Abstract

Space-saving design is a requirement that is encountered in biological systems and the development of modern technological devices alike. Many living organisms dynamically pack their polymer chains, filaments or membranes inside deformable vesicles or soft tissue-like cell walls, chorions and buds. Surprisingly little is known about morphogenesis due to growth in flexible confinements—perhaps owing to the daunting complexity lying in the nonlinear feedback between packed material and expandable cavity. Here we show by experiments and simulations how geometric and material properties lead to a plethora of morphologies when elastic filaments are growing far beyond the equilibrium size of a flexible thin sheet they are confined in. Depending on friction, sheet flexibility and thickness, we identify four distinct morphological phases emerging from bifurcation and present the corresponding phase diagram. Four order parameters quantifying the transitions between these phases are proposed.

Similar content being viewed by others

Introduction

What morphologies will a thin object adopt when subjected to tight spatial confinement? This fundamental question of morphogenesis arises on a large range of length scales, from DNA strands packed in bacteriophage capsids and globules1,2,3 to the folding of pop-up tents4. Packing problems have played a major role in the understanding of spatial self-organization in living organisms and technological applications alike. Thin sheets of foil or paper, for instance, develop complex ridge networks when folded and crumpled5,6,7,8,9,10.

Significant progress has recently been made in the understanding of dense packings of elastic and elasto-plastic wires, in absence of thermal fluctuations, inside of rigid three-dimensional confinement11,12,13,14. A particular restriction shared by all these studies is the perfect rigidity of the cavities—a constraint rarely met in nature or biomedical applications. Detachable platinum coils, for example, which have revolutionized the surgical treatment of saccular cerebral aneurysms15, are many orders of magnitude stiffer than the arterial walls they are fed into16. Microtubules confined in lipid bilayer membranes17,18 and erythrocytes19,20 as well as actin/filamin networks in vesicles21,22 are able to deform their weak confinements significantly. In turn, such cavities force the contained filaments to buckle and reorder if their persistence length grows large enough. Recent experiments on coiled elastic nanowires and nanotubes encapsulated in swelling polymer shells and emulsion droplets have demonstrated how mechanical work can be stored and deployed through deformable spatial confinement23,24,25.

Knowing the mechanisms that govern morphogenesis in constrained spaces is key to understanding the ordering in dense packing problems. Here we present computer simulations and table-top experiments with everyday materials carried out to explore the morphological phase space of filament packings in a regime that is conceptually very different from previous systematic studies. A regime where the growing filament can strongly deform the cavity, allowing for a surprisingly enriching mutual feedback between the two structures. A decisive set of two geometric and two material parameters are identified that control this complex interaction, giving rise to no less than four distinct morphologies vastly differing in their packing evolution and energetics. Our findings provide the foundation for a new research field in which packing processes and growth are governed by the complex interplay of thin deformable bodies made of different materials. The reported observations exemplify the dramatic influence of friction and confinement rigidity on packing processes in both natural and technological applications.

Results

Model and parametrization

The most intelligible and pure way of gaining quantitative insight into morphogenesis in flexible confinements is by continuum mechanical simulations with linearly elastic materials. Many of the aforementioned applications are best matched by a circular ring filament growing inside of a closed spherical thin sheet. Figure 1 shows a cut-out of our computational model (see also Supplementary Note 1). Both filament and sheet are characterized by three homogeneous isotropic material parameters, labelled with subscripts f and s, respectively: the Young’s modulus E, Poisson’s ratio ν and mass density ρ. In accordance with a suggestion for condensed DNA3, Coulomb’s law is assumed for dry stick–slip friction between any two contacting surfaces (filament–filament, filament–shell, shell–shell) with an isotropic static friction coefficient, μs, and a slightly lower dynamic friction coefficient, μd. To simplify the parameter space, we use the same coefficients for all the three contact types and fix μd=0.9μs, which is adequate for a broad class of materials26.

Both the circular filament and the confining spherical sheet are characterized by a Young’s modulus E, Poisson’s ratio ν and mass density ρ. We assume stick–slip Coulomb friction between any contacting surfaces. The morphogenesis is governed by only four dimensionless numbers: the nominal system size σ=R/r, the Föppl–von Kármán number γ=(R/h)2, the relative confinement flexibility ε=Ef/Es, and the Coulomb friction coefficient μ=μs.

The initial condition at time t=0 consists of a ring filament with length L and cross-sectional radius r, surrounded by a close-fitting spherical shell with thickness h, whose middle surface has radius R. As the filament grows, it bears against the confining wall until the critical buckling load  (where If=πr4/4 is the second moment of area) is exceeded and it buckles out of plane with harmonic mode m. Excited modes m>2 are unstable in the quasi-static frictionless limit27, but our simulations show that they can be observed when inertia is not negligible (that is, large mass densities, fast growth or viscous overdamping) and in the presence of significant friction. The ground state buckling mode m=2, which is the most relevant in practice, develops a saddle shape as depicted in the middle of Fig. 2 until two filament segment pairs touch. This first contact occurs at l :=L(t)/L(0)=l*≈2.127 for rigid spherical cavities in the theoretical thin filament limit r→0 (ref. 27). The bending energy Ub of the filament before l=l* can be approximated analytically by

(where If=πr4/4 is the second moment of area) is exceeded and it buckles out of plane with harmonic mode m. Excited modes m>2 are unstable in the quasi-static frictionless limit27, but our simulations show that they can be observed when inertia is not negligible (that is, large mass densities, fast growth or viscous overdamping) and in the presence of significant friction. The ground state buckling mode m=2, which is the most relevant in practice, develops a saddle shape as depicted in the middle of Fig. 2 until two filament segment pairs touch. This first contact occurs at l :=L(t)/L(0)=l*≈2.127 for rigid spherical cavities in the theoretical thin filament limit r→0 (ref. 27). The bending energy Ub of the filament before l=l* can be approximated analytically by

A confined growing ring buckles to a saddle shape (buckling mode m=2, middle). Beyond the point of first contact l=l*, four distinct morphologies can emerge. The folding at low friction and weak confinement is repeated during growth: filament bundles refold self-similarly, each time tripling the number of bundle strands (n=3k).

where κ is the geodesic curvature of the rim of a unit ‘excess cone’ (e-cone)28, and Rf :=L(0)/2π=R−h/2−r is the effective filament radius. Growth beyond l* in finite systems with real self-avoiding materials, however, has never been explored to date. Our simulations and experiments dispel this limitation, showing that four distinct morphologies emerge by bifurcation as the filament grows longer (Fig. 2). We denominate them ‘spiral’, ‘classical’, ‘folded’ and ‘warped’, motivated by their characteristics as detailed in the following.

A key result from the computer simulations is that this morphogenesis is controlled by four independent dimensionless non-negative quantities,

if inertial effects are negligible. Up to an irrelevant prefactor, γ is the Föppl–von Kármán number, a geometrical measure for a thin sheet’s tendency to bend rather than stretch. ε is the relative filament rigidity, which conversely may also be thought of as the confinement flexibility. γ and ε generalize the previously studied rigid cavities, which are attained in the limits γ→0 and ε→0. Together with γ, expressing the nominal system size by the non-dimensional ratio σ renders the problem scale-invariant, which attests to the wide applicability of our results from microscopic to macroscopic scales.

Morphological phases and phase transitions

The packing in frictionless rigid spheres can serve as a toy model for less idealized systems. When l>l*, a spiral (depicted in Fig. 2, top left; Supplementary Movie 1) develops analogous to unconfined e-cones29. In the spirit of refs 30, 31, we call this the ‘spiral phase’. Simple geometrical arguments (see Supplementary Note 2) allow for an analytical approximation of the predominating elastic contribution, the bending energy Ub of the confined filament:

where the coil inclination θ is implicitly determined by l≈sin(θ)Rf/r+π/2−θ. In Fig. 3a, we show that equations (1) and (3) are in excellent agreement with our numerical measurements. The measured energy weakly oscillates because the coil is slightly bent by the S-curves. These oscillations increase for larger σ. As the surface gets fully covered with a single layer of filament (l approaching Rf/r), the growing filament eventually buckles inward to release a large amount of elastic energy, and the packing process continues in a less ordered manner, much like some DNA molecules in phage capsids2,32.

(a) Filament bending energy in the spiral (blue) and classical (green) morphology at σ=20. The inset shows the inclination θ(l) of the spiral coil. (b) Folded morphology at σ=20, γ=202, ε=104, μ=0. The predominant elastic energy contribution alternates between the filament bending energy Ub and the membrane energy Um (stretching term of Supplementary Equation (2)). A cascade of four self-similar folds can be recognized by the repeated power law regions.

A crucial requirement for a growing filament to coil is tangential sliding, giving rise to the high degree of order in the spiral morphology by continuous rearrangements. Many practical materials, however, resist sliding by frictional forces and even DNA does so33,34,35. Friction induces locality by limiting rearrangments to the local neighbourhood, inhibiting relaxations to lower global energy conformations, thus trapping growing filaments in a disordered state (Fig. 2, bottom left; Supplementary Movie 2). Figure 3a clearly shows that the bending energy is bounded from below by the spiral phase. A similar situation is encountered in flat wire packings31, from where we adopt the term ‘classical phase'. To quantify the spontaneous breaking of spiral symmetry with increasing μ, we propose the following order parameter. Let [p1, p3, p3]T(s) denote the position of the centreline of the filament after transformation onto its own principal axes in the order of descending principal moments of inertia. Then, the sign of  indicates its turning direction as seen along the axis of minimal moment of inertia. Consequently, the circular convolution

indicates its turning direction as seen along the axis of minimal moment of inertia. Consequently, the circular convolution

is a natural measure for the degree of order of the filament when cut in half at s=q and s=q+L/2. Here we implicitly extend τ(s)=τ(s+L) periodically. If the two halves equally contain right- and left-turning segments, we have c(q)=0. Conversely, only if one half turns only left and the other half only right, we have c(q)=1. Thus, if we account for the periodic nature of the ring filament by maximizing over all bisection points q, the turning disorder D :=1−max{c(q)|q ∈ [0, L]} can serve as an order parameter to discriminate the spiral from the classical phase. It is evident from Fig. 4a that the transition occurs near μ≈0.5, with a slight dependence on σ. In stiff confinement, friction must thus be fairly strong to introduce local order, which contributes to explaining why viral DNA is often condensed into layered spools36,37,38,39.

(a) Half of the spiral filament turns right and half of it left, which is not the case in the classical phase (ε=0, l=10). (b) The dissimilarity between the filament and its own mirror image is strictly positive in the chiral spiral phase, but vanishes in the achiral folded phase (γ=104, μ=0, l=5). (c) The amount of torsion quantifies the transition from the folded to the warped phase (γ=ε=104, l=5). (d) The fraction of the sheet surface in contact with itself vanishes when the warped phase transitions to the classical phase (γ=104, μ=1.4, data maximized over l ∈ [1,10]). Error bars represent s.e.m. from 6–10 independent realizations.

The surface-covering spiral and classical morphologies bear resemblance to liquid crystals (LCs), an analogy that has already been drawn in the context of DNA packing in viral capsids40. Let us define a loop by an area surrounded by a filament segment with only one inner point of contact31. The spiral phase has only four such loops (two at each pole), while the classical phase is characterized by a broader spatial distribution of loops. At very high surface packing (l→Rf/r), the classical loops are compressed to point singularities with strength 1/2 delimiting line disclinations known from nematic LCs41. The spiral phase is in turn reminiscent of spherical smectic LCs with two closely bound disclinations ending at two 1/2-singularities at each pole42. The total disclination strength of a spherical LC is always 2, which is a direct consequence of the Gauss–Bonnet theorem. Indeed, this identity holds for growing ring filaments for all σ, μ in the spiral and classical phases. The number of topologically non-trivial loops is always four, but the classical phase can exhibit an arbitrary additional number of topologically trivial loops. However, we stress that the existence of topologically trivial loops is sufficient, but not necessary for D>0, and is thus not an order parameter.

The spiral and classical morphologies are highly metastable as the filament inevitably buckles away from the rigid wall. A qualitative stability condition was derived in ref. 40 and translates to l<<σ2 in our terms, suggesting that dense single-layered surface packings are found only in sufficiently large cavities. This explains why they are not common in biophysical environments and vesicles. Instead, such systems gain ultimate stability from weak or flexible confinement. In the computer simulations, we increased γ and ε to discover a completely altered morphogenesis beyond a certain transition. As the confining sheet is weakened or thinned, suddenly, the filament folds on itself as illustrated in the top right of Fig. 2 instead of coiling (see also Supplementary Movie 3). Bundles of n subthreads are formed similar to actin/filamin rings and microtubules in vesicles21,22,43 or folded poles in pop-up tents4. We hence refer to this as the ‘folded phase’. The folding process is repeated as the filament continues to grow. The winding number n obeys n=Πk(2mk−1), where mk ∈ {2, 3, 4,...} is the buckling mode and k=0, 1, 2,... is the number of folds in the cascade (see also Supplementary Note 3). The ground state (mk≡2) energy is plotted in Fig. 3b, revealing a series of self-similar folds that define the folded phase. Before buckling, the circular filament bundle with bulk radius Rb expands to release bending energy according to UbRf/EfIf≈nπRf/Rb~l−1, stretching the circumjacent sheet until a critical radius Rb=Rc is reached where the bundle buckles. The long-term trend is UbRf/EfIf~lα with α ∈ (0, 1), indicating that the critical radius increases as Rc/Rf~l(1−α)/2. For the set of parameters in Fig. 3b, α=0.80±0.02 (s.e.m.). This striking refolding of bundled rings provides a purely mechanical explanation for the spontaneous bundling of weakly confined filaments, such as actin networks21,22 and marginal microtubule bands in developing erythrocytes19,20, as a result of membrane or shell enclosure instead of cross-linkage. Only sufficiently deformable containers conform to pushing filaments, allowing them to pass one another to fold into energetically more favourable bundle configurations. This might also provide a paradigm to explain layered slime thread bundling in hagfish gland thread cells44, where the cell membrane deforms under high packing pressure. Our findings suggest that such thread bundle packings may be obtained only in systems where frictional forces are rather small. Other biological systems in which filament bundling provides a mechanism of mechanical stabilization in membrane confinement include filopodial protrusion45,46.

Remarkably, the gain in mechanical stability in flexible cavities goes hand in hand with the loss of chirality. A convenient order parameter describing the transition from the spiral to the folded phase is the chirality measure 1−S, where S is the degree of similarity of the filament with its own mirror image as defined in ref. 47, maximized over all possible mirror planes. In Fig. 4b, a pronounced discontinuity in 1−S is in evidence, suggesting that the phase transition is of first order. Chirality of confined rods is known to play a key role in the morphogenesis of Escherichia coli cells for instance, where the bacterial rod grows into a helical spiral, guided by proteins48. Our results provide evidence that, conversely, filament chirality can emerge as a purely mechanical consequence of a non-flexible confinement.

If growing filaments are inclined to form highly ordered bundles inside deformable membrane cavities (without friction), the question naturally arises whether purely mechanical material properties can also give rise to disordered packing morphogenesis with strongly warped or tangled filaments. Developing vertebrate intestines, where the gut tube grows into the body cavity at a different rate than the adhering mesenteric sheet, are in fact one example49. Here we are able to put this particular result in a broader, more general framework by controlling friction. As μ is increased, the thin flexible sheet grabs hold of the pushing filament by tightly wrapping around it. Just like in the classical phase, friction (or adhesion) enforces locality: the filament can no longer just freely fold up inside, and further growth causes it to locally twist in frustration, leading to a warped morphology (depicted in Fig. 2, bottom right; Supplementary Movie 4). For γ, μ→∞, this behaviour is reminiscent of the Euler–Plateau problem50, but significantly more complex due to the crucial role of twist and volumetric exclusion. The transition from the folded to the warped phase is accompanied by the breaking of torsional symmetry. As order parameter, the non-dimensional torsional energy 〈Θ32〉L2=2LUt/GfJf (see Supplementary Note 1) may be used, since it vanishes in the folded phase for σ→∞ and takes a significant, finite value in the warped phase. As can be recognized from Fig. 4c, the exact value of the corresponding critical friction coefficient, while depending on the system size σ, is generally very low, implying that the warped phase is relevant even in systems with moderate friction. Within the warped phase, the stored torsional energy quickly levels off. Our measurements thus provide a tight lower bound for the amount of twist in various vetrebrate guts49.

The direct transition from the classical to the warped morphology is less obvious. A large portion of the phase space is occupied by ‘mixed’ states in which the confinement is not stiff enough to keep the filament from buckling into the sphere, but at the same time not flexible enough to wrap around it and force it to twist. Such configurations are prevalent, for example, in brain aneurysms occluded by detachable coils (see, for example, ref. 51). It is nonetheless possible to define a sharp phase boundary (PB) by considering as an order parameter the area fraction of the sheet that is in contact with itself, Ωc/Ω, because it is non-zero only in the warped phase (Fig. 4d).

Morphological phase diagram

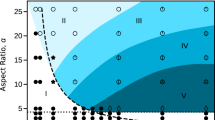

For the design and optimization of new materials and structures, for example, in nanorobotics or endovascular coiling, reliably predicting the packing behaviour is essential. We used our computer simulations to acquire a quantitative image of the morphological phase space, allowing us to accurately predict morphogenesis depending on the geometry and material parameters. In the low-friction regime (upper half of Fig. 5), the spiral and folded phases are separated by a smooth PB that is well approximated by quadratic curves in log(ε)–log(γ) space. Evidently, if the confining sheet is thin enough, filaments do not need to be substantially more rigid to fold instead of coiling. Bigger systems (larger σ) favour the spiral morphology as the PB is shifted towards weak confinements (large γ, ε). Very close to the PB, mixed configurations such as the one shown in Fig. 5f occur when the filament folds at only one of the two contact points, which is a dynamic effect.

For σ=30, individual coloured symbols denote numerical simulations producing the different phases and black symbols are mixed (see text). The lines represent least-squares-fitted phase boundaries. The fits for σ=20, 40 were obtained with equivalent parameter resolution (individual realizations not shown). (b,c) Polyurethane wires (r=1 mm) tangentially fed from opposite directions into rigid polystyrene spheres (R=24 mm, h=1 mm). (a,d) Polycaprolactam wires (r=0.75 mm) in natural rubber balloons (R=27 mm, h=0.25 mm). (e–i) Simulation snapshots at σ=30, l=4. (e) Very thin confinements exhibit tension wrinkles57. (f) An exemplary mixed configuration close to the phase boundary. (g) Very flexible confinements are stretched similar to lipid vesicles18. Warped filaments typically first crumple the sheet (h, l=2) before strongly twisting (i, l=4). Scale bars, 1 cm.

A cut through the phase space at fixed σ and γ unveils its full complexity (lower half of Fig. 5). All phase boundaries are σ-dependent, and the spiral and classical morphologies prevail towards large σ as predicted by the stability condition. Perhaps most intriguingly, we find straight single-parameter lines along which all morphologies are traversed, including the mixed region (uncoloured area). An example is the line along the ε-axis, at σ=40, γ=104, μ=0.5. This shows how delicate the choice of parameters is for targeting a specific morphology—possibly too delicate for nature to rely on this selection in some parameter regions. Another striking feature is reentrancy of the warped phase in small systems with strong friction (Fig. 5 at σ=20, γ=104, ε≈102–103, μ≈1.2), where the folded phase extends far into the large-μ region. Anyway, in its low-μ end near the boundary to the folded phase, the warped morphology is just a temporary interstate. The filament first warps (including the characteristic twist and sheet–sheet contact), but on further growth, some sliding allows it to rearrange and fold nevertheless, defining a region in phase space where the warped and folded phases coexist.

Discussion

Natural shell tissue is often softer than other thin bodies it gets in contact with. We have emphasized the importance of taking this flexibility into account in the study of morphogenesis in spatially confined systems. Depending on the involved size ratios and friction, the confinement need not be substantially less rigid to allow for a very rich nonlinear mutual interaction, giving way to completely changed morphogenesis. We have identified four morphological phases in the linear growth of confined thin filaments, building a bridge between the packing of confined DNA, the growth of guts, the bundling of actin networks in cell-sized liposomes and even LCs. Our results from computer simulations are fully consistent with the experiments we conducted on off-the-shelf materials at the human length scale (Fig. 5a–d).

The presented morphological phase diagram is independent of how growth is realized in detail. In the simulations, we grew the filament uniformly everywhere, whereas the tangential injection of an invariant wire in the experiments corresponds to concentrated growth at the point of insertion. These two extremes are exactly equivalent in the low-friction phases owing to global rearrangements, and they similarly produce the high-friction morphologies with the exception that reorganization is somewhat condensed to a neighbourhood about the growth/injection zone. Even the converse problem, an invariant filament getting gradually compressed by a shrinking shell, yields the same morphologies as simulations revealed (Supplementary Movie 5). The only difference is that σ (and possibly γ) decrease over time and the phase diagram must be interpreted accordingly. All presented analytical and scaling arguments hold also for this case without modification (where Rf is no longer constant, and l :=L/2πRf).

Our findings establish a paradigm for understanding morphogenesis of thin filaments in a multitude of biological mechanisms. Most importantly, we showed how nature may employ flexible envelopment and low-frictional forces as a mechanical trick to realize spontaneous bundling and alignment of confined threads, as it is observed in giant vesicles21,22, erythrocytes19,20, hagfish cells44 and so on, without the need for filament interlinking. On the technological side, the morphologies we discovered in flexible confinement should find direct impact in nanorobotics and nanomotors, for which the reported folding of elastic rings provides a new method to stably store and deploy mechanical work in tightly confined spaces. Unlike open nanowires, which coil into quasi-two-dimensional spirals23, ring-like filaments fold in three dimensions and possess no sharp ends that could pierce their environment. Such systems need to be designed with as little friction as possible to avoid the energetically and spatially less optimal warped phase.

Methods

Computer simulations

We minimized the total elastic energy numerically with the finite element method. The filament was modelled by locking-free beam elements with an exact shear representation52 embedded into a co-rotational formulation53 for geometric nonlinearity, while the shell was represented by Loop subdivision surface elements54 that provide the C1-continuity required for boundedness of the curvature integral in Supplementary Equation (2). These descriptions have been published in full detail elsewhere14,55. Up to 4,000 elements were used to discretize the filament, whereas the shell consisted of 20,480 triangles. We let the filament grow uniformly in length according to l :=L(t)/L(0)=exp(λt). The growth rate λ was set sufficiently small for inertial effects to have a negligible effect on the outcome. Volumetric exclusion was imposed by repulsive normal forces upon overlap according to the Kelvin–Voigt model where the elastic part was determined using Hertzian contact theory. A dry slip–stick friction model56 was applied for the tangential Coulomb forces. Inertial terms with mass densities ρf and ρs to account for dynamics as well as small subcritical viscous damping for equilibration were added. Newton’s equations of motion were integrated in time with the predictor–corrector constant–average acceleration method and adaptive time-stepping. A tiny random perturbative deflection was imposed on the ring filament to allow it to break the system’s initial symmetry by Euler buckling and to allow for independent repetitions of the simulations. Our aim was to simulate realistic yet generic materials, and thus we chose 2r=1 mm, Ef=1 GPa, ρf=ρs=1 g cm−3, νf=νs=1/3, but note that our results are reported in dimensionless units and are hence valid on any scale.

Experiments

In the experiments shown in Fig. 5, we tangentially attached straight steel pipes to rigid polystyrene spheres and manually fed polyurethane wires from both sides at equal speed through the pipes into the spheres. Starting from an initially preset loop, the wire then developed into the spiral or classical morphology depending on friction, which we controlled with a silicone lubricant. For the morphologies in weak confinement, we used stiffer polycaprolactam wires and customary stretchable balloons made of natural rubber into which the wires were tangentially pushed by hand.

Additional information

How to cite this article: Vetter, R. et al. Morphogenesis of filaments growing in flexible confinements. Nat. Commun. 5:4437 doi: 10.1038/ncomms5437 (2014).

References

Smith, D. E. et al. The bacteriophage φ29 portal motor can package DNA against a large internal force. Nature 413, 748–752 (2001).

Kindt, J., Tzlil, S., Ben-Shaul, A. & Gelbart, W. M. DNA packaging and ejection forces in bacteriophage. Proc. Natl Acad. Sci. USA 98, 13671–13674 (2001).

Odijk, T. Statics and dynamics of condensed DNA within phages and globules. Phil. Trans. R. Soc. A 362, 1497–1517 (2004).

Mouthuy, P.-O., Coulombier, M., Pardoen, T., Raskin, J.-P. & Jonas, A. M. Overcurvature describes the buckling and folding of rings from curved origami to foldable tents. Nat. Commun. 3, 1290 (2012).

Lobkovsky, A., Gentges, S., Li, H., Morse, D. & Witten, T. A. Scaling properties of stretching ridges in a crumpled elastic sheet. Science 270, 1482–1485 (1995).

Ben Amar, M. & Pomeau, Y. Crumpled paper. Proc. R. Soc. A 453, 729–755 (1997).

Blair, D. L. & Kudrolli, A. Geometry of crumpled paper. Phys. Rev. Lett. 94, 166107 (2005).

Vliegenthart, G. A. & Gompper, G. Forced crumpling of self-avoiding elastic sheets. Nat. Mater. 5, 216–221 (2006).

Tallinen, T., Åström, J. A. & Timonen, J. Deterministic folding in stiff elastic membranes. Phys. Rev. Lett. 101, 106101 (2008).

Tallinen, T., Åström, J. A. & Timonen, J. The effect of plasticity in crumpling of thin sheets. Nat. Mater. 8, 25–29 (2009).

Gomes, M. A. F., Brito, V. P. & Araújo, M. S. Geometric properties of crumpled wires and the condensed non-solid packing state of very long molecular chains. J. Braz. Chem. Soc. 19, 293–298 (2008).

Stoop, N., Najafi, J., Wittel, F. K., Habibi, M. & Herrmann, H. J. Packing of elastic wires in spherical cavities. Phys. Rev. Lett. 106, 214102 (2011).

Najafi, J., Stoop, N., Wittel, F. & Habibi, M. Ordered packing of elastic wires in a sphere. Phys. Rev. E 85, 061108 (2012).

Vetter, R., Wittel, F. K., Stoop, N. & Herrmann, H. J. Finite element simulation of dense wire packings. Eur. J. Mech. A 37, 160–171 (2013).

Guglielmi, G., Viñuela, F., Sepetka, I. & Macellari, V. Electrothrombosis of saccular aneurysms via endovascular approach. Part 1: Electrochemical basis, technique, and experimental results. J. Neurosurg. 75, 1–7 (1991).

Steiger, H. J., Aaslid, R., Keller, S. & Reulen, H.-J. Strength, elasticity and viscoelastic properties of cerebral aneurysms. Heart Vessels 5, 41–46 (1989).

Elbaum, M., Kuchnir Fygenson, D. & Libchaber, A. Buckling microtubules in vesicles. Phys. Rev. Lett. 76, 4078–4081 (1996).

Kuchnir Fygenson, D., Marko, J. F. & Libchaber, A. Mechanics of microtubule-based membrane extension. Phys. Rev. Lett. 79, 4497–4500 (1997).

Nemhauser, I., Joseph-Silverstein, J. & Cohen, W. D. Centriole as microtubule-organizing centers for marginal bands of molluscan erythrocytes. J. Cell Biol. 96, 979–989 (1983).

Cohen, W. D., Sorokina, Y. & Sanchez, I. Elliptical versus circular erythrocyte marginal bands: isolation, shape conversion, and mechanical properties. Cell Motil. Cytoskel. 40, 238–248 (1998).

Honda, M., Takiguchi, K., Ishikawa, S. & Hotani, H. Morphogenesis of liposomes encapsulating actin depends on the type of actin-crosslinking. J. Mol. Biol. 287, 293–300 (1999).

Limozin, L. & Sackmann, E. Polymorphism of cross-linked actin networks in giant vesicles. Phys. Rev. Lett. 89, 168103 (2002).

Xu, J. et al. Mechanical nanosprings: Induced coiling and uncoiling of ultrathin Au nanowires. J. Am. Chem. Soc. 132, 11920–11922 (2010).

Chen, L. et al. Controlling reversible elastic deformation of carbon nanotube rings. J. Am. Chem. Soc. 133, 9654–9657 (2011).

Chen, L. et al. General methodology of using oil-in-water and water-in-oil emulsions for coiling nanofilaments. J. Am. Chem. Soc. 135, 835–843 (2013).

Feynman, R. P., Leighton, R. P. & Sands, M. The Feynman Lectures on Physics vol. I (Addison-Wesley (1964).

Guven, J. & Vázquez-Montejo, P. Confinement of semiflexible polymers. Phys. Rev. E 85, 026603 (2012).

Müller, M. M., Ben Amar, M. & Guven, J. Conical defects in growing sheets. Phys. Rev. Lett. 101, 156104 (2008).

Stoop, N., Wittel, F. K., Ben Amar, M., Müller, M. M. & Herrmann, H. J. Self-contact and instabilities in the anisotropic growth of elastic membranes. Phys. Rev. Lett. 105, 068101 (2010).

Boué, L. et al. Spiral patterns in the packing of flexible structures. Phys. Rev. Lett. 97, 166104 (2006).

Stoop, N., Wittel, F. K. & Herrmann, H. J. Morphological phases of crumpled wire. Phys. Rev. Lett. 101, 094101 (2008).

Arsuaga, J., Tan, R. K.-Z., Vazquez, M., Sumners, D. W. & Harvey, S. C. Investigation of viral DNA packaging using molecular mechanics models. Biophys. Chem. 101–102, 475–484 (2002).

Koster, D. A., Croquette, V., Dekker, C., Shuman, S. & Dekker, N. H. Friction and torque govern the relaxation of DNA supercoils by eukaryotic topoisomerase IB. Nature 434, 671–674 (2005).

Ghosal, S. Capstan friction model for DNA ejection from bacteriophages. Phys. Rev. Lett. 109, 248105 (2012).

Otto, O., Sturm, S., Laohakunakorn, N., Keyser, U. F. & Kroy, K. Rapid internal contraction boosts DNA friction. Nat. Commun. 4, 1780 (2013).

Earnshaw, W. C. & Harrison, S. C. DNA arrangement in isometric phage heads. Nature 268, 598–602 (1977).

Cerritelli, M. E. et al. Encapsidated conformation of bacteriophage T7 DNA. Cell 91, 271–280 (1997).

Olson, N. H., Gingery, M., Eiserling, F. A. & Baker, T. S. The structure of isometric capsids of bacteriophage T4. Virology 279, 385–391 (2001).

Jiang, W. et al. Structure of epsilon15 bacteriophage reveals genome organization and DNA packaging/injection apparatus. Nature 439, 612–616 (2006).

Katzav, E., Adda-Bedia, M. & Boudaoud, A. A statistical approach to close packing of elastic rods and to DNA packaging in viral capsids. Proc. Natl Acad. Sci. USA 103, 18900–18904 (2006).

Chandrasekhar, S. Liquid Crystals 2nd edn Cambridge University Press (1992).

Jia, L. et al. Smectic polymer vesicles. Soft Matter 5, 3446–3451 (2009).

Pinot, M. et al. Effects of confinement on the self-organization of microtubules and motors. Curr. Biol. 19, 954–960 (2009).

Winegard, T. et al. Coiling and maturation of a high-performance fibre in hagfish slime gland thread cells. Nat. Commun. 5, 3534 (2014).

Svitkina, T. M. et al. Mechanism of filopodia initiation by reorganization of a dendritic network. J. Cell Biol. 160, 409–421 (2003).

Mogilner, A. & Rubinstein, B. The physics of filopodial protrusion. Biophys. J. 89, 782–795 (2005).

Meyer, A. Y. & Richards, W. G. Similarity of molecular shape. J. Comput. Aided Mol. Des. 5, 427–439 (1991).

Wang, S., Furchtgott, L., Huang, K. C. & Shaevitz, J. W. Helical insertion of peptidoglycan produces chiral ordering of the bacterial cell wall. Proc. Natl Acad. Sci. USA 109, E595–E604 (2012).

Savin, T. et al. On the growth and form of the gut. Nature 476, 57–62 (2011).

Giomi, L. & Mahadevan, L. Minimal surfaces bounded by elastic lines. Proc. R. Soc. A 468, 1851–1864 (2012).

van Rooij, W. & Sluzewski, M. Packing performance of GDC 360° coils in intracranial aneurysms: a comparison with complex orbit coils and helical GDC 10 coils. Am. J. Neuroradiol. 28, 368–370 (2007).

Reddy, J. N., Wang, C. M. & Lam, K. Y. Unified finite elements based on the classical and shear deformation theories of beams and axisymmetric circular plates. Commun. Numer. Meth. Eng. 13, 495–510 (1997).

Crisfield, M. A. A consistent co-rotational formulation for non-linear, three-dimensional, beam-elements. Comput. Meth. Appl. Mech. Eng. 81, 131–150 (1990).

Cirak, F., Ortiz, M. & Schröder, P. Subdivision surfaces: a new paradigm for thin-shell finite-element analysis. Int. J. Numer. Meth. Eng. 47, 2039–2072 (2000).

Vetter, R., Stoop, N., Jenni, T., Wittel, F. K. & Herrmann, H. J. Subdivision shell elements with anisotropic growth. Int. J. Numer. Meth. Eng. 95, 791–810 (2013).

Margolis, D. Fixed causality slip-stick friction models for use in simulation of non-linear systems. Proc. Inst. Mech. Eng. I 219, 199–206 (2005).

Cerda, E., Ravi-Chandar, K. & Mahadevan, L. Thin films: Wrinkling of an elastic sheet under tension. Nature 419, 579–580 (2002).

Acknowledgements

Financial support from ETH Zurich by ETHIIRA grant no. ETH-03 10-3 as well as from the European Research Council Advanced Grant no. 319968-FlowCCS is gratefully acknowledged. We thank N. Stoop for valuable discussions.

Author information

Authors and Affiliations

Contributions

Software development and simulations: R.V. Experiments: R.V. and F.K.W. Theoretical approximations: R.V. Visualization: R.V. Analysis and interpretation: R.V., F.K.W. and H.J.H. Manuscript: R.V., F.K.W. and H.J.H.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Figures, Notes and References

Supplementary Figures 1-2, Supplementary Notes 1-3 and Supplementary References (PDF 3103 kb)

Supplementary Movie 1

Evolution of the spiral morphology. Simulation at σ= 20 in a rigid sphere (ε= 0). Tangential sliding allows the growing filament to rearrange to a spiral after self-contact. (MOV 4318 kb)

Supplementary Movie 2

Evolution of the classical morphology. Simulation at σ= 20 in a rigid sphere (ε= 0). Friction restricts rearrangements of the growing filament to local neighbourhoods, inducing many topologically trivial loops. (MOV 2964 kb)

Supplementary Movie 3

Evolution of the folded morphology. Simulation at σ= 20 in a flexible sphere (γ= 202, ε= 104). Flexible confinements conform to pushing filament bundles, allowing them to pass one another to fold into even thicker bundles. (MOV 4717 kb)

Supplementary Movie 4

Evolution of the warped morphology. Simulation at σ= 40 in a flexible sphere (γ= 1002, ε= 104). Sufficiently strong frictional forces cause the flexible sheet to tightly wrap around the expanding filament, thereby preventing bundle formation. The sheet is first stretched, then crumpled, and finally stretched again by the strongly twisting filament. (MOV 3777 kb)

Supplementary Movie 5

Morphogenesis of filaments in shrinking flexible confinements. Shrinkage of the confining shell induces the same morphological phases as filament growth. The shown simulations use fixed r, h and L, while the equilibrium container radius R (and with it, σ and γ) is decreased over time. (MOV 6326 kb)

Rights and permissions

About this article

Cite this article

Vetter, R., Wittel, F. & Herrmann, H. Morphogenesis of filaments growing in flexible confinements. Nat Commun 5, 4437 (2014). https://doi.org/10.1038/ncomms5437

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms5437

This article is cited by

-

Bending the rules

Nature Materials (2023)

-

Reconstitution of contractile actomyosin rings in vesicles

Nature Communications (2021)

-

Emergence of active nematics in chaining bacterial biofilms

Nature Communications (2019)

-

Compaction of quasi-one-dimensional elastoplastic materials

Nature Communications (2017)

-

Shapes of minimal-energy DNA ropes condensed in confinement

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.