffine displacement fluctuations. Phys. Rev. E 100, 033002 (2019).

Nath, P. et al. On the existence of thermodynamically stable rigid solids. Proc. Natl Acad. Sci. USA 115, 4322–4329 (2018).

Zaccone, A. & Terentjev, E. M. Disorder-assisted melting and the glass transition in amorphous solids. Phys. Rev. Lett. 110, 178002 (2013).

Lemaître, A. & Maloney, C. Sum rules for the quasi-static and visco-elastic response of disordered solids at zero temperature. J. Stat. Phys. 123, 415–453 (2006).

Palyulin, V. V. et al. Parameter-free predictions of the viscoelastic response of glassy polymers from non-affine lattice dynamics. Soft Matter 14, 8475–8482 (2018).

Milkus, R. & Zaccone, A. Local inversion-symmetry breaking controls the boson peak in glasses and crystals. Phys. Rev. B 93, 094204 (2016).

Hess, S. Shear-flow-induced distortion of the pair-correlation function. Phys. Rev. A 22, 2844–2848 (1980).

Huang, G. R., Wu, B., Wang, Y. Y. & Chen, W. R. Characterization of microscopic deformation through two-point spatial correlation functions. Phys. Rev. E 97, 012605 (2018).

Evans, D. J., Hanley, H. J. M. & Hess, S. Non-Newtonian phenomena in simple fluids. Phys. Today 37, 26–35 (1984).

Wang, Z. et al. Fingerprinting molecular relaxation in deformed polymers. Phys. Rev. X 7, 031003 (2017).

Dmowski, W., Iwashita, T., Chuang, C. P., Almer, J. & Egami, T. Elastic heterogeneity in metallic glasses. Phys. Rev. Lett. 105, 205502 (2010).

Suzuki, Y., Haimovich, J. & Egami, T. Bond-orientational anisotropy in metallic glasses observed by X-ray diffraction. Phys. Rev. B 35, 2162–2168 (1987).

Wang, H. et al. Nonaffine strains control ductility of metallic glasses. Phys. Rev. Lett. 128, 155501 (2022).

Egami, T., Iwashita, T. & Dmowski, W. Mechanical properties of metallic glasses. Metals 3, 77–113 (2013).

Dmowski, W. & Egami, T. Observation of structural anisotropy in metallic glasses induced by mechanical deformation. J. Mater. Res. 22, 412–418 (2011).

Ott, R. T. et al. Anelastic strain and structural anisotropy in homogeneously deformed Cu64.5Zr35.5 metallic glass. Acta Mater. 56, 5575–5583 (2008).

Choi, I. C. et al. Indentation size effect and shear transformation zone size in a bulk metallic glass in two different structural states. Acta Mater. 60, 6862–6868 (2012).

Fan, Y., Iwashita, T. & Egami, T. How thermally activated deformation starts in metallic glass. Nat. Commun. 5, 5083 (2014).

Maloney, C. E. & Lemaître, A. Amorphous systems in athermal, quasistatic shear. Phys. Rev. E 74, 016118 (2006).

Miracle, D. B. A structural model for metallic glasses. Nat. Mater. 3, 697–702 (2004).

Sheng, H. W., Luo, W. K., Alamgir, F. M., Bai, J. M. & Ma, E. Atomic packing and short-to-medium-range order in metallic glasses. Nature 439, 419–425 (2006).

Lan, S. et al. A medium-range structure motif linking amorphous and crystalline states. Nat. Mater. 20, 1347–1352 (2021).

Ye, J. C., Lu, J., Liu, C. T., Wang, Q. & Yang, Y. Atomistic free-volume zones and inelastic deformation of metallic glasses. Nat. Mater. 9, 619–623 (2010).

Wang, W. H., Yang, Y., Nieh, T. G. & Liu, C. T. On the source of plastic flow in metallic glasses: concepts and models. Intermetallics 67, 81–86 (2015).

Pan, D., Inoue, A., Sakurai, T. & Chen, M. W. Experimental characterization of shear transformation zones for plastic flow of bulk metallic glasses. Proc. Natl Acad. Sci. USA 105, 14769–14772 (2008).

Sun, Y. H. et al. Flow-induced elastic anisotropy of metallic glasses. Acta Mater. 112, 132–140 (2016).

Mendelev, M. I. et al. Development of suitable interatomic potentials for simulation of liquid and amorphous Cu-Zr alloys. Philos. Mag. 89, 967–987 (2009).

Rossi, G., Monticelli, L., Puisto, S. R., Vattulainen, I. & Ala-Nissila, T. Coarse-graining polymers with the MARTINI force-field: polystyrene as a benchmark case. Soft Matter 7, 698–708 (2011).

Acknowledgements

This research was supported by the National Key Research and Development Plan with grant no. 2018YFA0703603 (B.S.); the Guangdong Major Project of Basic and Applied Basic Research of China with grant nos. 2019B030302010 (W.W.) and 2020B1515120092 (B.S.); the National Natural Science Foundation of China (NSFC) with grant nos. 52192601 (H.B.), 52192602 (B.S.), 61888102 (W.W.) and 52001272 (Y.T.); and the Strategic Priority Research Program of Chinese Academy of Sciences with grant no. XDB30000000 (W.W.). W.D. and T.E. were supported by the US Department of Energy, Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division. H.P. acknowledges the computer resources provided by High Performance Computing Cluster (HPC) of Central South University.

Author information

Authors and Affiliations

Contributions

H.B. and B.S. conceived and supervised the project. J.D. prepared the materials and performed the mechanical and thermal experiments. H.P. performed the MD simulations. H.W., Y.T. and W.D. performed the high-energy XRD experiments. J.D., Y.T., H.P., Y.W. and B.S. performed the data analysis and wrote the manuscript with input from all the other co-authors. T.E., W.W. and H.B. discussed the results and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Physics thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–9 and Texts I and II.

Supplementary Data 1

Statistical source data for Supplementary Fig. 2.

Supplementary Data 2

Statistical source data for Supplementary Fig. 3.

Source data

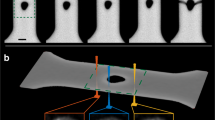

Source Data Fig. 1

Unprocessed diffraction patterns.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, J., Peng, H., Wang, H. et al. Non-affine atomic rearrangement of glasses through stress-induced structural anisotropy. Nat. Phys. 19, 1896–1903 (2023). https://doi.org/10.1038/s41567-023-02243-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41567-023-02243-9

This article is cited by

-

Rearranged under stress

Nature Physics (2023)