Abstract

Immobilizing organocatalyst onto helical polymers not only facilitates the catalyst recycling from homogeneous reactions, but also boosts enantioselectivity. In this work, achiral organoiodine-functionalized single left- and right-handed helical polyisocyanides were prepared from the same monomers, which catalyzed three asymmetric oxidations gave the desired products in high yields and excellent enantioselectivity. The enantiomeric excess of the target products was up to 95%. Remarkably, the enantioselectivity can be switched by reversing the helicity of the polymer backbone. The polymer catalysts can be facilely recovered and recycled in different asymmetric oxidations with maintained excellent activity and enantioselectivity.

Similar content being viewed by others

Introduction

Chemical catalysts are important for industrial applications and laboratory use. Considering the disadvantages of contemporary catalysts, catalytic systems are currently being further developed and improved. For example, homogeneous catalysts generally exhibiting a higher catalytic activity than comparable heterogeneous systems are more difficult to isolate, thereby often remaining in the final product1,2,3. In contrast, heterogeneous catalysts facilitate the separation and recycling processes, often with low activity and selectivity4,5. In recent years, catalyst recycling has increasingly become more important with regard to resource conservation and environmental protection6,7. Therefore, seeking an elegant balance between homogeneous and heterogeneous catalyzes is particularly significant8,9.

From a practical asymmetric synthesis point of view, soluble polymer-supported chiral catalysts are of great interest because of their ease of separation from the reaction mixture and their ability to facilitate recycling10,11,12,13,14,15. Polymer-supported chiral catalysts are generally obtained by embedding a well-established chiral molecular catalyst onto readily available achiral polymers16,17,18,19. Activity and selectivity are decreased in many cases with respect to the chiral molecular catalyst. In contrast, fabricating chiral polymer-supported catalysts by decorating an achiral molecular catalyst onto a chiral polymer skeleton has rarely been realized20,21,22. In this case, the polymer skeleton provides a chiral environment for the asymmetric reaction, while the catalyst moiety only serves as a catalytic site23,24. Thus, a variety of polymer-supported chiral catalysts can be facilely developed.

Biological systems apply homochirality (e.g., l-amino acids and d-sugars) and result in biological macromolecules adopting well-ordered helical structures like the right-handed α-helix in proteins and the right-handed double-strand helix in deoxyribonucleic acid (DNA)25,26,27. The high efficiency and stereospecificity of enzyme catalysis rely on the homochirality of the biomacromolecules28,29. Inspired by exquisite biological helices, an increasing number of artificial helical polymers has been developed30,31,32,33,34,35,36. These polymers exhibit a large optical activity solely due to the excess of a one-handed helicity23,37,38,39,40,41,42. Therefore, incorporating catalytic moieties onto helical polymers may establish novel polymer-supported chiral catalysts. This strategy has many advantages. For example, it provides a model system for elucidating the origin of natural homochirality and a path for developing chiral catalysts43. Moreover, enantioselectivity can be tuned through regulation on the polymer helicity. However, the lack of control over helical polymer structures prevents their applications in asymmetric reactions. We recently developed a series of alkyne-Pd(II) catalysts that promote living polymerizations of various isocyanides and give helical polyisocyanides with a predicted chain length, low dispersity, and controlled helicity42,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58. The precisely synthesized helical polyisocyanides are a good chiral skeleton for catalyst supports. Chiral organoiodine-catalyzed asymmetric oxidation reactions have recently attracted great attention due to their mild reaction condition, low toxicity, and environmental friendliness49,50,51,52,53,54,55,56,57. However, owing to the low catalytic activity, the loading of molecular organoiodine catalysts is quite high and generally larger than 10 mol%. Furthermore, it is difficult to recycle small molecular catalysts from a homogeneous reaction solution. Thus, immobilizing organoiodine catalysts on helical polymers to boost enantioselectivity, facilitate catalyst separation, and recycling is greatly desirable. Immobilizing organoiodine onto rigid helical polyisocyanide has various superiorities. In addition to the facilitations on catalyst isolation and recycling, the unique rigid helical polyisocyanide facilitates the remote chirality transfer of helical backbone and renders the asymmetric reaction with high stereoselectivity. The high rigidity can effectively avoid the polymer chains entanglement and aggregation. Thus the asymmetric catalysis can be performed homogeneous and provides the polymer catalysts with high catalytic activity and efficiency. Owing to the high molar mass, the helical polyisocyanide-based catalysts can be readily recovered and recycled from the homogenous solution just by solvent precipitation.

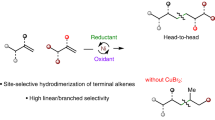

In this work, a family of chiral polymer-supported catalysts is developed by immobilized achiral organoiodine catalyst onto one-handed helical polyisocyanides. First, left- and right-handed helical polyisocyanides (i.e., M-poly-L-1150 and P-poly-L-150) in different molar masses are simultaneously prepared via the Pd(II)-catalyzed living polymerization of chiral isocyanide (L-1)45,58. The chain extension of these two polymers with organoiodine-functionalized achiral isocyanide (2) afford left-handed M-poly(L-1150-b-2m) and right-handed P-poly(L-150-b-2m). These polymers can catalyze multiple asymmetric oxidations and give the desired products in acceptable yields and high enantioselectivity. Enantioselectivity is completely controlled by the backbone helicity. Although M-poly(L-1150-b-2m) and P-poly(L-150-b-2m) are prepared from the same chiral materials, they produced enantiomeric products in similar yields but in opposite enantioselectivities. The enantiomeric excess (ee) of the generated product is up to 95% with 86% yield. The catalysts can be facilely separated from the homogeneous reaction mixture and recycled 10 times with maintained activity and selectivity. Remarkably, the polymer catalysts can successively catalyze three different asymmetric reactions with maintained high activity and enantioselectivity.

Results

Synthesis and characterization of achiral organoiodine-functionalized helical polyisocyanide catalysts

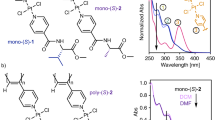

Figure 1 shows that L-1 was polymerized by the alkyne-Pd(II) catalyst in chloroform at 55 °C under a living manner ([L-1]0/[Pd]0 = 100). The polymerization simultaneously generated a left-handed M-poly-L-1150 with a high molar mass (Mn) and a right-handed P-poly-L-150 with a low Mn, which were readily separated by solvent fractionation44,45,46,47,48. Supplementary Information (SI) presents further details (Supplementary Fig. 1-5). Mn and its dispersity (Mw/Mn) of M-poly-L-1150 were 57.7 kDa and 1.10, respectively, as measured by size exclusion chromatography (SEC) (Fig. 2a). Mn and Mw/Mn of P-poly-L-150 were 20.3 kDa and 1.14, respectively. The single-handed helicity of the two polymers was verified by circular dichroism (CD) analyses. Both M-poly-L-1150 and P-poly-L-150 showed intense CD in the absorption region of the poly(phenyl isocyanide) backbone and was a mirror image of each other (Fig. 2b). The molecular CD intensity (Δε1st) at the first cotton band that reflected the backbone helicity was −21.02 M−1cm−1 for M-poly-L-1150 and +20.62 M−1cm−1 for P-poly-L-150, confirming the single left- and right-handed helicities of the backbone, respectively44,45,46,47,48.

The isolated M-poly-L-1150 and P-poly-L-150 carrying active Pd(II)-complex on the chain end are active for chain extension although the molar mass of the two polymers are quite different45. By virtue of the living chain end of the isolated polyisocyanides, a block copolymerization of iodine-functionalized monomer 2 with M-poly-L-1150 and P-poly-L-150 was performed. The SEC profiles of the generated block copolymers shifted to a high-Mn region with respect to the precursors and maintained a mono-distribution (Fig. 2a). For instance, Mn and Mw/Mn of the chain-extended M-poly(L-1150-b-210) were 63.1 kDa and 1.15, respectively. Similarly, the block copolymerization of 2 with P-poly-L-150 gave P-poly(L-150-b-210) with Mn = 25.3 kDa and Mw/Mn = 1.18 (Fig. 2a). For comparison, homopolymer poly-220 was prepared via the living polymerization of 2 by the alkyne-Pd(II) catalyst. The structures of these polymers were further confirmed by 1H NMR and Fourier transform infrared spectroscopy (FT-IR) spectra together with SEC analyses (Supplementary Figs. 6–15 and Supplementary Table 1). 1H NMR of the block copolymer showed characteristic signals at 3.60–3.05 ppm corresponding to the methylene protons of the poly-2m segment. FT-IR of the block copolymers exhibited the characteristic vibrations of the C=N, OC=O, and NHC=O bonds at 1600, 1626, and 1750 cm−1, respectively, which confirmed the formation of the expected block copolymers (Supplementary Figs. 6–15).

The molecular CD profiles of the block copolymers were almost similar to their macroinitiators, suggesting that the helicity of the newly formed poly-2m segments adopted the same helical structures to the precursors (Fig. 2b). The Δɛ1st was −22.18 M−1cm−1 for M-poly(L-1150-b-210) and +21.87 M−1cm−1 for P-poly(L-150-b-210). The analyses confirmed the single-handed helicity of the whole backbone of the block copolymers44,45,46,47,48. No other chiral moiety was involved in the poly-2m block; hence, the optical activity of the poly-2m segment in the block copolymers was solely from the one-handed helical backbone. Note that the helicity was quite stable. Both M-poly(L-1150-b-210) and P-poly(L-150-b-210) could maintain their CD and absorption profiles at a temperature ranging from −30 °C to 50 °C in tetrahydrofuran (THF) (Supplementary Fig. 16a). Moreover, the helical structures were stable in various organic solvents, regardless of the polarity (e.g., THF, toluene, dichloromethane, and chloroform) (Supplementary Fig. 16b).

Catalytic performance of catalysts in Kita-Spirocyclization

To investigate the catalytic activity of the synthetic polymers, an achiral poly-220 homopolymer was prepared and used to catalyze the Kita spirocyclization of 1-naphthol carboxylic acid 355. The reaction was conducted in dichloromethane (CH2Cl2) at 0 °C with 5 mol% catalyst loading in the presence of m-chloroperoxybenzoic acid (mCPBA, 0.03 mmol) as the oxidant. As a result, it provided the targeted product in 80% yield, but without enantioselectivity (run 1 in Table 1) because of the inexistence of chirality in the catalyst and substrate. Meanwhile, M-poly-L-1150 could not catalyze the reaction due to the inexistence of an organoiodine moiety (run 2 in Table 1). The catalytic performance of the helical polymer-supported catalyst M-poly(L-1150-b-25) on the spirocyclization of 3 was then conducted59,60. As anticipated, the target product 4 s was presented in 75% yield (run 3 in Table 1). The enantiomeric excess (ee) of 4s was 62%, as determined by chiral high-performance liquid chromatography (HPLC). With the increased content of the poly-2m segment, M-poly(L-1150-b-210) gave the same product in 79% yield and 62% ee, suggesting that the organoiodine content slightly affected the reaction (runs 3–4 in Table 1, and Supplementary Table 2). The M-poly(L-1150-b-215) and M-poly(L-1150-b-220) with longer poly-2m segment gave 4 s in 78% yields with ee decreased to 59% and 57%, respectively (runs 5–6 in Table 1). Because inexistence of chiral pendants, the longer poly-2m could not fully maintaine the one-handed helicity, and thus the enantioselectivity was decreased. Detailed study revealed that the helicity of M- and P-poly-1m blocks could be transfer to poly-2m with degree of the polymerization of 20. Further increase the length of poly-2m segment, it could not effectively maintain the one-handed helicity, as revealed by CD and UV-vis analyses (Supplementary Fig. 17). Thus, M-poly(L-1150-b-210) was used in the subsequent studies. The helicity of the organoiodine-immobilized helical polymers was quite stable; hence, the spirocyclization of 3 catalyzed by M-poly(L-1150-b-210) was performed in various solvents, including chloroform, THF, toluene, and chlorobenzene (runs 7–10 in Table 2). Consequently, chloroform showed the best performance, giving 4s in 83% yield and 72% ee (run 7 in Table 1). A further attempt of optimizing the condition using ethanol (EtOH) and methanol (MeOH) as additives resulted in an increased yield, but decreased ee (runs 11, 12 in Table 1). Lowering the reaction temperature further improved the enantioselectivity. For example, conducting the reaction at ‒30 °C gave 4s in 87% yield and 95% ee. Further lowering the temperature caused the catalyst precipitation. M-poly(L-1150-b-210) contained chiral L-1 moieties and a left-handed helical backbone; thus, to disclose the origination of the enantioselectivity, a right-handed helical P-poly(L-150-b-210) was used to catalyze the same spirocyclization of 3. Interestingly, the enantiomeric product 4r in 85% yield and −93% ee was obtained. Note that M-poly(L-1150-b-210) and P-poly(L-150-b-210) were prepared from the same monomers, but had opposite backbone helicities. The opposite enantioselectivity of the reaction was ascribed to the helical backbone of the polymer catalysts. These results demonstrate that the enantioselectivity in asymmetric reactions completely depends on the helical backbone, not on the chiral pendants of L-1. Therefore, enantiomeric products could be facilely produced from the same chiral source mediated by helical polymers.

The recovery and recycling of catalysts

The block copolymer catalysts are solvable in chloroform, dichloromethane, toluene, and THF, but insoluble in acetone, methanol, and n-hexane. These features provide them with great potential in catalyzing asymmetric reactions in homogeneous catalysts and transferring into heterogeneous catalysts by adding poor solvents after the reaction is accomplished. Thus, we explored herein the catalyst separation and recycling, which are major advantages of polymer-supported catalysts. In Fig. 3a, the reaction of 3 catalyzed by M-poly(L-1150-b-210) in CHCl3 was homogeneous all throughout the whole reaction process, even if the reaction was performed at −30 °C. However, the solution became heterogeneous after methanol or other poor solvent (e.g., n-hexane) was added. The high-Mn M-poly(L-1150-b-210) was precipitated from the reaction solution, while the generated product, unreacted substrate, and other additives were dissolved (Fig. 3a). After centrifugation and filtration, the polymer-supported catalyst M-poly(L-1150-b-210) was facilely recovered and isolated in an almost quantitative yield (Supplementary Fig. 18-20). The recovered M-poly(L-1150-b-210) was reused to catalyze the spirocyclization of 3 again under the abovementioned condition and verify the catalytic activity. The reaction gave the desired product 4 s in 85% yield and 93% ee, suggesting that the recovered M-poly(L-1150-b-210) catalyst maintained excellent activity and enantioselectivity. The catalyst was recycled 10 times without significant losses on selectivity and activity (Fig. 3b, and Supplementary Table 3).

Catalytic performance of catalysts in others asymmetric oxidations

We investigated another asymmetric oxidative spirocyclization of 1-hydroxy-N-methyl-N-phenyl-2-naphthamide 5 (Table 2) to prove the general activity of this helical polymer-supported chiral catalyst60. For comparison, poly-220 and M-poly-L-1150 were first used in this reaction. As expected, achiral poly-220 generated the target product 6 in 62% yield but without enantioselectivity (run 1 in Table 2). Meanwhile, M-poly-L-1150 could not catalyze this reaction because of the lack of organoiodine pendants (run 2 in Table 2). M-poly(L-1150-b-210) that catalyzed the dearomatizing spirolactonization of 5 gave the target product 6r in 56% yield and 33% ee (run 4 in Table 2). Accordingly, the polymer composition and the reaction solvent were screened (runs 7–12 in Table 2), thanks to the high stability of the helical structure in various solvents. In terms of the yield and the ee of the product, CHCl3 showed the best performance. The ee and the yield of the afforded 6r using M-poly(L-1150-b-210) as catalyst were 64% and 68%, respectively (run 8 in Table 2). Interestingly, the ee was enhanced to 91% when the reaction temperature was lowered to −30 °C in CHCl3, and the yield was 65% (run 13 in Table 2). The corresponding enantiomeric product 6s was obtained in ‒90% ee and 64% yield when the right-handed helical copolymer P-poly(L-150-b-210) was used (run 14 in Table 2). These results once again showed that the asymmetric selectivity was controlled by the helical backbone of the polyisocyanides. The helical polymer-supported catalyst can also be recovered and recycled for 10 times at least, and the catalytic activity and the enantioselectivity were generally maintained (Supplementary Fig. 21 and Supplementary Table 4).

As anticipated, poly-220 catalyzed the oxidation of 2-naphthol carboxylic acid (7) without enantioselectivity, and M-poly-L-1150 had no catalytic activity on this reaction (runs 1, 2 in Table 3)61. However, M-poly(L-1150-b-2m) composed the same poly-L-1100, and the poly-2m blocks showed an excellent performance on the oxidation reaction of 7 and yielded the desired product 8 s in 75% yield and 57% ee (runs 1–3 in Table 3). The reaction condition optimization revealed that the best result could be obtained in CH2Cl2 at −20 °C using M-poly(L-1150-b-210) as a catalyst (runs 3–11 in Table 3). In this case, target 8 s was produced in 83% yield and 86% ee (run 11 in Table 3). When P-poly(L-150-b-210) with opposite handedness was used, the enantiomeric 8r was obtained in 82% yield and −83% ee (run 12 in Table 3), further supporting that the reaction enantioselectivity was determined by the polyisocyanide backbone helicity.

Lastly, we investigated the utilization of a single helical polymer-supported catalyst to promote three different asymmetric reactions. Figure 4a depicts that the recovered M-poly(L-1150-b-210) from the reaction of 3 was directly used to catalyze the reaction of 5, giving the expected product 6r in 61% yield and 90% ee. After the reaction, M-poly(L-1150-b-210) was recovered and reused to catalyze the reaction of 7. It generated the desired 8s in 82% yield and 85% ee. M-poly(L-1150-b-210) was recycled six times for the three different asymmetric oxidations with high reactivity and enantioselectivity (Fig. 4b, and Supplemenatry Table 5).

Discussion

Mechanism study

A mechanism for the helical polyisocyanide catalyzed asymmetric reactions was proposed (Fig. 5a)62,63,64. Taking the asymmetric Kita-Spirocyclization as an example, the phenyl iodine pendants of polyisocyanide were initially oxidized to active hypervalent iodane (IA) by mCPBA. Then, the acetate on the hypervalent iodine was replaced by the hydroxyl of substrate 3. In the resulting intermediate (IIA), the attack of carboxylic acid to the ipso position of naphthol can be happened from Re- or Si-face and lead to 4r or 4s, respectively. Owing to the asymmetric environment provided by remote chirality transfer of helical polyisocyanide, the carboxylic acid attack was selectively occurred on the favored Si-face with less steric hindrance, thus gave the target 4r in good yield with high ee value. Other asymmetric reactions catalyzed by the iodine-functionalized polyisocyanides may proceed under mechanism similar to that of Kita-Spirocyclization due to the chiral environments induced by the one-handed helix.

Owing to the effectively remote chirality transfer of the rigid helical polyisocyanide backbone, the organoiodine-functionalized polyisocyanides also showed high performance on a more challenging intermolecular asymmetric sulfonyl-oxylactonization reaction (Fig. 5b). For example, M-poly(L-1150-b-210) catalyzed the reaction of 4-pentenoic acid with p-toluenesulfonic acid in ethyl ether at −30 °C with the presence of TFE and mCPBA, gave the target product (5-oxotetrahydrofuran-2-yl)methyl 4-methylbenzenesulfonate (10r) in 72% yield with 74% ee (run 7 in Supplementary Table 6). This result suggests the organoiodine-functionalized helical polyisocyanides have great potentials in various asymmetric catalysis.

In summary, this work facilely obtained single left- and right-handed helical polyisocyanides immobilized with achiral organoiodine catalysts. These polymers exhibited a large optical activity and had a high helical stability. Interestingly, the helical polymer-supported catalysts showed an excellent performance on asymmetric oxidations. The product ee was up to 95%. Although the left- and right-handed helical polymers were prepared from the same materials, they exhibited opposite enantioselectivities on the asymmetric reactions. The enantioselectivity can readily be switched through regulation on the helix-sense of the polymer backbone. The catalyst can be facilely recycled and successively catalyze three different asymmetric reactions with excellent activity and enantioselectivity. This study provides not only a series of excellent polymer-supported chiral organocatalysts, but also a clue for the design and synthesis of advanced catalysts for asymmetric reactions.

Methods

Synthesis of M-poly-L-1150 and P-poly-L-150

These polymers were prepared according to the reported procedure44,45. Monomer L-1 (600 mg, 1.68 mmol) and alkyne-Pd(II)-catalyst (8.55 mg, 0.0168 mmol) were dissolved in dry CHCl3 (7.5 mL). The solution was stirred for 8 h at 55 °C, then cooled to ambient temperature and precipitated by methanol. The precipitated polymer was collected and dried in vacuum. The afforded crude polymer was suspended in acetone (180 mL) for 3 h with stirring and was filtrated. The filtrate was dried by evaporation under reduced pressure, afforded the expected P-poly-L-150 (52 mg, 11% yield). SEC: Mn = 20.3 kDa, Mw/Mn = 1.14; 1H NMR (600 MHz, CDCl3, 25 °C): δ 9.34–7.89 (br, NH), 7.10–5.47 (br, ArH), 5.05–3.65 (br, CH and CH2), 2.12–0.61 (br, CH2 and CH3); FT-IR (KBr, cm−1): ν 2919 (νC–H), 2849 (νC–H), 1744 (νNHC=O), 1633 (νOC=O), 1604 (νC=N); [α]25D = 1788 (0.1, CHCl3). The filter cake was dissolved in CHCl3 (6 mL) and then precipitated in acetone. The precipitate solid was collected by filtration and dried in vacuum. After this procedure was repeated 3 times, the left-handed M-poly-L-1150 was obtained (339 mg, 60%). SEC: Mn = 57.7 kDa, Mw/Mn = 1.10; 1H NMR (600 MHz, CDCl3, 25 °C): δ 9.24–8.00 (br, NH), 7.16–5.70 (br, ArH), 4.88–3.50 (br, CH and CH2), 1.95–0.45 (br, CH2 and CH3); FT-IR (KBr, cm−1): ν 2925 (νC–H), 2857 (νC–H), 1751 (νNHC=O), 1636 (νOC=O), 1600 (νC=N); [α]25D = –1820 (0.1, CHCl3).

Synthesis of M-poly(L-1150-b-2m) and P- poly(L-150-b-2m)

Taking M-poly(L-1150-b-210) as an example, the solution of 2 (8.13 mg, 0.014 mmol) and M-poly-L-1150 (50 mg) in CHCl3 (1.0 mL) was stirred for 10 h at 55 °C, then cooled to 25 °C and precipitated in acetone. After centrifugation, the polymer was collected and dried in vacuum, which was re-dissolved in CH2Cl2 (1 mL) and cooled to 0 °C. To this solution, trifluoroacetic acid (22 μL, 0.3 mmol) was added. The mixture was warmed to 25 °C and stirred for 12 h. Then, the solution was precipitated into methanol, and the precipitated polymer was collected and dried to afford a yellow solid M-poly(L-1150-b-210) (46 mg, 80% yield). SEC: Mn = 63.1 kDa, Mw/Mn = 1.15. 1H NMR (600 MHz, CDCl3, 25 °C): δ 8.95–8.15 (br, NH), 7.45–4.80 (br, ArH), 4.93–3.78 (br, CH and CH2), 3.64–2.89 (br, CH2), 2.02–0.65 (br, CH2 and CH3); FT-IR (KBr, cm−1): ν 2921 (νC–H), 2853 (νC–H), 1750 (νNHC=O), 1626 (νOC=O), 1600 (νC=N); [α]25D = –1906 (0.1, CHCl3). P-poly(L-150-b-210) was prepared followed the similar procedure in 82% yield by using P-poly-L-150 as macro initiator. SEC: Mn = 25.3 kDa, Mw/Mn = 1.18; 1H NMR (600 MHz, CDCl3, 25 °C): δ 8.87–8.13 (br, NH), 7.67–5.35 (br, ArH), 5.02–3.75 (br, CH and CH2), 3.58–2.95 (br, CH2), 2.63–0.66 (br, CH2 and CH3); FT-IR (KBr, cm−1): ν 2929 (νC–H), 2852 (νC–H), 1749 (νNHC=O), 1630 (νOC=O), 1609 (νC=N); [α]25D = 1894 (0.1, CHCl3).

Typical procedure for asymmetric reaction

Taking the reaction of 3 as an example (see Supplementary Information for the procedure of 5 and 7). The compound 3 (4.28 mg, 0.02 mmol) was dissolved in CHCl3 (2.0 mL) at 0 °C. Then M-poly(L-1150-b-210) (5 mol% of the phenyl iodine pendants) and mCPBA (4.47 mg, 0.03 mmol) were consecutively added. The mixture was stirred at ‒30 °C for 3 days, then saturated Na2S2O3 and 1 M aq. Na2CO3 were added. The aqueous layer was extracted with ethyl acetate and the combined organic layers were washed with brine and dried over Na2SO4. After evaporation, the crude product was purified by column chromatography on silica gel (petroleum ether/ethyl acetate, v/v = 5/1) to afford compound 4 as a white solid. 1H NMR (600 MHz, CDCl3, 25 °C): δ 8.02 (d, J = 6.8 Hz, 1H), 7.63 (td, J = 7.6, 1.4 Hz, 1H), 7.41 (td, J = 7.6, 1.2 Hz, 1H), 7.26 (d, J = 12.0 Hz, 1H), 6.66 (d, J = 9.8 Hz, 1H), 6.21 (d, J = 9.8 Hz, 1H), 2.91 (ddd, J = 17.6, 11.2, 9.6 Hz, 1H), 2.60 (ddd, J = 17.6, 9.6, 2.2 Hz, 1H), 2.42 (ddd, J = 13.6, 9.6, 2.2 Hz, 1H), 2.21–2.16 (m, 1H).

Data availability

The synthetic details and experimental data generated in this study are provided in the Supplementary Information.

References

Gao, C., Wang, J., Xu, H. & Xiong, Y. Coordination chemistry in the design of heterogeneous photocatalysts. Chem. Soc. Rev. 46, 2799–2823 (2017).

Taccardi, N. et al. Gallium-rich Pd–Ga phases as supported liquid metal catalysts. Nat. Chem. 9, 862–867 (2017).

Kothandaraman, J., Goeppert, A., Czaun, M., Olah, G. A. & Prakash, G. K. S. Conversion of CO2 from air into methanol using a polyamine and a homogeneous ruthenium catalyst. J. Am. Chem. Soc. 138, 778–781 (2016).

Meemken, F. & Baiker, A. Recent progress in heterogeneous asymmetric hydrogenation of C=O and C=C bonds on supported noble metal catalysts. Chem. Rev. 117, 11522–11569 (2017).

Ye, R., Zhukhovitskiy, A. V., Deraedt, C. V., Toste, F. D. & Somorjai, G. A. Supported dendrimer-encapsulated metal clusters: toward heterogenizing homogeneous catalysts. Acc. Chem. Res. 50, 1894–1901 (2017).

Zhang, Y.-Y. et al. Scalable, durable, and recyclable metal-free catalysts for highly efficient conversion of CO2 to cyclic carbonates. Angew. Chem. Int. Ed. 59, 23291–23298 (2020).

Knöfel, N. D., Rothfuss, H., Willenbacher, J., Barner-Kowollik, C. & Roesky, P. W. Platinum(II)-crosslinked single-chain nanoparticles: an approach towards recyclable homogeneous catalysts. Angew. Chem. Int. Ed. 56, 4950–4954 (2017).

McMorn, P. & Hutchings, G. J. Heterogeneous enantioselective catalysts: strategies for the immobilisation of homogeneous catalysts. Chem. Soc. Rev. 33, 108–122 (2004).

Kim, H. Y., Kim, S. & Oh, K. Orthogonal enantioselectivity approaches using homogeneous and heterogeneous catalyst systems: Friedel–Crafts alkylation of indole. Angew. Chem. Int. Ed. 49, 4476–4478 (2010).

Altava, B., Burguete, M. I., García-Verdugo, E. & Luis, S. V. Chiral catalysts immobilized on achiral polymers: effect of the polymer support on the performance of the catalyst. Chem. Soc. Rev. 47, 2722–2771 (2018).

Yashima, E., Maeda, K., Iida, H., Furusho, Y. & Nagai, K. Helical polymers: synthesis, structures, and functions. Chem. Rev. 109, 6102–6211 (2009).

Wang, H., Li, N., Yan, Z., Zhang, J. & Wan, X. Synthesis and properties of a novel Cu(II)–pyridineoxazoline containing polymeric catalyst for asymmetric Diels–Alder reaction. RSC Adv. 5, 2882–2890 (2015).

Tao, L. et al. Efficient asymmetric hydrogenation of quinolines over chiral porous polymers integrated with substrate activation sites. ACS Catal. 10, 1783–1791 (2020).

Reggelin, M., Doerr, S., Klussmann, M., Schultz, M. & Holbach, M. Helically chiral polymers: a class of ligands for asymmetric catalysis. Proc. Natl Acad. Sci. 101, 5461–5466 (2004).

Chi, Y., Scroggins, S.-T. & Fréchet, J. M. J. One-pot multi-component asymmetric cascade reactions catalyzed by soluble star polymers with highly branched non-interpenetrating catalytic cores. J. Am. Chem. Soc. 130, 6322–6323 (2008).

Zhou, L. et al. Signifificant improvement on enantioselectivity and diastereoselectivity of organocatalyzed asymmetric aldol reaction using helical polyisocyanides bearing proline pendants. ACS Macro Lett. 6, 824–829 (2017).

Takeda, K., Oohara, T., Anada, M., Nambu, H. & Hashimoto, S. A polymer-supported chiral dirhodium(II) complex: highly durable and recyclable catalyst for asymmetric intramolecular C-H insertion reactions. Angew. Chem. Int. Ed. 49, 6979–6983 (2010).

Wang, H., Li, N., Zhang, J. & Wan, X. Synthesis and properties of a novel pyridineoxazoline containing optically active helical polymer as a catalyst ligand for asymmetric Diels–Alder reaction. Chirality 27, 523–531 (2015).

Shen, L., Xu, L., Hou, X.-H., Liu, N. & Wu, Z.-Q. Polymerization amplified stereoselectivity (PASS) of asymmetric michael addition reaction and aldol reaction catalyzed by helical Poly(phenyl isocyanide) bearing secondary amine pendants. Macromolecules 51, 9547–9554 (2018).

Yamamoto, T., Murakami, R. & Suginome, M. Single-handed helical poly(quinoxaline-2,3-diyl)s bearing achiral 4-aminopyrid-3-yl pendants as highly enantioselective, reusable chiral nucleophilic organocatalysts in the steglich reaction. J. Am. Chem. Soc. 139, 2557–2560 (2017).

Akai, Y., Yamamoto, T., Nagata, Y., Ohmura, T. & Suginome, M. Enhanced catalyst activity and enantioselectivity with chirality-switchable polymer ligand PQXphos in Pd-catalyzed asymmetric silaborative cleavage of meso-methylenecyclopropanes. J. Am. Chem. Soc. 134, 11092–11095 (2012).

Yamamoto, T. & Suginome, M. Helical poly(quinoxaline-2,3-diyl)s bearing metal-binding sites as polymer-based chiral ligands for asymmetric catalysis. Angew. Chem. Int. Ed. 48, 539–542 (2009).

Nagata, Y., Nishikawa, T. & Suginome, M. Poly(quinoxaline-2,3-diyl)s bearing (S)−3-octyloxymethyl side chains as an efficient amplifier of alkane solvent effect leading to switch of main-chain helical chirality. J. Am. Chem. Soc. 136, 15901–15904 (2014).

Yamamoto, T., Yamada, T., Nagata, Y. & Suginome, M. High-molecular-weight polyquinoxaline-based helically chiral phosphine (PQXphos) as chirality-switchable, reusable, and highly enantioselective monodentate ligand in catalytic asymmetric hydrosilylation of styrenes. J. Am. Chem. Soc. 132, 7899–7901 (2010).

Glavin, D. P., Burton, A. S., Elsila, J. E., Aponte, J. C. & Dworkin, J. P. The search for chiral asymmetry as a potential biosignature in our solar system. Chem. Rev. 120, 4660–4689 (2020).

Wang, M. et al. Unexpected role of achiral glycine in determining the suprastructural handedness of peptide nanofibrils. ACS Nano 15, 10328–10341 (2021).

Zhao, X., Zang, S.-Q. & Chen, X. Stereospecific interactions between chiral inorganic nanomaterials and biological systems. Chem. Soc. Rev. 49, 2481–2503 (2020).

Nguyen, H. V.-Y. et al. Bottlebrush polymers with flexible enantiomeric side chains display differential biological properties. Nat. Chem. 14, 85–93 (2022).

Zhang, M., Qing, G. & Sun, T. Chiral biointerface materials. Chem. Soc. Rev. 41, 1972–1984 (2012).

Yashima, E. et al. Supramolecular helical systems: helical assemblies of small molecules, foldamers, and polymers with chiral amplification and their functions. Chem. Rev. 116, 13752–13990 (2016).

Cobos, K., Quiñoá, E., Riguera, R. & Freire, F. Chiral-to-chiral communication in polymers: a unique approach to control both helical sense and chirality at the periphery. J. Am. Chem. Soc. 140, 12239–12246 (2018).

Sakamoto, T., Fukuda, Y., Sato, S. I. & Nakano, T. Photoinduced racemization of an optically active helical polymer formed by the asymmetric polymerization of 2,7-bis(4-tertbutylphenyl) fluoren-9-yl acrylate. Angew. Chem. Int. Ed. 48, 9308–9311 (2009).

Echizen, K., Taniguchi, T., Nishimura, T. & Maeda, K. Synthesis of stereoregular telechelic poly(phenylacetylene)s: facile terminal chain-end functionalization of poly(phenylacetylene)s by terminative coupling with acrylates and acrylamides in rhodium-catalyzed living polymerization of phenylacetylenes. J. Am. Chem. Soc. 143, 3604–3612 (2021).

Ikai, T., Kurake, T., Okuda, S., Maeda, K. & Yashima, E. Racemic monomer-based one-handed helical polymer recognizes enantiomers through auto-evolution of its helical handedness excess. Angew. Chem. Int. Ed. 60, 4625–4632 (2021).

Varni, A. J. et al. Photostable helical polyfurans. J. Am. Chem. Soc. 141, 8858–8867 (2019).

Pietropaolo, A. & Nakano, T. Molecular mechanism of polyacrylate helix sense switching across its free energy landscape. J. Am. Chem. Soc. 135, 5509–5512 (2013).

Ishidate, R., Markvoort, A. J., Maeda, K. & Yashima, E. Unexpectedly strong chiral amplification of chiral/achiral and chiral/chiral copolymers of biphenylylacetylenes and further enhancement/inversion and memory of the macromolecular helicity. J. Am. Chem. Soc. 141, 7605–7614 (2019).

Ishiwari, F., Nakazono, K., Koyama, Y. & Takata, T. Induction of single-handed helicity of polyacetylenes using mechanically chiral rotaxanes as chiral sources. Angew. Chem. Int. Ed. 56, 14858–14862 (2017).

Chu, J.-H., Xu, X.-H., Kang, S.-M., Liu, N. & Wu, Z.-Q. Fast living polymerization and helix-sense-selective polymerization of diazoacetates using air-stable palladium(II) catalysts. J. Am. Chem. Soc. 140, 17773–17781 (2018).

Chen, C. et al. Proximity-induced cooperative polymerization in “hinged” helical polypeptides. J. Am. Chem. Soc. 141, 8680–8683 (2019).

Zheng, W., Ikai, T. & Yashima, E. Synthesis of single-handed helical spiro-conjugated ladder polymers through quantitative and chemoselective cyclizations. Angew. Chem. Int. Ed. 60, 11294–11299 (2021).

Liu, N., Zhou, L. & Wu, Z.-Q. Alkyne-palladium(II)-catalyzed living polymerization of isocyanides: an exploration of diverse structures and functions. Acc. Chem. Res. 54, 3953–3967 (2021).

Nagata, Y., Takeda, R. & Suginome, M. Asymmetric catalysis in chiral solvents: chirality transfer with amplification of homochirality through a helical macromolecular scaffold. ACS Cent. Sci. 5, 1235–1240 (2019).

Xue, Y.-X. et al. Air-stable (Phenylbuta-1,3-diynyl)palladium(II) complexes: highly active initiators for living polymerization of isocyanides. J. Am. Chem. Soc. 136, 4706–4713 (2014).

Wu, Z.-Q. et al. Enantiomer-selective and helix-sense-selective living block copolymerization of isocyanide enantiomers initiated by single-handed helical poly(phenyl isocyanide)s. J. Am. Chem. Soc. 131, 6708–6718 (2009).

Xu, L. et al. Crystallization-driven asymmetric helical assembly of conjugated block copolymers and the aggregation induced white-light emission and circularly polarized luminescence. Angew. Chem. Int. Ed. 59, 16675–16682 (2020).

Li, Y.-X. et al. Helicity- and molecular-weight-driven self-sorting and assembly of helical polymers towards two-dimensional smectic architectures and selectively adhesive gels. Angew. Chem. Int. Ed. 60, 7174–7179 (2021).

Zhou, L. et al. Selective synthesis of single-handed helical polymers from achiral monomer and a mechanism study on helix-sense-selective polymerization. Angew. Chem. Int. Ed. 60, 806–812 (2021).

Yoshimura, A. & Zhdankin, V. V. Advances in synthetic applications of hypervalent iodine compounds. Chem. Rev. 116, 3328–3435 (2016).

Maity, A., Hyun, S.-M. & Powers, D. C. Oxidase catalysis via aerobically generated hypervalent iodine intermediates. Nat. Chem. 10, 200–204 (2018).

Charpentier, J., Früh, N. & Togni, A. Electrophilic trifluoromethylation by use of hypervalent iodine reagents. Chem. Rev. 115, 650–682 (2015).

Richardson, R. D. et al. Enantioselective α-oxytosylation of ketones catalysed by iodoarenes. Synlett 4, 0538–0542 (2007).

Shimogaki, M., Fujita, M. & Sugimura, T. Metal-free enantioselective oxidative arylation of alkenes: hypervalent-iodine-promoted oxidative C-C bond formation. Angew. Chem. Int. Ed. 55, 15797–15801 (2016).

Hashimoto, T., Shimazaki, Y., Omatsu, Y. & Maruoka, K. Indanol-based chiral organoiodine catalysts for enantioselective hydrative dearomatization. Angew. Chem. Int. Ed. 57, 7200–7204 (2018).

Dohi, T. et al. Chiral hypervalent iodine(III) reagent for enantioselective dearomatization of phenols. Angew. Chem. Int. Ed. 47, 3787–3790 (2008).

Abazid, A. H. & Nachtsheim, B. J. Triazole-substituted aryl iodide with omnipotent reactivity in enantioselective oxidations. Angew. Chem. Int. Ed. 59, 1479–1484 (2020).

Uyanik, M., Yasui, T. & Ishihara, K. Hydrogen bonding and alcohol effects in asymmetric hypervalent iodine catalysis: enantioselective oxidative dearomatization of phenols. Angew. Chem. Int. Ed. 52, 9215–9218 (2013).

Onouchi, H. et al. Two- and three-dimensional smectic ordering of single-handed helical polymers. J. Am. Chem. Soc. 130, 229–236 (2008).

Uyanik, M., Yasui, T. & Ishihara, K. Enantioselective Kita oxidative spirolactonization catalyzed by in situ generated chiral hypervalent iodine(III) species. Angew. Chem. Int. Ed. 49, 2175–2177 (2010).

Zhang, D.-Y., Xu, L., Wu, H. & Gong, L.-Z. Chiral iodine-catalyzed dearomatizative spirocyclization for the enantioselective construction of an all-carbon stereogenic center. Chem. Eur. J. 21, 10314–10317 (2015).

Uyanik, M., Kato, T., Sahara, N., Katade, O. & Ishihara, K. High-performance ammonium hypoiodite/oxone catalysis for enantioselective oxidative dearomatization of arenols. ACS Catal. 9, 11619–11626 (2019).

Song, X., Li, Y.-X., Zhou, L., Liu, N. & Wu, Z.-Q. Controlled synthesis of one-handed helical polymers carrying achiral organoiodine pendants for enantioselective synthesis of quaternary all-carbon stereogenic centers. Macromolecules 55, 4441–4449 (2022).

Dohi, T. et al. Asymmetric dearomatizing spirolactonization of naphthols catalyzed by spirobiindane-based chiral hypervalent iodine species. J. Am. Chem. Soc. 135, 4558–4566 (2013).

Haubenreisser, S. et al. Structurally defined molecular hypervalent iodine catalysts for intermolecular enantioselective reactions. Angew. Chem. Int. Ed. 55, 413–417 (2016).

Acknowledgements

We acknowledge National Natural Science Foundation of China (NSFC, Nos. 92256201 (Z.W.), 52273006 (N.L.), 52273204 (L.Z.), 22071041 (Z.W.), 21971052 (N.L.), 51903072 (L.Z.), and 21871073 (Z.W.)) for financial support. L. Zhou thanks the Fundamental Research Funds for the Central Universities of China (Grant Nos. PA2019GDPK0057 and PA2020GDJQ0028).

Author information

Authors and Affiliations

Contributions

Z.-Q.W., N.L., and L.Z. designed and directed the project; X.S. and Y.-X.L. performed the experiments. Z.-Q.W., Y.-Y.Z. and Z.C. wrote the manuscript with input from all other authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Xinhua Wan, and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, ZQ., Song, X., Li, YX. et al. Achiral organoiodine-functionalized helical polyisocyanides for multiple asymmetric dearomative oxidations. Nat Commun 14, 566 (2023). https://doi.org/10.1038/s41467-023-36327-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-36327-0

This article is cited by

-

Novel Chiral Helical Polyisocyanides Containing Cyclohexanediamine Pendants for Asymmetric Michael Addition Reaction and Aldol Reaction

Catalysis Letters (2024)

-

Thermo-responsive chiral micelles as recyclable organocatalyst for asymmetric Rauhut-Currier reaction in water

Nature Communications (2023)

-

Recent Advances in Helical Polyisocyanide-based Block Copolymers: Preparation, Self-assembly and Circularly Polarized Luminescence

Chemical Research in Chinese Universities (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.