Abstract

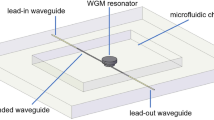

Nanofluidic devices make use of molecular-level forces and phenomena to increase their density, speed and accuracy1. However, fabrication is challenging, because dissimilar materials need to be integrated in three dimensions with nanoscale precision. Here, we report a three-dimensional nanoscale liquid glass electrode made from monolithic substrates without conductive materials by femtosecond-laser nanomachining. The electrode consists of a nanochannel terminating at a nanoscale glass tip that becomes a conductor in the presence of high electric fields through dielectric breakdown, and returns to being an insulator when this field is removed. This reversibility relies on control of nanoampere breakdown currents and extremely fast heat dissipation at nanoscale volumes. We use the nanoscale liquid glass electrode to fabricate a nano-injector that includes an electrokinetic pump, 4 µm across with 0.6 µm channels, which is capable of producing well-controlled flow rates below 1 fl s−1. The electrode can be integrated easily into other nanodevices and fluidic systems, including actuators and sensors.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Schoch, R. B., Han, J. & Renaud, P. Transport phenomena in nanofluidics. Rev. Mod. Phys. 80, 839–883 (2008).

Bayley, H. & Cremer, P. S. Stochastic sensors inspired by biology. Nature 413, 226–230 (2001).

Saleh, O. A. & Sohn, L. L. Quantitative sensing of nanoscale colloids using a microchip Coulter counter. Rev. Sci. Instrum. 72, 4449–4451 (2001).

Chang, H.-C. & Yossifon, G. Understanding electrokinetics at the nanoscale: a perspective. Biomicrofluidics 3, 012001 (2009).

Fu, J., Schoch, R. B., Stevens, A. L., Tannenbaum, S. R. & Han, J. A patterned anisotropic nanofluidic sieving structure for continuous-flow separation of DNA and proteins. Nature Nanotech. 2, 121–128 (2007).

Wang, Y., Stevens, A. L. & Han, J. Million-fold preconcentration of proteins and peptides by nanofluidic filter. Anal. Chem. 77, 4293–4299 (2005).

Karnik, R., Castelino, K., Fan, R., Yang, P. & Majumdar, A. Effects of biological reactions and modifications on conductance of nanofluidic channels. Nano Lett. 5, 1638–1642 (2005).

Zhou, K., Kovarik, M. L. & Jacobson, S. C. Surface-charge induced ion depletion and sample stacking near single nanopores in microfluidic devices. J. Am. Chem. Soc. 130, 8614–8616 (2008).

Joglekar, A. P., Liu, H., Meyhöfer, E., Mourou, G. & Hunt, A. J. Optics at critical intensity: applications to nanomorphing. Proc. Natl Acad. Sci. USA 101, 5856–5861 (2004).

Kim, T. N., Campbell, K., Groisman, A., Kleinfeld, D. & Schaffer, C. B. Femtosecond laser-drilled capillary integrated into a microfluidic device. Appl. Phys. Lett. 86, 201106 (2005).

McDonald, J. P., Mistry, V. R., Ray, K. E. & Yalisove, S. M. Femtosecond pulsed laser direct write production of nano- and microfluidic channels. Appl. Phys. Lett. 88, 183113 (2006).

Ke, K., Hasselbrink, E. F. & Hunt, A. J. Rapidly prototyped three-dimensional nanofluidic channel networks in glass substrates. Anal. Chem. 77, 5083–5088 (2005).

Lee, S., Bull, J. L. & Hunt, A. J. Acoustic limitations on the efficiency of machining by femtosecond laser-induced optical breakdown. Appl. Phys. Lett. 91, 023111 (2007).

Harrison, D. J., Manz, A., Fan, Z. H., Ludi, H. & Widmer, H. M. Capillary electrophoresis and sample injection systems integrated on a planar glass chip. Anal. Chem. 64, 1926–1932 (1992).

Takamura, Y. et al. Low-voltage electroosmosis pump for stand-alone microfluidics devices. Electrophoresis 24, 185–192 (2003).

Hong, C. C. et al. A functional on-chip pressure generator using solid chemical propellant for disposable lab-on-a-chip. Lab Chip 3, 281–286 (2003).

Baldock, S. J., Fielden, P. R., Goddard, N. J., Prest, J. E. & Treves Brown, B. J. Integrated moulded polymer electrodes for performing conductivity detection on isotachophoresis microdevices. Chromatogr. A 990, 11–22 (2003).

Hebert, N. E., Snyder, B., McCreery, R. L., Kuhr, W. G. & Brazill, S. A. Performance of pyrolyzed photoresist carbon films in a microchip capillary electrophoresis device with sinusoidal voltammetric detection. Anal. Chem. 75, 4265–4271 (2003).

Wu, C. C., Wu, R. G., Huang, J. G., Lin, Y. C. & Chang, H.-C. Three-electrode electrochemical detector and platinum film decoupler integrated with a capillary electrophoresis microchip for amperometric detection. Anal. Chem. 75, 947–952 (2003).

Baldwin, R. P. et al. Fully integrated on-chip electrochemical detection for capillary electrophoresis in a microfabricated device. Anal. Chem. 74, 3690–3697 (2002).

Laugere, F. et al. On-chip contactless four-electrode conductivity detection for capillary electrophoresis devices. Anal. Chem. 75, 306–312 (2003).

Paul, P. H., Garguilo, M. G. & Rakestraw, D. J. Imaging of pressure- and electrokinetically driven flows through open capillaries. Anal. Chem. 70, 2459–2467 (1998).

Probstein, R. F. Physicochemical Hydrodynamics 2nd edn (Wiley-Interscience, 2003).

Pu, Q., Yun, J., Temkin, H. & Liu, S. Ion-enrichment and ion-depletion effect of nanochannel structures. Nano Lett. 4(6), 1099–1103 (2004).

Eijkel, J. C. T. & Van den Berg, A. Nanofluidics: what is it and what can we expect from it? Microfl. Nanofl. 1, 249–267 (2005).

Chau, R. S. Intel's breakthrough in high-K gate dielectric drives Moore's Law well into the future. Technology@Intel Magazine, 1–7 (2004).

Sune, J., Nafria, M. & Aymerich, X. Reversible dielectric breakdown of thin gate oxides in mos devices. Microelectron. Reliab. 33, 1031–1039 (1993).

Gamow, G. Matter, Earth & Sky rev. edn (Prentice-Hall, 1965).

Reichmuth, D. S., Chirica, G. S. & Kirby, B. J. Increasing the performance of high-pressure, high-efficiency electrokinetic micropumps using zwitterionic solute additives. Sens. Actuat. B 92, 37–43 (2003).

Acknowledgements

The authors are grateful to S. Yalisove and Kwan Hyoung Kang for useful discussions. We thank Intralase Corp. for the laser. This work was supported by NIH R21 EB006098.

Author information

Authors and Affiliations

Contributions

S.L. discovered the phenomena and the governing mechanism. S.L. conceived and designed the experiments. S.L. performed all the experiments except the I–V measurements in fused silica substrates, which were carried out by R.A. S.L. performed the numerical simulation and analysed the simulation results. S.L. developed the nano-injector and analysed the performance. S.L. and A.J.H. developed the breakdown model, discussed the results, and co-wrote the paper. A.J.H. guided the overall thrust and direction of this research.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 1506 kb)

Rights and permissions

About this article

Cite this article

Lee, S., An, R. & Hunt, A. Liquid glass electrodes for nanofluidics. Nature Nanotech 5, 412–416 (2010). https://doi.org/10.1038/nnano.2010.81

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2010.81

This article is cited by

-

Fully explicit dissipative particle dynamics simulation of electroosmotic flow in nanochannels

Microfluidics and Nanofluidics (2016)

-

Ionic liquid flow along the carbon nanotube with DC electric field

Scientific Reports (2015)

-

Nanowire liquid pumps

Nature Nanotechnology (2013)

-

Vertical oxide nanotubes connected by subsurface microchannels

Nano Research (2012)

-

Multifunctional carbon-nanotube cellular endoscopes

Nature Nanotechnology (2011)