Abstract

The widespread use of phosphine ligand libraries is frequently hampered by the challenges associated with their modular preparation. Here, we report a protocol that appends arenes to arylphosphines to access a series of biaryl monophosphines via rhodium-catalyzed P(III)-directed ortho C–H activation, enabling unprecedented one-fold, two-fold, and three-fold direct arylation. Our experimental and theoretical findings reveal a mechanism involving oxidative addition of aryl bromides to the Rh catalyst, further ortho C–H metalation via a four-membered cyclometalated ring. Given the ready availability of substrates, our approach opens the door to developing more general methods for the construction of phosphine ligands.

Similar content being viewed by others

Introduction

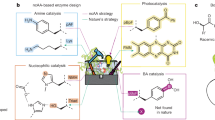

Phosphines have found numerous applications in all facets of chemical science1,2,3,4,5. Among them, biaryl monophosphines have emerged as a class of privileged ligands for transition metals in a variety of transformations, especially in cross-coupling reactions6,7,8,9,10,11. To date, multiple generations of biaryl monophosphines have been designed by Buchwald12,13 and other groups14,15,16,17, and many of them are now commercialized (Fig. 1a). Traditionally, these compounds can be produced via a one-pot protocol through the addition of an aryl metal reagent to an in situ-generated benzyne, then phosphination of intermediate with a chlorophosphine reagent enabled by a copper catalyst (Fig. 1b)18. This approach is efficient, but its use in sensitive organometallic species is often limited, requiring preinstallation of halides into the substrates and complicated operating steps. Compared to traditional coupling methods, the direct arylation strategy through C–H activation has emerged as a valuable methodology that enables the formation of biaryl compounds with excellent atom and step economy19,20,21,22,23. We hypothesized that the catalytic arylation of C–H bond in phosphines might allow an alternative, but a far easier path to biaryl monophosphines.

Typically, the assistance of metal-coordinating directing groups in substrates can lead to excellent regioselectivity24,25,26,27,28,29,30. Within this paradigm, transition metal-catalyzed C–H arylation of phosphine oxides through O-chelation has been developed to build biaryl monophosphines31,32,33,34,35. However, this method requires additional steps for preinstallation and removal of O atoms. Due to the strong coordination between transition metals and P(III) atoms, arylphosphines have long been known to form four-membered chelate rings via ortho C–H metalation, but catalytic variants represent a critical challenge36. Until recently, we and Takaya group have respectively reported catalytic ortho C–H borylation37,38 and silylation39 of arylphosphines. However, a further palladium-catalyzed Suzuki–Miyaura or Hiyama cross-coupling with aryl halides needs to be used for construction of biaryl monophosphines. Therefore, direct arylation of arylphosphines to access diverse biaryl monophosphines in a catalytic fashion is still in high demand.

Here, we report a rhodium-catalyzed P(III)-directed C–H activation of arylphosphines with aryl halides to rapidly access a library of biaryl monophosphines. Notably, onefold, twofold, and threefold C–H activation can proceed by steric control of aryl bromides, providing biaryl monophosphine ligands with sterically encumbered architectures and electronically tuned substituents in a tunable way (Fig. 1c). In the first C–H arylation, the reaction proceeds via a four-membered chelate ring of arylphosphines, and the second and third arylation of the in situ formed biaryl phosphines via a six-membered chelate ring40,41,42,43. Therefore, the use of sterically hindered aryl bromides only can show one-fold C–H activation; Treatment of aryl bromides with moderate size can undergo two-fold C–H activation; The selection of aryl bromides only with para-substituents can lead to three-fold C–H activation.

Results

Reaction design

Our investigation began with the direct arylation of PPh3 (1a) using a sterically hindered aryl bromide 2a (Table 1). Treatment of [Rh(cod)Cl]2 (2.5 mol%) as the catalyst along with K2CO3 (2.0 equiv) as the base in THF at 130 °C for 24 h allowed us to get the desired coupling product 3aa in 21% yield through onefold C–H activation (entry 1). The solvent effect was then evaluated, and 1,4-dioxane proved to be the best (entries 2-3). Further increasing the stoichiometric amount of base to 5.0 equiv is critical to the high conversion of the reaction (entry 4). It should be noted that increasing the concentration of reaction components can enhance the reactivity, affording product 3aa in 77% yield (entry 5). Other bases such as Na2CO3 and Li2CO3 showed much lower results for this reaction (entries 6–7), and the use of LiOtBu also maintained good reactivity leading to compound 3aa in 74% yield (entry 8). Under these reaction conditions, conducting the reaction at 110 °C led to a lower conversion (entry 9). Other rhodium sources, such as [Rh(coe)2Cl]2 and [Rh(OAc)2]2, were also effective for this transformation, albeit with lower yields (entries 10–11). However, other transition metals, such as [Ir(cod)Cl]2 and Pd(OAc)2, failed to trigger this transformation (entries 12–13). In addition to aryl bromide, aryl iodide 2a’ could be coupled with PPh3 (1a), affording the product 3aa in 62% yield (entry 14).

Scope of the methodology

With optimized reaction conditions in hand, we first explored the scope of one-fold direct arylation between tertiary phosphines 1 and arylbromides 2 (Fig. 2). Using PPh3 (1a) as the coupling partner, arylbromides 2b-c bearing sterically hindered benzhydryl and silyl ether groups at the meta positions formed desired products 3ab-ac with good efficiency. Less sterically hindered arylbromides 2d-e and bromonaphthalene 2f were also compatible with excellent chemoselectivity, and twofold C–H activation could be inhibited by shortening the reaction time and lowering the reaction temperature. Importantly, the selection of OMe at ortho position of arylbromides had a strong impact on the reactivity, other functional groups such as NMe2, SMe, and Ac led to very low conversions under the current reaction conditions. In addition, the reaction is also amenable to 9-bromophenanthrene (2g) and 3,5-di-substituted arylbromides 2h-i, affording desired products 3ag-ai in 60–75% yields. Subsequently, a variety of triarylphosphines were investigated with arylbromide 2a. Triarylphosphines are generally competent, with a diverse range of electron-neutral (3ba-bc), electron-donating (3da-3ea), and electron-withdrawing (3fa-3ga) groups.

We next sought to evaluate the scope of the two-fold C–H activation by steric control of aromatic halides (Fig. 3). We were pleased to find that two molecules of 2-bromoanisole (1j) could participate in this reaction through tandem C–H activation to generate product 3aj in 77% yield under slightly modified reaction conditions. To determine the structure, a crystal of compound 3aj was generated and subjected to X-ray crystallographic analysis. Bromoanisole analogs 1k and 1l with F and Cl at the para position also generated desired products 3ak and 3al in 72% and 61% yields, respectively. Gratifyingly, substrate 1m with a fluorene motif can be utilized in this transformation as well, generating product 3am in 62% yield together with a monoarylation byproduct in trace amounts.

We further turned our attention to direct arylation of phosphines through threefold C–H activation (Fig. 4). Treatment of the simple bromoarene 2n, PPh3 (1a) could be arylated with three molecules of 2n, providing compound 3an in 66% yield. It’s noted that the use of tBuOLi showed much higher reactivity than that of K2CO3 in these reaction conditions. This approach has a good substrate scope and is tolerant of a range of substituents in para positions of the aromatic ring. A broad range of bromoarenes bearing Me (1o), OMe (1p), F (1q), Cl (1r), and CF3 (1s) substituents underwent threefold direct arylation and gave the corresponding products 3ao-at in 51-73% yield. In addition, bromoferrocene (1t) was successfully introduced into the phosphine framework, affording the compound 3at with three ferrocene motifs. The structures of products 3ap and 3at were respectively confirmed by X-ray analysis.

We also sought to explore the cascade C–H arylation of arylphosphines with two different aryl bromides. However, a mixture of biaryl phosphines was generated, because the excess amount of aryl halides needs to be employed. To solve this issue, we conducted the first direct arylation with PPh3 (1a) and aryl bromide 2f in the presence of rhodium catalyst. The desired product 3af was isolated in 45% yield, which could be arylated with another aryl bromide 2o through C–H activation to provide biaryl phosphine 3afo efficiently (Fig. 5).

Discussion

To gain insight into the reaction pathway, some mechanistic experiments were performed (Fig. 6). The reaction of [Rh(cod)Cl]2 with PPh3 (1a) in 1,4-dioxane formed the well-known Wilkinson’s catalyst, which could further react with aryl bromide 2a to give product 3aa in 67% yield (Fig. 6a). This result indicated that the complex was a visible intermediate in this catalytic reaction. In addition, a kinetic isotope effect (KIE) of 2.4 was observed from five parallel reactions of 1a/d-1a with aryl bromide 2a, suggesting that the C–H cleavage step was rate-determining (Fig. 6b)44.

To better understand the selective C‒H direct arylation process, density functional theory (DFT) calculations45,46,47,48 were conducted with model substrates 1a and 2a (Fig. 7). Initially, the dimer Rh catalyst is associated with 1a to form Wilkinson’s catalyst, which then undergoes ligand exchange to generate four-coordinate complex INT1A. Bromoarene 2a coordinates with the Rh center to form intermediate INT2A through an energy barrier of 31.4 kcal mol−1, which facilitates subsequent C‒Br bond cleavage (black line, Fig. 7a). Ortho-C‒H metalation is a competitive pathway for the oxidative addition of the C‒Br bond (blue line, Fig. 7a). The ortho-C‒H bond undergoes oxidative addition to the Rh(I) center through transition state TS2B with a free energy of 41.7 kcal·mol−1, which is 9.3 kcal mol−1 higher than transition state TS3A (41.7 kcal mol−1 vs 32.4 kcal mol−1). These calculated results indicate that the most favorable pathway involves the oxidative addition of the C‒Br bond to the rhodium(I) center, resulting in intermediate INT3A. Then, INT3A occurs ortho-C‒H metalation to form INT5A through a concerted metalation deprotonation (CMD) process49,50,51,52 with a 31.5 kcal mol−1 energy barrier (Fig. 7b). This process possesses very similar high energy to the C-Br bond oxidative addition (32.3 kcal mol−1 vs. 32.4 kcal mol−1). Furthermore, the calculation for a deuterated transition state of TS4A was also performed (see Supporting Information). The energy barrier of C-D metalation is 0.9 kcal mol−1 higher than that of C-H, in consistent with the experimental KIE results, illustrating that C-H metalation is involved in the rate-determining step. K2CO3 as a base was found to be indispensable in this transformation, which abstracts a Br atom and a proton from complex INT4A in a concerted manner via transition state TS6A with an energy barrier of only 5.0 kcal mol−1. Followed by reductive elimination, the aryl group connected with Rh(III) center transfers to the ortho-position of phosphines to deliver intermediate INT7A. The excess amount of 2a then coordinates at the vacant site of INT7A to generate intermediate INT8A. Finally, the C-Br bond oxidative addition and further ligand exchanges occur to result in the formation of the desired product 3aa and the regeneration of catalyst INT3A to complete the catalytic cycle.

a DFT-computed free energies of the two competitive pathways for C-Br and C-H bond oxidative addition. b The free energy profiles for the catalytic cycle of the onefold direct arylation. Energies are in kcal mol−1 and bond lengths are in Å. The energies were computed at the M06/SDD-6-311 + G(d, p)/SMD (solvent = 1,4-dioxane) level of theory, with geometries optimized at the B3LYP/SDD–6-31 G(d) level.

Subsequently, DFT calculations were conducted to investigate the chemoselectivity of twofold arylation (Fig. 8). Using bromoarene 2a with sterically hindered substituents at the meta positions as the substrate, ligand exchange of INT10A with 1a is found to be a favorable process, and its barrier height is 11.2 kcal mol−1 lower than the C‒H metalation through six-membered cyclic transition state TS11A (18.2 kcal mol−1 vs 29.4 kcal mol−1), suggesting that onefold arylation will proceed to the end until 1a was completely consumed out (Fig. 8a). In addition, the meta-substitutions of bromoarenes increase the difficulty of the second reductive elimination, making the activation barrier of transition state TS14A as high as 35.6 kcal mol−1. Therefore, controlling the reaction time and increasing the steric hindrance of meta-substituents could effectively tune the chemoselectivity. Instead, using bromoarene 2j as the substrate, the reductive elimination of intermediate INT13A-2j proceeds smoothly via transition state TS14A-2j with an energy barrier of 22.5 kcal mol−1, thus producing the twofold arylation product 3aj, in accordance with the experimental results (Fig. 8b)40. The second arylation on different sites was also calculated (Fig. 8c). The ortho’-C-H activation undergoes a CMD process through six-membered cyclic transition state TS11A-2j with a free energy of 32.2 kcal mol−1, which is much lower than that of four-membered cyclic transition state TS11B-2j (42.8 kcal mol−1) and TS11C-2j (42.5 kcal mol−1). In the disfavored transition states TS11B-2j and TS11C-2j, the dihedral angle of biphenyl is deformed to 75.1° and 64.3°, respectively, indicating the distinct repulsion between the incorporated aryl group and second aryl group of P, thus increasing the activation energy barriers to >40 kcal/mol.

a the calculated key transition states and intermediates for the twofold direct arylation of PPh3 and 2a. b the calculated key transition states and intermediates for the twofold direct arylation of PPh3 and 2j. c DFT-computed free energies for the three competitive C-H metalation pathways in the second-fold direct arylation of PPh3 with 2j. Energies are in kcal mol−1 and bond lengths are in Å.

The use of tBuOLi as the base in the threefold C‒H arylation was studied as well (Fig. 9). The above-used K2CO3 showed lower reactivity than tBuOLi in this transformation. In the onefold arylation process, the ortho-substituents of bromoarene donate electron effect into the vacant d orbital of Rh, which facilitates the dissociation of oxygen connected with Rh and increases the alkalinity of the carbonate, thus making the energy barrier of the CMD process lower to 31.5 kcal mol−1. However, the bromoarene without ortho-substituents are suitable substrates in the threefold arylation process, the carbonate-assisted CMD process via TS4A-1 has an energy barrier of 37.7 kcal mol−1, which is much higher than the corresponding process in onefold C-H arylation (37.7 kcal mol−1 vs 31.5 kcal mol−1). For the LiOtBu used in the experiment, anion-assisted CMD transition state TS4A-2n is calculated to be 36.3 kcal mol−1 in energy relative to INT1A-2n, indicating that the mechanism of alkoxy base assisted CMD process is also difficult. To explore a more plausible reaction mechanism, the C‒H bond oxidative addition with Rh(I) through transition state TS2B-2n was also calculated. This step is more favorable, since the free energy of rate-determining step is 33.9 kcal·mol−1 relative to INT1A-2n, which is 1.5 kcal·mol−1 higher than the overall barrier of 32.4 kcal mol−1 in onefold arylation. This explains well that the threefold arylation is able to proceed well when the reaction temperature was elevated from 130 to 150 °C. The whole energy profiles for the threefold C‒H arylation have been shown in Supporting Information.

In summary, we have developed an effective method for the direct arylation of arylphosphines with aryl bromides enabled by rhodium catalysts. The reaction can proceed through onefold, twofold, and threefold C–H activation by steric control of aromatic halides, affording a series of biarylphosphine ligands with architecture and electronically tuned substituents. Mechanistic experiments and density functional theory calculations showed the preferred pathway for this tunable direct arylation process. Further applications of the developed phosphine ligand library, as well as other C–H functionalization of arylphosphines, are underway.

Methods

General procedures for synthesis of 3

To an oven-dried Schlenk tube, arylphosphines 1 (1.0 equiv, 0.20 mmol), arylbromides 2 (3.0 equiv, 0.60 mmol), [Rh(cod)Cl]2 (2.5 mol%, 2.5 mg, 0.005 mmol), K2CO3 (5.0 equiv, 138 mg, 1.0 mmol) were dissolved in 1,4-dioxane (0.3 mL). The mixture was stirred at 130 °C under argon for 24 h. Upon the completion of the reaction, the solvent was removed. The crude mixture was directly subjected to column chromatography on silica gel using petroleum-ether/EtOAc as eluent to give the desired products 3.

Data availability

The crystallography data have been deposited at the Cambridge Crystallographic Data Center (CCDC) under accession number CCDC: 2082986 (3aj), 2082987 (3ap), 2082989 (3at) and can be obtained free of charge from www.ccdc.cam.ac.uk/getstructures.

References

Rodriguez, J. B. & Gallo-Rodriguez, C. The role of the phosphorus atom in drug design. ChemMedChem 14, 190–216 (2019).

Seweryn, P. et al. Structural insights into the bacterial carbon–phosphorus lyase machinery. Nature 525, 68–72 (2015).

Hilton, M. C. et al. Heterobiaryl synthesis by contractive C-C coupling via P(V) intermediates. Science 362, 799–804 (2018).

Zhang, X. et al. Phosphorus-mediated sp2–sp3 couplings for C–H fluoroalkylation of azines. Nature https://doi.org/10.1038/s41586-021-03567-3 (2021).

Schlummer, B. & Scholz, U. Palladium-catalysed C–N and C–O coupling–a practical guide from an industrial vantage point. Adv. Syn. Cat. 346, 1599–1626 (2004).

Lian, Z., Bhawal, B. N., Yu, P. & Morandi, B. Palladium-catalysed carbon-sulfur or carbon-phosphorus bond metathesis by reversible arylation. Science 356, 1059–1063 (2017).

Fernández-Pérez, H., Etayo, P., Panossian, A. & Vidal-Ferran, A. Phosphine−phosphinite and phosphine−phosphite ligands: preparation and applications in asymmetric catalysis. Chem. Rev. 111, 2119–2176 (2011).

Pereira, M. M., Calvete, M. J. F., Carrilho, R. M. B. & Abreu, A. R. Synthesis of binaphthyl based phosphine and phosphite ligands. Chem. Soc. Rev. 42, 6990–7027 (2013).

Genet, J.-P., Ayad, T. & Ratovelomanana-Vidal, V. Electron-deficient diphosphines: the impact of DIFLUORPHOS in asymmetric catalysis. Chem. Rev. 114, 2824–2880 (2014).

Ruiz-Castillo, P. & Buchwald, S. L. Applications of palladium-catalysed C–N cross-coupling reactions. Chem. Rev. 116, 12564–12649 (2016).

Sather, A. C. & Buchwald, S. L. The evolution of Pd0/PdII-catalysed aromatic fluorination. Acc. Chem. Res. 49, 2146–2157 (2016).

Martin, R. & Buchwald, S. L. Palladium-catalysed Suzuki-Miyaura cross-coupling reactions employing dialkylbiaryl phosphine ligands. Acc. Chem. Res. 41, 1461–1473 (2008).

Ingoglia, B. T., Wagen, C. C. & Buchwald, S. L. Biaryl monophosphine ligands in palladium-catalysed C-N coupling: an updated User’s guide. Tetrahedron 75, 4199–4211 (2019).

Hayashi, T. Chiral monodentate phosphine ligand MOP for transition-metal-catalysed asymmetric reactions. Acc. Chem. Res. 33, 354–362 (2000).

Rodriguez, S. et al. Dihydrobenzooxaphosphole-based monophosphorus ligands for palladium-catalysed amination reactions. Adv. Syn. Cat. 353, 533–537 (2011).

Muriel., B., Orcel., U. & Waser, J. Palladium-catalysed carboamination of allylic alcohols using a trifluoroacetaldehyde-derived tether. Org. Lett. 19, 3548–3551 (2017).

Ni, H., Chan, W.-L. & Lu, Y. Phosphine-catalysed asymmetric organic reactions. Chem. Rev. 118, 9344–9411 (2018).

Kaye, S., Fox, J. M., Hicks, F. A. & Buchwald, S. L. The use of catalytic amounts of CuCl and other improvements in the benzyne route to biphenyl-based phosphine ligands. Adv. Synth. Catal. 343, 789–794 (2018).

Alberico, D., Scott, M. E. & Lautens, M. Aryl−aryl bond formation by transition-metal-catalysed direct arylation. Chem. Rev. 107, 174–238 (2007).

McGlacken, G. P. & Bateman, L. M. Recent advances in aryl–aryl bond formation by direct arylation. Chem. Soc. Rev. 38, 2447–2464 (2009).

Ackermann, L., Vicente, R. & Kapdi, A. R. Transition-metal-catalysed direct arylation of (hetero)arenes by C−H bond cleavage.Angew. Chem. Int. Ed. 48, 9792–9826 (2009).

Bellina, F. & Rossi, R. Transition metal-catalysed direct arylation of substrates with activated sp3-hybridized C−H bonds and some of their synthetic equivalents with aryl halides and pseudohalides. Chem. Rev. 110, 1082–1146 (2010).

Baudoin, O. Transition metal-catalysed arylation of unactivated C(sp3)–H bonds. Chem. Soc. Rev. 40, 4902–4911 (2011).

Lyons, T. W. & Sanford, M. S. Palladium-catalysed ligand-directed C−H functionalization reactions. Chem. Rev. 110, 1147–1169 (2010).

Neufeldt, S. R. & Sanford, M. S. Controlling site selectivity in palladium-catalysed C–H bond functionalization. Acc. Chem. Res. 45, 936–946 (2012).

Engle, K. M., Mei, T.-S., Wasa, M. & Yu, J.-Q. Weak coordination as a powerful means for developing broadly useful C–H functionalization reactions. Acc. Chem. Res. 45, 788–802 (2012).

Colby, D. A., Tsai, A. S., Bergman, R. G. & Ellman, J. A. Rhodium catalysed chelation-assisted C–H bond functionalization reactions. Acc. Chem. Res. 45, 814–825 (2012).

Zhang, F. & Spring, D. R. Arene C–H functionalisation using a removable/modifiable or a traceless directing group strategy. Chem. Soc. Rev. 43, 6906–6919 (2014).

Huang, Z. et al. Transition metal-catalysed ketone-directed or mediated C–H functionalization. Chem. Soc. Rev. 44, 7764–7786 (2015).

Sambiagio, C. et al. A comprehensive overview of directing groups applied in metal-catalysed C–H functionalisation chemistry. Chem. Soc. Rev. 47, 6603–6743 (2018).

Ma, Y.-N., Li, S.-X. & Yang, S.-D. New approaches for biaryl-based phosphine ligand synthesis via P=O directed C–H functionalizations. Acc. Chem. Res. 50, 1480–1492 (2017).

Zhang, Z., Dixneuf, P. H. & Soulé, J.-F. Late stage modifications of P-containing ligands using transition-metal-catalysed C–H bond functionalisation. Chem. Commun. 54, 7265–7280 (2018).

Unoh, Y., Satoh, T., Hirano, K. & Miura, M. Rhodium(III)-catalysed direct coupling of arylphosphine derivatives with heterobicyclic alkenes: a concise route to biarylphosphines and dibenzophosphole derivatives. ACS Catal. 5, 6634–6639 (2015).

Liu, Z., Wu, J.-Q. & Yang, S.-D. Ir(III)-catalysed direct C–H functionalization of arylphosphine oxides: a strategy for MOP-Type ligands synthesis. Org. Lett. 19, 5434–5437 (2017).

Jang, Y.-S., Woźniak, L., Pedroni, J. & Cramer, N. Access to P- and axially chiral biaryl phosphine oxides by enantioselective CpxIrIII-catalysed C−H arylations. Angew. Chem. Int. Ed. 57, 12901–12905 (2018).

Mohra, F., Privér, S. H., Bhargava, S. K. & Bennett, M. A. Ortho-metallated transition metal complexes derived from tertiary phosphine and arsine ligands. Coord. Chem. Rev. 250, 1851–1888 (2006).

Wen, J. et al. Rhodium-catalysed PIII-directed ortho-C-H borylation of arylphosphines. Angew. Chem. Int. Ed. 58, 2078 (2019).

Fukuda, K., Iwasawa, N. & Takaya, J. Ruthenium-catalysed ortho C−H borylation of arylphosphines. Angew. Chem. Int. Ed. 58, 2850–2853 (2019).

Wen, J. et al. Revealing silylation of C(sp2)/C(sp3)–H bonds in arylphosphines by ruthenium catalysis. Angew. Chem. Int. Ed. 59, 10909 (2020).

Qiu, X., Wang, M., Zhao, Y. & Shi, Z. Rhodium(I)-catalysed tertiary phosphine directed C-H arylation: rapid construction of ligand libraries. Angew. Chem. Int. Ed. 56, 7233–7237 (2017).

Li, J.-W. et al. Ruthenium-Catalyzed Gram-Scale Preferential C−H Arylation of Tertiary Phosphine. Org. Lett. 21, 2885–2889 (2019).

Wang, L.-N. et al. Double ligands enabled ruthenium catalyzed ortho-C-H arylation of dialkyl biarylphosphines: straight and economic synthesis of highly steric and electron-rich aryl-substituted buchwald-type phosphine. Adv. Syn. Cat. 363, 2843–2849 (2021).

Wang, D. et al. Rhodium-catalysed direct hydroarylation of alkenes and alkynes with phosphines through phosphorous-assisted C-H activation. Nat. Commun. 10, 3539 (2019).

Simmons, E. M. & Hartwig, J. F. On the interpretation of deuterium kinetic isotope effects in C−H bond functionalizations by transition-metal complexes. Angew. Chem. Int. Ed. 51, 3066–3072 (2012).

Piou, T. et al. Correlating reactivity and selectivity to cyclopentadienyl ligand properties in Rh(III)-catalysed C-H activation reactions: an experimental and computational study. J. Am. Chem. Soc. 139, 1296–1310 (2017).

Yu, S. et al. Rhodium-catalysed C-H activation of phenacyl ammonium salts assisted by an oxidizing C-N bond: a combination of experimental and theoretical studies. J. Am. Chem. Soc. 137, 1623–1631 (2015).

Park, S. H. et al. Mechanistic studies of the rhodium-catalysed direct C-H amination reaction using azides as the nitrogen source. J. Am. Chem. Soc. 136, 2492–2502 (2014).

Mu, X. et al. Mechanistic insight into the rhodium-catalysed, P-directed selective C7 arylation of indoles: a DFT study. Mol. Catal. 495, 111147–111152 (2020).

Davies, D. L., Donald, S. M. & Macgregor, S. A. Computational study of the mechanism of cyclometalation by palladium acetate. J. Am. Chem. Soc. 127, 13754–13755 (2005).

García-Cuadrado, D. et al. Proton-abstraction mechanism in the palladium-catalysed intramolecular arylation: substituent effects. J. Am. Chem. Soc. 129, 6880–6886 (2007).

Lapointe, D. & Fagnou, K. Overview of the mechanistic work on the concerted metallation–deprotonation pathway. Chem. Lett. 39, 1118–1126 (2010).

Ackermann, L. Carboxylate-assisted transition-metal-catalysed C−H bond functionalizations: mechanism and scope. Chem. Rev. 111, 1315–1345 (2011).

Acknowledgements

We would like to thank the National Natural Science Foundation of China (Grants 22025104, 22171134, 21972064, and 21901111), the Fundamental Research Funds for the Central Universities (Grant 020514380254) for their financial support, and the “Innovation & Entrepreneurship Talents Plan” of Jiangsu Province for their financial support. We are also grateful to the High-Performance Computing Center (HPCC) of Nanjing University for doing the numerical calculations in this paper on its blade cluster system. The project was also supported by Open Research Fund of School of Chemistry and Chemical Engineering, Henan Normal University.

Author information

Authors and Affiliations

Contributions

Z.S. conceived and designed the study, and wrote the paper. D.W. and M. L. performed the experiments, mechanistic studies, and analyzed the data. C.S. guided the study and made contributions during the revision. M.W. and Y. L. performed the DFT calculations. Y.Z. performed the crystallographic studies.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, D., Li, M., Shuang, C. et al. Rhodium-catalyzed selective direct arylation of phosphines with aryl bromides. Nat Commun 13, 2934 (2022). https://doi.org/10.1038/s41467-022-30697-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-30697-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.