Abstract

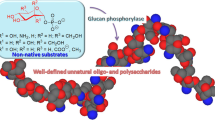

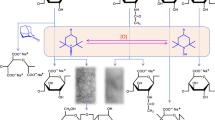

The composition, sequence, length and type of glycosidic linkage of polysaccharides profoundly affect their biological and physical properties. However, investigation of the structure–function relationship of polysaccharides is hampered by difficulties in accessing well-defined polysaccharides in sufficient quantities. Here we report a chemical approach to precision polysaccharides with native glycosidic linkages via living cationic ring-opening polymerization of 1,6-anhydrosugars. We synthesized well-defined polysaccharides with tunable molecular weight, low dispersity and excellent regio- and stereo-selectivity using a boron trifluoride etherate catalyst and glycosyl fluoride initiators. Computational studies revealed that the reaction propagated through the monomer α-addition to the oxocarbenium and was controlled by the reversible deactivation of the propagating oxocarbenium to form the glycosyl fluoride dormant species. Our method afforded a facile and scalable pathway to multiple biologically relevant precision polysaccharides, including d-glucan, d-mannan and an unusual l-glucan. We demonstrated that catalytic depolymerization of precision polysaccharides efficiently regenerated monomers, suggesting their potential utility as a class of chemically recyclable materials with tailored thermal and mechanical properties.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are available in the manuscript or the Supplementary Information. Experimental data and characterization data for all new compounds prepared during these studies are provided in the Supplementary Information of this paper. Source data are provided with this paper.

References

Varki, A. et al. Essentials of Glycobiology 2nd edn (Cold Spring Harbor Laboratory Press, 2009).

Ragauskas, A. J. et al. The path forward for biofuels and biomaterials. Science 311, 484–489 (2006).

Zhu, Y., Romain, C. & Williams, C. K. Sustainable polymers from renewable resources. Nature 540, 354–362 (2016).

Dumitriu, S. Polysaccharides: Structural Diversity and Functional Versatility 2nd edn (Marcel Dekker, 2005).

Fittolani, G., Tyrikos-Ergas, T., Vargová, D., Chaube, M. A. & Delbianco, M. Progress and challenges in the synthesis of sequence controlled polysaccharides. Beilstein J. Org. Chem. 17, 1981–2025 (2021).

Kadokawa, J. Precision polysaccharide synthesis catalyzed by enzymes. Chem. Rev. 111, 4308–4345 (2011).

Zhu, Q. et al. Chemical synthesis of glycans up to a 128-mer relevant to the O-antigen of Bacteroides vulgatus. Nat. Commun. 11, 4142–4148 (2020).

Guberman, M. & Seeberger, P. H. Automated glycan assembly: a perspective. J. Am. Chem. Soc. 141, 5581–5592 (2019).

Panza, M., Pistorio, S. G., Stine, K. J. & Demchenko, A. V. Automated chemical oligosaccharide synthesis: novel approach to traditional challenges. Chem. Rev. 118, 8105–8150 (2018).

Xiao, R. X. & Grinstaff, M. W. Chemical synthesis of polysaccharides and polysaccharide mimetics. Prog. Polym. Sci. 74, 78–116 (2017).

Saxon, D. J. et al. Architectural control of isosorbide-based polyethers via ring-opening polymerization. J. Am. Chem. Soc. 141, 5107–5111 (2019).

McGuire, T. M. et al. Control of crystallinity and stereocomplexation of synthetic carbohydrate polymers from d- and l-xylose. Angew. Chem. Int. Ed. 60, 4524–4528 (2021).

Stubbs, C. J. et al. Sugar-based polymers with stereochemistry-dependent degradability and mechanical properties. J. Am. Chem. Soc. 144, 1243–1250 (2022).

Debsharma, T., Yagci, Y. & Schlaad, H. Cellulose-derived functional polyacetal by cationic ring-opening polymerization of levoglucosenyl methyl ether. Angew. Chem. Int. Ed. 58, 18492–18495 (2019).

Mikami, K. et al. Polycarbonates derived from glucose via an organocatalytic approach. J. Am. Chem. Soc. 135, 6826–6829 (2013).

Dane, E. L. & Grinstaff, M. W. Poly-amido-saccharides: synthesis via anionic polymerization of a β-lactam sugar monomer. J. Am. Chem. Soc. 134, 16255–16264 (2012).

Ruckel, E. R. & Schuerch, C. Preparation of high polymers from 1,6-anhydro-2,3,4-tri-O-substituted β-d-glucopyranose. J. Org. Chem. 31, 2233–2239 (1966).

Aoshima, S. & Kanaoka, S. A renaissance in living cationic polymerization. Chem. Rev. 109, 5245–5287 (2009).

Porwal, M. K. et al. Stereoregular functionalized polysaccharides via cationic ring-opening polymerization of biomass derived levoglucosan. Chem. Sci. 13, 4512–4522 (2022).

Abel, B. A., Snyder, R. L. & Coates, G. W. Chemically recyclable thermoplastics from reversible-deactivation polymerization of cyclic acetals. Science 373, 783–789 (2021).

Uchiyama, M., Satoh, K. & Kamigaito, M. Cationic RAFT polymerization using ppm concentrations of organic acid. Angew. Chem. Int. Ed. 54, 1924–1928 (2015).

Kottisch, V., Michaudel, Q. & Fors, B. P. Cationic polymerization of vinyl ethers controlled by visible light. J. Am. Chem. Soc. 138, 15535–15538 (2016).

Nielsen, M. M. & Pedersen, C. M. Catalytic glycosylations in oligosaccharide synthesis. Chem. Rev. 118, 8285–8358 (2018).

Yoshida, D. & Yoshida, T. Elucidation of high ring-opening polymerizability of methylated 1,6-anhydro glucose. J. Polym. Sci. A. Polym. Chem 47, 1013–1022 (2009).

Zhu, Q. Q. et al. Structural identification of (1→6)-α-d-glucan, a key responsible for the health benefits of longan, and evaluation of anticancer activity. Biomacromolecules 14, 1999–2003 (2013).

Williams, S. J. & Withers, S. G. Glycosyl fluorides in enzymatic reactions. Carbohydr. Res. 327, 27–46 (2000).

Stone, B. A., Svensson, B., Collins, M. E. & Rastall, R. A. in Glycoscience 2nd edn (eds Fraser-Reid, B. O., Tatsuta, K. & Thiem, J.) 2325–2375 (Springer, 2008).

Apostolou, I. et al. Murine natural killer cells contribute to the granulomatous reaction caused by mycobacterial cell walls. Proc. Natl. Acad. Sci. USA. 96, 5141–5146 (1999).

Calin, O., Eller, S. & Seeberger, P. H. Automated polysaccharide synthesis: assembly of a 30mer mannoside. Angew. Chem. Int. Ed. 52, 5862–5865 (2013).

Getzler, Y. D. Y. L. & Coates, G. W. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 5, 501–516 (2020).

Shi, C. et al. Design principles for intrinsically circular polymers with tunable properties. Chem 7, 2896–2912 (2021).

Mohadjer Beromi, M. et al. Iron-catalysed synthesis and chemical recycling of telechelic 1,3-enchained oligocyclobutanes. Nat. Chem. 13, 156–162 (2021).

Sathe, D. et al. Olefin metathesis-based chemically recyclable polymers enabled by fused-ring monomers. Nat. Chem. 13, 743–750 (2021).

Hong, M. & Chen, E. Y.-X. Completely recyclable biopolymers with linear and cyclic topologies via ring-opening polymerization of γ-butyrolactone. Nat. Chem. 8, 42–49 (2016).

Zhu, J. B., Watson, E. M., Tang, J. & Chen, E. Y.-X. A synthetic polymer system with repeatable chemical recyclability. Science 360, 398–403 (2018).

Häußler, M., Eck, M., Rothauer, D. & Mecking, S. Closed-loop recycling of polyethylene-like materials. Nature 590, 423–427 (2021).

Yuan, J. S. et al. 4-Hydroxyproline-derived sustainable polythioesters: controlled ring-opening polymerization, complete recyclability, and facile functionalization. J. Am. Chem. Soc. 141, 4928–4935 (2019).

Christensen, P. R., Scheuermann, A. M., Loeffler, K. E. & Helms, B. A. Closed-loop recycling of plastics enabled by dynamic covalent diketoenamine bonds. Nat. Chem. 11, 442–448 (2019).

Song, Y. et al. Advancing the development of highly-functionalizable glucose-based polycarbonates by tuning of the glass transition temperature. J. Am. Chem. Soc. 140, 16053–16057 (2018).

Sangroniz, A. et al. Packaging materials with desired mechanical and barrier properties and full chemical recyclability. Nat. Commun. 10, 3559–3565 (2019).

Acknowledgements

This work was supported by the Arnold and Mabel Beckman Foundation through a Beckman Young Investigator Award to J.N. NMR characterizations were supported by the National Science Foundation Major Research Instrumentation (NSF-MRI) Program, under award number CHE-2117246. We thank W. Z. Fan for assistance with the computational studies and J. B. Matson, S. Blosch, M. J. Zhong, M. X. Cao, C. F. Ke, Q. M. Lin, T. S. Emerick, T. Goodwin, M. W. Grinstaff, S. EI-Arid, M. Zhou, C. J. Yang, C. Liu, T. Jayasundera, M. Domin, S.-Y. Liu, J. A. Byers and J. Morken for characterization assistance and helpful discussions.

Author information

Authors and Affiliations

Contributions

L.W. and J.N. conceived and designed the project. J.N. oversaw the project. L.W., S.D. and Z. Zhao performed the experiments. Z. Zhou performed the computational studies. D.S., J.Z. and J.W. performed tensile testing. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

A PCT patent application (PCT/US2022/078036) based on this work has been filed by Boston College. J.N. and L.W. are listed as inventors in this application. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Chemistry thanks Brooks Abel, Cassandra Callmann and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–150, Tables 1–9 and synthetic Procedures.

Supplementary Data 1

The XYZ coordinates for the DFT calculations.

Source data

Source Data Fig. 2

MALDI-MS, SEC and kinetic data.

Source Data Fig. 4

SEC data for enzymatic degradation.

Source Data Fig. 5

SEC, TGA, DSC, PXRD and tensile test data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, L., Zhou, Z., Sathe, D. et al. Precision native polysaccharides from living polymerization of anhydrosugars. Nat. Chem. 15, 1276–1284 (2023). https://doi.org/10.1038/s41557-023-01193-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41557-023-01193-2

This article is cited by

-

Towards glycan foldamers and programmable assemblies

Nature Reviews Materials (2024)