Abstract

The development of sustainable polymers that possess useful material properties competitive with existing petroleum-derived polymers is a crucial goal but remains a formidable challenge for polymer science. Here we demonstrate that irreversible ring-opening polymerization (IROP) of biomass-derived five-membered thionolactones is an effective and robust strategy for the polymerization of non-strained five-membered rings—these polymerizations are commonly thermodynamically forbidden under ambient conditions, at industrially relevant temperatures of 80–100 °C. Computational studies reveal that the selective IROP of these thionolactones is thermodynamically driven by S/O isomerization during the ring-opening process. IROP of γ-thionobutyrolactone, a representative non-strained thionolactone, affords a sustainable polymer from renewable resources that possesses external-stimuli-triggered degradability. This poly(thiolactone) also exhibits high performance, with its key thermal and mechanical properties comparing well to those of commercial petroleum-based low-density polyethylene. This IROP strategy will enable conversion of five-membered lactones, generally unachievable by other polymerization methods, into sustainable polymers with a range of potential applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data that support the findings of this study are available within the article and its Supplementary Information, and/or from the corresponding author on reasonable request.

References

Schneiderman, D. K. & Hillmyer, M. A. 50th anniversary perspective: there is a great future in sustainable polymers. Macromolecules 50, 3733–3749 (2017).

Zhang, X., Fevre, M., Jones, G. O. & Waymouth, R. M. Catalysis as an enabling science for sustainable polymers. Chem. Rev. 118, 839–885 (2018).

Hong, M. & Chen, E. Y.-X. Future directions for sustainable polymers. Trends Chem. 1, 148–151 (2019).

Hillmyer, M. A. The promise of plastics from plants. Science 358, 868–870 (2017).

Zhu, Y., Romain, C. & Williams, C. K. Sustainable polymers from renewable resources. Nature 540, 354–362 (2016).

Bomgardner, M. M. Biobased polymers. Chem. Eng. News Arch. 92, 10–14 (2014).

Albertsson, A.-C. & Hakkarainen, M. Designed to degrade. Science 358, 872–873 (2017).

Jehanno, C., Pérez-Madrigal, M., Demarteau, J., Sardon, H. & Dove, A. P. Organocatalysis for depolymerization. Polym. Chem. 10, 172–186 (2019).

Hong, M. & Chen, E. Y.-X. Chemically recyclable polymers: a circular economy approach to sustainability. Green Chem. 19, 3692–3706 (2017).

Rahimi, A. & García, J. M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 1, 0046 (2017).

Wang, X.-J. & Hong, M. Lewis pair-mediated selective dimerization and polymerization of lignocellulose-based β-angelica lactone to biofuel and acrylic bioplastic. Angew. Chem. Int. Ed. 59, 2664–2668 (2020).

Xiong, M., Schneiderman, D. K., Bates, F. S., Hillmyer, M. A. & Zhang, K. Scalable production of mechanically tunable block polymers from sugar. Proc. Natl Acad. Sci. USA 111, 8357–8362 (2014).

Jones, G. O., Yuen, A., Wojtecki, R. J., Hedrick, J. L. & García, J. M. Computational and experimental investigations of one-step conversion of poly(carbonate)s into value-added poly(aryl ether sulfone)s. Proc. Natl Acad. Sci. USA 113, 7722–7726 (2016).

García, J. M. et al. Recyclable, strong thermosets and organogels via paraformaldehyde condensation with diamines. Science 344, 732–735 (2014).

Häußler, M., Eck, M., Rothauer, D. & Mecking, S. Closed-loop recycling of polyethylene-like materials. Nature 590, 423–427 (2021).

Shieh, P. et al. Cleavable comonomers enable degradable, recyclable thermoset plastics. Nature 583, 542–547 (2020).

Zhang, F. et al. Polyethylene upcycling to long-chain alkylaromatics by tandem hydrogenolysis/aromatization. Science 370, 437–441 (2020).

Bozell, J. J. & Petersen, G. R. Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “top 10” revisited. Green Chem. 12, 539–554 (2010).

Geilen, F. M. A. et al. Selective and flexible transformation of biomass-derived platform chemicals by a multifunctional catalytic system. Angew. Chem. Int. Ed. 49, 5510–5514 (2010).

Alonso, D. M., Wettstein, S. G. & Dumesic, J. A. Gamma-valerolactone, a sustainable platform molecule derived from lignocellulosic biomass. Green Chem. 15, 584–595 (2013).

Hong, M. & Chen, E. Y.-X. Completely recyclable biopolymers with linear and cyclic topologies via ring-opening polymerization of γ-butyrolactone. Nat. Chem. 8, 42–49 (2016).

Tang, X. et al. The quest for converting biorenewable bifunctional α-methylene-γ-butyrolactone into degradable and recyclable polyester: controlling vinyl-addition/ring-opening/cross-linking pathways. J. Am. Chem. Soc. 138, 14326–14337 (2016).

Duda, A. & Kowalski, A. in Handbook of Ring-Opening Polymerization (eds Dubois, P., Coulembier, O. & Raquez, J.-M.) Ch. 3 (Wiley-VCH, 2009).

Houk, K. H., Jabbari, A., Hall, H. K. Jr. & Alemán, C. Why γ-valerolactone polymerizes and γ-butyrolactone does not. J. Org. Chem. 73, 2674–2678 (2008).

Olsén, P., Odelius, K. & Albertsson, A.-C. Thermodynamic presynthetic considerations for ring-opening polymerization. Biomacromolecules 17, 699–709 (2016).

Hong, M. & Chen, E. Y.-X. Towards truly sustainable polymers: a metal-free recyclable polyester from biorenewable nonstrained γ-butyrolactone. Angew. Chem. Int. Ed. 55, 4188–4193 (2016).

Zhao, N. et al. Selective ring-opening polymerization of non-strained γ-butyrolactone catalyzed by a cyclic trimeric phosphazene base. Angew. Chem. Int. Ed. 56, 12987–12990 (2017).

Lin, L. et al. Nonstrained γ-butyrolactone to high-molecular-weight poly(γ-butyrolactone): facile bulk polymerization using economical ureas/alkoxides. Macromolecules 51, 9317–9322 (2018).

Zhang, C.-J., Hu, L.-F., Wu, H.-L., Cao, X.-H. & Zhang, X.-H. Dual organocatalysts for highly active and selective synthesis of linear poly(γ-butyrolactone)s with high molecular weights. Macromolecules 51, 8705–8711 (2018).

Shen, Y. et al. A facile method to prepare high molecular weight bio-renewable poly(γ-butyrolactone) using a strong base/urea binary synergistic catalytic system. Polym. Chem. 10, 1231–1237 (2019).

Walther, P., Frey, W. & Naumann, S. Polarized olefins as enabling (co)catalysts for the polymerization of γ-butyrolactone. Polym. Chem. 9, 3674–3683 (2018).

Zhu, J.-B., Watson, E. M., Tang, J. & Chen, E. Y.-X. A synthetic polymer system with repeatable chemical recyclability. Science 360, 398–403 (2018).

Zhu, J.-B. & Chen, E. Y.-X. Living coordination polymerization of a six-five bicyclic lactone to produce completely recyclable polyester. Angew. Chem. Int. Ed. 57, 12558–12562 (2018).

Zhu, J.-B. & Chen, E. Y.-X. Catalyst’s sidearm-induced stereoselectivity switching in polymerization of a racemic lactone for stereocomplexed crystalline polymer with a circular life cycle. Angew. Chem. Int. Ed. 58, 1178–1182 (2019).

Cywar, R. M., Zhu, J.-B. & Chen, E. Y.-X. Selective or living organopolymerization of a six-five bicyclic lactone to produce fully recyclable polyesters. Polym. Chem. 10, 3097–3106 (2019).

Chung, W. J. et al. The use of elemental sulfur as an alternative feedstock for polymeric materials. Nat. Chem. 5, 518–524 (2013).

Yanagisawa, Y., Nan, Y., Okuro, K. & Aida, T. Mechanically robust, readily repairable polymers via tailored noncovalent crosslinking. Science 359, 72–76 (2018).

Boyd, D. A. Sulfur and its role in modern materials science. Angew. Chem. Int. Ed. 55, 15486–15502 (2016).

Shi, C. et al. High-performance pan-tactic polythioesters with intrinsic crystallinity and chemical recyclability. Sci. Adv. 6, eabc0495 (2020).

Yuan, J. et al. 4‑Hydroxyproline-derived sustainable polythioesters: controlled ring-opening polymerization, complete recyclability, and facile functionalization. J. Am. Chem. Soc. 141, 4928–4935 (2019).

Xiong, W. et al. Geminal dimethyl substitution enables controlled polymerization of penicillamine-derived β-thiolactones and reversed depolymerization. Chem 6, 1831–1843 (2020).

Luo, M., Zhang, X.-H. & Darensbourg, D. J. Poly(monothiocarbonate)s from the alternating and regioselective copolymerization of carbonyl sulfide with epoxides. Acc. Chem. Res. 49, 2209–2219 (2016).

Smith, R. A. et al. Radical approach to thioester-containing polymers. J. Am. Chem. Soc. 141, 1446–1451 (2019).

Yue, T.-J. et al. Precise synthesis of poly(thioester)s with diverse structures by copolymerization of cyclic thioanhydrides and episulfides mediated by organic ammonium salts. Angew. Chem. Int. Ed. 58, 618–623 (2019).

Kikuchi, H., Tsubokawa, N. & Endo, T. First example of cationic ring-opening polymerization of γ-thionobutyrolactone. Chem. Lett. 34, 376–377 (2005).

Sarazin, Y. & Carpentier, J.-F. Discrete cationic complexes for ring-opening polymerization catalysis of cyclic esters and epoxides. Chem. Rev. 115, 3564–3614 (2015).

Carpentier, J.-F. Rare-earth complexes supported by tripodal tetradentate bis(phenolate) ligands: a privileged class of catalysts for ring-opening polymerization of cyclic esters. Organometallics 34, 4175–4189 (2015).

Kamber, N. E. et al. Organocatalytic ring-opening polymerization. Chem. Rev. 107, 5813–5840 (2007).

Kiesewetter, M. K., Shin, E. J., Hedrick, J. L. & Waymouth, R. M. Organocatalysis: opportunities and challenges for polymer synthesis. Macromolecules 43, 2093–2107 (2010).

Naumann, S. & Dove, A. P. N-Heterocyclic carbenes as organocatalysts for polymerizations: trends and frontiers. Polym. Chem. 6, 3185–3200 (2015).

Ottou, W. N., Sardon, H., Mecerreyes, D., Vignolle, J. & Taton, D. Update and challenges in organo-mediated polymerization reactions. Prog. Polym. Sci. 56, 64–115 (2016).

Zhang, X., Jones, G. O., Hedrick, J. L. & Waymouth, R. M. Fast and selective ring-opening polymerizations by alkoxides and thioureas. Nat. Chem. 8, 1047–1053 (2016).

Hong, M., Chen, J. & Chen, E. Y.-X. Polymerization of polar monomers mediated by main-group Lewis acid−base pairs. Chem. Rev. 118, 10551–10616 (2018).

Sanda, F., Jirakanjana, D., Hitomi, M. & Endo, T. Anionic ring-opening polymerization of ϵ‑thionocaprolactone. Macromolecules 32, 8010–8014 (1999).

Sanda, F., Jirakanjana, D., Hitomi, M. & Endo, T. Cationic ring-opening polymerization of ϵ‑thionocaprolactone: selective formation of polythioester. J. Polym. Sci. A Polym. Chem. 38, 3656–3664 (2000).

Datta, P. P. & Kiesewetter, M. K. Controlled organocatalytic ring-opening polymerization of ϵ‑thionocaprolactone. Macromolecules 49, 774–780 (2016).

Hong, M., Tang, X., Newell, B. S. & Chen, E. Y.-X. “Nonstrained” γ-butyrolactone-based copolyesters: copolymerization characteristics and composition-dependent (thermal, eutectic, cocrystallization, and degradation) properties. Macromolecules 50, 8469–8479 (2017).

Nishikubo, T., Kameyama, A. & Kawakami, S. A novel synthesis of poly(ester-alt-sulfide)s by the ring-opening alternating copolymerization of oxiranes with γ-thiobutyrolactone using quaternary onium salts or crown ether complexes as catalysts. Macromolecules 31, 4746–4752 (1998).

Langlais, M. et al. Scope and limitations of ring-opening copolymerization of trimethylene carbonate with substituted γ-thiolactones. Polym. Chem. 9, 2769–2774 (2018).

Puchelle, V. et al. Functional poly(ester-alt-sulfide)s synthesized by organo-catalyzed anionic ring-opening alternating copolymerization of oxiranes and γ‑thiobutyrolactones. Macromolecules 53, 5188–5198 (2020).

Espeel, P., Goethals, F. & Du Prez, F. E. One-pot multistep reactions based on thiolactones: extending the realm of thiol-ene chemistry in polymer synthesis. J. Am. Chem. Soc. 133, 1678–1681 (2011).

Espeel, P. et al. Multifunctionalized sequence-defined oligomers from a single building block. Angew. Chem. Int. Ed. 52, 13261–13264 (2013).

Espeel, P. & Du Prez, F. E. One-pot multi-step reactions based on thiolactone chemistry: a powerful synthetic tool in polymer science. Eur. Polym. J. 62, 247–272 (2015).

Langlais, M., Coutelier, O. & Destarac, M. Thiolactone-functional reversible deactivation radical polymerization agents for advanced macromolecular engineering. Macromolecules 51, 4315–4324 (2018).

Teator, A. J. & Leibfarth, F. A. Catalyst-controlled stereoselective cationic polymerization of vinyl ethers. Science 363, 1439–1443 (2019).

Acknowledgements

This work was supported by the NSFC (grant numbers 51973232, 21774141, 21821002), the Science and Technology Commission of Shanghai Municipality (grant number 19QA1411100) and the K.C. Wong Education Foundation for the study carried out at the Shanghai Institute of Organic Chemistry, and by the NSFC (grant numbers 21674014, U1862115) for the study performed at the Dalian University of Technology. We thank members of Y. Li’s group at Tianjin University for assistance with wide-angle X-ray diffraction, contact angle, dynamic mechanical analysis and tensile stress–strain measurements.

Author information

Authors and Affiliations

Contributions

P.Y., Y.S. and M.H. conceived the idea and designed the experiments. P.Y. and Y.S. performed the experiments. X.X. and Y.L. performed theoretical calculations. All of the authors participated in the data analyses and discussions, and manuscript writing. M.H. directed the project.

Corresponding author

Ethics declarations

Competing interests

M.H., P.Y. and Y.S. are named inventors on a Chinese patent application (number 201910972944.8) submitted by Shanghai Institute of Organic Chemistry, Chinese Academy of Sciences that covers the preparation of high-molar-mass poly(γ-thiobutyrolactone) via isomerization-driven irreversible ring-opening polymerization as well as the aspects of its physical properties and triggered degradation. The other authors (X.X. and Y.L.) declare no competing interests.

Additional information

Peer review information Nature Chemistry thanks Hua Lu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 13C NMR spectrum of PTBL produced by tBu-P4/Ph2CHOH.

13C NMR spectrum (CDCl3) of PTBL produced by tBu-P4/Ph2CHOH (Table 1, run 6). The observation of chemical resonances at 198.04 (>C = O) and 27.88 (–S–CH2–) ppm clearly demonstrated the occurrence of IROP to form PTBL.

Extended Data Fig. 2 1H NMR spectra of PTBL sample before and after TBD-triggered degradation.

1H NMR spectra (25°C, CDCl3) of PTBL sample (Mn of 162.6 kg/mol) before (a) and after (b) TBD-triggered degradation. The quantitative conversion of PTBL into TBL, a valuable small molecule that can be employed as a versatile building block for synthesizing sulfur-contained functional materials, thus established PTBL as an external stimuli-triggered degradable polymer with a sensible end of life option.

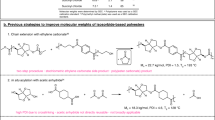

Extended Data Fig. 3 Outlined synthetic routes to methyl-substituted TnBL derivatives.

Outlined synthetic routes to methyl-substituted TnBL derivatives from renewable resources for the synthesis of sustainable poly(thiolactone)s via IROP.

Supplementary information

Supplementary Information

Full descriptions of the methods, computational details, Cartesian coordinates of optimized geometries, Supplementary Table 1, Schemes 1 and 2 and Figs. 1–55.

Rights and permissions

About this article

Cite this article

Yuan, P., Sun, Y., Xu, X. et al. Towards high-performance sustainable polymers via isomerization-driven irreversible ring-opening polymerization of five-membered thionolactones. Nat. Chem. 14, 294–303 (2022). https://doi.org/10.1038/s41557-021-00817-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41557-021-00817-9

This article is cited by

-

Circular olefin copolymers made de novo from ethylene and α-olefins

Nature Communications (2024)

-

Cyclic-acyclic monomers metathesis polymerization to access photodegradable polydicyclopentadiene and polyethylene-like materials

Science China Chemistry (2024)

-

Biorenewable and circular polydiketoenamine plastics

Nature Sustainability (2023)

-

Precise cooperative sulfur placement leads to semi-crystallinity and selective depolymerisability in CS2/oxetane copolymers

Nature Communications (2023)

-

A recyclable polyester library from reversible alternating copolymerization of aldehyde and cyclic anhydride

Nature Communications (2023)