Abstract

In this study, a calcium-containing monomer, namely calcium lactate, was used for the synthesis of calcium-containing polyurethane for use in biomedical applications. Ether-based polyurethane was prepared using poly(oxytetramethylene)glycol, hexamethylene diisocyanate and calcium lactate. The prepared polymer was characterized by FTIR spectroscopy, which confirmed the presence of ionic linkages in the main chain. The thermal behavior, mechanical properties and viscosity of the polymer were studied, and the properties were compared with those of a control polyurethane sample without any metal. Because of ionic clustering in calcium lactate-incorporated ionic polyurethane, the mechanical properties and storage modulus were enhanced compared with those of nonionic polyurethane. The prepared calcium-containing polyurethane was evaluated for its blood compatibility. An evaluation of blood–material interactions revealed that the material is blood compatible and that the polymer does not induce any hemolysis.

Similar content being viewed by others

Introduction

Segmented polyurethanes consisting of alternating hard and soft segments represent a broad family of polymers whose properties can be tailored according to specific applications. By properly choosing the reagents, specific groups can be introduced into the polyurethane, which modifies the final properties of the polymer. The ratio of hard to soft segments and the chemical structure of the chain extender, diisocyanate, and diol all influence the final properties of polyurethanes. The literature reveals many studies in which researchers have tried to modify the properties of polyurethane by incorporating suitable reagents. One such modification includes the incorporation of ionic groups into polyurethanes. Many investigators have incorporated metal-containing ionic groups into polyurethanes because of the wide variety of properties that make them useful in various fields of materials science, including the biomedical field.1, 2, 3, 4 This wide variety of properties arises due to the combination of covalent hydrocarbon polymer chains and ionic salt species in the same molecule.5 Metal-containing ionic groups can be incorporated into polyurethane either by an ionic bond6, 7 or by coordination interactions.8, 9 By incorporating an ionic group, the blood compatibility of polyurethane can be improved. Previous studies indicate that the incorporation of ionic carboxylate and sulfonate groups into polyurethane results in good blood compatibility.10, 11 Copper et al. investigated the blood-contacting properties of sulfonated polyurethanes based on poly(oxytetramethylene) glycol as a soft segment and observed an improvement in blood compatibility with an increase in ionic content.12 Jozefowicz et al. carried out a series of studies on the blood compatibility behavior of sulfonate and carboxylate derivatized polystyrene and dextran.13, 14 In addition to improving the blood compatibility of polyurethanes, ion incorporation also influences the physicochemical properties of such polymers. Another added advantage of introducing metals into polymers is that it increases the hydrophilicity of the polymer, resulting in decreased protein adsorption.15

Metal-containing ionic diols with ionic bonds between the carboxylate groups and metal are used to synthesize ionic metal-containing polymers. According to the literature, various types of ionic diols, such as divalent metal salts of p-aminobenzoic acid,16 mono(hydrodxylbutyl)phthalate17 and mono(hydroxyethoxyethyl)phthalate,18 have been used to synthesize ionic metal-containing polymers. The objective of this investigation was to develop calcium-containing polyurethane using calcium lactate, which was used as the chain extender. Previous studies report having used calcium lactate as a binder with polyvinyl alcohol to improve the mechanical properties of the resulting materials.19 To the best of the authors’ knowledge, this is the first time that calcium lactate has been used as an ionic diol for the preparation of ionic calcium-containing polyurethanes. Calcium lactate is traditionally used as a food supplement to treat osteoporosis and as an antacid. If some type of polymer degradation occurs in a physiological medium, calcium lactate produces only lactic acid and calcium, which are non-cytotoxic. Because of this wide acceptability of calcium lactate in the biomedical field, we have used calcium lactate as the ionic diol. Aliphatic polyurethane was prepared using a poly(oxytetramethylene) glycol soft segment and hexamethylene diisocyanate as the diisocyanate. The ether linkage in the poly(oxytetramethylene) glycol soft segment provides elasticity to the polymer and makes the polymer more biocompatible.20 In this paper, we describe the synthesis, characterization and hemocompatibility of a calcium-containing polyurethane.

Experimental Procedure

Materials

Hexamethylene diisocyanate (HDI; Merck, Mumbai, India), di-n-butyltin-dilaurate 1,4-butanediol (Spectrochem, Mumbai, India) and N,N-dimethyl formamide (DMF) specially dried GR (Merck) were used without further purification. Calcium l-lactate hydrate (CaL; Sigma-Aldrich, St Louis, MO, USA) and hydroxyl-terminated poly(oxytetramethylene) glycol (PTMG) with a molecular weight of 1000 (Terathane 1000; Sigma-Aldrich) were dehydrated under vacuum at 60 °C for 48 h before use.

Synthesis of calcium-containing polyurethane

Calcium-incorporated polyurethane was synthesized with an one-step process. The calcium-containing monomer CaL (2.3 mmol) and PTMG (2.3 mmol) were dissolved in 25 ml DMF in a three-necked round-bottom flask equipped with a stirrer, an addition funnel and a nitrogen inlet. A solution of HDI (4.6 mmol) in 25 ml of DMF was added to the reaction mixture dropwise over a period of 30 min. Di-n-butyltin-dilaurate (0.1 wt.%) was added as a catalyst. The reaction mixture was heated at 80 °C for 8 h. Finally, the reaction mixture was cooled to room temperature, and stirring was continued for another 18 h. The reaction mixture was poured into stirring water to precipitate the product. The polymer was filtered, washed several times with methanol and dried in vacuum at 60 °C The monomers CaL, PTMG and HDI were combined in the molar ratio 1:1:2.

Characterization techniques

FTIR spectrere recorded using a Thermo Nicolet 5700 spectrometer with a diffuse reflectance sample holder (Thermo Scientific, Langenselbold, Germany). The amount of calcium present in the polymer was estimated using optical emission spectroscopy with inductively coupled plasma (Perkin Elmer OES-ICP, 5300DV, Perkin Elmer, Shelton, CT, USA). Weighed amounts of the samples were incinerated at 800 °C for 5 h, and the ash was digested in aqua regia and diluted to a known volume with deionized water. The concentration of the analyte element was determined from the calibration plot that was obtained by analyzing standard solutions. The results were analyzed and processed using Win Lab 32 software (Version 3.1.0.0107, Perkin Elmer). The thermal behavior of the polymer was analyzed by thermogravimetric analysis (TGA) and dynamic mechanical analysis (DMA). TGA analysis was carried out using a TA Thermal Analyzer (TA Instruments Inc., New Castle, DE, USA, Model SDT-2960) under nitrogen atmosphere at a heating rate of 10 °C min−1. An average of 50 mg of solid sample was used for the TGA experiment. DMA was carried out using a Tritec 2000 DMA (Triton Technology Limited, Lincolnshire, UK) in tension mode at a frequency of 1 Hz and a heating rate of 1 °C. Rectangular strips measuring 10 mm in length and 4 mm in width were cut from the polymer film and used for the DMA. The inherent viscosity of the synthesized polyurethanes was determined using an Ubbelohde viscometer in DMF at a concentration of 0.2 g dl−1 at 30 °C. The mechanical tensile stress–strain properties of the polyurethane films were measured with an Instron 3345 Universal Testing Machine (Walker Way, Bristol, UK) with a load cell of 100 N. The polymer films were cast from a 10 wt% solution of polymer in DMF solvent, and the solvent was allowed to evaporate at room temperature. The film was subsequently dried in a vacuum oven at 50 °C for 48 h to remove the residual solvent. Five dumbbell-shaped samples were punched out according to American Society for Testing and Materials (ASTM) standards. The samples were conditioned at 23±2 °C and at 50% relative humidity, and the test was performed at a crosshead speed of 100 mm min−1.

In vitro biostability studies

The in vitro biostability of polyurethane was evaluated by aging the polymer in phosphate-buffered saline (PBS; pH 7.4). Dumbbells cut from polyurethane films were immersed in the medium and kept at 37 °C in a shaking water bath. At each observation time, samples were retrieved, and the mechanical stability of the sample was evaluated by tensile testing. The results represent the averages of five replicate samples.

Hemocompatibility evaluation

The hemocompatibility of the polyurethane samples was evaluated according to ISO 10993-4:2002. Blood from a human volunteer was collected into the anticoagulant acid citrate dextrose. Polymer samples were placed in polystyrene culture plates and agitated with PBS before they were exposed to blood. To each plate, 2 ml of blood was added, and a 1-ml sample was collected immediately for analysis; the remaining 1 ml was exposed to the materials for 30 min under agitation at 75±5 r.p.m. using a shaker (Environ, Birsfelden, Switzerland) thermostated at 35±2 °C. Four polystyrene culture dishes were exposed to blood as references. The consumption of platelets and leukocytes (white blood cells) on contact with the sample and the total hemoglobin in the initial samples were analyzed using a Haematology Analyzer (Sysmex-K 4500, Sysmex, Kobe, Japan). The free hemoglobin liberated into the plasma after exposure was measured using a diode array spectrometer. The percentage hemolysis was calculated using the following formula:

Percentage hemolysis=(Free hemoglobin/Total hemoglobin) × 100.

Results and Discussion

Synthesis of polyurethane

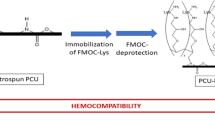

Calcium-containing polyurethane was prepared with an one-step method; the synthetic pathway and reaction conditions are depicted in Scheme 1. The synthetic yield for the calcium-containing polymer after purification was 80%. The product is hereafter referred to as CLHPTMG. To study the effects of calcium incorporation on the thermal and mechanical properties of the polyurethane, a control polyurethane sample was prepared. The control polyurethane, which did not contain calcium metal, was prepared using 1,4-butanediol as the chain extender, along with PTMG and HDI. The chemical composition of the control polyurethane was same as that of CLHPTMG. The control polyurethane was designated as BHPTMG.

Characterization of polyurethane

Infrared spectroscopy

The chemical structure of CLHPTMG was confirmed by FTIR spectroscopy (Figure 1). The absorption peak at 3330 cm−1 corresponds to the N-Hstr of the urethane group. The peak at approximately 2900 cm−1 corresponds to aliphatic C-Hstr. The urethane carbonyl shows absorption at 1718 cm−1. The peaks at 1600 and 1400 cm−1 (appear as a shoulder peak of the 1464 cm−1 absorption peak) are attributed to the ionic carboxylate group. The carboxylate ion usually generates two peaks, an asymmetric stretching band near 1650–1550 cm−1 and a symmetric stretching band near 1400 cm−1.21 The presence of these two peaks in the spectra confirms the presence of an ionized carboxylate group in the polymer main chain. Similar observations have been reported for metal-containing polymers prepared from the calcium salt of p-aminobenzoic acid and that of mono(hydroxybutyl)phthalate.16, 17 The absorption band at 1103 cm−1 corresponds to the C–O stretching of the ether group. The calcium content in CLHPTMG was determined using OES-ICP analysis, which showed that the polymer contained 2.028% of calcium.

Viscosity studies

Viscosity studies on CLHPTMG and BHPTMG were performed in DMF solvent at 30 °C. The inherent viscosities of CLHPTMG and BHPTMG were found to be 0.225 and 0.291 dl g−1, respectively. The low inherent viscosity of CLHPTMG relative to that of BHPTMG is due to the presence of ionic linkages in the polymer main chain. The viscosity behavior of ionic metal-containing polymers in polar solvents has been studied by several researchers such as Matsuda and Takechi,16, 22 Prasath et al.17 and Qiu et al.23 In their studies, the authors have reported that the presence of ionic groups in such polymers decreases the inherent viscosity of the polymers. This effect is presumably due to the dissociation of ionic groups into low-molecular-weight fractions in polar solvents, resulting in low inherent viscosities. A similar trend was observed in the case of CLHPTMG. In a polar solvent such as DMF, the ionic carboxylate groups along the polymer backbone dissociate to form low-molecular-weight fractions, resulting in lower viscosity.

Thermal studies

The TGA curve of the calcium-containing polyurethane, CLHPTMG, along with that of the control polyurethane without metal, BHPTMG, is shown in Figure 2. The thermogram shows that the metal-containing polymer was stable up to 198 °C. The control polyurethane shows thermal stability up to 284 °C. The lower thermal stability of CLHPTMG is due to the catalytic action of metal upon the thermal decomposition of polyurethane. This type of catalytic action was observed in the metal-containing polyurethane prepared using the metal salts of mono(hydroxybutyl)phthalate17 and polyurethane ureas prepared using the calcium salt of p-aminobenzoic acid.22 The polymer showed single-stage decomposition. The weight at the end temperature of analysis was 2.02%, which corresponds to the amount of calcium oxide formed.

Dynamic mechanical analysis

The thermomechanical properties of the polyurethanes were evaluated using DMA over a temperature range of −100 to 20 °C. The comparative dynamic mechanical behavior of CLHPTMG and BHPTMG is shown in Figure 3. The glass transition temperature (Tg) of polyurethanes can be easily identified from the peak of their tan δ curve. The calcium-containing polymer CLHPTMG showed a Tg at −48.7 °C, and the control polyurethane showed a Tg at −56.3 °C. This increase in the Tg is attributed to the ionic group in the polymer backbone. The presence of ionic groups in the polymer makes the chain stiffer, which in turn increases the Tg. At −100 °C, the calcium-containing polymer has a storage modulus of 3E08 Pa, and the control polyurethane without calcium has a storage modulus of 2E08 Pa. At all temperatures, the metal-containing polymer has a higher storage modulus than the control polyurethane, which is due to the phenomenon of ionic clustering in ionic calcium-containing polymers.

Stress–strain behavior

Typical stress–strain curves of CLHPTMG and BHPTMG are shown in Figure 4. The measured mechanical parameters are summarized in Table 1. The calcium-containing polymer showed a tensile strength of 12 MPa, and the control polyurethane showed a tensile strength of 5.258 MPa. The ionic and nonionic polyurethanes had a comparable percent elongation, 930 and 621, respectively. The initial modulus of CLHPTMG is higher than that of BHPTMG. This improvement in the mechanical properties of the metal-containing polymer is due to the presence of an ionic calcium-containing chain extender in the polymer main chain. The electrostatic interaction between the ionic species results in the aggregation of the ionic species. In ionomers, the ions are held by chemical bonds within a low-dielectric medium of hydrocarbon chains, in which the ions are incompatible. Therefore, the ions force the polymer backbone into conformations that allow the ions to associate together, resulting in the formation of ionic aggregates. Because these aggregates are formed between ions from different chains, they act as physical crosslinks, which improved the mechanical properties of the ionomers. A schematic representation of ionic aggregation is shown in Figure 5. This type of ionic aggregation has been observed in ionomers based on styrene and poly(2,6-dimethyl-1,4-phenylene oxide).24, 25

Stability study of polyurethane in PBS

The objective of this study was to evaluate the effect of various ions on the stability and mechanical properties of ionic polyurethane. The tensile strengths of aged samples are plotted as the percentage of the original untreated sample versus time in Figure 6. After 2 days of incubation in PBS, polyurethane showed a 20% decrease in tensile strength; this decrease was due to the presence of absorbed water in the sample. Ionic domains impart a degree of hydrophilicity to the polymer, resulting in increased water absorption. This absorbed water act as a plasticizer and influences the mechanical properties of the polymer.26 After 2 days, a minimal decrease in tensile strength was observed up to 1 month. This finding indicates that in aqueous media, only the absorption of water occurs; no significant hydrolysis occurs. In addition, no significant change in the morphology of the sample was observed. These findings confirmed that ionic polyurethane is stable in aqueous medium and will not dissolve in the presence of various ions.

Hemocompatibility evaluation

Because polyurethanes are widely used in the biomedical field for various blood-contacting applications, such as vascular prostheses, blood pumps, heart valves, catheters and artificial hearts, among others,27 it is important to verify the blood compatibility of this newly developed polyurethane. The blood compatibility of the ionic polyurethane CLHPTMG and the nonionic polyurethane BHPTMG was evaluated, and the obtained results were compared with those of a standard reference material, polystyrene. Preliminary blood compatibility tests, such as those that screen for platelet and leukocyte consumption in blood on sample exposure, were performed to assess the blood compatibility of the prepared polyurethanes. The total platelet and leukocyte count in blood before and after contact with the polymer material was assessed. The percentage count reduction was calculated from these values and is shown in Table 2. The results show that for CLHPTMG, the change in the leukocyte and platelet count is within 5% of the allowed measure of uncertainty. The polymer BHPTMG showed a large decrease in the platelet and leukocyte count. This result indicates that CLHPTMG did not support platelet and leukocyte adhesion. Another problem associated with the biocompatibility of the material is the hemolysis of blood. Red blood cells hemolyze when placed in contact with implant material. The percent hemolysis after 30 min of contact with the material was evaluated and is reported in Table 2. The results show that the percentage of hemolysis for CLHPTMG is <1% and is comparable to that of the reference material, indicating that the material will not induce any hemolysis. The results also show that the percentage of hemolysis of ionic polyurethane is lower than that of the nonionic polyurethane BHPTMG. Thus, the hemocompatibility of the material improved with the incorporation of ionic moieties.

Conclusion

In this study, a novel calcium-containing polyurethane was synthesized using CaL, PTMG and HDI. The polyurethane was characterized by FTIR spectroscopy, and the properties of the material were compared with those of control samples prepared without any calcium metal. Calcium-containing polyurethane showed stronger mechanical properties compared with the control polyurethane because of the formation of ionic aggregates. These ionic aggregates act as physical crosslinks, providing improved tensile strength and modulus relative to the nonionic polyurethane. Preliminary in vitro hemocompatibility tests reveal that the polymer is hemocompatible and does not induce any hemolysis of blood. These results suggest that this newly developed polyurethane can be used as a blood-contacting biomaterial.

Synthesis of CLHPTMG.

References

Manners, I. Ring opened polyferrocenes: metal-containing polymers material science, self assembly and nanostructure applications. Polym. Mater. Sci. Eng. 86, 85–86 (2002).

Nair, P. R., Nair, C. P. R. & Francis, D. J. Polyurethanes with polybutyl acrylate grafts via macromonomer technique: thermal and mechanical properties. Eur. Polym. J. 33, 89–95 (1997).

Silver, J. H., Hart, A. P., Williams, E. C., Copper, S. L., Charef, S., Labarre, D. & Jozefowicz, M. Anticoagulant effects of sulphonated polyurethanes. Biomaterials 13, 339–344 (1992).

Okkema, A. Z. & Copper, S. L. Effect of carboxylate and/or sulphonate ion incorporation on the physical and blood-contacting properties of polyetherurethane. Biomaterials 12, 668–676 (1991).

Lantman, C. W. & MacKnight, W. J. Structural properties of ionomers. Annu. Rev. Mater. Sci. 19, 295–317 (1989).

Jayakumar, R., Rajkumar, M., Nagendran, R. & Nanjundan, S. Synthesis and characterization of metal-containing polyurethanes with antibacterial activity. J. Appl. Polym. Sci. 85, 1194–1206 (2002).

Jayakumar, R., Lee, Y. S. & Nanjundan, S. Studies on metal-containing copolyurethanes. React. Funct. Polym. 55, 267–276 (2003).

Senthilkumar, N., Raghavan, A. & Nasar, A. S. Novel metal-containing polyurethane elastomers prepared using tetradentate schiff base metal complexes. Macromol. Chem. Phys. 206, 2490–2500 (2005).

Chantarasiri, N., Chulamanee, C., Mananunsap, T. & Muangsin, N. Thermally stable metal-containing polyureas from hexadentate Schiff base metal complexes and diisocyanates. Polym. Degrad. Stab. 86, 505–513 (2004).

Lelah, M. D., Pierce, J. A., Lambrecht, L. K. & Copper, S. L. Polyether—urethane ionomers: surface property/ex vivo blood compatibility relationships. J. Colloid Interface Sci. 104, 422–439 (1985).

Grasel, T. G. & Copper, S. L. Properties and biological interactions of polyurethane anionomers: effect of sulphonate incorporation. J. Biomed. Mater. Res. 23, 311–338 (1989).

Okkema, A. Z., Yu, X. H. & Copper, S. L. Physical and blood contacting characteristics of propyl sulphonate grafted biomer. Biomaterials 12, 3–12 (1991).

Fougnot, C., Dupillier, M. P. & Jozefowicz, M. Anticoagulant activity of amino acid modified polystyrene resins: Influence of the carboxylic acid function. Biomaterials 4, 101–104 (1983).

Douzon, C., Kanmangne, F. M., Serne, H., Labarre, D. & Jozefowicz, M. Heparin-like activity of insoluble sulphonated polystyrene resins part III: binding of dicarboxylic amino acids. Biomaterials 8, 190–194 (1987).

Acharya, V., Prabha, C. R. & Narayanamurthy, C. Synthesis of metal incorporated low molecular weight polyurethanes from novel aromatic diols, their characterization and bactericidal properties. Biomaterials 25, 4555–4562 (2004).

Matsuda, H. & Takechi, S. Synthesis and properties of polyureas from divalent metal salts of p-aminobenzoic acid, diamine, and diisocyanate. J. Polym. Sci. Part A Polym. Chem. 28, 1895–1908 (1990).

Prasath, R. A., Nanjundan, S., Pakula, T. & Klapper, M. Synthesis and characterization of calcium containing poly(urethane-ether)s. Eur. Poymer. J. 40, 1767–1778 (2004).

Jayakumar, R., Lee, L. S. & Nanjundan, S. Synthesis and characterization of calcium containing poly(urethane-urea)s. J. Appl. Polym. Sci. 90, 3488–3496 (2003).

Sedlarik, V., Galya, T., Emri, I. & Saha, P. Structure and conditioning effect on mechanical behavior of poly(vinyl alcohol)/calcium lactate biocomposites. Polym. Compos. 30, 1158–1165 (2009).

Pierce, B. F., Brown, A. H. & Sheares, V. V. Thermoplastic poly(ester urethane)s with novel soft segments. Macromolecules 41, 3866–3873 (2008).

Silverstein, R. M. & Webster, F. X. Spectroscopic Identification of Organic Compounds 96–97 John Wiley & Sons Inc., India, (2009).

Matsuda, H. & Takechi, S. Synthesis and properties of halato-telechelic polyurethane-ureas from divalent metal salts of p-aminobenzoic acid, diamine, dialkylene glycols, and diisocyanate. J. Polym. Sci. Part A Polym. Chem. 29, 83–91 (1991).

Qiu, W., Yang, Y., Yang, X., Lu, L. & Wang, X. Synthesis and characterization of polyimides from divalent metal salts of p-aminobenzoic acid. J. Appl. Polym. Sci. 59, 1437–1442 (1996).

Eisenberg, A. & Navratil, M. Ion clustering and viscoelastic relaxation in styrene-based ionomers. II. Effect of ion concentration. Macromolecules 6, 604–612 (1973).

Huang, Y., Cong, G. & MacKnight, W. J. Synthesis and properties of carboxylated poly(2,6-dimethyl-1,4-phenylene oxide) and its ionomer. Macromolecules 19, 2267–2273 (1989).

Sharlene, R. W., Wenqin, W., Karen, I. W. & Timothy, E. L. Synthesis and morphology of segmented poly(tetramethyleneoxide)-based polyurethanes containing phosphonium salts. Macromolecules 41, 9072–9079 (2008).

Korematsu, A., Takemoto, Y., Tadao, T., Nakaya, T. & Inoue, H. Synthesis, characterization and platelet adhesion of segmented polyurethanes grafted phospholipid analogous vinyl monomer on surface. Biomaterials 23, 263–271 (2003).

Acknowledgements

Priya A Nair is thankful to the Council of Scientific and Industrial Research (CSIR), New Delhi, India, for the Senior Research Fellowship. We also thank the Director of SCTIMST for the laboratory facilities provided and the permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nair, P., Ramesh, P. Synthesis and characterization of calcium-containing polyurethane using calcium lactate as a chain extender. Polym J 44, 1009–1014 (2012). https://doi.org/10.1038/pj.2012.51

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.51

Keywords

This article is cited by

-

Structures, properties and applications of the polyurethane ionomers

Journal of Materials Science (2020)