Abstract

Immobilization of enzymes and proteins on activated supports permits the simplification of the reactor design and may be used to improve some enzyme properties. In this sense, supports containing epoxy groups seem to be useful to generate very intense multipoint covalent attachment with different nucleophiles placed on the surface of enzyme molecules (e.g., amino, thiol, hydroxyl groups). However, the intermolecular reaction between epoxy groups and soluble enzymes is extremely slow. To solve this problem, we have designed “tailor-made” heterofunctional epoxy supports. Using these, immobilization of enzymes is performed via a two-step process: (i) an initial physical or chemical intermolecular interaction of the enzyme surface with the new functional groups introduced on the support surface and (ii) a subsequent intense intramolecular multipoint covalent reaction between the nucleophiles of the already immobilized enzyme and the epoxy groups of the supports. The first immobilization may involve different enzyme regions, which will be further rigidified by multipoint covalent attachment. The design of some heterofunctional epoxy supports and the performance of the immobilization protocols are described here. The whole protocol to have an immobilized and stabilized enzyme could take from 3 days to 1 week.

Similar content being viewed by others

Introduction

Immobilization–stabilization of enzymes

The main application of enzyme immobilization is the industrial reuse of enzymes for many reaction cycles1,2,3,4,5,6. In addition, enzyme immobilization should always result in an increase in enzyme stability. The development of simple protocols for immobilization and stabilization of industrial enzymes is therefore a very exciting goal in enzyme biotechnology, because immobilized and highly stabilized enzyme preparations could be very useful for a massive implementation of sustainable chemical processes catalyzed by enzymes.

Multipoint covalent attachment is one of the most interesting approaches to link immobilization and stabilization of enzymes. Stabilization factors ranging between 100 and 1,000,000 have been reported1,2,3,4,5,6. Theoretically, an enzyme molecule attached to a rigid support through many covalent linkages, and via very short spacer arms, should be highly stabilized, that is, the enzyme residues involved in the covalent immobilization should keep their relative positions unaltered during any conformational changes of the protein promoted by any distorting agent (heat, organic solvents, etc.). In this way, the intensity of these conformational changes should be strongly reduced. In fact, it should be similar to a multi-intramolecular crosslinking, where the support acts as a rigid multicrosslinking agent. In this way, even if only 20–30% of the enzyme surface is involved in the immobilization on the support surface, the stabilization of the whole immobilized enzyme molecule may be very intense7,8.

To take full advantage of this technique, immobilization needs to fulfill two requirements: (i) the reaction should proceed in such a way that the activity of the enzyme is not highly reduced, and (ii) a relatively high number of reactive groups in the enzyme should be involved in the reaction. It has been shown that different surface regions of the protein have different relevance for the enzyme stability9,10. An optimal immobilization–stabilization strategy should involve multipoint covalent immobilization through surface regions that are rich in residues able to react with activated supports as well as being relevant to enzyme stability. It is therefore useful to perform multipoint covalent attachment through each of the different regions of enzyme surfaces in order to develop the best stabilization strategy for a particular enzyme.

Immobilization of proteins on monofunctional epoxy supports

At first glance, epoxy-activated supports are almost ideal matrices to perform a very easy immobilization–stabilization of proteins via multipoint covalent attachment11,12. Epoxy groups bear short spacer arms and may react with many nucleophilic groups present on the protein surface (e.g., Lys, Cys, His, Tyr) and, in a slower way, with carboxylic groups. Moreover, these groups may also react with carboxylic groups producing an ester bond, although this reaction proceeds in a much slower fashion11. In addition, epoxy groups are very stable, making it possible to perform long-term incubations of immobilized enzymes under alkaline conditions in order to get an intense multipoint covalent attachment (e.g., involving a number of Lys residues with a relatively high pK value)13,14. Furthermore, a very intense multipoint covalent immobilization promotes only very mild chemical modifications of the protein surface (e.g., secondary amine, thioether, ether).

It has, however, been reported that soluble proteins are scarcely reactive with epoxy-activated supports even under slightly alkaline conditions15,16,17,18. At first glance, this extremely low intermolecular reactivity between epoxy groups and nucleophiles on the protein surface constitutes a serious drawback of monofunctional epoxy supports as supports for single enzyme immobilization protocols and for more interesting enzyme immobilization–stabilization protocols.

Multipoint covalent immobilization of proteins on heterofunctional epoxy supports

This very low intermolecular reactivity between epoxy supports and proteins does however open new exciting possibilities to rigidify each protein through different regions of its surface. By preparing different heterofunctional epoxy supports19,20,21, diverse two-step immobilization protocols can be developed. The overall steps of this procedure are

-

I

Rapid physical or chemical fixation of protein on the support surface (through different regions of the protein surface) and

-

II

Promotion of intramolecular multipoint attachment between the epoxy groups of the support and the nucleophiles placed in the vicinity of the region of the protein participating in the first fixation.

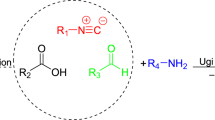

Heterofunctional epoxy supports contain a low concentration of chemical moieties (easily introduced on a few epoxy groups) (Fig. 1a) able to promote the adsorption or attachment of the protein molecule to the support as well as a very high concentration of epoxy groups able to promote an intense additional multipoint covalent attachment between the protein and the support17.

(a) Physical or chemical immobilization of proteins (blue). Groups in the protein able to interact with the groups in the support. Groups in the support able to promote a rapid physical or chemical fixation of the protein on the support surface. (b) Multipoint reaction of nucleophiles of immobilized proteins and epoxy groups.

As an exception, commercial hydrophobic epoxy supports do not need any kind of extrafunctionalization. At high ionic strength, adsorption through the external hydrophobic pockets of the proteins occurs, allowing covalent attachment between nucleophiles and epoxy groups15,16,17,18. In fact, this kind of two-step immobilization using hydrophobic supports has already been reported for many enzymes11,12. However, protocols for covalent immobilization of enzymes through epoxy groups at low ionic strength or on hydrophilic supports had not yet been reported until the proposal of heterofunctional epoxy supports19. Table 1 shows some examples of different chemical moieties able to promote a rapid physical or chemical binding (under very mild conditions) of proteins to heterofunctional hydrophobic or hydrophilic epoxy supports. Each chemical moiety promotes different interactions involving different regions of the protein surface.

Although long-term incubation of the already immobilized proteins under neutral pH may promote the formation of a few covalent linkages between the protein and the epoxy groups in the support11,12, the highest intensity of multipoint covalent attachment is achieved via a long-term incubation under alkaline conditions because of the increase in the reactivity of nucleophiles (mainly Lys residues usually present on the protein surface)13,14,22 (Fig. 1b).

Likely applications

The use of several of these supports may permit the immobilization of a particular enzyme with different orientations, resulting in each preparation having very different activity/stability/selectivity. Examples of this approach include: immobilization of β-galactosidase (Aspergillus niger)23, epoxyde hydrolase (A. niger)24, glutaryl acylase25, β-galactosidase (Thermus sp)26 on different heterofunctional epoxy supports. In all the cases, different enzyme activity recoveries and stabilities resulted from immobilization of the enzymes on different heterofunctional epoxy supports.

These supports permit immobilization under a very broad range of conditions; the only requirement is that the enzyme must become adsorbed on supports activated with the new groups19. Thus, immobilization may be performed at low ionic strength from pH 4 to 10 by combining carboxy-epoxy or amino-epoxy supports. Boronate-epoxy19 or disulfide-epoxy20 have an even broader range of conditions under which they may be used.

Recently, it has been shown that the immobilization of enzymes that suffer significant conformational changes during catalysis (e.g., lipases, penicillin G acylase (PGA)) permits that the properties of these may be altered by involving different regions of the protein in the immobilization27,28,29,30,31,32. In this sense, heterofunctional supports enable the preparation of lipases having very different enantio-specificities32.

When the protein to be immobilized (e.g., antibodies, proteases, amylases) needs to recognize very large substrates (other proteins, starch, etc.), the orientation of the immobilized enzyme regarding the support is a key point: only if the active center is exposed to the medium, the protein will be able to recognize these large substrates33,34,35,36. In these cases, the use of different supports immobilizing the protein via different regions may yield at least one immobilized protein preparation having the biological activity.

The use of epoxy supports bearing a second group able to specifically adsorb the target protein has proved to be a very useful tool for the one-step purification–immobilization–stabilization of proteins. Thus, tailor-made metal-chelate-epoxy supports (having an extremely low amount of metal-chelate groups) have been used to purify, immobilize and stabilize polyhistidine-tagged proteins (e.g., glutaryl acylase37, β-galactosidase from Thermus sp38 or peroxidase39). Considering that the second group may be any kind of ligand, it may be expected that this technique may be applicable to many other cases (except using inhibitors, because that should yield an inhibited enzyme).

Another very exciting application of this two-step immobilization protocol may be the covalent immobilization of antibodies with the correct orientation (the Fab region opposite to the support surface) on a fully inert support surface. For example, the immobilization of antibodies on epoxy-metal-chelate supports afforded fully functional antibodies40. This kind of immobilized antibody (on porous supports or on magnetic nanoparticles) can be very useful to design immunoaffinity supports or immunobiosensors. After the two-step immobilization, epoxy groups on the support may be blocked with very high concentrations of, for example, glycine or cysteine, yielding a fully inert hydrophilic support surface.

Finally, disulfide-epoxy supports, which may not be able to immobilize many native proteins, are a powerful tool to get a site-directed rigidification of proteins. By coupling site-directed mutagenesis and this support, it is possible to prepare different mutants each having one superficial Cys residue. If each mutant has this Cys residue in different regions of the protein surface, it may be possible to get an immobilization via this Cys residue, and after that, rigidification of that area of the protein surface. This permits detection of the most relevant areas for enzyme stabilization against different inactivation agents (T, drastic pH values, solvents, etc.). Moreover, this may permit to modulate the properties of enzymes like PGA or lipases. In our laboratory, we have got some very nice supports and experiments are ongoing to improve even that.

Materials

Reagents

-

Epoxy Sepabeads (EC-EP-Sepabeads; Resindion SRL, Mitsubishi Chemical Corporation) (ethylenediamine (EDA)-epoxy supports (EES))

-

Eupergit C or 250 (Degussa, Röhm GmbH & Co. KG) (EES and thiol-epoxy supports (TES))

-

EDA (Sigma Chemical Company) (EES)

Caution

Corrosive, flammable and harmful in contact with skin and if swallowed. Working with gloves and in a fume hood is recommended.

-

Amino-Support modification solution: 0.3 M ethylenediamine in distilled water at pH 8.5 and 25 °C (adjusted with 1 M HCl) (EES)

Critical

To prevent the oxidation of the ethylenediamine, when the pH is adjusted to 8.5 by adding HCl, the temperature should not exceed 30 °C.

-

Washing solution 1: 1 M NaCl/100 mM sodium hydrogen carbonate at pH 8.5 (EES)

-

Washing solution 2: 1 M NaCl/100 mM sodium acetate at pH 5.0 (EES)

-

Protein immobilization buffer 1: 5 mM sodium dihydrogen phosphate buffer at pH 7.0 (adjusted with 5 M NaOH) (EES)

-

Protein desorption solution 1: 1.5 M sodium dihydrogen phosphate at pH 7.0 (adjusted with 5 M NaOH) (EES)

-

Multipoint covalent attachment incubation buffer: 0.1 M sodium hydrogen carbonate at pH 8.5 or 10 (adjusted with 5 M NaOH) (EES)

-

Blocking solution: 3 M glycine at pH 8.5 (EES)

-

Mercaptoethanol was from Sigma Chemical Company (EES)

Caution

Harmful if swallowed. Toxic in contact with skin. Causes burns. Working in a fume hood and with protective gloves is recommended.

-

Blocking solution b: 1 M mercaptoethanol in 50 mM sodium dihydrogen phosphate pH 8.5 (EES)

-

Epoxy Sepabeads (FP-EP-Sepabeads) from Resindion SRL (Mitsubishi Chemical Corporation) (TES)

-

Sodium sulfide was from Sigma Chemical Co. (TES)

Caution

Causes burns, and when in contact with acids liberates toxic gas. Working in a fume hood and using protective clothing is recommended.

-

Thiol-Support modification solution: 50 mM sodium hydrogen carbonate at pH 8.5 containing 1 mM sodium sulfide at 25 °C (TES)

-

2,2′-dipyridyl disulfide(2-PDS) (this compound is also named 2,2′-dithiodipyridine) (Sigma Chemical Co.) (TES)

Caution

Irritating to eyes, respiratory system and skin. Wear protective clothing and gloves.

-

Thiol determination buffer: 0.1 M sodium dihydrogen phosphate (adjusted with 5 M NaOH at pH 8.0) containing 1.5 mM 2-PDS (TES)

-

Thiol activating solution: 60% acetone/40% (v/v) 50 mM sodium hydrogen carbonate containing 0.2 M 2-PDS (TES)

-

Ethylene diamine tetraacetic acid (Sigma Chemical Co.) (TES)

-

Washing solution 3: 60% acetone/40% water (v/v) (TES)

-

Washing solution 4: 1 mM ethylene diamine tetraacetic acid dissolved in water (TES)

-

Washing solution 5: 5 mM sodium dihydrogen phosphate pH 7 (adjusted with 5 M NaOH) (TES)

-

Washing solution 6: 0.2 M sodium acetate at pH 5.0 (TES)

-

D,L-Dithiothreitol (DTT) (Sigma Chemical Co.) (TES)

Caution

Harmful if swallowed. Irritating to eyes, respiratory system and skin. Wear suitable protective clothing.

-

N-succinimidyl 3-(2-pyridyldithio)propionate (SPDP) (Sigma Chemical Co.) (TES)

-

Chemical thiolation solution: 25 mM SPDP in ethanol (TES)

-

Protein disulfide reducing solution: 500 mM DTT in 0.1 M sodium acetate pH 4.5 (TES)

-

Protein elution solution: 50 mM sodium dihydrogen phosphate containing 400 mM DTT (final pH value is pH 8.0 adjusted with 5 M NaOH) (TES)

-

Multipoint covalent attachment incubation buffer: 0.1 M sodium hydrogen carbonate at pH 8.5 or 10 (adjusted with 5 M NaOH) (TES)

-

Blocking solution: 3 M glycine at pH 8.5 (TES)

-

PD-10 columns (Sephadex G-25) (Pharmacia BTG-LKB) (TES)

Equipment

-

Magnetic bars

-

Sintered glass filter

-

Vacuum filtering systems: to recover the supports and immobilized enzymes, these systems are simpler than centrifuges

-

pH stat

-

Micropipettes to take samples

-

Fume hood. Thiol compounds smell very strongly

Reagent setup

-

Protein immobilization buffer 2 10 mM sodium dihydrogen phosphate buffer at pH 7.0 (adjusted with 5 M NaOH). Low concentrations (upto 10 mM) of protein stabilizers could be added to this buffer as long as they did not present primary amino groups or thiol groups (TES).

Equipment setup

-

Stirring systems The use of suspensions makes the use of mild stirring systems in order to have a homogenous suspension when taking samples necessary. This may be, for example, magnetic stirring, mechanical stirring with helix, orbital stirring or shakers.

Critical

Using heterogeneous suspensions, an adequate stirring system must be used in most of the steps (in activation of the support, immobilization of the enzymes or enzyme activity determination); however, this may not be used when the enzyme has been already immobilized and we only intend a more intense multipoint covalent attachment.

Procedure

Preparation of supports

-

1

Prepare the supports using by following the steps in options A, B and C, respectively. The moieties introduced in the support may be almost any molecule able to react with the epoxy groups and permit the adsorption of the target protein. To favor multipoint covalent attachment, always introduce the minimum amount of these groups to achieve the adsorption of our target protein in a reasonable time. Option A describes the preparation of EDA-epoxy, EDA-mercaptoethanol and EDA-supports; option B describes the preparation of thiol-epoxy and thiol-glycine supports; and option C describes the preparation of disulfide-epoxy and disulfide-glycine supports.

-

A

EDA-epoxy, EDA-mercaptoethanol and EDA supports

-

i

Wash 10 g of EP-Sepabeads or Eupergit C (five times with 10 volumes of deionized water).

-

ii

Incubate the washed supports in 100 ml of amino support modification solution at 25 °C under gentle stirring for 1 h (modification of around 20% of the epoxy groups is achieved). If the target enzyme does not become adsorbed on this low-activated support, the degree of modification of the epoxy groups in the support may be increased by longer incubation time with the amino support modification solution.

-

iii

To modify all epoxy groups with EDA (EDA-support), increase the pH of the amino support modification solution to pH 10 and allow the reaction to proceed for 24 h.

-

iv

Filter the EDA-epoxy supports and EDA-support on a sintered glass filter and wash thoroughly with washing solutions 1 and 2, and finally with distilled water. Eliminate the interparticle water by vacuum filtering. At this stage, the quantification of EDA groups introduced on the support may be performed by titrating the amino groups in the support by using a pH stat. Considering that the pKa of these groups is around 7 for the primary and around 10 for the secondary amine, a titration with 10 mM NaOH from pH 4.8 to 8.8 will determine the concentration of the first group. It is recommended that 1.5 M of KCl be added to the medium41.

-

v

The remaining epoxy groups can be blocked with mercaptoethanol by incubation with the blocking solution 2 for 14–18 h to avoid reaction of the enzyme with the epoxy groups. EDA-mercaptoethanol-blocked supports should then be washed with washing solutions 1 and 2 and distilled water. This support may be used as a reference to check if the target protein becomes adsorbed on this support.

-

vi

Store the wet (with pores full of water) EDA-epoxy supports at 4 °C. The adsorption and covalent immobilization properties remain almost unaltered after 1 month.

-

i

-

B

Thiol-epoxy and thiol-glycine supports

-

i

Wash 10 g of EP-Sepabeads or Eupergit C with deionized water.

-

ii

Incubate the washed supports in 400 ml of thiol support modification solution at 25 °C under gentle stirring for 5 h.

-

iii

Filter the thiol-epoxy supports on a sintered glass filter and thoroughly wash with washing solutions 1, 2 and 5. Eliminate the interparticle water by vacuum filtering.

-

iv

The thiol-epoxy supports can be stored at 4 °C (supports may be stored for a maximum of 1 week). To store these supports, wash them with washing solution 6.

-

v

To determine the amount of thiol groups introduced in the support, incubate 0.5 g of the thiol containing supports with 20 ml of thiol determination buffer at 25 °C under gentle stirring for 1 h. Take a sample of the supernatant and determine the amount of pyridine-2-thione released from the support by measuring the absorbance of the supernatant at 343 nm. The molar extinction coefficient of pyridine-2-thione42 is 8.02 × 103 M−1 cm−1. The concentration of the thiol groups present on the support can be calculated using the following equation:

Vtotal= 20 ml, g of support = 0.5 g. The basic reaction scheme of this titration is outlined in Figure 2. The thiol groups of the support react forming a 2-pyridyl disulfide. Thereby, a 2-pyridyl thiol is produced in equimolecular amount to the reactive thiol groups on the support. The 2-pyridyl thiol is stabilized by its tautomeric thione form, which serves as chromophoric reporter as it strongly absorbs at 343 nm. Owing to this stabilization, the position of equilibrium favors the products, and the reaction occurs quantitatively43,44,45.

-

vi

To prepare a support where the attachment proceeds only via the thiol group, the remaining epoxy groups can be blocked with glycine by incubation with the blocking solution for 14–18 h to leave the thiol moieties as the only reactive group (thiol-glycine-blocked supports). The thiol-glycine-blocked supports should then be washed with washing solutions 1, 2 and 5 and vacuum-dried. This support may be used in order to check if thiol-disulfide exchange is the first step of the enzyme immobilization, and to have a protein immobilized but not rigidificated to be used as reference.

Pause point

Thiol-glycine supports can be stored at 4 °C for a maximum of 1 week. In general, thiol groups are not very stable and the stability decreases with the concentration. It may be convenient to check if the thiol groups are still reactive if the enzymes or supports have been stored for more than 2–3 days.

-

i

-

C

Disulfide-epoxy and disulfide-glycine supports

-

i

Prepare thiol-epoxy or thiol-glycine supports as described in option B.

-

ii

To activate the thiol group, incubate 10 g of thiol supports in 100 ml of the thiol-activating solution for 1 h at 25 °C.

Critical Step

The control of the modification of epoxide is critical, as too low will result in a very low immobilization and too high can hinder the multipoint covalent attachment. In some cases, the disulfide group may be in the protein. In this case, thiol supports could be directly used in immobilization.

-

iii

Wash the thiol-reactive (epoxy or glycine) supports with washing solutions 3, 4 and 5 (approximately five times with each washing solution, each wash having a volume five times that of the support).

Pause point

The thiol-reactive supports can be stored at 4 °C for 1 month.

-

i

-

A

Immobilization of proteins

-

2

Immobilize the proteins on EDA-epoxy, disulfide or thiol-epoxy supports by performing the steps in options A, B and C, respectively. In these methods, it is necessary to first determine whether the support is able to immobilize the target protein and then to optimize the conditions for this reaction. For EDA-epoxy supports, for example, the pH should be adjusted to conditions where the target protein is adsorbed. The standard protein immobilization buffer 1 should, however, be valid for around 70% of proteins at pH 7. Immobilization on disulfide-epoxy and thiol-epoxy supports is via thiol-disulfide exchange and therefore only proteins bearing exposed thiol groups can be immobilized on the support. Immobilization on thiol-epoxy supports is possible only when the protein has been chemically modified to introduce a disulfide group on its surface.

-

A

On EDA-epoxy supports

-

i

Feasibility of the support to immobilize the target protein: dissolve the proteins in 90 ml of protein immobilization buffer 1. Add 7 g of EDA support (without epoxy groups) to the protein solution and stir this immobilization suspension gently. To this first approximation, 1 mg of protein per g of support may be enough.

Critical Step

It is necessary to be sure that the enzyme becomes adsorbed on the support; otherwise, immobilization will be too slow. However, although the use of supports having many amino groups can accelerate the adsorption, it will hinder the multipoint covalent attachment.

-

ii

Periodically take samples of the supernatants and analyze for enzyme activity (Fig. 3; for an example using β-galactosidase, see Box 1). If the enzyme was adsorbed on the EDA-support, go to Step 2A(ix). If no adsorption of the protein was observed on the support, go to Step 2A(iii).

-

iii

Prepare immobilization buffer 1 at pH values from 5 to 9.

-

iv

Dissolve the proteins in immobilization buffer 1 of different pH values.

-

v

Add 7 g of EDA-support to the different protein solutions at the different pH values and stir these immobilization suspensions gently.

-

vi

Periodically, take samples of the supernatants and analyze for enzyme activity. Choose the milder pH value for enzyme stability where the enzyme becomes adsorbed on the EDA-support and continue with the next section.

-

vii

Immobilization on EDA-epoxy supports: add 7 g of EDA-epoxy support to 90 ml of the protein solution at the pH value where the target enzyme becomes adsorbed on the EDA-support, and stir this immobilization suspension gently. Incubate a solution of enzyme under the same conditions as a reference.

-

viii

Periodically, take samples of the supernatants and the reference, and analyze these for enzyme activity. If the enzyme becomes adsorbed on the support, go to Step 2A(xi). If there is no significant immobilization after 5 h, assume that the amount of cationic groups on the support is not enough to adsorb the target enzyme and go to Step 2A(ix).

-

ix

Prepare new EDA-epoxy supports, this time using longer reaction times with the amino support modification solution in order to increase the amount of EDA groups introduced in the support. Try modifications of 30, 40 and 50% of the epoxy groups (remember that although higher modification may permit adsorption, it will also result in decreased rate for the subsequent covalent reaction).

-

x

Choose the EDA-epoxy support with the lowest concentration of EDA groups able to immobilize the protein.

-

xi

Take 10 ml of the chosen immobilization suspension; wash with washing solution 5 to eliminate all the proteins not bound to the support and dry under vacuum filter.

-

xii

Add 0.7 g sample of the support with the immobilized proteins to 9 ml of protein desorption solution 1.

-

xiii

Stir this suspension gently for 30 min.

-

xiv

Determine the activity or the protein concentration in the supernatant. If the EDA-support released all the proteins whereas the EDA-reactive epoxy did not release any protein at all, this implies that covalent immobilization has occurred. If some protein was still released, longer enzyme–support incubation may be necessary to get the covalent immobilization.

-

xv

When there is no desorption of proteins in Step 2A(xiv), the covalent immobilization is considered complete; wash the insoluble derivatives with washing solution 5 and distilled water (approximately five times with 5 volumes of each solution).

-

i

-

B

On disulfide-epoxy supports

-

i

Feasibility of the support to immobilize the target protein: dissolve the enzyme in 80 ml of immobilization buffer 2. Protein stabilizers can be added to this buffer as long as they do not present any primary amino or thiol groups.

Critical Step

Only some few proteins have free superficial Cys; thus, only if the enzyme may be immobilized in disulfide support, these supports will be valid for the natural enzyme.

-

ii

Add 7 g of thiol-reactive glycine supports to the solution and stir this immobilization suspension gently at 25 °C.

-

iii

Periodically, take samples of the supernatants and analyze them for enzyme activity. If the enzyme was immobilized on the thiol-reactive glycine, go to Step 2B(xii). If immobilization of the protein on the support was not observed after 3 h, this implies that the protein does not have exposed reactive thiol groups. In this case, sulfydryl groups need to be generated from reduction of indigenous disulfides (go to Step 2B(iv)) or created via site-directed mutagenesis or via controlled chemical modification (go to Step 2C(iv). Both procedures would need to be focused on the protein surface21,45.

-

iv

Generation of sulfydryl groups by reduction of indigenous disulfides (an example of this, using β-galactosidase, is described in Box 2). Prepare a protein solution at a concentration of 1–20 mg ml−1 in 50 mM sodium phosphate pH 7.0.

-

v

Add protein disulfide reducing solution to a final concentration of 25 mM, that is 50 μl per ml of protein solution.

-

vi

Incubate the reaction mixture for 30 min at 25 °C.

-

vii

Purify the reduced enzyme from the excess of DTT by gel filtration using 50 mM sodium phosphate pH 7.0. The thiol-enzyme must be used immediately in immobilization to prevent sulfidryl oxidation (Fig. 4).

-

viii

Immobilization on disulfide-epoxide supports: add 10 g of disulfide-epoxy or disulfide-glycine support to 90 ml of reduced enzyme in 50 mM sodium phosphate pH 7.0. Use a control with soluble enzyme and without support to determine the possible inactivating effect of incubating conditions (pH, ionic strength, temperature) on the enzyme during the incubation period.

-

ix

Periodically, take samples of the supernatant and suspension and analyze these for enzyme activity.

Critical Step

To take samples of immobilized enzymes, it is necessary to use cut tips in the pipettes and use a vigorous stirring to ensure full dispersion.

-

x

Take 10 ml of immobilization suspension, filter it and wash with washing solution 5 to eliminate all the proteins not bound to the support, and dry under a vacuum filter.

-

xi

Add 1 g (wet weight) of the support with the immobilized proteins to 9 ml of protein elution solution. Stir this suspension gently for 30 min at 25 °C. Determine the activity or the protein concentration in the supernatant. If the thiol-reactive glycine support released all the proteins whereas the thiol-reactive-epoxy support did not release any protein at all, this implies that additional covalent immobilization have occurred between nucleophiles of the protein surface and epoxide groups of the support. If some protein is released, it is necessary to perform the enzyme–support reaction for longer times.

-

xii

When the covalent immobilization is considered complete (that is, no release of protein to the supernatant is observed), the insoluble derivatives should be thoroughly washed with washing solution 5 and distilled water.

-

i

-

C

On thiol-epoxy supports

-

i

Chemical thiolation of the protein surface (an example is described in Box 3). Prepare a protein solution at a concentration of 1–20 mg ml−1 in 50 mM sodium phosphate pH 7.0 (ref. 46).

-

ii

Then slowly add the chemical thiolation solution and incubate the reaction mixture at 25 °C for 30 min under gentle stirring.

Critical Step

The introduction of just one disulfide on the enzyme surface is enough to permit the immobilization on a thiol-reactive support; thus, it is recommended to adjust the amount of SPDP to an equimolecular relation with the enzyme molecules to ensure a very mild modification of the protein, decreasing the negative effect of this modification on the enzyme activity.

-

iii

Then, by dialysis or gel filtration, eliminate the reaction by-products. The SPDP-modified protein contains pyridildisulfide groups; therefore, it is not necessary to activate the thiol groups of the bifunctional supports with 2-PDS, and the protein could be immobilized directly to bifunctional supports containing thiol and epoxide groups (Fig. 4).

-

iv

Immobilization on thiol-epoxide and thiol-glycine supports: add 10 g of thiol-epoxy supports to 100 ml of SPDP-modified enzyme in 50 mM sodium phosphate pH 7.0. Incubate a solution of enzyme under the same conditions as a reference.

-

v

Periodically, take samples of the supernatant and suspension and analyze for enzyme activity (for around 12 h). The non-immobilized protein should correspond to the percentage of enzyme molecules without disulfide groups.

Critical Step

To take samples of immobilized enzymes, it is necessary to use cut tips in the pipettes and use a vigorous stirring to ensure full dispersion.

-

vi

Complete the immobilization by performing Steps 2B(viii)–(xii).

-

i

Critical Step

Suitable references must be used to ensure that the immobilization is really due to the groups introduced in the support.

-

A

-

3

In some cases, these preparations are used directly in the blocking step. If higher stability is desired, multipoint covalent attachment is necessary.

Immobilized enzymes on supports bearing epoxy groups may become more stable if multipoint covalent attachment is achieved between the nucleophilic groups of the already covalently immobilized enzyme and the remaining epoxy groups in the support13,14. To achieve this, perform the following steps: (i) wash the immobilized preparations 5 times with 3 volumes of incubation buffer and resuspend in 3 volumes of that buffer. As this is a “pseudo-intramolecular” reaction, continuous stirring is not necessary. (ii) Periodically, take samples of the suspensions and analyze the enzyme activity. (iii) To stop the support–enzyme reaction (e.g., when the activity decreases and/or the stabilization was in the desired range), go to the next section.

Critical Step

To take samples of immobilized enzymes, it is necessary to use cut tips in the pipettes and use a vigorous stirring to ensure full dispersion.

Blocking of the remaining epoxy groups on the support

Critical Step

This step permits one to stop the enzyme–support reaction and also alter the physical properties of the support surface, critical in many cases for the enzyme stability. Moreover, it prevents substrates of the enzyme from reacting with the support during biocatalyst use.

-

4

Vacuum-dry the immobilized preparations, resuspend in 3 volumes of blocking solution and stir gently at 25 °C.

-

5

After 24 h, wash the preparations with washing solutions 1 and 2 and distilled water. Store the immobilized preparations at 4 °C. Never freeze the immobilized preparation, as this will result in physical destruction of the support.

Timing

Immobilization on amino-epoxy supports

Synthesis of amino-epoxy supports: 4 h

Synthesis of amino supports: 20–25 h

Adsorption of proteins: 1–6 h

Multipoint covalent attachment: 18–48 h

Blocking of the remaining epoxy groups on the support: 20 h

Immobilization on thiol or disulfide–epoxy supports

Synthesis of thiol-epoxy supports: 6 h

Synthesis of thiol-glycine supports: 20–25 h

Synthesis of thiol-reactive-epoxy and thiol-reactive-glycine supports: 7 h, 21–26 h

Disulfide reduction of protein: 24 h

Chemical thiolation of proteins: 24 h

Immobilization of thiol-proteins or SPDP-modified proteins on disulfide or thiol-epoxy supports: 1–18 h

Stabilization of immobilized enzymes by multipoint covalent attachment: 18–48 h

Blocking of the remaining epoxy groups on the support: 20 h

Anticipated results

Example 1: Immobilization of enzymes on different heterofunctional supports: effect of activity recovery.

As discussed in INTRODUCTION, the immobilization of enzymes on different heterofunctional epoxy supports may permit the immobilization of the enzyme through different parts of the protein. In this way, it is possible that immobilization has very different effects on the enzyme activity when different supports are used.

Table 2 shows some of the most relevant results obtained in our laboratory.

Some enzymes are not significantly immobilized on certain supports19; for example, PGA from Escherichia coli is not immobilized on EDA-epoxy supports (this enzyme did not become adsorbed on mild anionic exchangers)47,48. The lack of external Cys on the enzyme means that the immobilization on the disulfide-epoxide support was very poor. This problem was solved by chemical thiolation of the enzyme, which enabled its immobilization on thiol-epoxy supports (Box 3). In other cases, although the enzymes are immobilized, the expressed activity is very different. For example, β-galactosidase from A. oryzae is fully inactivated when immobilized on conventional hydrophobic epoxy-supports, but retains almost full activity when immobilized on EDA-epoxy supports19. Similarly, epoxide hydrolase from A. niger retained only 30% of its activity when immobilized on hydrophobic epoxy supports, whereas recovered activity was nearly 100% using EDA-epoxy supports24. β-Galactosidase from E. coli is an example where the enzyme has many exposed Cys residues. This permits the rapid immobilization on disulfide-epoxy Eupergit. For the lipase from Candida rugosa, the highest activity recovery was obtained using the conventional hydrophobic-epoxy support19.

Example 2. Immobilization of enzymes on different heterofunctional supports: effect of the kind of support on the enzyme stabilization by multipoint covalent attachment.

As discussed in INTRODUCTION, stabilization of enzymes by multipoint covalent or multisubunit attachment is a well-established technique, requiring a suitable system to permit intense support–enzyme interactions1,2,3,4,5,6. However, final results depend on different factors: (i) the area of the enzyme near the support must contain a relatively high number of groups able to react with the support; (ii) this area must be relevant for the enzyme stability; and (iii) in the case of multimeric enzymes, this orientation must be such that several protein subunits can be involved in the immobilization.

Immobilization of the proteins via different orientations may give very different final stability of the immobilized enzymes. For example, Figure 5 shows that when β-galactosidase from Thermus sp T2 is immobilized on any epoxy support, it is more stable than the soluble enzyme. However, when using conventional hydrophobic epoxy supports or EDA-epoxy supports, the stabilization is very poor; using boronate-epoxy or IDA-Me2+-epoxy supports, the stabilization factor becomes very significant26.

Derivatives were immobilized at pH 7 for 24 h and further incubated for 24 h at pH 10 and 25 °C before blocking with 3 M glycine. Inactivations were carried out at 80 °C in Novo buffer pH 6.5 in triplicate, (circles) Sepabeads-boronic-epoxy; (squares) Sepabeads-Co-IDA-epoxy; (triangles) Sepabeads-EDA-epoxy; (stars) Sepabeads-epoxy; (rhombus) Soluble Htag-BgaA.

Similarly, Figure 6 shows that glutaryl acylase immobilized on conventional hydrophobic-epoxy supports is much less stable than the enzyme immobilized on EDA-epoxy-supports25.

Figure 7 shows that epoxyde hydrolase from A. niger immobilized on EDA-epoxy supports is much more stable than the same enzyme immobilized on conventional hydrophobic supports22.

Example 3: Immobilization of enzymes on different heterofunctional supports: effect on the enantiospecificity of lipases.

It has been shown that the properties of lipases, owing to the peculiar mechanism of catalysis (involving dramatic conformational changes), may be strongly modulated by involving different regions of the enzyme in the immobilization27,28,29,30. Modified conformational changes of lipases produce lipase preparations yielding very different properties.

Lipases may be immobilized on commercial epoxy supports (having a hydrophobic matrix) even at low ionic strength. This is due to the fact that they can become adsorbed on the hydrophobic surface of the support via interfacial activation (even at low ionic strength). This particular feature of lipases has been used to immobilize, purify and hyperactivate lipases in just one step using supports like octyl-agarose49, but in this case it is a problem because it has been assessed that the partial modification of the support surface, even with hydrophilic groups like EDA or IDA, is not enough to prevent the interfacial adsorption. However, by adding a small concentration of detergents (e.g., 0.5% Triton X-100), adsorption via interfacial activation may be fully prevented29, and lipases will become adsorbed by the groups inserted in the matrix. Other possible problems using lipases is their tendency to form lipase–lipase dimers with altered properties; this is also solved using detergents50,51,52.

Therefore, considering that the use of different heterofunctional epoxy supports may result in the immobilization of lipases via different areas, different epoxy-heterofunctional supports were used to immobilize the lipase from Mucor miehei and the enantioselectivity of these preparations against ±butyroyl-2 phenylacetic acid was studied32. Table 3 shows the different results obtained at 25 and 4 °C. While the enzyme immobilized on IDA-Me2+-epoxy or EDA-epoxy supports was hardly enantioselective, the enzyme immobilized on IDA-epoxy supports (adsorbed via cationic exchange), was highly enantioselective (E=60)32.

References

Bickerstaff, G.F. Immobilization of enzymes and cells. in Methods in Biotechnology 1st edn. (ed. Bickerstaff, G.), Humana Press, Totowa, NJ, USA (1997).

Chibata, I., Tosa, T. & Sato, T. Biocatalysis: immobilized cells and enzymes. J. Mol. Catal. 37, 1–24 (1986).

Hartmeier, W. Immobilized biocatalysts-from simple to complex systems. TIBTECH 3, 149–153 (1985).

Katchalski-Katzir, E. Immobilized enzymes: learning from past successes and failures. TIBTECH 11, 471–478 (1993).

Gupta, M.N. Thermostabilization of proteins. Biotechnol. Appl. Biochem. 14, 1–11 (1991).

Klibanov, A.M. Stabilization of enzymes against thermal inactivation. Adv. Appl. Microb. 14, 1–11 (1982).

Pedroche, J. et al. Effect of the support and experimental conditions in the intensity of the multipoint covalent attachment of proteins on glyoxyl-agarose supports. Correlation between enzyme-support linkages and thermal stability. Enzyme Microb. Technol. 40, 1160–1166 (2007).

Mateo, C. et al. Some special features of glyoxyl supports to immobilize proteins. Enzyme Microb. Technol. 37, 456–462 (2005).

Mansfeld, J. & Ulbrich-Hofmann, R. Site-specific and random immobilization of thermolysin-like proteases reflected in the thermal inactivation kinetics. Biotechnol. Appl. Biochem. 32, 189–195 (2000).

Mansfeld, J., Vriend, G., Van den Burg, B., Eijsink, V.G. & Ulbrich-Hofmann, R. Probing the unfolding region in a thermolysin-like protease by site-specific immobilization. Biochemistry 38, 8240–8245 (1999).

Turkova, J. et al. Methacrylate gels with epoxide groups as supports for immobilization of enzymes in pH range 3–12. Biochim. Biophys. Acta (BBA)—Enzymol. 524, 162–169 (1978).

Katchalski-Katzir, E. & Kraemer, D.M. Eupergit® C, a carrier for immobilization of enzymes of industrial potential. J. Mol. Catal. B Enzymatic 10, 157–176 (2000).

Mateo, C. et al. Epoxy Sepabeads: a novel epoxy support for stabilization of industrial enzymes via very intense multipoint covalent attachment. Biotechnol. Progr. 18, 629–634 (2002).

Mateo, C., Abian, O., Fernandez-Lafuente, R. & Guisan, J.M. Increase in conformational stability of enzymes immobilized on epoxy-activated supports by favoring additional multipoint covalent attachment. Enzyme Microb. Technol. 26, 509–515 (2000).

Wheatley, J.B. & Schmidt, D.E. Salt induced immobilization of affinity ligands onto epoxide-activated supports. J. Chromatogr. A 849, 1–12 (1999).

Wheatley, J.B. & Schmidt, D.E. Salt induced immobilization of proteins on a high-performance liquid chromatographic epoxide affinity support. J. Chromatogr. 644, 11–16 (1993).

Wheatley, J.B., Lyttle, M.H., Hocker, M.D. & Schmidt, D.E. Jr. Salt-induced immobilizations of DNA oligonucleotides on an epoxide-activated high-performance liquid chromatographic affinity support. J. Chromatogr. A 726, 77–90 (1996).

Bauer-Arnaz, K. et al. Salt-induced immobilization of small affinity ligands on an epoxide activated affinity support. J. Chromatogr. A 803, 73–82 (1998).

Mateo, C., Fernández-Lorente, G., Abian, O., Fernández-Lafuente, R. & Guisán, J.M. Multifunctional epoxy-supports: a new tool to improve the covalent immobilization of proteins. The promotion of physical adsorptions of proteins on the supports before their covalent linkage. Biomacromolecules 1, 739–745 (2000).

Mateo, C. et al. Epoxy-amino groups: a new tool for improved immobilization of proteins by the epoxy method. Biomacromolecules 4, 772–777 (2003).

Grazú, V. et al. A novel bifunctional epoxy/thiol-reactive support to immobilize thiol containing proteins by the epoxy chemistry. Biomacromolecules 4, 1495–1501 (2003).

Blanco, R.M., Calvete, J.J. & Guisan, J.M. Immobilization-stabilization of enzymes. Variables that control the intensity of the trypsin (amine)-agarose (aldehyde) multi-point covalent attachment. Enzyme Microb. Technol. 11, 353–359 (1988).

Torres, R. et al. A novel heterofunctional epoxy-amino Sepabeads for a new enzyme immobilization protocol: immobilization-stabilization of beta-galactosidase from Aspergillus oryzae . Biotechnol. Progr. 19, 1056–1060 (2003).

Mateo, C., Archelas, A., Fernandez-Lafuente, R., Guisan, J.M. & Furstoss, R. Enzymatic transformations. Immobilized A. niger epoxide hydrolase as a novel biocatalytic tool for repeated-batch hydrolytic kinetic resolution of epoxides. Org. Biomol. Chem. 1, 2739–2743 (2003).

López-Gallego, F. et al. Optimization of an industrial biocatalyst of glutaryl acylase. Stabilization of the enzyme by multipoint covalent attachment onto new amino-epoxy-sepabeads. J. Biotechnol. 111, 219–227 (2004).

Pessela, B.C.C. et al. Stabilization of a multimeric β-galactosidase from Thermus sp. strain T2 by immobilization on novel hetero-functional epoxy supports plus aldehyde-dextran cross-linking. Biotechnol. Progr. 20, 388–392 (2004).

Fernández-Lorente, G. et al. Modulation of lipase properties in macro-aqueous systems by controlled enzyme immobilisation: enantioselective hydrolysis of a chiral ester by immobilised Pseudomonas lipase. Enzyme Microb. Technol. 28, 389–396 (2001).

Palomo, J.M., Fernandez-Lorente, G., Mateo, C., Fernandez-Lafuente, R. & Guisan, J.M. Modulation of the enantioselectivity of lipases via controlled immobilization and medium engineering: hydrolytic resolution of mandelic acid esters. Enzyme Microb. Technol. 31, 775–783 (2002).

Palomo, J.M. et al. Modulation of the enantioselectivity of Candida antarctica B lipase via conformational engineering: kinetic resolution of (±)-α-hydroxy-phenylacetic acid derivatives. Tetrahedron Asymmetry 13, 1337–1345 (2002).

Palomo, J.M. et al. Synthesis of enantiomerically pure glycidol via a fully enantioselective lipase-catalyzed resolution. Tetrahedron Asymmetry 16, 869–874 (2005).

Fernandez-Lorente, G. et al. Glutaraldehyde crosslinking in the presence of detergents of lipases adsorbed on aminated supports: improving lipases performance. Biomacromolecules 7, 2610–2615 (2006).

Palomo, J.M. et al. Modulation of Mucor miehei lipase properties via directed immobilization on different heterofunctional epoxy resins. Hydrolytic resolution of (R,S)-2-phenyl-2-butyroylacetic acid. J. Mol. Catal. B Enzymatic 21, 201–210 (2003).

Turkova´, J. Oriented immobilization of biologically active proteins as a tool for revealing protein interactions and function. J. Chromat. B Biomed. Sci. Appl. 722, 11–31 (1999).

Penzol, G., Armisen, P., Fernández-Lafuente, R., Rodes, L. & Guisán, J.M. Use of dextrans as long, inert and hydrophilic spacer arms to improve the performance of immobilized proteins acting on macromolecules. Biotechnol. Bioeng. 60, 518–523 (1998).

Tardioli, P.W., Fernandez-Lafuente, R., Guisán, J.M. & Giordano, R.L.C. Design of new immobilized-stabilized carboxypeptidase A derivative for production of aromatic free hydrolysates of proteins. Biotechnol. Prog. 19, 565–574 (2003).

Fuentes, M., Mateo, C., Guisán, J.M. & Fernández-Lafuente, R. Preparation of inert magnetic nano-particles for the directed immobilization of antibodies Biosen . Bioelec. 20, 1380–1387 (2005).

Mateo, C. et al. One step purification, covalent immobilization and additional stabilization of poly-His-tagged proteins using novel heterofunctional chelate-epoxy supports. Biotechnol. Bioeng. 76, 269–277 (2001).

Pessela, B.C.C. et al. One step purification, covalent immobilization and additional stabilization of a thermophilic poly-His-tagged beta-galactosidase of Thermus sp. strain T2, novel heterofunctional chelate-epoxy supports. Biomacromolecules 4, 107–113 (2003).

Abad, J.M. et al. Immobilization of peroxidase glycoprotein on gold electrodes modified with mixed epoxy-boronic acid monolayers. J. Am. Chem. Soc. 124, 12845–12853 (2002).

Grazu, V. et al. Solid-phase reducing agents as alternative for reducing disulfide bonds in proteins. Appl. Biochem. Biotechnol. 110, 23–32 (2003).

Fernández-Lafuente, R. et al. Preparation of activated supports containing low pK amino groups. A new tool for protein immobilisation via the carboxyl coupling method. Enzyme Microb. Technol. 15, 546–550 (1993).

Hermanson, G.T. Bioconjugate Techniques. (Academic Press Inc., San Diego, CA, 1996).

Brocklehurst, K., Carlsson, J., Kierstan, M. & Crook, E. Covalentchromatography by thiol-disulfide interchange. Methods Enzymol. 34, 531–544 (1973).

Nogueira, R., Lämmerhoder, M., Maier, N.M. & Lindner, W. Spectrophotometric determination of sulphidryl concentration on the surface of thiol-modified chromatographic silica particles using 2,2′-dipyridyl disulfide reagent. Anal. Chim. Acta 533, 179–183 (2005).

Grazú, V. et al. Stabilization of enzymes by multipoint immobilization of thiolated proteins on new epoxy-thiol supports. Biotechnol. Bioeng. 90, 597–605 (2005).

Hunt, P.D., Tolley, S.P., Ward, R.J., Hill, C.P.y. & Dodson, G.G. Expression, purification and crystallization of penicillin G acylase from E. coli ATCC11105. Prot. Eng. 3, 635–639 (1990).

Montes, T. et al. Genetic modification of the protein surface to improve its reversible enzyme immobilization on ionic exchangers. Appl. Environ. Microb. 73, 312–319 (2007).

Fuentes, M. et al. Mixed ion exchange supports as useful ion exchangers for protein purification: purification of penicillin G acylase from Escherichia coli . Biomacromolecules 8, 703–707 (2007).

Fernández-Lafuente, R., Armisén, P., Sabuquillo, P., Fernández-Lorente, G. & Guisan, J.M. Immobilization of lipases by selective adsorption on hydrophobic supports. Chem. Phys. Lipids 93, 185–197 (1998).

Palomo, J.M., Fuentes, M., Fernández-Lorente, G., Mateo, C., Guisan, J.M. & Fernández-Lafuente, R. General trend of lipase to self-assemble giving bimolecular aggregates greatly modifies the enzyme functionality. Biomacromolecules 4, 1–6 (2003).

Palomo, J.M. et al. Use of immobilized lipases for lipase purification via specific lipase–lipase interactions. J. Chromatogr. A. 1038, 267–273 (2004).

Palomo, J.M. et al. Lipase–lipase interactions as a new tool to immobilize and modulate the lipase properties. Enzyme Microb. Technol. 36, 447–454 (2005).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Mateo, C., Grazu, V., Palomo, J. et al. Immobilization of enzymes on heterofunctional epoxy supports. Nat Protoc 2, 1022–1033 (2007). https://doi.org/10.1038/nprot.2007.133

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2007.133

This article is cited by

-

Immobilization of microbial multienzyme preparation on calcium alginate beads as well as lyophilization with mosambi peel matrix improved its shelf-life and stability

Folia Microbiologica (2024)

-

Isocyanide-based multi-component reactions for carrier-free and carrier-bound covalent immobilization of enzymes

Nature Protocols (2023)

-

Development of a magnetic separation immunoassay with high sensitivity and time-saving for detecting aflatoxin B1 in agricultural crops using nanobody

European Food Research and Technology (2023)

-

Laccase multi-point covalent immobilization: characterization, kinetics, and its hydrophobicity applications

Applied Microbiology and Biotechnology (2023)

-

Nano-biocatalytic Systems for Cellulose de-polymerization: A Drive from Design to Applications

Topics in Catalysis (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.