Abstract

Precise understanding of interfacial metal−hydrogen interactions, especially under in operando conditions, is crucial to advancing the application of metal catalysts in clean energy technologies. To this end, while Pd-based catalysts are widely utilized for electrochemical hydrogen production and hydrogenation, the interaction of Pd with hydrogen during active electrochemical processes is complex, distinct from most other metals, and yet to be clarified. In this report, the hydrogen surface adsorption and sub-surface absorption (phase transition) features of Pd and its alloy nanocatalysts are identified and quantified under operando electrocatalytic conditions via on-chip electrical transport measurements, and the competitive relationship between electrochemical carbon dioxide reduction (CO2RR) and hydrogen sorption kinetics is investigated. Systematic dynamic and steady-state evaluations reveal the key impacts of local electrolyte environment (such as proton donors with different pKa) on the hydrogen sorption kinetics during CO2RR, which offer additional insights into the electrochemical interfaces and optimization of the catalytic systems.

Similar content being viewed by others

Introduction

Metal−hydrogen (M−H) interactions and the correlated chemical/catalytic hydrogen processes (H adsorption, absorption, evolution, and oxidation) participate in multiple applications such as hydrogen fuel cells1,2, hydrogen/pH sensors3,4,5,6, metal hydride batteries7, and electrocatalytic hydrogen evolution reaction (HER) and hydrogenation reactions8,9,10. To this end, Palladium (Pd) is one of the mostly adapted materials, which serves as a typical model catalyst for the fundamental investigation of M−H states and dynamic hydrogen transitions, owing to its unique and rich interactions with hydrogen9,10,11,12,13. Among various Pd-catalyzed electrochemical reactions, electrochemical carbon dioxide reduction (CO2RR) attracts most research attentions as it represents a sustainable means to reduce CO2 emissions by converting it into valuable chemicals and hydrocarbon fuels, providing an effective and economical approach towards carbon neutralization14,15,16,17. Numerous studies have been focused on the compositional and morphological innovations on Pd-based nanostructures18,19,20,21,22,23,24 to obtain high current densities and Faradaic efficiencies (FEs) of desired products, and one particular effective approach is the use of bimetallic catalysts where alloying elements such as Ag20,21 and Au25,26 can alter the electronic structure of Pd, regulate the intermediate adsorption energy, and finally improve the CO2RR performance. In analogy, H can be viewed as another alloying source for Pd: the formation of Pd−H bond involves a charge transfer process16,18,22,24, followed by the consequent transition to PdHx as a separate phase. H atoms either adsorb on the surface or diffuse into the subsurface, and significantly alter the adsorption energy of reaction intermediates, such as *CO, *HCOO, and *COOH18,24.

Despite the significant influence on the adsorption of intermediates in CO2RR and other hydrogenation reactions, there are only few experimental approaches for the quantitative measurement of adsorbed/absorbed H atoms and corresponding H sorption kinetics in Pd-based catalysts under operando conditions. Specifically, the phase transition of Pd is buried at a solid/liquid interface, which is difficult for in situ characterizations and poses a particular challenge in the study of corresponding electrocatalytic mechanisms. In most cases, in situ X-ray absorption spectroscopy (XAS) and in situ X-ray diffraction (XRD) were typically employed to characterize the Pd–Pd bond lengths and the lattice expansion during phase transition17,18,22,27,28, which successfully revealed the impact of catalyst morphologies on the potential range (with difference up to 100~300 mV) for PdHx formation. Alternating current (AC) impedance29, quartz crystal microbalance30, and cyclic voltammetry31,32,33 are the commonly employed approaches for directly studying Pd−H interactions, however, each individual methodology typically produces information on restricted dimension. To fully elucidate the comprehensive electrocatalytic mechanisms that include interfacial chemical processes and the local environments, it is essential to bring up additional in situ approaches (better with alternative signaling mechanism) to complement the existing characterization toolbox for the systematic investigation of Pd−H interactions and corresponding hydrogenation processes.

The transition between Pd and Pd hydride (α-phase or β-phase, PdHx) occurs naturally in hydrogen atmosphere, which sharply increases the resistivity that is proportional to the H content. This serves as the basis for the fabrication of Pd-based H2 gas sensors4,6,34. In principle, similar resistivity change would occur during electrochemical H sorptions in Pd-based nanomaterials. To this end, a recently developed in situ transport-based characterization technique, electrical transport spectroscopy (ETS), coupled with on-chip cyclic voltammetry (CV), enables the in situ electrical transport measurement of electrochemical interfaces, which is particularly suitable for the in situ investigation of H sorptions during electrocatalytic processes35,36. Here we report a comprehensive mechanistic study with quantitative measurements of interfacial hydrogen sorption processes in Pd-based CO2RR, including both intermediate states of surface hydrogen adsorption and subsurface PdHx formation (i.e., diffusion and absorption of H into the Pd lattice), using in situ transport-based measurements on a micro-electrochemical platform. By dynamically probing the in situ conductivities of Pd nanocatalysts in varying reactions and electrolytes, accompanied with rigorous electrochemical and electrokinetic investigations, we revealed the competitive relationship between CO2RR and surface/sub-surface H processes of Pd-based catalysts, and elucidated the key impacting factor of electrolytes (proton donors with different pKa) that determined the hydrogen sorption kinetics and CO2RR performances. The new mechanistic understandings were further demonstrated to provide valuable insights into the principles of performance enhancement in alloying catalysts.

Results and discussion

Catalyst preparation and device fabrication

Pd (with other metals as comparison) and Pd4Ag alloy were studied as model catalysts for the elucidation of H adsorption/absorption and catalytic activities. Pt, Pd, and Pd4Ag nanowires were prepared according to the previously reported methods20,37,38 with slight modifications (see Methods). The transmission electron microscopy (TEM) images of the as-synthesized catalysts are shown in Fig. 1c. The diameters of Pt, Pd, and Pd4Ag nanowires are 3 nm, 8 nm, and 6 nm, respectively. The crystalline structures were studied by X-ray diffraction (XRD). As shown in Fig. S1, the diffraction peaks of pure Pd are well consistent with (111), (200), (220), (311), and (222) planes of Pd fcc crystal structure. The diffraction peaks of Pd4Ag are located between pure Pd and Ag, but are closer to Pd, indicating the formation of Pd-rich alloy20,39. Inductively coupled plasma (ICP) analysis suggests that Pd4Ag alloy is composed of 80.96 at.% of Pd and 19.04 at.% of Ag, consistent with the starting Pd/Ag molar ratio. The interaction between Pd and Ag in Pd4Ag was further probed by X-ray photoelectron spectroscopy (XPS). The Pd 3d doublet of Pd4Ag shifts to lower binding energy as compared to pure Pd, indicating the electron transfer from Ag to Pd, resulting in negatively charged Pdδ− (Fig. S2), which can be rationalized by the lower work function and higher electron density of Ag20.

a Schematic illustration of the structure of the integrated electronic device and on-chip electrochemical (EC) cell. b Schematic illustration of circuits (left) and representative results (right) in concurrent CV and ETS measurements of Pt and Pd-based nanocatalysts. Hads and Habs represent the adsorbed H on the surface and absorbed H in the bulk, respectively. c Typical TEM images of the as-synthesized Pt, Pd, and Pd4Ag nanowires. The insets show SEM images of the on-chip nanowire films. CE, counter electrode; RE, reference electrode; WE, working electrode; S, source; D, drain.

Figure 1a, b depicts the schematic experimental setup and working principle for the concurrent on-chip CV and ETS measurements. A two-channel source-measure-unit (SMU, Key-sight 2902a) was employed for ETS measurements, with simultaneous IG − VG (CV) and ISD − VG (ETS) readouts (Fig. S3). More experimental details can be found in Methods. The devices were fabricated by selectively depositing the nanowires films onto the Si wafer with prepatterned gold electrodes35,40 (Fig. S4). For in situ electrical transport measurements, the as-prepared devices were then covered with an inert layer (PMMA) to define an electrochemical window (Fig. S4). Typical optical microscopic (OM) images of on-chip nanowires are shown in Fig. S5. For the stable measurements of hydrogen phenomena especially during electrocatalytic processes, the mean thicknesses of the films were typically controlled at about 200 nm (Fig. S5).

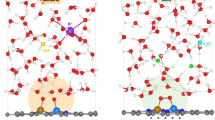

ETS identification of in situ H sorption processes in perchloric acid

Surface hydrogen adsorption and subsurface hydride formation were first investigated in 0.1 M HClO4 (Fig. 2). Stable CV and ETS curves of Pt, Pd and Pd4Ag were acquired after several cycles of electrochemical activation (Fig. S6). As shown in Fig. 2a, CV and ETS of Pt show characteristic behaviors similar to the previously reported results on polycrystalline Pt surface35,36,40, serving as a convenient baseline for the further investigation of other unknown systems. The ETS curve of Pt can be typically divided into three regions: H adsorption and evolution region (region I), double-layer region (D.L., region II), and reversible adsorption of hydroxyl groups and surface oxide formation region (M−OH and M−O, region III). For the ease of analysis, the ETS curves Pd and Pd4Ag are correspondingly divided into these same regions (Fig. 2b, c). Notably, significant differences in region I can be observed for the three materials, indicating the diverse phenomena of M−H interactions. With the gradually reducing potential, the ETS current (ISD) of Pt rises first and then reaches to a plateau (pink arrow in Fig. 2a), a typical indication of a stabilized state of saturated monolayer surface hydrogen adsorption (Pt−H)35. In sharp contrast, the ETS current of Pd rises first but then shows a unique and dramatic decline to a plateau at a much lower level (green arrow in Fig. 2b). As previously established in the studies of Pt35,36,40, when the potential decreased from 0.5 VRHE (D.L. region) to less than 0 VRHE (HER region), the adsorbate on the Pt surface changed from water to active hydrogen (Hads). Due to the less diffusive scattering of charge carriers from a Pt−H surface than a Pt−H2O surface35,36,40,41, higher ISD can be obtained (schematic illustration presented in Fig. 2e). In principle, this phenomenon can also be observed on other metals including Pd that form strong surface (covalent) M−H bonding. Therefore, at a less negative potential higher than 0.07 VRHE, ETS of Pd mainly reflects the H adsorption on surface. However, when potential continues to decline, the H diffuses into the lattice and leads to the formation of hydride (phase transition) that is unique to the Pd system, resulting in additional electron scattering (Fig. 2e) and decrease in density of states (DOS) at the Fermi level12,34, thus the decline of ISD. Fortunately, the opposite conductivity trend from surface H adsorption and consequent hydride formation offer a clear, convenient and sensitive approach for the detailed in situ mechanistic investigation of H-involving processes in Pd-catalyzed electrochemical reactions.

a–c IG−VG (CV, dash) and ISD−VG (ETS, solid) curves of Pt (a), Pd (b), and Pd4Ag (c) in 0.1 M HClO4. Film thickness is ~200 nm. I, II, and III represent the different states of the metals. Solid arrows in (a–c) indicate the potential sweeping direction. d The relationship between thicknesses of Pd (red) and Pd4Ag (blue) nanowire films and phase transition responses (△RMHx) reflected on ETS. Inset shows the schematic illustration of hydride with H/M ratio of 0.42 in PdHx and 0.29 in (Pd4Ag)Hx. Ag randomly occupies the Pd position and H preferentially occupies the octahedral vacancy close to Pd. The error bars in (d) present the standard error in nanowire film thicknesses and ETS experiments. e Schematic illustration of electron scattering (red arrows) in metal with surface adsorbates and hydrides. The black arrows indicate the decrease or increase of electron scattering during the change of states of electrodes. The yellow and brown cycles represent the adsorbed H on the surface (Hads) and absorbed H in the bulk (Habs), respectively. The red and white cycles represent the oxygen and hydrogen atoms of water molecules, respectively. D.L. region, double layer region. Source data are provided as a Source data file.

Generally, the phase transition from Pd to PdHx can be quantified by the ratio of Pd and absorbed H atoms, which can be obtained through calculating the Faradaic quantity during H electro-oxidation on a well-defined electrode31,32,33,42. Lasia et al. separated H adsorption and absorption on Pd films with different thicknesses deposited on Au(111), and concluded that the β-PdHx is obtained at potentials lower than 0.05 VRHE while the α-PdHx is obtained at more positive potentials31. It is also found that the generation of α- and β-PdHx both leads to decreases of conductivity12. However, no obvious decline of ISD was observed at the relatively positive potentials (0.07–0.30 VRHE) on Pd (Fig. 2b). This indicates the low level of absorbed H, and the rise of ISD caused by Hads is dominant in this potential range during the dynamic (non-equilibrium) CV scan. Meanwhile, the onset potential of 0.07 VRHE on ETS (highlighted by green color in Fig. 2b) corresponds to the rapid phase transition (PdHx formation), which is consistent with the reported result (0.05 VRHE)31, indicating the successful detection of H adsorption and consequent absorption by ETS.

Since the precise number of Pd atoms varies in each device, it is difficult to quantitatively describe PdHx simply by H electro-oxidation. We can quantify the phase transition level of Pd through its resistance change (phase transition response):

where Rsat is the resistance of catalyst film fully saturated by absorbed H (Habs), and Ronset is the resistance of catalyst film at the onset potential for rapid phase transition. The △RPdHx of pure Pd system within −0.20–0.07 VRHE is calculated to be 3.40% (Fig. 2b), which is obviously lower than the widely accepted value (>70%) for the full β-PdHx formation12,43. This is probably due to the insufficient electrolyte and hydrogen diffusion to the underlying layer of nanowires when the film thickness is large in the devices. To address this issue, film responses were systematically measured with the varying thicknesses of nanowires films to establish a calibration. We found that △RPdHx was highly relevant to the film thickness with a linear correlation (Fig. 2d, Fig. S9). The intercept of 45% represents the maximum in situ phase transition response of Pd in 0.1 M HClO4 electrolyte environment. Further increase in the size of electrochemical window does not significantly affect △RPdHx (Fig. S10).

As for the Pd4Ag alloying catalyst, the onset potential for H absorption is at 0.074 VRHE, which is close to that of Pd. However, the ISD drop in response to hydride formation is considerably lower (Fig. 2c), and the △R(Pd4Ag)Hx is calculated to be only 0.14%, which is about 4.12% of △RPdHx, clearly indicating a significantly different M−H interaction compared to pure Pd44. As shown in Fig. 2d, the △R(Pd4Ag)Hx is lower than that of pure Pd at each film thickness, with a theoretical intercept of 13%. The M−H interactions in Pd4Ag and pure Pd were further revealed by DFT calculations, as shown in Fig. S13 and Table S1. With a much weaker Ag−H interaction, the alloying Ag atoms can reduce the H adsorption and absorption in Pd4Ag from both electronic structure and proximity effects. As an alloying element, Ag does not change the lattice distance of Pd4Ag significantly, as evidenced by XRD results (Fig. S1). However, with the electron transfer between Ag and Pd in Pd4Ag, the d orbital of Pd is filled with more electrons compared to pure Pd, weakening the ability of Pd to bond with H and reducing the resistivity change caused by Pd−H interactions44. Based on the on-chip △RMHx of Pd and Pd4Ag, we can estimate the number of the absorbed H atoms by referring to the known relationship between the resistivity and H/M ratio (H/M represents the ratio of hydrogen atoms to the combined total of Pd and Ag atoms) of Pd80Ag40 alloy and pure Pd (Fig. S14)43,45. The on-chip △RPdHx of 45% corresponds to an H/M ratio of 0.42, and △R(Pd4Ag)Hx of 13% corresponds to an H/M ratio of 0.29. The lower in situ H/M ratio of Pd4Ag shows that the doping of Ag weakens the phase transition from Pd to Pd hydride, which provides solid experimental evidence to the weakened M−H interaction and thus phase transition.

Electrochemical CO2RR performances and their kinetic dependence on H sorptions in buffered electrolytes

Based on the identification and quantification of in situ H sorption processes in the acidic electrolyte enabled by transport measurements, we next aim to study the H sorption impacts on Pd-catalyzed CO2RR in a commonly used bicarbonate buffer electrolyte (KHCO3), and a similar phosphate buffer electrolyte (K2HPO4/KH2PO4) for comparison. The CO2RR product distributions were firstly obtained under constant potential electrolysis from −0.5 to 0.0 VRHE, as shown in Fig. 3a–c. In KHCO3, formate starts to form at ~0 VRHE on Pd with low FE of 35.87%, which increases to 97.54% at −0.33 VRHE and then drops back to 42.47% at −0.42 VRHE. In comparison, formate also starts to form on Pd4Ag at ~0 VRHE but with an obviously higher FE of 89.14%, and FE remains at high level (>80% between 0 to −0.30 VRHE, 72.64% at −0.43 VRHE) at the high overpotential region (indicating the resistance to competing HER). Moreover, the chronoamperometric (i–t) curves of Pd4Ag indicates a high working stability, whereas the current density of pure Pd starts to decline with working potential less than −0.23 VRHE owing to the CO poisoning, in line with previous reports15,16,17,20 (Fig. S15). Figure 3b further shows that Pd4Ag has higher formate production rates than Pd at all tested potentials. The above results indicate an overall better CO2RR performance after the alloying with Ag atoms.

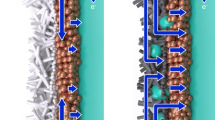

a–c Potential-dependent selectivity for formate production (a), and current densities for formate production (b), and hydrogen evolution (c) with Pd (red) and Pd4Ag (blue) catalysts in 0.1 M CO2-saturated KHCO3 (solid curves) and K2HPO4/KH2PO4 (dash curves). d Phase transition responses of Pd in 0.1 M Ar-saturated KHCO3 and HClO4 with varying scan rates. Film thickness is ~200 nm. e–h On-chip IG−VG (CV, dash, left y axis) and ISD−VG (ETS, solid, right y axis) curves of Pd (e, g) and Pd4Ag (f, h) in 0.1 M Ar- and CO2-saturated KHCO3. g and h depict the enlarged negative-potential-sweeping ETS curves (0.2 to −0.5 VRHE) in (e) and (f), respectively. i–l On-chip IG−VG (CV, dash, left y axis) and ISD−VG (ETS, solid, right y axis) curves of Pd (i, k) and Pd4Ag (j, l) in 0.1 M Ar- and CO2-saturated K2HPO4/KH2PO4. k and l depict the enlarged negative-potential-sweeping ETS curves (0.2 to −0.5 VRHE) in (i) and (j), respectively. Solid arrows in (d–l) indicate the potential sweeping direction. Film thickness is ~200 nm. The gradient background (from red to blue color) in (a–c, g, h, k, l) represents the increased CO poisoning effect concluded from Figs. S15, 16. The rectangular shadings in (d, e, f, i, j) highlight the H sorption regions reflected on ETS in specific electrolytes (green in KHCO3 and red in K2HPO4/KH2PO4). m Schematic illustration of different Pd−H states in KHCO3 (left panel) and K2HPO4/KH2PO4 (right panel), and the corresponding CO2RR processes at the interfaces. The yellow and brown cycles represent the adsorbed H on the surface (Hads) and absorbed H in the bulk (Habs), respectively. n Summary of phase transition potentials of Pd (blue) and Pd4Ag (red) under CO2RR conditions in KHCO3 and K2HPO4/KH2PO4 obtained at 10 mV/s. The error bars in (n) present the standard error in two ETS experiments with film thicknesses of ~25 nm and ~200 nm. Source data are provided as a Source data file.

Interestingly, when the electrolyte was switched to K2HPO4/KH2PO4, the overall formate FEs on pure Pd were reduced (Fig. 3a). In comparison, Pd4Ag showed even more complex changes in CO2RR performance. The formate FEs also experienced an obvious decrease at low overpotentials (−0.15 to −0 VRHE), yet a unique increase by ~8% was observed at the high overpotential region (−0.4 to −0.2 VRHE). Overall, the different CO2RR performances in KHCO3 and K2HPO4/KH2PO4 indicate distinct interfacial processes sensitive to the proton-donating electrolytes, which are presumably connected to the phase transition level of catalysts, CO poisoning/site blocking, formate production rates (Fig. 3b) and HER kinetics (Fig. 3c). It should be noted that the XRD after chronoamperometric studies reveal that H sorption processes during CO2RR alloy does not cause a segregation (or any other structural or compositional change) in the Pd4Ag (Fig. S17), indicating its reversibility during the reaction.

ETS measurements were further conducted to elucidate the H sorption kinetics and rationalize the distinct CO2RR performances of different Pd-based catalysts in different electrolyte environments. First, we compared the H sorption kinetics by ETS in Ar-saturated KHCO3 and HClO4 at varying scan rates (Figs. 3d and S18). In HClO4, significantly larger ETS hysteresis loops were observed to achieve complete H adsorption/desorption when the scan rate was increased from 10 to 80 mV/s, which confirms that the H sorption process is kinetic-dependent. In addition, while the degree of phase transition (corresponding to the ETS current level) kept unchanged in HClO4, a lower degree of phase transition (dashed arrow in Fig. 3d) was observed in KHCO3 with the increasing scan rate. These results suggest the slow H sorption kinetics in the near neutral electrolyte, which is reasonable due to the low concentration of hydronium ion and slow kinetics of water reduction in neutral/alkaline electrolytes46,47,48,49.

Figure 3e depicts the CV and ETS curves of Pd under CO2RR conditions (in 0.1 M CO2-saturated KHCO3). An obvious alternation in the H sorption hysteresis loop in ETS can be observed (marked with blue colored area and dashed arrow in Fig. 3e) after the introduction of CO2, which may originate from the change of proton source and competitive surface reactions. Specifically, the addition of CO2 increases the concentration of H2CO3 in the electrolyte:

and the Faradaic current concerning H-containing species thus follows:

The contribution by hydronium ions can be ignored as its concentration is relatively low (≤10−6 M) in near neutral electrolytes50. The introduction of CO2 changes the pH of electrolyte from 8.3 to 6.8. A neutral condition is not beneficial to the hydrogen kinetics due to the low hydronium ion concentration and the insufficient driving force for H2O reduction49, which further contributes to the negatively shifted potential for hydrogen adsorption (dashed arrow in Fig. 3g) and phase transition potential (i and ii in Fig. 3g) reflected on ETS. Moreover, H2CO3 has a lower pKa than HCO3− and H2O (Table 1), which allows it to act as the first proton donor (PD) for H sorptions, as the pKa of a PD is related to the thermodynamic driving force for proton-donating50. This effect tends to shift the potential of H adsorption to a more positive position, which is, however, contrary to our ETS results (dashed arrow in Fig. 3g). Furthermore, the onset potential for phase transition splits from point i (Fig. 3g) to two points (ii and iii in Fig. 3g) in CO2-saturated KHCO3, and the same phenomenon can be observed in successive cycles as shown in Fig. S19. It is only when the negative potential goes beyond point iii (Fig. 3g) that strong H absorption occurs. The non-linear variation of ISD and phase transition with the negative shift of potential therefore strongly indicate the competition between CO2RR and H sorption at potentials <0 VRHE in KHCO3. Two parallel pathways were generally proposed for Pd-catalyzed CO2RR, leading to formate or CO products24:

in the formate or formic acid pathway:

in the CO pathway:

The formate mechanism involves a proton-coupled electron transfer (PCET) process, during which the proton transfer and electron transfer occur in a same elementary step, and the M−H bond is formed on the surface51,52. Although H adsorption on the surface is thermodynamically more favorable (by 0.33 eV) compared to subsurface H absorption (which leads to hydride formation), H could diffuse into the subsurface and then bulk fcc Pd lattice at more negative potentials18,53,54. The overall hydrogen sorption process within Pd and Pd4Ag systems can be described by55:

where the diffusion between Hads and Hsubsurface follows the equilibrium that is determined by the chemical potentials of H atoms in each phase (μHads vs. μHsubsurface). During active CO2RR, the C1 intermediates occupy the Pd sites and inhibit the production of Hads, shift the equilibrium between Hads and Hsubsurface, and eventually alter the level of hydride formation. In addition, the more favorable formate pathway (Eqs. 4–6) will largely consume Hads and slow down the kinetics of subsurface H diffusion and phase transition process. Importantly, these H-involving processes during CO2RR can be reflected on the ETS signals corresponding to the H sorptions. On this basis, as the unusual change in ISD (Fig. 3g) is in well correspondence with the high formate FE (>70%) in the potential range (>−0.2 VRHE), our results therefore confirm that proton consumption and site blocking by intermediate adsorptions during formate production significantly reduce the H diffusion kinetics and level of phase transition under scanning potential (non-equilibrium) condition. When the potential continues to decrease to a more negative potential (−0.3 VRHE, indicated by iv in Fig. 3g), the decline of ISD is slowed down (leading to a clear two-stage, non-linear ETS characteristic within the range of −0.2 to −0.4 VRHE) probably due to severe CO poison, which inhibits the production of Hads and subsequent H absorption32. Overall, the near neutral electrolyte condition in KHCO3 and the CO2RR process both reduce the kinetics of H sorption processes under scanning potentials (as illustrated in Fig. 3m), finally causing a smaller ETS hysteresis loop (Fig. 3e). In such case, the excess of proton-donating KHCO3 could facilitate the H sorption kinetics and enlarge the loop (Fig. S20). Similar competition also exists in Pd-catalyzed hydrogenation of formaldehyde, benzaldehydeand, benzonitrile, etc.56,57.

Similarly, Fig. 3f depicts the CV and ETS curves of Pd4Ag in 0.1 M Ar- and CO2-saturated KHCO3 that reveal the H sorption kinetics during CO2RR. The onset potential for phase transition shifted negatively from −0.145 VRHE (i in Fig. 3h) to −0.324 VRHE (ii in Fig. 3h) after the introduction of CO2 in the electrolyte, and both are considerably lower than that of pure Pd. The more negative phase transition potentials of Pd4Ag further confirm its weakened M−H interaction after Ag alloying. In addition, no change of fine ETS characteristics at high overpotentials (−0.2 to −0.4 VRHE) was observed, which indicates unobvious CO poisoning effect, and H sorption kinetics is expectedly hindered due to the H consumption for intense formate production (dashed arrow in Fig. 3h). These in situ observations are also consistent with the strong CO poisoning resistance in Pd4Ag alloying catalysts, which results in the considerably improved conversion rate and stability for CO2RR (Figs. S15, 16). As shown in Fig. S13 and Table S1, our DFT calculation results also confirm that Ag can reduce the binding energy of poisonous *CO at its surrounding sites20,21,25. Finally, for similar reason to the Pd case, the inhibition by CO2RR leads to a smaller ETS hysteresis loop for H sorption in Pd4Ag (indicated by dashed arrow in Fig. 3f).

ETS investigations were further conducted in K2HPO4/KH2PO4 electrolyte to better clarify the fundamental connections between CO2RR and H sorption processes. As shown in Fig. 3i, the similar hysteresis loops (marked with red area) suggest that the H absorption in pure Pd is not inhibited by CO2RR in K2HPO4/KH2PO4 environment, which is in sharp contrast to the KHCO3 case. Correspondingly, H absorption in Pd4Ag is even accelerated by the introduction of CO2 (dashed arrow in Fig. 3j). These results can be rationalized by the one major variation in these electrolytes, i.e., different proton-donating capacities of the corresponding anions. As shown in Table 1, anions with smaller pKa have stronger proton-donating capacity and tend to accelerate the H sorption kinetics. In Ar-saturated electrolytes, the onset potential for phase transition of Pd in K2HPO4/KH2PO4 (0.012 VRHE, i in Fig. 3k) is higher than that in KHCO3 (−0.024 VRHE, i in Fig. 3g), which is consistent with the stronger proton-donating capacity of H2PO4− over HCO3− without the influence of CO2RR inhibition. For Pd4Ag, the onset potential for phase transition (without CO2RR) is also largely shifted from −0.145 VRHE in KHCO3 (i in Fig. 3h) to 0.052 VRHE in K2HPO4/KH2PO4 (i in Fig. 3l). Under CO2RR conditions, the addition of CO2 can increase the local concentration of H2CO3 which has low pKa (6.35) and strong proton-donating capacity for H sorptions. In this case, H2PO4− (with lower pKa of 7.21) tends to more efficiently maintain the concentration of interfacial H2CO3 through equilibrium50:

thus supporting the H sorption processes and causing even stronger H absorptions during CO2RR (dashed arrow in Fig. 3j). For the same reason, the onset potentials for phase transition in Pd and Pd4Ag both show a slight positive shift during CO2RR (0.012 to 0.044 VRHE, 0.052 to 0.056 VRHE, respectively), as shown in Fig. 3k, l (i and ii). In addition to the proton-donating effect, the influence of formate production and CO poisoning (as a result of the CO2RR process) on H sorption in K2HPO4/KH2PO4 is also presented on ETS curves of Pd (ii, iii and iv in Fig. 3k, respectively). Again for Pd4Ag, no obvious CO poisoning signal (lake of point iv in Fig. 3l) is reflected on ETS in K2HPO4/KH2PO4.

As summarized in Fig. 3m, while the H sorption kinetics is inhibited by CO2RR-related H consumption and/or CO poisoning, it can be promoted by the local proton-donating species including H2CO3 in equilibrium with CO2. It should also be noted that the H sorption is essentially a kinetic-dependent process, and the phase transition potentials may vary under different test conditions (potential scan rates, electrode geometries, etc.). Additional ETS tests indeed show positive shifts of the phase transition potential at smaller film thickness or slower scan rates (Fig. S21), emphasizing the importance of consistence in test conditions. To this end, the ETS measurements conducted with 25 nm thin film thickness and 10 mV/s scan rate represent the experimental condition that gives close-to-intrinsic properties of the electrode materials, where the impact from the insufficient electrolyte diffusion to the sub-layer nanowires within the thin film device was minimized. With precise control of these experimental factors, the phase transition potential of Pd was determined to be about 150 mV more positive than that of Pd4Ag in KHCO3, reflecting the different M−H interactions. In addition, by switching the electrolyte from KHCO3 to K2HPO4/KH2PO4, the phase transition potentials of both Pd and Pd4Ag markedly shift to 0–0.1 VRHE, reflecting the strong proton-donation and fast H sorption kinetics in K2HPO4/KH2PO4. The key results and the corresponding conclusions were summarized in Fig. 3n.

Potentiostatic ETS analysis for near-equilibrium operando H sorption quantifications

The above ETS investigations in KHCO3 and K2HPO4/KH2PO4 were all conducted with scanning potentials (CV), revealing the in situ competitive relationship between CO2RR and H sorption processes under dynamic, diffusion-controlled, and non-equilibrium conditions. To further analyse and quantify the level of operando subsurface H absorption in Pd-based materials at their equilibrium conditions during CO2RR, we carried out transient ETS measurements during potentiostatic electrolysis, and the results are shown in Fig. 4a. The potential was first kept at 0.5 VRHE, where the ETS signal under no phase transition serves as baseline, and was then switched to −0.38 VRHE, which represents the typical potential for formate production with relatively high current density and selectivity. In all electrolytes, a clear drop in ETS currents can be observed after the potential shift, indicating a rapid phase transition of Pd and Pd4Ag at this potential. A consequent plateau, presumably correlated to an equilibrium state, was reached after a period of electrolysis. The phase transition response at 100 s in each electrolyte is converted into the in situ H/M ratio (see details in Fig. S14), as shown in Fig. 4c. In the absence of CO2RR, the formation of subsurface hydride (MHsubsurface) is in chemical equilibrium with surface adsorbed hydrogen (Hads), as shown in Eq. 10. This equilibrium could be significantly shifted by the H+ concentration (i.e., pH) in the electrolyte. As a result, the H/M ratio in Pd was considerably higher when in strong acid HClO4, as compared to KHCO3 and K2HPO4/KH2PO4 environments (see red bars in Fig. 4c). Interestingly, a similar trend was not observed in Pd4Ag, demonstrating the unique H sorption thermodynamics in response to the H+ concentration in this alloying structure (blue bars in Fig. 4c). First, due to the alternation in the electronic structure of Pd and the proximity effect after Ag doping, the H binding energy is reduced on Pd4Ag surface, leading to the lower H/M ratio in Pd4Ag as compared to pure Pd (Fig. 4c). Similar conclusions have also been reached in dynamic ETS-CV investigations (Fig. 2). Second, when acidic HClO4 was switched to more neutral electrolytes such as KHCO3 and K2HPO4/KH2PO4, no significant decrease in the H/M ratio in Pd4Ag was observed (in sharp contrast to Pd). This is probably due to the influence of pH on the hydrogen binding energy (HBE) of surface Hads. Zhu et al. demonstrated that the HBE on Pt is increased at low pH through in situ surface-enhanced infrared absorption spectroscopy (SEIRAS), which contributes to its higher HER activity58. This conclusion theoretically applies to Pd as the electrolyte-dependent HER1 or other hydrogenation59activities can also be observed on Pd and other metals. As a result, while a low H+ concentration (from HClO4 to KHCO3 and K2HPO4/KH2PO4) tends to shift the equilibrium in Eq. 10 to the left, reducing the hydrogen concentration in both M−Hads and M−Hsubsurface phases, the concurrently reduced HBE only on surface Hads facilitates the hydrogen diffusion into the subsurface Pd lattice54, promoting M−Hsubsurface formation. Therefore, the influence of electrolyte can cast different influences on the sub-surface hydride formation in opposite directions. For Pd4Ag (Pdδ−) system that intrinsically has smaller HBE than Pd, the electrolyte-induced alternation in surface HBE plays a more critical role that is significant enough to counterpart the influence from H+ concentration, thus leading to a more balanced H soption kinetics in different electrolytes as revealed in Fig. 4c. The similar phenomenon was also demonstrated in a PdPt alloy by in situ XAS and XRD, where substantially strong HBE on surface Pt inhibited the subsurface H diffusion28. For further confirmation, we have also conducted same ETS investigations on pure Au, showing that for metals with considerably weak HBE, the sub-surface hydride formation can only be observed in KHCO3 rather than HClO4 (Fig. S24). Overall, our ETS-derived in situ H/M ratios effectively reveal the role of electrolyte in surface HBE for Pd-based catalysts.

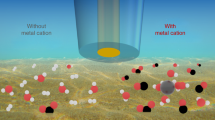

a Phase transition response of Pd and Pd4Ag under potentiostatic conditions in different electrolytes (0.1 M). The potential was first kept at 0.5 VRHE for 10 s and then shifted to −0.38 VRHE for 100 s. Film thickness is ~25 nm. b Schematic illustration of M−H states and CO2RR performances of Pd and Pd4Ag in near neutral conditions. “PD” in (b) represents proton donor. The yellow and brown cycles represent the adsorbed H on the surface (Hads) and absorbed H in the bulk (Habs), respectively. c Summary of equilibrium H/M ratios obtained in different electrolytes at 100 s. The H/M ratios are obtained by first normalizing the responses in (a) with reference to the maximum phase transition responses (Pd: 45%, Pd4Ag: 13%) obtained in 0.1 M HClO4, and then referring to the published quantitative relationship between the resistivity and H/M ratios of pure Pd and Pd80Ag20 alloy (Fig. S14). On the top shows the pH and pKa values of the proton donors with relatively high proton-donating capacities. The pKa of 0, 10.33, 7.21, and 6.35 corresponds to H3O+, HCO3−, H2PO4−, and H2CO3, respectively. d Summary of the time for 50% and 90% level of maximum phase transition in Pd and Pd4Ag. The error bars in (c, d) present the standard errors in two repeated ETS experiments. e Proposed mechanism for proton donation, H sorption and CO2RR on Pd-based materials in near neutral conditions. “M−int” in (e) represents the surface adsorbed intermediates on metals during CO2RR. Source data are provided as a Source data file.

Under CO2RR conditions, much higher H/M ratios in both KHCO3 and K2HPO4/KH2PO4 were observed in the pure Pd system (Fig. 4c), which are not completely consistent with the dynamic CV-ETS results shown in Fig. 3. The equilibrium H/M ratio in these near neutral electrolytes follows a sequence: K2HPO4/KH2PO4 (CO2) > KHCO3 (CO2) > K2HPO4/KH2PO4 (Ar)> KHCO3 (Ar) (indicated by the arrow in Fig. 4c), which is highly correlated with the pH sequence of electrolytes (8.3 > 7.2 > 6.8 > 6.3). Different to the extreme low pH in the acidic electrolyte (HClO4), we speculate that the pH effect on HBE of surface Hads is similar in these four buffered electrolytes, and the difference in proton-donating capacity indicated by the different pKa values of proton donors (Fig. 4c) is critical to the formation of Hads and MHsubsurface. In this case, H+ in Eq. 10 can be replaced by proton-donating HAx−, and the pKa value of a buffer electrolyte can serve as a better descriptor for the evaluation of electrolyte-modulated sub-surface phase transition, as shown in Fig. 4c. It can be noted that the same trend in the H/M ratio-electrolyte pKa correlation is observed in Pd4Ag (Pdδ−) system, indicating the critical role of proton-donating capacities of local electrolyte environments. Meanwhile, the overall subsurface H/M level in Pd4Ag is still below Pd under CO2RR, revealing the actual equilibrium state under operando electrolysis, again providing the direct evidence that the general HBE (both for Hads and M−Hsubsurface) is relatively reduced in Pd4Ag, even with comprehensive surface/subsurface physical chemical processes. In addition, the H/M ratio in both Pd and Pd4Ag under CO2RR conditions are even higher than in HClO4, which highlights the presence of local (within electrochemical double layer) equilibrium between CO2 and H2CO3 (Eq. 2) during CO2RR.

The transient ETS measurement also allowed for the investigation of time-dependent phase transition kinetics. The t50 and t90 (time for 50% and 90% level of maximum phase transition) in different electrolytes are subtracted and summarized in Fig. 4d. Both Pd and Pd4Ag demonstrated a fast kinetics to reach equilibrium hydride formation in HClO4 (<0.1 s), which originates from the same reason that accounts for high equilibrium H/M ratios: the high H+ concentration and high HBE for surface Hads under strong acidic electrolytes (also see Fig. S25). In KHCO3 and K2HPO4/KH2PO4, much lower H+ concentration certainly slows down the H sorption kinetics (t50 between 0.4–5 s) despite the compensation from proton-donating anions that maintains the equilibrium states, clearly differentiating the H sorption kinetics with two different hydrogen sources (H3O+ and HAx−). The change of H sorption kinetics under CO2RR shows consistent conclusions with dynamic CV-ETS tests, the addition of CO2 slows down the hydride formation in KHCO3 (Fig. 4d and Fig. 3e, f) while accelerates it in K2HPO4/KH2PO4 (Fig. 4d and Fig. 3i, j). These transient results again demonstrate the comprehensive H sorption kinetics under the balance between CO2RR inhibition (competing for surface Hads) and proton donation from surrounding electrolytes (including H2CO3 formed in near-surface CO2-electrolyte equilibrium). Furthermore, it is evident that the transient H sorption kinetics of Pd4Ag is overall slower than that of pure Pd, which is more obvious in t90, further confirming the weak M−H interaction in Pd4Ag from the kinetic point of view.

Connection between CO2RR performances and H sorption processes

The dynamic, equilibrium and transient quantification of the subsurface H/M level (and therefore the H sorption kinetics) can be correlated to the CO2RR performance under each specific condition. We first performed the density functional theory (DFT) calculations (see Fig. S13) to rationalize the reduced CO poisoning and high formate production activity on Pd4Ag surface (as compared to pure Pd), demonstrating the role of charge transfer and geometric effects on the reduced M−H interaction and CO poisoning20. In addition, we found that both Pd and Pd4Ag exhibit different CO2RR performances in varying H-donating electrolytes (Fig. 3a–c). K2HPO4/KH2PO4 can accelerate the H sorption kinetics, which is reflected by the increased phase transition degree (H/M ratio) in Pd4Ag (from 0.38 in KHCO3 to 0.48 in KH2PO4/K2HPO4) during CO2RR (see Fig. 4c and Table S2). Correspondingly, an increase in formate FE of about 8% on Pd4Ag was obtained at −0.4~−0.2 VRHE (Fig. 3a), proving that strong proton supply in KH2PO4/K2HPO4 electrolyte and high degree in operando phase transition (H doping) would be beneficial for reducing CO poisoning and promoting formate production18,24,28 (Fig. 3b). As a result, Pd4Ag demonstrated a significantly enhanced current density and stability for formate production compared with pure Pd (Fig. 3a, b). It should also be mentioned that the enhanced proton reduction kinetics in KH2PO4/K2HPO4, as revealed by ETS investigation, simultaneously promotes the competing HER (Fig. 3c)50,51 and thus leads to obviously diminished formate FEs (Fig. 3a) at low overpotential region (−0.15~−0 VRHE), where CO poisoning and CO2RR is relatively weak and less dominant. As a comparison, the H/M ratios of pure Pd in the CO2-saturated KHCO3 and KH2PO4/K2HPO4 (0.48 and 0.51) are close due to its originally strong Pd−H interaction, and KH2PO4/K2HPO4 mostly accelerates the HER activity and the formate FEs are thus reduced (Fig. 3a). Therefore, both CO2RR and HER performances can be modulated by electrolyte environments that fundamentally determines the H sorption equilibrium and kinetics, and it is important to strike a balance among different and comprehensively connected near-surface, on-surface and sub-surface reactions, as summarized in Fig. 4e.

In summary, in situ electrical transport measurements were utilized to monitor and quantify the H sorption processes during CO2RR in either metallic (Pd, Pt, and Au) or bimetallic (Pd4Ag) catalytic materials under scanning voltametric (dynamic) or potentiostatic (steady-state) electrolysis conditions. While fast subsurface hydride formations were observed in strong acidic environments, the proton-donating capacity (indicated by the pKa) of near neutral electrolytes, including the near-surface H2CO3 in equilibrium with CO2, was found to serve as a key impacting factor to the H sorption kinetics and CO2RR performances. Compared to pure Pd, more negative phase transition potentials and lower equilibrium H/M ratios were observed in bimetallic Pd4Ag, providing direct evidence for the weakened M−H interaction and origin of promoted CO2RR in alloy catalysts. The high degree of in situ M−Hsubsurface along with the fast H sorption kinetics would also be beneficial for reducing CO poisoning and promoting formate production. The H sorption features identified and quantified in various electrolyte environments under operando reaction conditions therefore provide a general and effective platform for the mechanistic investigation of electrocatalytic reactions involving hydrogenation processes.

Methods

Chemicals

Silver nitrate (AgNO3, 99.98%), Ethylene glycol (EG, 99%), and palladium chloride (PdCl2, 60% Pd basis) were purchased from Sigma-Aldrich. Ascorbic acid (99.98%), potassium hydrogen carbonate (KHCO3, 99.7%), perchloric acid (HClO4, 48–50%), n-butyl alcohol (99.4%), and nafion solution (5 wt%) were purchased from Alfa Aesar. Dihexadecyldimethylammonium chloride (75%) was purchased from Beijing Warwick Chemical Co., Ltd. Potassium hydroxide (KOH, 99.999% metal trace) was purchased from Innochem. Sodium bicarbonate (NaHCO3, 99.8%), potassium phosphate dibasic anhydrous (K2HPO4, 99.0%), potassium phosphate monobasic (KH2PO4, 99.95%), and sodium perchlorate (NaClO4, 99%) were purchased from Aladdin. Chloroauric acid (HAuCl4, 99%) and chloroplatinic acid (H2PtCl6, 99.9%) were purchased from AdamasBeta. Ethanol (EtOH, 99.7%), isopropanol (99.7%), and N,N-Dimethylformamide (DMF, 99.5%) were purchased from Sinopharm Chemical Reagent Co. Ltd. (Shanghai, China). Sodium citrate dihydrate (Na3Citrate·2H2O, 99.0%) was purchased from Macklin. Polyvinyl pyrrolidone (PVP, MW=30000) was purchased from Shanghai yuanye Bio-Technology Co., Ltd. Sodium iodide (NaI, 99.2%) was purchased from Bide Pharmatech Ltd. HCl (36~38%) was purchased from Yonghua Chemical Co., Ltd. To prepare 10 mM H2PdCl4 solution, 0.355 g of PdCl2 was dissolved with 20 mL of 0.2 M HCl solution in a 200 mL volumetric flask and further diluted to 200 mL by deionized (DI) H2O. K2HPO4/KH2PO4 electrolyte was prepared by dissolving K2HPO4 and KH2PO4 in DI H2O with total concentration of 0.1 M and a molar ratio of 72/28. All chemicals were used without further purification.

Synthesis of Pd nanowires

Pd nanowires were synthesized using a previously reported method with slight modification38. Typically, PdCl2 (17.7 mg), NaI (300 mg), PVP (800 mg), and 12.0 mL DI H2O were mixed, followed by ultrasonic treatment for 30 min and magnetic stirring for 12 h. The resulting homogeneous solution was then transferred to a 25 mL Teflon-lined autoclave and then maintained at 200 °C for 2 h. After cooling down to ~25°C, the products were cleaned with ethanol and DI H2O for several times and dispersed in 4 mL DI H2O for further use.

Synthesis of Pd4Ag nanowires

Pd4Ag nanowires were synthesized using a previously reported method20. Typically, 0.1 mM of dihexadecyldimethylammonium chloride was dissolved in 10 mL of DI H2O in a round-bottom flask, heated to and kept at 95 °C for 30 min. It was added with 2 mL of 10 mM AgNO3 and 8 mL of 10 mM H2PdCl4 to form a homogeneous solution, and then with 1 mL of freshly prepared 0.3 M ascorbic acid solution to initiate the co-reduction of Pd2+ and Ag+. After 40 min continuous reaction, the solution was naturally cooled down to ~25 °C. The final product was cleaned with isopropanol, ethanol and DI H2O for several times and dispersed in 2 mL ethanol for further use.

Synthesis of Pt nanowires

Pt nanowires were synthesized using a previously reported method with slight modification37. Typically, 0.1 M H2PtCl6 aqueous solution (400 μL) was added to a mixed solvent containing 12 mL EG, 12 mL DMF, and 700 mg KOH. After stirring for 30 min, the resulting solution was transferred into a 50 mL Teflon-lined autoclave and then maintained at 170 °C for 8 h. After cooling down to ~25 °C, the products were cleaned with ethanol and DI H2O for several times and then dispersed in 4 mL ethanol for further use.

Synthesis of Au nanoparticles

Au nanoparticles were synthesized using a previously reported method with slight modification60. Typically, 51.5 mg Na3Citrate·2H2O was dissolved in 200 mL DI water, and the mixture was then heated to boiling in an oil bath under magnetic stirring. 0.1 M HAuCl4 aqueous solution (500 μL) was then added into the Na3Citrate solution and the resulting mixture was kept in boiling for 10 min. After cooling down to ~25 °C, the products were collected by centrifugation and finally dispersed in 4 mL EtOH for further use.

Characterizations

XRD were conducted on a PANalytical X-ray diffractometer with a Cu Kα resource. XPS spectra were carried out on an Ultra DLD XPS spectrometer. The morphology of the as-synthesized nanomaterials were measured by TEM (JEM-2100). The morphology and thicknesses of on-chip films were measured by SEM (Hitachi S-4800) and AFM (Bruker Dimension Icon). The pH of electrolytes were measured by a pH meter (PB-10, Sartorius). ICP analysis was carried out on Aurora M90 inductively coupled plasma optical emission spectrometer.

Electrochemical CO2RR measurements

CO2RR measurements were performed at the temperature range of 23–25 °C in a custom-designed H-cell using the standard three-electrode system. The working electrode was a catalyst-loaded glassy carbon plate with a size of 1 × 1 cm2. For its preparation, 1 mg of catalyst powder, 0.5 mg of Ketjenblack carbon, and 6 µL of Nafion solution (5 wt%) were dispersed in 250 µL of ethanol, and subjected to ultrasonication for 30 min to form a homogeneous ink. The ink was then drop-casted onto the glassy carbon plate to achieve a catalyst areal loading of 1 mg/cm2. The working electrode and a saturated calomel reference electrode (SCE) were located at the cathodic compartment; a graphitic rod as the counter electrode was located at the anodic compartment. These two compartments were each filled with 25 mL of 0.1 M KHCO3 or 0.1 M K2HPO4/KH2PO4 (n(K2HPO4)/n(KH2PO4) = 72/28), and separated by a Nafion membrane. Before CO2RR measurements, the electrolyte was bubbled with high-purity CO2 (>99.999%) at 20 sccm for >40 min. During CO2RR measurements, the gas flow was maintained to ensure the CO2 saturation of the electrolyte. All potential readings were recorded in SCE and subsequently converted to RHE with necessary iR compensation. Chronoamperometric (i−t) curves were collected at selected potentials between −0.5–0 VRHE. Formate in the catholyte from CO2RR was analyzed using an ion chromatograph (Dionex ICS-600).

Preparation of free-standing films from nanowires and nanoparticles

The films were prepared using a previously reported method with slight modification35,40. In a typical self-assembly experiment for nanowires or nanoparticles films, 1 mL as-prepared EtOH dispersion of Pd4Ag, Pt, or Au was mixed with 2 mL H2O, followed by ultrasonication for 5 min. 2.5 mL n-butanol was then added into the mixture, followed by ultrasonication for another 1 min. The final suspension was then added drop by drop into a flask (about 7.5 cm in diameter) filled with Milli-Q water. A piece of catalyst film was finally formed at the water/air interface and was later transferred onto the Si wafer.

Fabrication of the devices

Devices were fabricated using a previously reported method35, as schematically illustrated in Fig. S4. Typically, Si wafer (p++ with 300 nm thermal oxide) with pre-patterned Au electrodes (Ti/Au, 20 nm/50 nm) was used as substrate. A poly(methyl methacrylate) (PMMA, A8, MicroChem Corp.) film (~1000 nm thick) was spin-coated on the Si wafer, and consequent E-beam lithography (EBL) was used to open windows with defined shape. The pre-prepared (by co-solvent evaporation) free-standing film of Pd4Ag, Pt, or Au (on the water surface) was then transferred into the window. To obtain the on-chip films with different thicknesses, the transfer process is repeated for 1–3 times. For a fine-controlled deposition, the substrate was treated by oxygen plasma before deposition. Due to the presence of a small amount of surfactant on the surface of nanowires even after centrifugation and cleaning, the preparation of free-standing films from the as-prepared Pd nanowires is hard to proceed. The Pd devices were fabricated by direct drop-casting of the Pd nanowires (dispersed in water) into the PMMA window. To obtain Pd devices with thin thicknesses, the dispersion of Pd nanowires were diluted by 6 or 24 times. After the removal of PMMA template, nanowires were then patterned on the device substrate with desired designs. To eliminate the influence of electrolyte and to avoid electrochemical reactions on the metal electrodes, another layer of PMMA (~500 nm thick, electrochemically inert) was then deposited on device with spin-coating. A smaller window that only exposes catalysts was opened by e-beam lithography. A drop (2 μL) of Nafion solution (0.1 wt% in EtOH) was added on the top of the sample to ensure its mechanical stability during electrochemical reactions. The final device, with exposed catalysts and PMMA-protected electrodes was used for on-chip electrochemistry and in situ electrical transport spectroscopy.

Concurrent voltammetry (CV) and conductance (ETS) measurements

Concurrent CV and ETS measurements were performed at the range of 23–25 °C, using a two-channel source-measure unit (SMU, Keysight B2902a). A first SMU channel was used as a potentiostat to perform the on-chip CV by applying the potential (VG) of source/drain electrode (acting as working electrode) as to the reference electrode (leak-free Ag/AgCl), while collecting the current (IG) through the counter electrode (platinum wire). A second SMU channel was used to record ETS signals by supplying a small bias potential (50 mV) between source and drain electrodes and collecting the electrically conductive current (ISD). For a typical measurement in this study, the Gate (Faradaic) current approaches several microamperes. Therefore, the in-device CV current may affect the ETS current and a background subtraction is needed before the data analysis (Fig. S3).

Computational method

The DFT calculations were performed using the revised Perdew-Burke-Ernzerhof functionals (RPBE)61 of generalized gradient approximation (GGA) implemented in the Vienna Ab-initio Simulation Package (VASP) code62,63. The projector-augmented wave (PAW) method64,65 was applied to describe the electron-ion interactions. A kinetic energy cutoff for the plane wave expansions was set to be 520 eV. The method of Methfessel-Paxton (MP) was applied and the width of the smearing was chosen as 0.2 eV. The supercell of (√13 × √7) R19° with five atomic layers was chosen to construct the Pd (111) surface, and two Pd atoms were replaced by Ag atoms in each atomic layer to construct the Pd4Ag surface. More than 10 Å of vacuum space was used to avoid the interaction of the adjacent images. For sampling the reciprocal space, k-points of Γ-centered 4 × 3 × 1 were used for surface calculations. All structures were fully relaxed until the force components were less than 0.03 eV·Å−1. Implicit solvent model was used in our calculations by VASPsol66,67. A Debye screening length of 9.61 Å was chosen, which corresponds to a bulk ion concentration of 0.1 M. The non-electrostatic parameter, TAU, was set to zero for the purpose of convergence.

The adsorption energy of CO is defined as:

where E*CO, E* and ECO are the total energy of the surface with adsorbed CO, pristine surface, and CO molecule in the gas phase, respectively.

The adsorption energy of H is defined as:

where E*H, E*, and EH2 are the total energy of the surface with adsorbed H, pristine surface and H2 molecule in the gas phase, respectively.

Data availability

The data supporting the conclusions of this study are available within the paper and its Supplementary Information. Additional data are available from the corresponding author upon reasonable request. Source data for Figs. 2–4 are provided with this paper. Source data are provided with this paper.

References

Durst, J. et al. New insights into the electrochemical hydrogen oxidation and evolution reaction mechanism. Energy Environ. Sci. 7, 2255–2260 (2014).

Eftekhari, A. & Fang, B. Electrochemical hydrogen storage: opportunities for fuel storage, batteries, fuel cells, and supercapacitors. Int. J. Hydrog. Energy 42, 25143–25165 (2017).

Serrapede, M., Pesce, G. L., Ball, R. J. & Denuault, G. Nanostructured Pd hydride microelectrodes: in situ monitoring of pH variations in a porous medium. Anal. Chem. 86, 5758–5765 (2014).

Lee, E., Lee, J. M., Koo, J. H., Lee, W. & Lee, T. Hysteresis behavior of electrical resistance in Pd thin films during the process of absorption and desorption of hydrogen gas. Int. J. Hydrog. Energy 35, 6984–6991 (2010).

Ding, M. et al. Highly sensitive chemical detection with tunable sensitivity and selectivity from ultrathin platinum nanowires. Small 13, 1602969 (2017).

Yang, F., Kung, S.-C., Cheng, M., Hemminger, J. C. & Penner, R. M. Smaller is faster and more sensitive: the effect of wire size on the detection of hydrogen by single palladium nanowires. ASC Nano 4, 5233–5244 (2010).

Oumellal, Y., Rougier, A., Nazri, G. A., Tarascon, J.-M. & Aymard, L. Metal hydrides for lithium-ion batteries. Nat. Mater. 7, 916–921 (2008).

Rebollar, L. et al. “Beyond adsorption” descriptors in hydrogen electrocatalysis. ACS Catal. 10, 14747–14762 (2020).

Sherbo, R. S., Delima, R. S., Chiykowski, V. A., MacLeod, B. P. & Berlinguette, C. P. Complete electron economy by pairing electrolysis with hydrogenation. Nat. Catal. 1, 501–507 (2018).

Sherbo, R. S., Kurimoto, A., Brown, C. M. & Berlinguette, C. P. Efficient electrocatalytic hydrogenation with a palladium membrane reactor. J. Am. Chem. Soc. 141, 7815–7821 (2019).

Caputo, R. & Alavi, A. Where do the H atoms reside in PdHx systems? Mol. Phys. 101, 1781–1787 (2003).

Tripodi, P., Gioacchino, D. D. & Vinko, J. D. AC electrical resistance measurements of PdHx samples versus composition x. J. Alloy. Compd. 486, 55–59 (2009).

Zhang, Y. & Kornienko, N. C≡N triple bond cleavage via transmembrane hydrogenation. Chem. Catal. 2, 499–507 (2022).

Gao, D. et al. Pd-containing nanostructures for electrochemical CO2 reduction reaction. ACS Catal. 8, 1510–1519 (2018).

Jiang, T.-W. et al. Spectrometric study of electrochemical CO2 reduction on Pd and Pd-B electrodes. ACS Catal. 11, 840–848 (2021).

Min, X. & Kanan, M. W. Pd-catalyzed electrohydrogenation of carbon dioxide to formate: high mass activity at low overpotential and identification of the deactivation pathway. J. Am. Chem. Soc. 137, 4701–5708 (2015).

Gao, D. et al. Switchable CO2 electroreduction via engineering active phases of Pd nanoparticles. Nano Res. 10, 2181–2191 (2017).

Zhu, W., Kattel, S., Jiao, F. & Chen, J. G. Shape-controlled CO2 electrochemical reduction on nanosized Pd hydride cubes and octahedra. Adv. Energy Mater. 9, 1802840 (2019).

Wang, Y. et al. Ensemble effect in bimetallic electrocatalysts for CO2 reduction. J. Am. Chem. Soc. 141, 16635–16642 (2019).

Han, N. et al. Alloyed palladium-silver nanowires enabling ultrastable carbon dioxide reduction to formate. Adv. Mater. 33, 2005821 (2021).

Zhou, Y. et al. Mesoporous PdAg nanospheres for stable electrochemical CO2 reduction to formate. Adv. Mater. 32, 2000992 (2020).

Chang, Q. et al. Boosting activity and selectivity of CO2 electroreduction by pre-hydridizing Pd nanocubes. Small 16, 2005305 (2020).

Gao, D. et al. Size-dependent electrocatalytic reduction of CO2 over Pd nanoparticles. J. Am. Chem. Soc. 137, 4288–4291 (2015).

Jiang, B., Zhang, X.-G., Jiang, K., Wu, D.-Y. & Cai, W.-B. Boosting formate production in electrocatalytic CO2 reduction over wide potential window on Pd Surfaces. J. Am. Chem. Soc. 140, 2880–2889 (2018).

Yuan, X. et al. Ultrathin Pd-Au shells with controllable alloying degree on Pd nanocubes toward carbon dioxide reduction. J. Am. Chem. Soc. 141, 4791–4794 (2019).

Bellini, M. et al. A gold–palladium nanoparticle alloy catalyst for CO oroduction from CO2 electroreduction. Energy Technol. 7, 1800859 (2019).

Sheng, W. et al. Electrochemical reduction of CO2 to synthesis gas with controlled CO/H2 ratios. Energy Environ. Sci. 10, 1180–1185 (2017).

Lee, J. H. et al. Tuning the activity and selectivity of electroreduction of CO2 to synthesis gas using bimetallic catalysts. Nat. Commun. 10, 3724 (2019).

Yang, T.-H. & Pyun, S.-I. Hydrogen absorption and diffusion into and in palladium: ac-impedance analysis under impermeable boundary conditions. Electrochim. Acta 41, 843–848 (1996).

Gabrielli, C., Grand, P. P., Lasia, A. & Perrot, H. Study of the hydrogen/palladium system by fast quartz microbalance techniques. Electrochim. Acta 47, 2199–2207 (2002).

Duncan, H. & Lasia, A. Separation of hydrogen adsorption and absorption on Pd thin films. Electrochim. Acta 53, 6845–6850 (2008).

Martin, M. H. & Lasia, A. Hydrogen sorption in Pd monolayers in alkaline solution. Electrochim. Acta 54, 5292–5299 (2009).

Vigier, F., Jurczakowski, R. & Lasia, A. Determination of hydrogen absorption isotherm and diffusion coefficient in Pd81Pt19 alloy. J. Electroanal. Chem. 588, 32–43 (2006).

Dekura, S. et al. The electronic state of hydrogen in the α phase of the hydrogen-storage material PdH(D)x: does a chemical bond between palladium and hydrogen exist? Angew. Chem. Int. Ed. 57, 9823–9827 (2018).

Ding, M. et al. An on-chip electrical transport spectroscopy approach for in situ monitoring electrochemical interfaces. Nat. Commun. 6, 7867 (2015).

Ding, M. et al. On-chip in situ monitoring of competitive interfacial anionic chemisorption as a descriptor for oxygen reduction kinetics. ACS Cent. Sci. 4, 590–599 (2018).

Xia, B. Y., Wu, H. B., Yan, Y., Lou, X. W. & Wang, X. Ultrathin and ultralong single-crystal platinum nanowire assemblies with highly stable electrocatalytic activity. J. Am. Chem. Soc. 135, 9480–9485 (2013).

Huang, X. & Zheng, N. One-pot, high-yield synthesis of 5-Fold twinned Pd nanowires and nanorods. J. Am. Chem. Soc. 131, 4602–4603 (2009).

Lv, H., Wang, Y., Lopes, A., Xu, D. & Liu, B. Ultrathin PdAg single-crystalline nanowires enhance ethanol oxidation electrocatalysis. Appl. Catal. B Environ. 249, 116–125 (2019).

Mu, Z. et al. On-chip electrical transport investigation of metal nanoparticles: characteristic acidic and alkaline adsorptions revealed on Pt and Au surface. J. Phys. Chem. Lett. 11, 5798–5806 (2020).

Yang, F., Donavan, K. C., Kung, S.-C. & Penner, R. M. The surface scattering-based detection of hydrogen in air using a platinum nanowire. Nano Lett. 12, 2924–2930 (2012).

Jansonius, R. P. et al. Strain influences the hydrogen evolution activity and absorption capacity of palladium. Angew. Chem. Int. Ed. 59, 12192–12198 (2020).

Barton, J. C., Lewis, F. A. & Woodward, M. Hysteresis of the relationships between electrical resistance and the hydrogen content of palladium. Trans. Faraday Soc. 59, 1201–1207 (1963).

Ke, X. & Kramer, G. J. Absorption and diffusion of hydrogen in palladium-silver alloys by density functional theory. Phys. Rev. B 66, 184304 (2002).

Tóth, J., Garaguly, J., Péter, L. & Tompa, K. Resistivity changes during hydrogenation of Pd80Ag20 alloy in non-equilibrium circumstances. J. Alloy. Compd. 312, 117–120 (2000).

Czerwiński, A., Kiersztyn, I., Grdeń, M. & Czapla, J. The study of hydrogen sorption in palladium limited volume electrodes (Pd-LVE) I. Acidic solutions. J. Electroanal. Chem. 471, 190–195 (1999).

Czerwiński, A., Kiersztyn, I. & Grdeń, M. The study of hydrogen sorption in palladium limited volume electrodes (Pd-LVE) Part II. Basic solutions. J. Electroanal. Chem. 492, 128–136 (2000).

Horkans, J. The hydrogen region of the cyclyc voltammetry of Pd: the effect of pH and anion. J. Electroanal. Chem. 209, 371–376 (1986).

Zhou, Z. et al. Electrocatalytic hydrogen evolution under neutral pH conditions: current understandings, recent advances, and future prospects. Energy Environ. Sci. 13, 3185–3206 (2020).

Marcandalli, G., Goyal, A. & Koper, M. T. M. Electrolyte effects on the Faradaic efficiency of CO2 reduction to CO on a gold electrode. ACS Catal. 11, 4936–4945 (2021).

Jackson, M. N., Jung, O., Lamotte, H. C. & Surendranath, Y. Donor-dependent promotion of interfacial proton-coupled electron transfer in aqueous electrocatalysis. ACS Catal. 9, 3737–3743 (2019).

Ryu, J. & Surendranath, Y. Polarization-induced local pH swing promotes Pd-catalyzed CO2 hydrogenation. J. Am. Chem. Soc. 142, 13384–13390 (2020).

Moreno-Gonzalez, M. et al. Sulfuric acid electrolyte impacts palladium chemistry at reductive potentials. Chem. Mater. 32, 9098–9106 (2020).

Greeley, J. & Mavrikakis, M. Surface and subsurface hydrogen: adsorption properties on transition metals and near-surface alloys. J. Phys. Chem. B 109, 3460–3471 (2005).

Birry, L. & Lasia, A. Effect of crystal violet on the kinetics of H sorption into Pd. Electrochim. Acta 51, 3356–3364 (2006).

Singh, N. et al. Aqueous phase catalytic and electrocatalytic hydrogenation of phenol and benzaldehyde over platinum group metals. J. Catal. 382, 372–384 (2020).

Cleghorn, S. J. C. & Pletcher, D. The mechanism of electrocatalytic hydrogenation of organic molecules at palladium black cathodes. Electrochim. Acta 38, 425–430 (1993).

Zhu, S., Qin, X., Yao, Y. & Shao, M. pH-dependent hydrogen and water binding energies on platinum surfaces as directly probed through surface-enhanced infrared absorption spectroscopy. J. Am. Chem. Soc. 142, 8748–8754 (2020).

Cheng, G. et al. Critical role of solvent-modulated hydrogen-binding strength in the catalytic hydrogenation of benzaldehyde on palladium. Nat. Catal. 4, 976–985 (2021).

Ji, X. et al. Size control of gold nanocrystals in citrate reduction: the third role of citrate. J. Am. Chem. Soc. 129, 13939–13948 (2007).

Hammer, B., Hansen, L. B. & Nørskov, J. K. Improved adsorption energetics within density-functional theory using revised Perdew-Burke-Ernzerhof. Phys. Rev. B 59, 7413–7421 (1999).

Botana, A. S. & Norman, M. R. Electronic structure and magnetism of transition metal dihalides: Bulk to monolayer. Phys. Rev. Mater. 3, 044001 (2019).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Kresse, G. & Hafner, J. Norm-conserving and ultrasoft pseudopotentials for first-row and transition elements. J. Phys. Condens. Matter, 6, 8245 (1994).

Blöchl, P. E., Jepson, O. & Anderson, O. K. Improved tetrahedron method for Brillouin-zone integrations. Phys. Rev. B 49, 16223 (1994).

Mathew, K., Sundararaman, R., Letchworth-weaver, K., Arias, T. A. & Hennig, R. G. Implicit solvation model for density-functional study of nanocrystal surfaces and reaction pathways. J. Chem. Phys. 140, 084106 (2014).

Mathew, K., Chaitanya Kolluru, V. S., Mula, S., Steinmann, S. N. & Hennig, R. G. Implicit self-consistent electrolyte model in plane-wave density-functional theory. J. Chem. Phys. 151, 234101 (2019).

Acknowledgements

We thank Xinnan Mao and Dr. Lu Wang for the assistance in DFT calculations. We acknowledge the support by the Natural Science Foundation of China (Project No. 22172075 and No. 92156024 to M.D.), the Fundamental Research Funds for the Central Universities in China (Project No. 14380273 and No. 0210/14380174 to M.D.), Natural Science Foundation of Jiangsu Province (Project No. BK20220069 to M.D.), Beijing National Laboratory for Molecular Sciences (Project No. BNLMS202107 to M.D.) and National Natural Science Foundation of China (Project No. 21902114 to N.H.).

Author information

Authors and Affiliations

Contributions

M.D. and Z.M. designed the research. M.D., Y.L., Z.M., and N.H. supervised the research. Z.M. carried out the device fabrication, ETS measurements, and investigations. N.H. carried out material preparations and CO2RR measurements. Z.M. and M.D. analyzed the data. D.X., B.T., F.W., Y.W., Y.S., C.L., and X.W. contributed to characterization of catalysts. P.Z. provided instrumental assistance for the micro-fabrication. Z.M., N.H., Y.L., and M.D. co-wrote the paper. All authors have read and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mu, Z., Han, N., Xu, D. et al. Critical role of hydrogen sorption kinetics in electrocatalytic CO2 reduction revealed by on-chip in situ transport investigations. Nat Commun 13, 6911 (2022). https://doi.org/10.1038/s41467-022-34685-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-34685-9

This article is cited by

-

Copper-based catalysts for carbon monoxide electroreduction to multicarbon products

Science China Materials (2024)

-

Electronic structural engineering of bimetallic Bi-Cu alloying nanosheet for highly-efficient CO2 electroreduction and Zn-CO2 batteries

Nano Research (2024)

-

Molecule-based vertical transistor via intermolecular charge transport through π-π stacking

Nano Research (2024)

-

The practice of reaction window in an electrocatalytic on-chip microcell

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.