Abstract

Functionalized, high-generation (G7) polyamidoamine (PAMAM) dendrimers are a convenient scaffold for the fully automated enzymatic synthesis of oligosaccharides such as biologically important sialyl Lewis X tetrasaccharide derivatives. In this study, we expanded this strategy to the synthesis of more complicated glycopeptides by assessing the feasibility of G7 PAMAM dendrimer-based polymer supports for attaching glycopeptide intermediates during the subsequent enzymatic modification steps. A monosaccharide-attached glycopeptide containing an N-terminal heterobifunctional linker was prepared by microwave-assisted solid-phase synthesis and was coupled with an aminooxy-functionalized G7 PAMAM dendrimer through oxime bond formation. This reaction proceeded smoothly at pH 4 and afforded the conjugates in 98% yield when 0.2 equivalents of the glycopeptide were combined with 1 equivalent of the aminooxy group of dendrimer. Although modifications using recombinant human β1,4-galactosyltransferase/uridine-5′-diphospho-α-D-galactose disodium salt and recombinant rat α2,3-sialyltransferase/cytidine-5′-monophospho-β-D-N-acetylneuraminic acid disodium salt gave the trisaccharide Neu5Acα2,3Galβ1,4GlcNAc in quantitative yields, treatment with recombinant human α1,3-fucosyltransferase in the presence of excess guanosine 5′-diphospho-β-L-fucose disodium salt did not convert this trisaccharide into the tetrasaccharide sialyl Lewis X tetrasaccharide on the dendrimer. Further optimization studies are required to improve the efficiency of branched-type sugar elongations and product release from polymers by selective peptidases for constructing a high-throughput glycopeptide synthetic system.

Similar content being viewed by others

Introduction

Protein glycosylation is one of the most important post-translational modifications in proteins, and it contributes to the structural control and biological functions involved in differentiation, cell–cell recognition, inflammation, immune response and tumor metastasis.1 Synthetic glycopeptides are, therefore, convenient tools that are necessary not only for biological research but also for pharmaceutical developments and diagnostic applications.2, 3, 4 Glycopeptides carrying small-sized glycans, such as mono- and disaccharide side chains, can be synthesized using general, solid-phase peptide synthesis protocols.5 However, the synthesis of glycopeptides containing longer, more complicated glycans often involve extremely difficult and challenging processes, because the chemical synthesis of large oligosaccharides (glycosides) routinely requires multi-step chemical manipulations based on selective protection–deprotection of the multiple hydroxyl groups present in each sugar residue to achieve regio- and stereoselective glycosylations.6, 7, 8 As a result, purification of individually pure glycosides requires tedious and time-consuming multi-step chromatographic separation procedures.

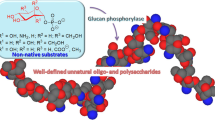

On the contrary, enzymatic oligosaccharide synthesis has the ability to accomplish regio- and stereoselective glycosylations for glycosyl acceptors in aqueous solution to generate the desired elongated glycoform.9, 10, 11, 12, 13, 14, 15 In present, despite a small repertoire of commercially available glycosyltransferases limiting the synthetic potential, enzymatic approaches allow for the exhaustive modification of various types of substrates containing common glycosyl acceptor moieties (non-reducing sugar residues).16, 17 As Zehavi et al.18 communicated the availability of glucose/cellobiose-attached polyacrylamide beads through the light-sensitive aglycon during enzymatic sugar elongation, various solid supports—such as water-compatible polyacrylamide gel,19, 20 sepharose21, 22 and polyethylene glycol polyacrylamide23—were also tested as alternate solid support materials. The polymer-supported synthesis has three major advantages: (a) promotion of the reactions using excess reactants and/or reagents, (b) releasing products from the supporting material by selective cleavage of the designated linker moiety, and (c) easy separation of small molecules from the polymer supports. However, the enzymatic glycosylation of acceptor substrates linked to the rigid solid supports provided low yields, which is clearly due to the poor accessibility of the macromolecular catalysts to the sugar moiety. Thus, little effort has been made to perform chemical and enzymatic glycopeptide syntheses on an entirely solid-phase platform.24, 25 Although designing focused on compound libraries that possess various and complicated O-glycans is crucial for discovering disease-relevant mucin glycopeptides,26, 27 no standardized protocol for versatile enzymatic synthesis has been established using a polymer support.

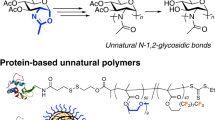

As the natural biosynthesis of glycans attached to the flexible proteins in the Golgi apparatus is achieved by combining a series of membrane-associated glycosyltransferases with soluble globular proteins as acceptor substrates, we considered that mimicking this biosynthetic system may create an ideal enzymatic glycan synthesis mechanism with regard to the reaction efficiency and throughput of the entire protocol. We have demonstrated previously that water-soluble polyacrylamide-based supports, such as glycoprotein models,28 facilitate the efficient chemical and enzymatic synthesis of oligosaccharide derivatives29, 30, 31, 32 in very high yields. It was also revealed that the combined use of certain artificially immobilized glycosyltransferases and water-soluble polymer supports bearing acceptor sugars allows for high throughput and efficient glycan synthesis in a recyclable manner.33, 34, 35 The concept of a ‘molecular shuttle’ between the two different polymer supports, namely solid-phase polymers for chemical peptide synthesis and water-soluble polymers for enzymatic glycan synthesis, made the seamless and parallel ‘catch-and-release’ protocol possible for glycopeptide synthesis.36, 37, 38 Recently,39 we have developed an aminooxy-functionalized dendrimer as a new class of water-soluble polymer supports, featuring a heterobifunctional linker that dramatically enhances the potential of the ‘catch-and-release’ strategy for the oligosaccharide derivatives by integrating three steps: (i) immobilization (catch) of chemically synthesized compounds containing a glycosyl acceptor by functional groups on the dendrimer surface, (ii) enzymatic sugar elongation with glycosyltransferases, and (iii) release of the oligosaccharide derivative from the dendrimer by selective cleavage using Bacillus licheniformis BLase at the C-terminal end of the Glu involved in the –Phe–Glu– dipeptidyl moiety.40 We demonstrated that an aminooxy-functionalized derivative synthesized from a monodispersed G7 polyamidoamine (PAMAM) dendrimer41 with a rigid spherical structure and a low viscosity in water exhibited many useful characteristics as a water-soluble polymer support versus the polydispersed linear polyacrylamide-based supports used in our previous studies. The dendrimer-supported ‘catch-and-release’ protocol enabled us to perform the fully automated, enzymatic synthesis of a sialyl Lewis X tetrasaccharide derivative on an high-performance liquid chromatography (HPLC)-based, automated glycan synthesizer ‘Golgi’ at a high level of purity over a period of 4 days in 16% overall yield, starting from the G7 PAMAM dendrimer and featuring simple N-acetyl-β-D-glucosamine (GlcNAc) residues.39

Our current interest focuses on the applicability of this methodology to the parallel enzymatic syntheses of various glycopeptides36, 37, 38 with more complex structures than simple oligosaccharides. Here we assess the feasibility of the synthetic protocol using a functionalized G7 PAMAM dendrimer as a water-soluble polymer support in the enzymatic parallel synthesis of glycopeptides carrying di-, tri- and tetrasaccharides as tentative model compounds.

Experimental Procedure

General materials and methods

All commercially available solvents and reagents were used without purification. The G6 and G7 PAMAM dendrimers (ethylenediamine core) were purchased from Sigma-Aldrich Chemical Company (Milwaukee, WI, USA). TentaGel S RAM resin was purchased from Hipep Laboratories (Kyoto, Japan), and Fmoc-amino acids and bis-benzyloxycarbonylaminooxyacetic acid were purchased from Novabiochem (San Diego, CA, USA). Bis-benzyloxycarbonylaminooxyacetic acid N-hydroxysuccinimide ester was synthesized according to the procedure reported previously.42 Fmoc-Ser(Ac3GlcNAcβ)-OH was synthesized according to a previous report.43 Recombinant human β1,4-galactocyltransferase (β1,4-GalT) was purchased from Toyobo Co., Ltd. (Osaka, Japan). Recombinant rat α2,3-(N)-sialyltransferase (α2,3-SiaT) and recombinant human α1,3-fucosyltransferase (α1,3-FucT) were obtained from Calbiochem (La Jolla, CA, USA). Uridine-5′-diphospho-α-D-galactose disodium salt, cytidine-5′-monophospho-β-D-N-acetylneuraminic acid disodium salt and guanosine 5′-diphospho-β-L-fucose disodium salt (GDP-Fuc) were procured from Yamasa Corporation (Chiba, Japan). BLase was obtained from Shionogi & Co., Ltd. (Osaka, Japan). Amicon Ultra-0.5 ml-10 k centrifugal filters were purchased from Millipore (Billerica, MA, USA). 1H-nuclear magnetic resonance (NMR) spectra were measured by using a Bruker Avance 600 NMR spectrometer (Bruker Biospin K.K., Kanagawa, Japan). HPLC analyses and purifications were performed on a Hitachi HPLC system (Hitachi High-Technologies Corporation., Tokyo, Japan) equipped with an L-7100 intelligent pump and an L-7405 UV detector, using an Inertsil ODS-3 column (250 × 4.6 mm I.D. for analytical reverse-phase (RP) HPLC or 250 × 20 mm I.D. for preparative RP-HPLC, GL Sciences, Tokyo, Japan), YMC-Pack Dial-200 column (500 × 8 mm I.D. for size-exclusion chromatography (SEC)-HPLC, YMC, Kyoto, Japan), or the Shodex Asahipak NH2P-50 4E column (250 × 4.6 mm I.D. for amino-column HPLC, Showa Denko K.K., Tokyo, Japan) at 25 °C by monitoring the UV absorption at 220 nm for RP-HPLC and amino-column HPLC or at 214 nm for SEC-HPLC. Matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI–TOFMS) data were recorded by a Bruker Ultraflex I (Bruker Daltonics K.K., Kanagawa, Japan) using 2,5-dihydroxybenzoic acid as the matrix. High-resolution electrospray ionization mass spectrometry using JEOL JMS-700TZ (JEOL Ltd., Tokyo, Japan) and amino acid analyses using JEOL JLC/500 (JEOL Ltd.) equipped with a ninhydrin detection system were performed in the Center of Instrumental Analysis at Hokkaido University.

Determination of the PAMAM dendrimer recovery yields following ultrafiltration using a centrifugal filter device

Solutions of the PAMAM dendrimers (G6 and G7) in methanol (5 wt%, 250 μl) were air dried to remove the methanol and then dissolved in water (250 μl) and lyophilized. Dried G6 (11.7 mg) or G7 (10.8 mg) was then dissolved in water (400 μl) and the solution was centrifuged (14 000 g) in a centrifugal filter device (Amicon Ultra-0.5 ml; molecular weight cut-off value, 10 000). After 15 min, water (400 μl) was added to the retentate, and the solution was centrifuged under the same conditions. This procedure was repeated five times, and then the retentate was collected by centrifugation (1000 g) for 5 min. The collected solution was lyophilized to obtain the retained G6 (10.5 mg) and G7 (10.6 mg) in 89% and 99% recovery, respectively.

Aminooxy functionalization of the G7 amino-terminated PAMAM dendrimer

The G7 PAMAM dendrimer 2 bearing aminooxy groups was synthesized using precursor 1 according to a previous report,39 with a slight modification. The detailed procedures and characterization by 1H-nuclear magnetic resonances are shown in the Supplementary Information.

Solid-phase synthesis of molecular shuttle 3 under microwave irradiation

A molecular shuttle carrying a glycopeptide precursor (3) was synthesized under microwave irradiation according to the methods reported previously.44, 45, 46 The detailed procedures and characterization by RP-HPLC and MALDI–TOFMS are described in the Supplementary Information. MALDI–TOFMS: C70H111N18O25 [M+H]+ calcd. (m/z) 1603.797, found (m/z) 1603.565.

Optimization of pH and reaction time for the conjugation of the molecular shuttle with the aminooxy-functionalized G7 PAMAM dendrimer

To a solution of dendrimer 2 in water (1.5 mM aminooxy group, 133 μl), 1 M sodium acetate buffer (pH 3.5, 4, 4.5, 5 or 5.5, 10 μl) and 4 mM molecular shuttle 3 (50 μl) were added and then allowed to stand at room temperature. A 10-μl sample of the reaction mixture after 0, 1, 2, 3, 6, 12, 24 and 48 h were analyzed by SEC-HPLC (column: YMC-Pack Diol-200 column, 500 × 8 mm I.D.; flow rate: 0.7 ml min−1; eluent: 50 mM sodium phosphate buffer, 0.3 M NaCl (pH 7)). The reaction mixture was concentrated and washed with water five times by centrifugal ultrafiltration (UF; Amicon Ultra-0.5 ml-10 k, 15 000 g, 5 × 15 min). The conjugate 4 collected by centrifugation (1 500 g, 5 min) was used directly for the subsequent BLase digestion without further purification.

General conditions for the enzymatic cleavage of a linker moiety

To the above solution of conjugate 4, 500 mM ammonium acetate buffer, pH 6.8 (10 μl) and 17.4 μg ml−1 BLase (11.5 μl) were added, and then the total volume of the reaction mixtures was adjusted to 100 μl with water. After allowing the mixture to stand at room temperature for 0, 1, 2, 3, 6 and 12 h, 20 μl of the reaction mixture was used for analytical RP-HPLC (column: Inertsil ODS-3 (250 × 4.6 mm I.D.); eluent A: 25 mm ammonium acetate buffer, pH 5; eluent B: 10% eluent A in acetonitrile. Eluent (A/B=95/5) was employed and the ratio of eluent B was increased linearly from 5% to 40% over 40 min and from 40% to 90% over 2 min, and kept at 90% over 2 min; then the ratio of eluent B was decreased linearly from 90% to 5% over 1 min and kept at 5% over 14 min with a flow rate of 1 ml min−1). The fraction corresponding to the peak at 16 min for the RP-HPLC of the reaction mixture taken at 12 h was collected and characterized by MALDI–TOFMS, high-resolution electrospray ionization mass spectrometry, and amino acid analysis, to confirm the release of glycopeptide 5. MALDI–TOFMS: C50H87N16O19 [M+H]+ calcd. (m/z) 1215.633, found (m/z) 1215.89. High-resolution electrospray ionization mass spectrometry: C50H87N16O19 [M+H]+ calcd. (m/z) 1215.6328, found (m/z) 1215.6303. Amino acid analysis (numbers in parentheses are theoretical values): Ala (1) 1, Ser (2) 2, Gly (2) 2, Val (2) 1.7, Pro (2) 1.8, Arg (1) 1.

Preparation of conjugates 6–10 having different degrees of molecular shuttle substitution (density)

To a solution of aminooxy-functionalized G7 PAMAM dendrimer 2 in water (1.5 mM aminooxy group, 1 ml), 1 M sodium acetate buffer, pH 4 (75 μl) was added; then, the stock solution containing 4 mM shuttle 3 and water was added to multiple vessels to give final reaction mixture volumes of 1.5 ml, with the final concentration of 3 at 0.2, 0.4, 0.6, 0.8 and 1 mM. After standing at room temperature for 48 h, 20 μl of each reaction mixture was used for SEC-HPLC analysis (Supplementary Figure S4 in the Supplementary Information). To determine the degree of dendrimer 2 modification with shuttle 3, SEC-HPLC chromatograms of both the shuttle 3-free control (blank) and the dendrimer 2 in ammonium acetate buffer were measured before all experiments. The rates of the reduced amount of 3 during the reaction against the initial amount of 3 used were estimated by comparing the net (buffer-subtracted) peak areas of 3 after 48 h. The surplus reaction mixtures were divided into three portions and concentrated by UF with water using centrifugal filter devices (Amicon Ultra-0.5 ml-10 k, 15 000 g, 5 × 15 min). The retained solutions collected by centrifugation (1500 g, 5 min) were combined into one portion to give the stock solution of individual conjugates 6–10. The solutions of 6–9 were subjected to the sugar elongation reaction by using β1,4-GalT without further purification.

Modification of conjugates 6–9 using β1,4-GalT and uridine-5′-diphospho-α-D-galactose disodium salt

To the solutions of 6–9 (∼1 μmol), 1 M HEPES buffer, pH 7 (45 μl), 1 M MnCl2 (9 μl), 4 U ml−1 recombinant human β1,4-GalT (6.9 μl) and 100 mM uridine-5′-diphospho-α-D-galactose disodium salt (5 equiv. for displayed 3 on the dendrimer) were added, and then the total volume was adjusted to 900 μl with water. After allowing the mixture to stand at room temperature for 24 h, the reaction mixture was divided into three portions, and one of the three was concentrated and washed with water using a centrifugal filter device (Amicon Ultra-0.5 ml-10 k, 15 000 g, 5 × 15 min). The retained solutions were collected by centrifugation (1500 g, 5 min) to give the stock solutions of 11–14. One of the three portions was employed directly for the BLase reaction without further purification; the other two portions of reaction mixture were subjected to subsequent modification with α2,3-SiaT in the presence of cytidine-5′-monophospho-β-D-N-acetylneuraminic acid disodium salt.

Modification of conjugates 11–14 using α2,3-SiaT and cytidine-5′-monophospho-β-D-N-acetylneuraminic acid disodium salt

To the stock solutions of conjugates 11–14, 1.4 U ml−1 recombinant rat α2,3-SiaT (6.4 μl) and 100 mM cytidine-5′-monophospho-β-D-N-acetylneuraminic acid disodium salt (5 equiv. for displayed 3 on the dendrimer) were added. After allowing the mixture to stand at room temperature for 24 h, each reaction mixture was concentrated and washed with water using a centrifugal filter device (Amicon Ultra-0.5 ml-10 k, 15 000 g, 5 × 15 min). The retained solutions were, respectively, collected by centrifugation (1500 g, 5 min) to give the stock solutions of 15–18. One of the two portions of each stock solution was used directly for the BLase digestion, and the other was employed for further modification experiments using α1,3-FucT in the presence of GDP-Fuc.

Modification of conjugates 15–18 using α1,3-FucT and GDP-Fuc

To the solutions of 15–18, 1 M Tris-HCl buffer, pH 7 (15 μl), 1 M MnCl2 (3 μl), 500 mU ml−1 recombinant human α1,3-FucT (18 μl) and 100 mM GDP-Fuc (5 equiv. for displayed 3 on the dendrimer) were added, and then the total volume was adjusted to 300 μl with water. After allowing the mixture to stand at room temperature for 48 h, the reaction mixture was concentrated and washed with water using a centrifugal filter device (Amicon Ultra-0.5 ml-10 k, 15 000 g, 5 × 15 min). The retained solutions were collected by centrifugation (1500 g, 5 min) to give stock solutions 19–22.

Glycopeptides 23–25 released from dendrimers 11–22

To the solutions of 11–22, 500 mM ammonium acetate buffer, pH 6.8 (10 μl) and 17.4 μg ml−1 BLase (11.5 μl) were added, and then the final volume of reaction mixture was adjusted to 100 μl with water. After allowing the mixture to stand at room temperature for 12 h, the reaction mixture was diluted with water (400 μl) and the solution was subjected to UF with a centrifugal filter device (Amicon Ultra-0.5 ml-10 k, 15 000 g, 15 min). The solutions that passed through the filter membrane by centrifugation (1500 g, 5 min) were lyophilized to give crude product. These crude materials were subjected directly to amino-column HPLC analysis (Asahipak NH2P-50 4E, 250 × 4.6 mm I.D.; flow rate: 1 ml min−1; eluent A: 25 mM ammonium acetate buffer, pH 5.8; eluent B: 25 mM acetic acid in acetonitrile; eluent (A/B=15/85) was employed and the ratio of eluent A was increased linearly from 15% to 50% over 58 min). MALDI–TOFMS: 23, C56H97N16O24 [M+H]+ calcd. m/z 1377.68, found m/z 1377.72; 24, C67H114N17O32 [M+H]+ calcd. m/z 1668.78, found m/z 1668.77; 24′, C64H109N16O30 [M+H]+ calcd. m/z 1581.75, found m/z 1581.64.; 25, C73H124N17O36 [M+H]+ calcd. m/z 1814.84, found m/z 1814.64.

Results and discussion

Enhancement of throughput in the separation of dendrimers

The purpose of this study is to establish a novel protocol for the parallel/combinatorial enzymatic synthesis of the glycopeptide libraries needed for array-based drug-discovery research. It was considered that the enhancement of throughput in the separation process by UF using a hollow-fiber module might be crucial, as this method allows seamless and multi-step enzymatic modifications to be performed on the HPLC-based, fully automated glycan synthesizer ‘Golgi’.39 In fact, this system will likely become a powerful tool for the straightforward and large-scale preparation of simple oligosaccharides or glycoproteins having homogeneous glycan chains. However, the hollow-fiber UF module involved in this on-line flow system is not suited for the parallel synthesis of multiplex glycopeptides when performed using a batch-wise method involving 96-well multiplates. The recent growing need for glycan microarrays in discovery research for new cancer-relevant biomarkers26, 27 greatly encouraged us to develop a rapid and combinatorial synthetic protocol for a large set of glycopeptides.

As an alternative method, the performance of the centrifugal UF device in the repetitive separation processes of various PAMAM dendrimers was tested in comparison with that of the hollow-fiber UF module. As summarized in Table 1, it was found that the G7 PAMAM dendrimer (116 kDa) can be recovered in quantitative yield using the centrifugal UF (10 kDa), whereas the recovery of the G7 PAMAM dendrimer with the hollow-fiber UF module was found to be 86%, as reported previously. This exciting result encouraged us to employ the centrifugal UF instead of the hollow-fiber UF module, and to assess the feasibility of this device in a total glycopeptides synthetic protocol using aminooxy-functionalized G7 PAMAM dendrimer 2 and a key intermediate glycopeptide (3) as a new class of molecular shuttle36, 37 capable of crosslinking solid-phase peptide synthesis and water-soluble dendrimer-based enzymatic glycan synthesis.

A novel molecular shuttle between solid-phase peptide synthesis and water-soluble dendrimer-based enzymatic modifications

Aminooxy-functionalized dendrimer 2 as a water-soluble polymer support was synthesized according to our previous report,39 with a slight modification (Scheme 1). Briefly, commercially available G7 amino-terminated PAMAM dendrimers (ethylenediamine core, 512 surface amino groups) were coupled with bis-Boc aminooxyacetic acid N-hydroxysuccinimide ester42 in methanol, and the subsequent removal of the Boc-protecting group with 4 M HCl afforded 2 with 512 surface hydroxyaminoacetyl groups as estimated by comparing the 1H-nuclear magnetic resonance with that of precursor 1. In addition, the molecular shuttle 3, containing the model glycopeptide sequence H–Ser–Val–Pro–Val–Ser–Gly–Ser–Ala–Pro–Gly–Arg–NH2 that bears a single GlcNAc residue at the underlined serine residue, was prepared by microwave-assisted solid-phase synthesis (Scheme 2).44 Compound 3 is composed of a model glycopeptide region with a glycosyl acceptor moiety (represented in the compound 3 structure with black in Scheme 3) and a heterobifunctional linker for ‘catch-and-release’ machinery in which the N terminus is capped by a 5-oxohexanoyl-Phe-Glu moiety. A keto group in the flexible 5-oxohexanoyl moiety (represented in the compound 3 structure with green in Scheme 3) can react with an aminooxy group on the G7 PAMAM dendrimer (represented in the compound 2 structure with red in Scheme 3) under mildly acidic conditions to form the dendrimer–glycopeptide conjugate 4 through a stable oxime bond, namely the ‘blotting’ step. As BLase preferentially recognizes the Phe–Glu dipeptidyl moiety (represented in the compound 3 structure with blue in Scheme 3) to cleave at the C-terminal side of Glu residue,40 it is thought that the product modified on the dendrimer should be isolated solely from the digested mixture after centrifugal UF.

To establish a general protocol based on the heterobifunctional machinery used for generating the G7 dendrimer derivative 2, we investigated the pH dependency in the blotting step and estimated the ideal molecular ratio of molecular shuttle 3 and aminooxy-functionalized G7 PAMAM dendrimer 2. As the efficiency in the oxime formation between common ketone compounds and aminooxy derivatives appeared to depend strongly on the pH of the reaction mixture, optimization of this step would greatly influence an overall yield of the target glycopeptides after the multi-step glycosyltransferase reactions. As a simple model system for testing the seamless blotting and releasing protocol shown in Scheme 3, we carefully assessed the efficiency of forming conjugate 4 through incubating an equivalent molar ratio of molecular shuttle 3 and the aminooxy group of dendrimer 2 at room temperature under various conditions, such as pH 3.5, 4, 4.5, 5 or 5.5. SEC-HPLC analysis of the reaction mixture uncovered that the highest yield in the blotting reaction is achieved at pH 4 (64%, 328 of 518 aminooxy groups were coupled with 3), whereas the reaction appeared to proceed at a different speed and eventually reached a plateau at 48 h in all cases (Figure 1a). After washing with water through the centrifugal UF module (five times) to remove unreacted shuttle 3, the dendrimer–glycopeptide conjugate 4 was subjected to treatment with BLase. It was indicated by RP-HPLC analysis that the release of 11 amino acids of glycopeptide 5 from conjugate 4 was observed at 1 h after incubation with BLase and completing within 6 h (Figure 1b).

Analyses of the ‘catch-and-release’ reaction. (a) Conjugation reaction between 2 and 3 to form 4 under various pH conditions. SEC-HPLC profiles of the reaction mixtures at pH 4 at each time over the course of the reaction (left) and the time course of the conjugation reaction efficacy under various pH. (b) BLase-catalyzed release of glycopeptide 5 from conjugate 4. RP-HPLC profiles of the reaction mixtures after 0, 1, 2, 3, 6 and 12 h. The peak at 16 min corresponds to product 5 (left). MALDI–TOFMS of the fraction corresponding to the peak at 16 min on the RP-HPLC chromatogram of the reaction mixture after 12 h (right). A full color version of this figure is available at Polymer Journal online.

Parallel enzymatic synthesis from various dendrimer–glycopeptide conjugates

The density of molecular shuttle 3 displayed on the surface of the dendrimer should strongly influence the acceptability/accessibility of the substrate by the enzymes. To estimate the surface density of the substrate on the G7 dendrimer, we determined the degree of substitution in the chemical ligation of the aminooxy-functionalized G7 dendrimer 2 with the molecular shuttle at pH 4 for 48 h under various molecular ratios (molecular shuttle 3/aminooxy groups of dendrimer 2) from 0.2 to 1 equiv. (Scheme 4 and Supplementary Figure S4 in the Supplementary Information). Judging from the analytical data for conjugates 6–10 summarized in Figure 2, the highest yield in this step was observed in the case where 0.2 equiv. of 3 was employed (98%), whereas this increase in the molecular ratio (>0.8) distinctly reduced the degree of substitution by molecular shuttle 3. It was discovered that the maximal substitution (332 sites of 512 aminooxy groups) was achieved by applying 0.8 equiv. of 3. Dendrimers 6–9, which were occupied by molecular shuttle 3 at between 100–332 out of 512 sites, were next subjected to a series of glycosylation reactions with recombinant human β1,4-GalT, rat α2,3-SiaT and human α1,3-FucT as shown in Scheme 4. After washing the dendrimers thoroughly by centrifugal UF, all products were released from dendrimers 11–22 by treatment with BLase and characterized by amino-column HPLC and MALDI–TOFMS (Figure 3). As shown in Figure 3A, glycopeptide 23, carrying the disaccharide Galβ1,4GlcNAc, was obtained quantitatively through 11–14. Similarly, glycopeptide 24, with Neu5Acα2,3Galβ1,4GlcNAc (tR=29 min), was derived as the major product by treating 11–14 with α2,3-SiaT and BLase through 15–18. However, it was also uncovered that the unusual byproduct 24′ (tR=26 min) can be released during the digestion of 15–18 by BLase. MALDI–TOFMS indicates that compound 24′ corresponds to the glycopeptide lacking the N-terminal serine residue of 24 (Figure 3C). The reason why such unusual digestion at the serine residue occurred is unclear, because this is the first case reported since BLase was discovered40 and utilized.37, 38 Finally, dendrimers 15–18 were subjected to glycosylation by α1,3-FucT in the presence of GDP-Fuc under general conditions,36, 39 and subsequently treated with BLase. As a consequence, none of the HPLC profiles for the entries were altered from those shown in Figure 3B, and no significant peak for glycopeptide 25 carrying tetrasaccharide Neu5Acα2,3Galβ1,4(Fucα1,3) GlcNAc36 was detected during HPLC analysis (data not shown), whereas MALDI–TOFMS indicated a detectable level of ion signal at m/z 1814.6, corresponding to 25 only when 15 was used. These results clearly suggest that the present protocol using the G7 PAMAM dendrimer needs considerable performance improvements in the linker moiety of molecular shuttle 3 to render glycosyltransferases more accessible to the hindered glycan side chains branching from the core peptides. In addition, it seems likely that other peptidases with different substrate specificities and chemoselective/photosensitive linkers may enhance the versatility of dendrimer-based supporting materials for the enzyme-assisted synthesis of a variety of complex glycopeptides.

Efficiency in the blotting reaction of molecular shuttle 3 by aminooxy-functionalized G7 PAMAM dendrimer 2. The number of modification sites on a dendrimer after conjugation reactions with various molar ratios (0.2, 0.4, 0.6, 0.8 or 1 equiv. against 1 equiv. of aminooxy group on dendrimer 2 of molecular shuttle 3 was estimated by quantifying the peak due to compound 3 during SEC-HPLC analysis. The average number of occupied (black) and unoccupied aminooxy groups (white) on conjugates 6–10 are represented. The scale markings on the y axis indicate the maximum number of theoretical modifications calculated from the individual molar ratio.

Dendrimer-supported enzymatic synthesis of various glycopeptides. (A) Amino-column HPLC chromatogram of crude glycopeptide 23 (peak at 20 min) derived from conjugates 6–9. The peak detected at 18 min on the top chromatogram corresponds to compound 5, which was spiked as a standard. (B) Amino-column HPLC chromatogram of crude glycopeptide 24 (peak at 24 min) derived from 6–9 after galactosylation, silylation and BLase digestion. The peak observed at 26 min is attributed to the byproduct 24′. The peak detected at 18 min on the top chromatogram corresponds to glycopeptide 23 and was used as a reference. (C) MALDI–TOFMS of the products obtained during a series of enzymatic treatments using conjugate 6 as a starting material. (a) Crude glycopeptide 23 released from dendrimer 11, (b) glycopeptide 24′ (peak at 26 min in (B)) derived from dendrimer 15, (c) glycopeptide 24 (peak at 29 min in (B)) derived from dendrimer 15, (d) crude product derived from dendrimer 19 following the fucosylation of dendrimer 15. Only a faint amount of glycopeptide 25 was observed at m/z 1814.64. A full color version of this figure is available at Polymer Journal online.

Conclusion

To advance the parallel enzymatic synthesis of biologically and pharmaceutically important glycopeptides, we investigated the feasibility of using aminooxy-functionalized G7 PAMAM dendrimer derivatives in the enzyme-assisted synthesis of glycopeptides bearing oligosaccharide side chains. The G7 PAMAM dendrimer was shown to be an effective supporting material that exhibited 99% recovery in a simple centrifugal UF procedure compared with the hollow-fiber UF module (86%) used in the HPLC-based automated glycan synthesizer.39 An optimization of the protocol using aminooxy-functionalized G7 PAMAM dendrimer derivative 2 and molecular shuttle 3 was performed for the synthesis of glycopeptides bearing di-, tri- and tetrasaccharide branches 23–25. It was discovered that sugar elongation reactions by β1,4-GalT and subsequent α2,3-SiaT proceeded smoothly to give 23 and 24 in high yields, whereas α1,3-FucT did not work well in the synthesis of 25. Although extensive efforts should be made to establish practical and reliable protocols for robust combinatorial synthesis, we demonstrated for the first time the feasibility of the molecular shuttle crosslinking solid-phase peptide synthesis and dendrimer-based enzymatic synthesis in the rapid and parallel synthesis of glycopeptides.

Synthesis of aminooxy-functionalized G7 PAMAM dendrimer 2. (a) Bis-Boc-aminooxyacetic acid N-hydroxysuccinimide ester, 4-methylmorpholine, MeOH; (b) 4 M HCl.

Microwave-assisted solid-phase synthesis of the molecular shuttle-carrying model glycopeptide 3. (a, i) 20% piperidine, DMF, microwave (MW) 6 min, 50 °C, 120 W; (ii) Fmoc-amino acid or Fmoc-Ser(Ac3GlcNAcβ)-OH, HBTU, HOBt, DIPEA, DMF, MW 12 min, 50 °C, 120 W; (iii) Ac2O, HOBt, DIPEA, DMF, MW 3 min, 50 °C, 120 W; (iv) repeating (i–iii); (b) 90% TFA; (c) 1 M NaOH, MeOH (1:1, v/v).

Preliminary test of ‘catch-and-release’ for molecular shuttle 3 by aminooxy-functionalized G7 PAMAM dendrimer 2.

Dendrimer-supported enzymatic synthesis of glycopeptides carrying di-, tri- and tetrasaccharides (23, 24 and 25). (a) 50 mM sodium acetate buffer, pH 4, r.t., 48 h; (b) UDP-Gal (uridine-5′-diphospho-α-D-galactose disodium salt; 5 equiv.), recombinant human β1,4-galactosyltransferase (30 mU ml−1), 10 mM MnCl2, 50 mM HEPES buffer, pH 7, r.t., 24 h; (c) CMP-Neu5Ac (cytidine-5′-monophospho-β-D-N-acetylneuraminic acid disodium salt; 5 equiv.), recombinant rat α2,3-(N)-sialyltransferase (30 mU ml−1), 5 mM HEPES buffer, pH 7, r.t., 24 h; (d) GDP-Fuc (guanosine 5′-diphospho-β-L-fucose disodium salt; 10 equiv.), recombinant human α1,3-fucosyltransferase (30 mU ml−1), 10 mM MnCl2, 50 mM HEPES buffer, pH 7, r.t., 48 h; (e) BLase, 50 mM ammonium acetate buffer, pH 6.8, r.t., 12 h.

References

Drickamer, K. & Taylor, M. E. Evolving views of protein glycosylation. Trends Biochem. Sci. 23, 321–324 (1998).

Dube, D. H. & Bertozzi, C. R. Glycans in cancer and inflammation-potential for therapeutics and diagnostics. Nat. Rev. Drug Discov. 4, 477–488 (2005).

Hattrup, C. L. & Gendler, S. J. Structure and function of the cell surface (tethered) mucins. Annu. Rev. Physiol. 70, 431–457 (2008).

Tarp, M. A. & Clausen, H. Mucin-type O-glycosylation and its potential use in drug and vaccine development. Biochim. Biophys. Acta 1780, 546–563 (2008).

Bennett, C. S., Payne, R. J., Koeller, K. M. & Wong, C. -H. in Glycoscience (eds Fraser-Reid, B. O., Tatsuta, K. & Thiem, J.) Ch. 8.3, 1795–1857 (Springer-Verlag, Berlin, Heidelberg, 2008).

Crich, D. & Dudkin, V. Why are the hydroxy groups of partially protected N-acetylglucosamine derivatives such poor glycosyl acceptors, and what can be done about it? a comparative study of the reactivity of N-acetyl-, N-phthalimido-, and 2-azido-2-deoxy-glucosamine derivatives in glycosylation. 2-Picolinyl ethers as reactivity-enhancing replacements for benzyl ethers. J. Am. Chem. Soc. 123, 6819–6825 (2001).

Zhu, X. & Schmidt, R. R. New principles for glycoside-bond formation. Angew. Chem. Int. Ed. 48, 1900–1934 (2009).

Guo, J. & Ye, X. -S. Protecting groups in carbohydrate chemistry: influence on stereoselectivity of glycosylations. Molecules 15, 7235–7265 (2010).

Paulson, J. C., Hill, R. L., Tanabe, T. & Ashwell, G. Reactivation of asialo-rabbit liver binding protein by resialylation with β-D-galactoside α2→6 sialyltransferase. J. Biol. Chem. 252, 8624–8628 (1977).

Wong, C. -H., Haynie, S. L. & Whiteside, G. M. Enzyme-catalyzed synthesis of N-acetyllactosamine with in situ regeneration of uridine 5′-diphosphate glucose and uridine 5′-diphosphate galactose. J. Org. Chem. 47, 5416–5418 (1982).

Sabesan, S. & Paulson, J. C. Combined chemical and enzymatic synthesis of sialyloligosaccharides and characterization by 500-MHz 1H and 13C NMR spectroscopy. J. Am. Chem. Soc. 108, 2068–2080 (1986).

Thiem, J. & Treder, W. Synthesis of the trisaccharide Neu-5-Ac-α (2→6)Gal-β(1→4)GlcNAc by the use of immobilized enzymes. Angew. Chem. Int. Ed. Engl. 25, 1096–1097 (1986).

Nilsson, K. G. Enzymic synthesis of di- and tri-saccharide glycosides, using glycosidases and β-D-galactoside 3-α-sialyl-transferase. Carbohydr. Res. 188, 9–17 (1989).

Palcic, M. M., Venot, A. P., Ratcliffe, R. M. & Hindsgaul, O. Enzymic synthesis of oligosaccharides terminating in the tumor-associated sialyl-Lewis-α determinant. Carbohydr. Res. 190, 1–11 (1989).

Unverzagt, C., Kunz, H. & Paulson, J. C. High-efficiency synthesis of sialyloligosaccharides and sialoglycopeptides. J. Am. Chem. Soc. 112, 9308–9309 (1990).

Hancock, S. M., Vaughan, M. D. & Withers, S. G. Engineering of glycosidases and glycosyltransferases. Curr. Opin. Chem. Biol. 10, 509–519 (2006).

Gamblin, D. P., Scanian, E. M. & Davis, B. G. Glycoprotein synthesis: an update. Chem. Rev. 109, 131–163 (2009).

Zehavi, U., Sadeh, S. & Herchman, M. Enzymic synthesis of oligosaccharides on a polymer support. Light-sensitive, substituted polyacrylamide beads. Carbohydr. Res. 124, 23–34 (1983).

Köpper, S. Polymer-supported enzymic synthesis on a preparative scale. Carbohydr. Res. 265, 161–166 (1994).

Köpper, S. & Zehavi, U. Improved acceptor polymers for enzymic glycosylation. React. Polym. 22, 171–180 (1994).

Blixt, O. & Norberg, T. Solid-phase enzymatic synthesis of a Lewis a trisaccharide using an acceptor reversibly bound to sepharose. J. Carbohydr. Chem. 16, 143–154 (1997).

Blixt, O. & Norberg, T. Solid-phase enzymatic synthesis of a sialyl Lewis X tetrasaccharide on a sepharose matrix. J. Org. Chem. 63, 2705–2710 (1998).

Meldal, M., Auzanneau, F. -I., Hindsgaul, O. & Palcic, M. M. A PEGA resin for use in the solid-phase chemical enzymatic synthesis of glycopeptides. J. Chem. Soc. Chem. Commun. 1849–1850 (1994).

Schuster, M., Wang, P., Paulson, J. C. & Wong, C. -H. Solid-phase chemical-enzymic synthesis of glycopeptides and oligosaccharides. J. Am. Chem. Soc. 116, 1135–1136 (1994).

Seitz, O. & Wong, C. -H. Chemoenzymatic solution-and solid-phase synthesis of O-glycopeptides of the mucin domain of MAdCAM-1. A general route to O-LacNAc, O-sialyl-LacNAc, and O-sialyl-Lewis-X peptides. J. Am. Chem. Soc 119, 8766–8776 (1997).

Ohyabu, N., Hinou, H., Matsushita, T., Izumi, R., Shimizu, H., Kawamoto, K., Numata, Y., Togame, H., Takemoto, H., Kondo, H. & Nishimura, S. -I. An essential epitope of anti-MUC1 monoclonal antibody KL-6 revealed by focused glycopeptide library. J. Am. Chem. Soc. 131, 17102–17109 (2009).

Wandall, H. H., Blixt, O., Tarp, M. A., Pedersen, J. W., Bennet, E. P., Mandel, U., Ragupathi, G., Livingston, P. O., Hollingsworth, M. A., Taylor-Papadimitriou, J., Burchell, J. & Clausen, H. Cancer biomarkers defined by autoantibody signatures to aberrant O-glycopeptide epitopes. Cancer Res. 70, 1306–1313 (2010).

Nishimura, S. -I., Lee, K. B., Matsuoka, K. & Lee, Y. C. Chemoenzymic preparation of a glycoconjugate polymer having a sialyloligosaccharide: Neu5Acα(2→3)Galβ(1→4)GlcNAc. Biochem. Biophys. Res. Commun. 199, 249–254 (1994).

Nishimura, S. -I., Matsuoka, K. & Lee, Y. C. Chemoenzymatic oligosaccharide synthesis on a soluble polymeric carrier. Tetrahedron Lett. 35, 5657–5660 (1994).

Nishimura, S. -I. & Yamada, K. Transfer of ganglioside GM3 oligosaccharide from a water soluble polymer to ceramide by ceramide glycanase. A novel approach for the chemical-enzymatic synthesis of glycosphingolipids. J. Am. Chem. Soc. 119, 10555–10556 (1997).

Yamada, K., Fujita, E. & Nishimura, S. -I. High performance polymer supports for enzyme-assisted synthesis of glycoconjugates. Carbohydr. Res. 305, 443–461 (1997).

Yamada, K., Matsumoto, S. & Nishimura, S. -I. Efficient synthesis of non-natural ganglioside (pseudo-GM3) and fluorescent labelled lysoGM3 on the basis of polymer-assisted enzymatic strategy. Chem. Commun. 507–508 (1999).

Nishiguchi, S., Yamada, K., Fuji, Y., Shibatani, S., Toda, A. & Nishimura, S.-I. Highly efficient oligosaccharide synthesis on water-soluble polymeric primers by recombinant glycosyltransferases immobilised on solid supports. Chem. Commun. 1944–1945 (2001).

Toda, A., Yamada, K. & Nishimura, S. -I. An engineered biocatalyst for the synthesis of glycoconjugates: utilization of β1,3-N-acetyl-D-glucosaminyltransferase from Streptococcus agalactiae type is expressed in Escherichia coli as a fusion with maltose-binding protein. Adv. Synth. Catal. 344, 61–69 (2002).

Naruchi, K. & Nishimura, S. -I. Membrane-bound stable glycosyltransferases: a noel and versatile method for protein immobilization inspired from functional role of C-terminal cationic amphipathic tail of human gastric pathogen Helicobacter pylori fucosyltransferases. Angew. Chem. Int. Ed. 80, 1328–1331 (2011).

Fumoto, M., Hinou, H., Matsushita, T., Kurogochi, M., Ohta, T., Ito, T., Yamada, K., Takimoto, A., Kondo, H., Inazu, T. & Nishimura, S. -I. Molecular transporter between polymer platforms: highly efficient chemoenzymatic glycopeptide synthesis by the combined use of solid-phase and water-soluble polymer supports. Angew. Chem. Int. Ed. 44, 2534–2537 (2005).

Fumoto, M., Hinou, H., Ohta, T., Ito, T., Yamada, K., Takimoto, A., Kondo, H., Shimizu, H., Inazu, T., Nakahara, Y. & Nishimura, S. -I. Combinatorial synthesis of MUC1 glycopeptides: polymer blotting facilitates chemical and enzymatic synthesis of highly complicated mucin glycopeptides. J. Am. Chem. Soc. 127, 11804–11818 (2005).

Matsushita, T., Sadamoto, R., Ohyabu, N., Nakata, H., Fumoto, M., Fujitani, N., Takegawa, Y., Sakamoto, T., Kurogochi, M., Hinou, H., Shimizu, H., Ito, T., Naruchi, K., Togame, H., Takemoto, H., Kondo, H. & Nishimura, S. -I. Functional neoglycopeptides: synthesis and characterization of a new class of MUC1 glycoprotein models having core 2-based O-glycan and complex-type N-glycan chains. Biochemistry 48, 11117–11133 (2009).

Matsushita, T., Nagashima, I., Fumoto, M., Ohta, T., Yamada, K., Shimizu, H., Hinou, H., Naruchi, K., Ito, T., Kondo, H. & Nishimura, S. -I. Artificial golgi apparatus: globular protein-like dendrimer facilitates fully automated enzymatic glycan synthesis. J. Am. Chem. Soc. 132, 16651–16656 (2010).

Kakudo, S., Kikuchi, N., Kitadokoro, K., Fujiwara, T., Nakamura, E., Okamoto, H., Shin, M., Tamaki, M., Teraoka, H. & Tsuzuki, H. Purification, characterization, cloning, and expression of a glutamic acid-specific protease from Bacillus licheniforrnis ATCC 14580. J. Biol. Chem. 267, 23782–23788 (1992).

Tomalia, D., Baker, H., Dewald, J., Hall, M., Kallos, G., Martin, S., Roeck, J., Ryder, J. & Smith, P. A new class of polymers: starburst-dendritic macromolecules. Polym. J. 17, 117–132 (1985).

Foillard, S., Rasmussen, M. O., Razkin, J., Boturyn, D. & Dumy, P. 1-ethoxyethylidene, a new group for the stepwise SPPS of aminooxyacetic acid containing peptides. J. Org. Chem. 73, 983–991 (2008).

Arsequell, G., Krippner, L., Dwek, R. A. & Wong, S. Y. C. Building blocks for solid-phase glycopeptide synthesis: 2-acetamido-2-deoxy-β-D-glycosides of FmocSerOH and FmocThrOH. J. Chem. Soc. Chem. Commun. 2383 (1994).

Matsushita, T., Hinou, H., Kurogochi, M., Shimizu, H. & Nishimura, S. -I. Rapid microwave-assisted solid-phase glycopeptide synthesis. Org. Lett. 7, 877–880 (2005).

Matsushita, T., Hinou, H., Fumoto, M., Kurogochi, M., Fujitani, N., Shimizu, H. & Nishimura, S. -I. Construction of highly glycosylated mucin-type glycopeptides based on microwave-assisted solid-phase syntheses and enzymatic modifications. J. Org. Chem. 71, 3051–3063 (2006).

Naruchi, K., Hamamoto, T., Kurogochi, M., Hinou, H., Shimizu, H., Matsushita, T., Fujitani, N., Kondo, H. & Nishimura, S. -I. Construction and structural characterization of versatile lactosaminoglycan-related compound library for the synthesis of complex glycopeptides and glycosphingolipids. J. Org. Chem. 71, 9609–9621 (2006).

Acknowledgements

We thank Ms S Oka and T Hirose from the Center for Instrumental Analysis at Hokkaido University for electrospray ionization mass spectrometry measurement and amino acid analysis. This work was supported in part by the program grant entitled ‘The matching program for innovation in future drug discovery and medical care’ from the Ministry of Education, Culture, Sports, Science and Technology in Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Matsushita, T., Handa, S., Naruchi, K. et al. A novel approach for the parallel synthesis of glycopeptides by combining solid-phase peptide synthesis and dendrimer-supported enzymatic modifications. Polym J 45, 854–862 (2013). https://doi.org/10.1038/pj.2013.14

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2013.14