Abstract

Recent statistics portray a stark reality, particularly highlighting the inadequate recycling measures and the consequent environmental threats, most notably in developing nations. The global ramifications of plastic pollution are elucidated, specifically focusing on the alarming accumulation in regions such as the “Great Pacific Garbage Patch” and evolving waste management practices in Southeast Asian countries. We emphasize the significance of Waste-to-Energy (W2E) and Waste-to-Fuel (W2F) technologies, e.g., pyrolysis and gasification, for converting difficult-to-recycle plastic waste into a dense-energy source. However, we identify a critical gap in current research: the emission of CO2 during these processes. This perspective spotlights emergent CO2 capture and utilization technologies, underscoring their role as a robust turnkey solution in making W2E and W2F methods more sustainable and unleashing the huge potential of using waste plastics as a dense-energy source. The scientific community is urged to develop tailored solutions for reducing CO2 emissions in plastic waste conversion processes. This approach promotes circular resource utilization and realizes the socio-economic and environmental advantages of plastic waste utilization technologies, advocating their implementation in economically disadvantaged regions.

Similar content being viewed by others

Introduction

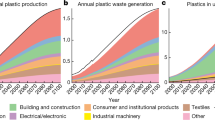

Borrowing a scene from “The Fabelmans”1, the culture of single-use plastics in the United States can be traced back to the late 1950s, a time when their usage and disposal were already rampant in average homes. For decades, consumers have followed a restricted narrative that begins with purchasing off-the-shelf products and ends with discarding them in the first bin without much thought of the aftermath. Fast forward to the present, despite society being a lot more environmentally conscious about waste plastics, especially with the growing concern over microplastics (tiny plastic particles <5 mm in size), there has been little significant change to our diehard habits2. The COVID-19 pandemic highlighted and simultaneously exacerbated this issue as our reliance on single-use plastics surged3. From the convenient packaging of food deliveries to the necessary use of personal protective equipment and medical supplies like masks, gloves, syringes, and blood bags, our consumption of plastics has increased, driven by both choice and necessity. The most pressing problem, we argue, is not with plastic as a material but instead with its lifecycle management and disposal, suggesting a critical re-evaluation of such practices. As a point of reference, the production of plastics in 1950 amounted to 2 million tonnes (Mt)4. By 2019, on the cusp of the COVID-19 pandemic, that number skyrocketed to 460 Mt. According to projections by the Organisation for Economic Co-operation and Development (OECD), global plastic use is expected to more than triple by 2060, reaching an astounding 1231 Mt (Fig. 1)5,6. Overall, the generated plastics waste per capita correlates well with gross domestic product (GDP); however, the precise magnitude of this correlation varies significantly across different regions, particularly with consumption habits (Fig. 2). For that reason, the level of waste per capita varies widely among high-income nations; One that is characterized by excessive consumptions (e.g., the United States) at the upper end, and one that is marked by environmentally conscious needs for recycling (e.g., Norway) at the lower end. Major contributors to plastics waste in 2016 include the United States, generating 34.0 Mt, India with 26.3 Mt, and China with 21.6 Mt7. While it is expected that most countries will see an increase in plastic consumption alongside GDP growth, we have not seen an overall bucking of the trend in terms of plastic waste generation. It suggests that plastic recycling is still insufficient, even among high-income nations. Most of these nations are net exporters of plastic waste. For example, the US exported ~5% of its plastic waste in 2010; France exported 11%, and the Netherlands exported 14%8.

The Sankey diagram (Fig. 3), illustrating the production, end-of-life, and recycling of packaging plastics, offers an overview of the present state of plastics management. Two critical observations emerge: (1) the low rate of plastic recycling, and (2) the dominant disposal practices via landfilling and dumping lack effective means for plastics decomposition at the end of their lifecycle. Other disposal methods, such as incineration and unregulated dumping—leading to ocean pollution, raise immediate environmental concerns due to excessive CO2 emissions and marine litter, respectively. A relatively recent study discloses an alarming 11.6–21.1 Mt of microplastics are suspended in the upper 200 meters of the Atlantic Ocean as of 20209. These microplastics, composed primarily of polyethylene (PE), polypropylene (PP), and polystyrene (PS), pose a dire threat to marine life and have the potential to enter the food chain, endangering both marine and human health.

98% of packaging plastics originate from fossil fuels, of which 32% of these plastics are mismanaged, with 2–5% of this mismanaged waste entering the oceans via rivers79.

As a matter of fact, land waste plastics are easily strayed into waterways and ultimately carried by ocean currents. A sea area of ~1.6 million km2 between Hawaii and California earned the moniker the “Great Pacific Garbage Patch” for trapping ~1.8 trillion pieces (or 80,000 tonnes) of plastics in the swirling ocean current10. Similar patches exist in every ocean around the world. The positively buoyant and float plastics represent just the tip of the iceberg, comprising ~1% of the total plastic waste entering the oceans11,12. The rest, including those that break down into microplastics, are found (1) among the sediment layers on the seafloor, (2) sinking, and (3) trapped or drifting near shorelines13. The presence of microplastics, whether in their original form or as fragments from larger pieces, has raised significant environmental and health concerns. Nations surrounded by vast water bodies, which act as conduits for drifting plastics, are particularly vulnerable to microplastic pollution. They include, for example, members of the Association of Southeast Asian Nations (ASEAN), India, Central and South America, New Zealand, the Pacific Islands, and the Mediterranean. While most plastics in their pristine states are inert and a nuisance in larger pieces, like any solid materials, they can adsorb potentially harmful chemicals and microbes. The sheer macrosize of these waste plastics limited the extent of our interactions with them. However, when these plastics break down into micron-sized fragments, they become small enough to be ingested by marine life, thereby entering the human food chain14,15. As these plastics further degrade into nanoparticles, there is a potential risk that these nanoplastics could penetrate the blood-brain barrier in humans16,17.

Recycling challenges and transboundary disposal

Forecasts by the United Nations indicate that by 2040, greenhouse gas (GHG) emissions stemming from the complete lifecycle of traditional, fossil fuel-based plastics are poised to contribute a significant 19% of the global carbon budget or ~2.1 gigatonnes of CO2 equivalent (GtCO2e)18. The figure is based on the current scenario where 98% of plastics are derived from virgin feedstocks or fossil fuels. Recycling remains the most environmentally friendly option, in the long run, to cope with the rising plastic demand and yet limit emissions.

Despite a global increase in recycling efforts, it may not yet be a comprehensive solution. The focus has been primarily on three types of high-demand plastics: rigid polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP) containers, which are plastics of categories 1, 2, and 5, respectively19,20. They resist natural degradation and accumulate in the soil and water bodies. In addition, most consumers are unaware of other plastic types that may end up in the recycling stream but are considered contaminants, for example, vinyl pipes and polystyrene cups. The issue arises due to specific recycling design and structural requirements needed for processing machinery. Ideally, the energy input for the recycling system requires using renewable energy coupled with energy storage to achieve carbon neutrality or negative at different times of the day. Effective recycling demands substantial materials recovery and sorting infrastructure, typically found in wealthier regions. This infrastructure, including roads and trucks necessary for expanding scalability, is often unavailable in poorer areas already burdened with plastic waste. Concurrently, although not the focus of this article, bioplastics are not yet fully proven to be a foolproof solution to the issues posed by waste plastics21,22.

Plastic waste distribution is a global issue that varies widely across socio-economic profiles, population density, and geographic locations. There have been instances where waste plastics are exported from one country to another, often to less developed economies. Policy decisions of the exporting countries significantly influence the movement of these waste plastics. For example, in 2017, when China implemented a ban on importing 24 types of plastic waste to prevent it from becoming the world’s dumping ground, there was an immediate surge in the importation of waste plastics from neighboring countries (Fig. 4)23,24. The Basel Convention, designed to regulate the movement of hazardous wastes, including waste plastics, is the primary international treaty overseeing such transboundary practices25. Despite this, “strategic” importation of plastics, often labeled for recycling, still occurs in countries with poor policies on waste management26. Malaysia and the Philippines have recently taken a stand against plastic waste imports. In 2019, they returned 5400 tonnes of waste plastics to their countries of origin, which included the United States, Canada, Australia, and the United Kingdom27,28,29.

The figure shows a noticeable rise in plastics waste import in some Asian countries following China’s ban on 24 types of solid waste from abroad8.

Navigating beyond conventional waste plastics management

Despite the challenge of the rapid accumulation of waste plastics, age-old landfilling, and incineration remain the most prevalent disposal methods. One preference over the other is essentially critical decision-making between the “lesser of two evils,” which in turn hinges on prioritizing key environmental and, to some extent, economic goals. Landfilling, while widespread, leads to long-term environmental contamination and space constraints. Incineration, while efficiently eliminating solid wastes, adds to direct CO2 emissions and is disastrous if adopted as the world’s sole disposal method. Conversion of plastics waste to textiles, building materials and 3D printing filaments are innovative solutions to circumvent the accumulation of waste plastics or direct emission of CO2. However, adoptions may be limited at the current trial stages.

As far as waste plastics incineration is concerned, direct CO2 generation is inevitable, although some degree of offsets in carbon emission can be made possible through the W2E conversion. Here, the exothermic heat from the combustion of plastics-containing trash is used to produce hot water for various domestic and industrial applications or to superheated steam to power turbines for electricity generation. Such processes have been successfully implemented in Germany, Sweden, Denmark, Norway, The Netherlands, Belgium, Singapore and Japan. Others, including China, India, Thailand, Turkey, and Mexico, are beginning to explore similar avenues. Nevertheless, the process is not without controversies due to excessive dioxin30 and CO2 emissions. Stringent exhaust treatment and CO2 capture and storage (CCS) are necessary to curb these emissions. To the best of our knowledge, W2E plant with coupled CCS remains unprecedented. This can be attributed to the limited accessibility to CO2 reservoirs at this early stage of development. Fly ashes recovered from incineration are valuable materials for CO2 adsorption and for creating geopolymers (i.e., green concrete), thereby further offsetting the GHG emissions from waste plastics incineration31,32.

When heated under restricted oxygen content, combustion of waste plastics or, for that matter, harnessing exothermic heat is not possible. Instead, the waste plastics undergo W2F conversion via pyrolysis or gasification. Pyrolysis is particularly effective for handling packaging films, pouch bags, and multi-layered materials, which most mechanical recycling methods struggle to process. Compared to incineration, pyrolysis decomposes plastics at lower temperatures, typically between 350 and 900 °C, in an oxygen-deficient environment or, in specific cases, with a very low oxygen concentration to increase the heating rate and resulting in a higher yield of product gas33,34. High temperatures lead to dehydration, depolymerization, and fragmentation of the plastics to produce volatile components. This process effectively breaks down the plastics into shorter-chain hydrocarbons. Notably, pyrolysis of mixed plastic waste emits 50% less CO2 than incineration, i.e., ~1 tonne less CO2 than incineration per 1 tonne of mixed plastic waste35. The pyrolysis product can be refined into diesel and other petrochemical materials. Selectivity control can be achieved through the addition of catalysts, e.g., silica-alumina and proton-exchanged zeolites like protonated Zeolite Socony Mobil–5, to obtain olefins that can, in turn, be repolymerized as virgin plastics thus facilitating the closed-loop recycling36.

Compared with pyrolysis, gasification is typically carried out at higher temperatures between 700 to 1500 °C, has a longer residence time, and may include the addition of steam. This results in simple molecules, primarily syngas (hydrogen and carbon monoxide), that can be further combusted to generate electricity or conversion to synthetic fuels, through water-gas shift reaction (CO + H2O → CO2 + H2), methanation (CO + 3H2 → CH4 + H2O), and Fischer-Tropsch synthesis (for example, paraffin synthesis: nCO + (2n+1)H2 → CnH2n+2 + nH2O)37,38.

Depending on the reaction temperature and, hence, the residue char/coke quality from W2E or W2F, they can be used as reinforcing agents in tyres, construction materials, soil conditioners, metallurgical coke, and adsorbents39,40,41,42. Such valorizations offset the carbon footprints of the W2E and W2F conversions. A point to practice with caution: despite the derived char/coke being considered a green fuel because it is converted from waste plastics, the emitted CO2 from its combustion to generate heat/electricity is ultimately traced to the original feedstock of the plastics, i.e., fossil fuels.

It is increasingly clear that fully realizing the benefits of waste plastic conversion necessitates, in one way or another, the management of direct CO2 emissions. In this context, carbon capture and storage (CCS) or utilization (CCU) is an essential downstream process and among the most urgently anticipated carbon mitigation technologies. There are two critical steps in CCU: firstly, the sequestration of CO2 from flue gas or other sources of mixed gases, and secondly, the conversion of concentrated CO2 into higher-value products. The former step is crucial for enhancing the reaction kinetics and, to some extent, the selectivity of CO2 conversion, leading to a higher yield per unit of energy input.

Pressure swing adsorption is the industry’s most widely adopted technology for gas separation. Its working principle is analogous to gas chromatography, where the gas of interest, CO2, is separated from others based on their adsorption affinity and elution time through a packed column filled with adsorbents. Once the CO2 is eluted, the column is evacuated to remove the remaining adsorbed gases for a new cycle of adsorption43. Given the cyclic pressure swings that are costly to operate, current research is focused on developing cost-effective and less energy-demanding CO2 adsorbents. Materials such as zeolites and metal-organic frameworks (MOFs) are chosen for their porous structure, facilitating effective CO2 retention44. Robust CO2-binding sites in MOFs like Al-PMOF and Al-PyrMOF show exceptional carbon capture capacity even in wet flue gas, which is a major challenge in realistic carbon capture processes45. Low-energy separation processes are favored for their clear environmental and process economics benefits46,47. Membrane separation, utilizing microporous zeolitic materials, is particularly noteworthy as these membranes are semi-permeable to CO2 and do not necessitate the ultra-high pressurization of flue gas48,49. Of special mention is ZIF-62, which exhibits high CO2 selectivity and permeability, making it suitable for industrial applications50.

Once CO2 is recovered in sufficiently high concentrations, it can be further converted into fuels (i.e., CCU) through chemical, photo(electro)chemical, and electrochemical methods51,52,53. The Sabatier or methanation reaction is particularly noteworthy for its ability to convert CO2 with high efficiency54, and can be readily injectable into existing natural gas pipelines. The catalytic conversion of CO2 to methanol is highly sought-after because methanol is the simplest form of liquid hydrocarbon at ambient conditions (thereby being highly transportable) and a versatile chemical intermediate55,56,57,58,59. Recent studies have been delving into the synergistic effects of multicomponent catalysts, such as Cu-ZnO-ZrO2 (CZZ), which show high CO2 conversion and methanol selectivity60. Additionally, there is increasing interest in non-Cu-based catalysts, as evidenced by the creation of palladium-promoted In2O3 sites that exhibit high methanol selectivity and stability61. Further, conversion from methanol to higher hydrocarbons can be carried out via the methanol-to-X (X = olefins, dimethyl ether, formaldehyde, hydrocarbons) reaction within the well-defined micropores of acidic zeolite catalysts62,63. Olefins can be returned as monomer feedstocks to close the loop of plastics recycling, while other products are downcycled as chemicals or fuels for different applications.

Concluding remarks

Managing waste plastics has evolved into a sophisticated practice intertwined with environmental impacts, carbon emissions, and economic viability. Compared to other non-perishable trash, such as metal scraps or E-waste, waste plastics have an economic value that is too low to justify tedious resource recoveries. The ongoing issue of transboundary disposal necessitates political commitment and collaboration between exporting and receiving nations to weed out unscrupulous practices involving false declaration of waste plastics for recycling.

Any efforts to close the recycling loop, either by recovering or reforming the monomers, is deemed the most emission-friendly. The challenge in recycling is to recover sufficiently high-purity monomers that reproduce plastics with comparable quality as that made of virgin monomers. Chemically, this requires meticulous sorting and segregation of different waste plastics and managing their additives.

Where options for monomer recoveries are not possible, the next best options are energy recovery from incineration (i.e., W2E) or as non-monomer fuels from pyrolysis (i.e., W2F). A notable concern arises with the emission of CO2, either directly during the W2E process or predominantly from the combustion of fuels produced via W2F. While the infrastructure requires significant investment, a comparison against landfilling needs to be made regarding environmental implications, land and maintenance costs, and the associated carbon emissions. Different countries are bound by other priorities due to different choices of solutions.

The Maldives, an island nation, is a notable case study of adopting W2E solutions for plastic waste management. Since the 1990s, the Maldives have been disposing of its waste in a lagoon known as Thilafushi64, which has transformed into a landfill over time. In this lagoon, waste plastics were commonly burned in the open air. It is estimated that the Maldives produces around 20,000 tonnes of waste plastic annually, with only 5% being recycled65. Most of this waste ended up in the lagoon landfill, where it was either openly burned or leaked into the ocean. In a significant shift towards sustainability, the government, since late 2021, has committed to transforming this waste lagoon into a large-scale “plastics-to-energy” facility. This project, costing around US$211 million, is targeted for completion in 202465. The initiative includes establishing a modern waste collection, transfer, and disposal system across the nation, covering 32 islands. When the produced energy reduces the demand for fossil fuel to do the same, it signifies a mutually beneficial outcome in terms of environmental sustainability and economic growth. An intriguing question remains concerning the large amount of drifting waste plastics at or near the shoreline that was washed from other countries, or for that matter, illegally imported waste plastics—whose carbon emissions should be accounted for in cleaning up, and are there adequate economic benefits to do so?

Data availability

No datasets were generated or analysed during the current study.

References

Spielberg, S. (Director). The Fabelmans [Film]. Universal Pictures (2022).

Qi, R., Jones, D. L., Li, Z., Liu, Q. & Yan, C. Behavior of microplastics and plastic film residues in the soil environment: a critical review. Sci. Total Environ. 703, 134722 (2020).

He, G., Pan, Y., Park, A., Sawada, Y. & Tan, E. S. Reducing single-use cutlery with green nudges: evidence from China’s food-delivery industry. Science 381, eadd9884 (2023).

Plastics Europe. Plastics — the facts 2011: an analysis of European plastics production, demand and recovery for 2010. https://plasticseurope.org/wp-content/uploads/2021/10/2011-Plastics-the-facts.pdf (2011).

OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options. OECD Publishing, Paris (2022).

UNEP. Drowning in plastics—marine litter and plastic waste vital graphics. http://www.unep.org/resources/report/drowning-plastics-marine-litter-and-plastic-waste-vital-graphics (2021).

World Population Review. Plastic pollution by country 2023. https://worldpopulationreview.com/country-rankings/plastic-pollution-by-country (2023).

Ritchie, H. Ocean plastics: how much do rich countries contribute by shipping their waste overseas? Our World in Data https://ourworldindata.org/plastic-waste-trade (2022).

Pabortsava, K. & Lampitt, R. S. High concentrations of plastic hidden beneath the surface of the Atlantic Ocean. Nat. Commun. 11, 4073 (2020).

Lebreton, L. et al. Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci. Rep. 8, 4666 (2018).

Cózar, A. et al. Plastic debris in the open ocean. Proc. Natl. Acad. Sci. USA. 111, 10239–10244 (2014).

Eriksen, M. et al. Plastic pollution in the world’s oceans: more than 5 trillion plastic pieces weighing over 250,000 tons afloat at sea. PLOS ONE 9, 1–15 (2014).

Onink, V., Jongedijk, C. E., Hoffman, M. J., Sebille, Evan, & Laufkötter, C. Global simulations of marine plastic transport show plastic trapping in coastal zones. Environ. Res. Lett. 16, 064053 (2021).

Zheng, X., Wu, X., Zheng, Q., Mai, B.-X. & Qiu, R. Transfer of microplastics in terrestrial and aquatic food webs: the impact of E-waste debris and ecological traits. Environ. Sci. Technol. 57, 1300–1308 (2023).

Huerta Lwanga, E. et al. Field evidence for transfer of plastic debris along a terrestrial food chain. Sci. Rep. 7, 14071 (2017).

Sun, A. & Wang, W.-X. Human exposure to microplastics and its associated health risks. Environ. Health 1, 139–149 (2023).

Leslie, H. A. et al. Discovery and quantification of plastic particle pollution in human blood. Environ. Int. 163, 107199 (2022).

UNEP. Our planet is choking on plastic. http://unep.org/interactive/beat-plastic-pollution/ (2023).

Chen, Y., Awasthi, A. K., Wei, F., Tan, Q. & Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total Environ. 752, 141772 (2021).

Royal Society Te Apārangi. Plastics in the environment: Te Ao Hurihuri—The changing world. https://www.royalsociety.org.nz/what-we-do/our-expert-advice/all-expert-advice-papers/plastics-in-the-environment-evidence-summary/ (2019).

Rosenboom, J.-G., Langer, R. & Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 7, 117–137 (2022).

Kubowicz, S. & Booth, A. M. Biodegradability of plastics: challenges and misconceptions. Environ. Sci. Technol. 51, 12058–12060 (2017).

Brooks, A. L., Wang, S. & Jambeck, J. R. The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 4, eaat0131 (2018).

Wen, Z., Xie, Y., Chen, M. & Dinga, C. D. China’s plastic import ban increases prospects of environmental impact mitigation of plastic waste trade flow worldwide. Nat. Commun. 12, 425 (2021).

UNEP. Basel convention on the control of transboundary movements of hazardous wastes. http://www.unep.org/resources/report/basel-convention-control-transboundary-movements-hazardous-wastes (2011).

Drewniok, M. P., Gao, Y., Cullen, J. M. & Cabrera Serrenho, A. What to do about plastics? Lessons from a study of United Kingdom plastics flows. Environ. Sci. Technol. 57, 4513–4521 (2023).

Khan, S. Wealthy nations seek solutions at home as more developing countries reject plastic waste exports. The Science Times https://www.sciencetimes.com/articles/22527/20190611/wealthy-nations-seek-solutions-at%C2%A0home-as-more-developing-countries-reject-plastic-waste-exports.htm (2019).

World Bank Group. Market study for the Philippines: plastics circularity opportunities and barriers. World Bank Open Knowledge Repository https://openknowledge.worldbank.org/entities/publication/61e2e030-9dc2-5013-a8ff-7565919e17ee (2021).

Picheta, R. Malaysia sent back tons of plastic waste to rich countries, saying it won’t be their ‘garbage dump’. CNN https://edition.cnn.com/2020/01/20/asia/malaysia-plastic-waste-return-scli-intl/index.html (2020).

Bei, J. et al. Revealing the mechanism of dioxin formation from municipal solid waste gasification in a reducing atmosphere. Environ. Sci. Technol. 56, 14539–14549 (2022).

Kwon, S. et al. Nonviable carbon neutrality with plastic waste-to-energy. Energy Environ. Sci. 16, 3074–3087 (2023).

Tang, G. et al. Waste plastic to energy storage materials: a state-of-the-art review. Green Chem 25, 3738–3766 (2023).

Almeida, D. & de Fátima Marques, M. Thermal and catalytic pyrolysis of plastic waste. Polímeros 26, 44–51 (2016).

Oliveux, G., Dandy, L. O. & Leeke, G. A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 72, 61–99 (2015).

Krüger, C. BASF: Results of the life cycle assessment (LCA) of ChemCyclingTM—CO2 emissions of pyrolyzed mixed plastic waste and the mass balance approach. https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach/chemcycling/dialog-forum-chemical-recycling.html (2020).

Kim, J.-R., Yoon, J.-H. & Park, D.-W. Catalytic recycling of the mixture of polypropylene and polystyrene. Polym. Degrad. Stabil. 76, 61–67 (2002).

Khan, W. U., Baharudin, L., Choi, J. & Yip, A. C. K. Recent progress in CO hydrogenation over bimetallic catalysts for higher alcohol synthesis. ChemCatChem 13, 111–120 (2021).

Mirzakhani, S., Yin, B. H., Masteri-Farahani, M. & Yip, A. C. K. Heterogeneous catalytic systems for carbon dioxide hydrogenation to value-added chemicals. ChemPlusChem 88, e202300157 (2023).

Wijesekara, D. A., Sargent, P., Ennis, C. J. & Hughes, D. Prospects of using chars derived from mixed post waste plastic pyrolysis in civil engineering applications. J. Clean. Prod. 317, 128212 (2021).

Kumar, A., Choudhary, R. & Kumar, A. Use of char derived from waste plastic pyrolysis for asphalt binder modification. 3rd International Conference on Innovative Technologies for Clean and Sustainable Development (eds. Ashish, D. K., de Brito, J. & Sharma, S. K.) 337–356 (Springer International Publishing, 2021).

Ligero, A. et al. Low-cost activated carbon from the pyrolysis of post-consumer plastic waste and the application in CO2 capture. Process Saf. Environ. Prot. 173, 558–566 (2023).

Singh, E. et al. Pyrolysis of waste biomass and plastics for production of biochar and its use for removal of heavy metals from aqueous solution. Bioresour. Technol. 320, 124278 (2021).

Sumida, K. et al. Carbon dioxide capture in metal–organic frameworks. Chem. Rev. 112, 724–781 (2012).

D’Alessandro, D. M., Smit, B. & Long, J. R. Carbon dioxide capture: prospects for new materials. Angew. Chem. Int. Ed. 49, 6058–6082 (2010).

Boyd, P. G. et al. Data-driven design of metal–organic frameworks for wet flue gas CO2 capture. Nature 576, 253–256 (2019).

Hou, R., Fong, C., Freeman, B. D., Hill, M. R. & Xie, Z. Current status and advances in membrane technology for carbon capture. Sep. Purif. Technol. 300, 121863 (2022).

Sholl, D. S. & Lively, R. P. Seven chemical separations to change the world. Nature 532, 435–437 (2016).

Khalilpour, R. et al. Membrane-based carbon capture from flue gas: a review. J. Clean. Prod. 103, 286–300 (2015).

Wang, S. et al. Advances in high permeability polymer-based membrane materials for CO2 separations. Energy Environ. Sci. 9, 1863–1890 (2016).

Wang, Y. et al. A MOF glass membrane for gas separation. Angew. Chem. Int. Ed. 59, 4365–4369 (2020).

Hung, S.-F. et al. A metal-supported single-atom catalytic site enables carbon dioxide hydrogenation. Nat. Commun. 13, 819 (2022).

Kumaravel, V., Bartlett, J. & Pillai, S. C. Photoelectrochemical conversion of carbon dioxide (CO2) into fuels and value-added products. ACS Energy Lett. 5, 486–519 (2020).

Liu, W. et al. Electrochemical CO2 reduction to ethylene by ultrathin CuO nanoplate arrays. Nat. Commun. 13, 1877 (2022).

Dreyer, J. A. H. et al. Influence of the oxide support reducibility on the CO2 methanation over Ru-based catalysts. Appl. Catal. B: Environ. 219, 715–726 (2017).

Behrens, M. et al. The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts. Science 336, 893–897 (2012).

Kattel, S., Pérez-Ramírez, J., Chen, J. G., Rodriguez, J. A. & Liu, P. Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts. Science 355, 1296–1299 (2017).

Li, Z. et al. Highly selective conversion of carbon dioxide to lower olefins. ACS Catal 7, 8544–8548 (2017).

Martin, O. et al. Indium oxide as a superior catalyst for methanol synthesis by CO2 hydrogenation. Angew. Chem. Int. Ed. 55, 6261–6265 (2016).

Ra, E. C. et al. Recycling carbon dioxide through catalytic hydrogenation: recent key developments and perspectives. ACS Catal 10, 11318–11345 (2020).

Wang, Y. et al. Exploring the ternary interactions in Cu–ZnO–ZrO2 catalysts for efficient CO2 hydrogenation to methanol. Nat. Commun. 10, 1166 (2019).

Frei, M. S. et al. Atomic-scale engineering of indium oxide promotion by palladium for methanol production via CO2 hydrogenation. Nat. Commun. 10, 3377 (2019).

Kirchberger, F. M. et al. Mechanistic differences between methanol and dimethyl ether in zeolite-catalyzed hydrocarbon synthesis. Proc. Natl. Acad. Sci. USA 119, e2103840119 (2022).

Hazari, N., Iglesia, E., Labinger, J. A. & Simonetti, D. A. Selective homogeneous and heterogeneous catalytic conversion of methanol/dimethyl ether to triptane. Acc. Chem. Res. 45, 653–662 (2012).

Cheriegate, E. et al. The trash island of the Maldives: Thilafushi. Save The WaterTM https://savethewater.org/the-trash-island-of-the-maldives-thilafushi/ (2022).

Board, J. Transforming ‘Trash Island’: Amid plastic crisis, skies are clear over the Maldives’ notorious mountain of waste. CNA https://www.channelnewsasia.com/sustainability/maldives-trash-island-thilafushi-mountain-plastic-waste-2578951 (2022).

The World Bank. Total population. https://data.worldbank.org/indicator/SP.POP.TOTL?end=2022&start=1960 (2023).

The World Bank. GDP (current US$). https://data.worldbank.org/indicator/NY.GDP.MKTP.CD (2023).

Law, K. L. et al. The United States’ contribution of plastic waste to land and ocean. Sci. Adv. 6, eabd0288 (2020).

von Kamake, L. APAC: plastic waste volume per capita by subregion 2060. Statista https://www.statista.com/statistics/1361987/apac-plastic-waste-volume-per-capita-by-country-subregion/ (2023).

Greenpeace. Circular claims fall flat again. Greenpeace Reports https://www.greenpeace.org/usa/reports/circular-claims-fall-flat-again/ (2022).

Pickin, J. et al. National waste report 2022. https://www.dcceew.gov.au/environment/protection/waste/national-waste-reports/2022 (2022).

Ramdhani, I. Indonesia has a serious garbage problem. Maritime Fairtrade https://maritimefairtrade.org/indonesia-serious-garbage-problem/ (2022).

Open Access Government. Climate change efforts in Denmark’s Ministry of Environment. https://www.openaccessgovernment.org/climate-change-efforts-in-denmarks-ministry-of-environment/145260/ (2022).

Klein, C. Disposal volume of plastic waste in Japan from 2012 to 2021. Statista https://www.statista.com/statistics/695382/japan-plastic-waste-disposal-volume/ (2023).

IUCN-EA-QUANTIS. National guidance for plastic pollution hotspotting and shaping action. https://plastichotspotting.lifecycleinitiative.org/wp-content/uploads/2020/12/kenya_final_report_2020.pdf (2020).

Innovation in plastics: the possibilities and potential. https://www.maricoinnovationfoundation.org/innovation_in_plastics_the_possibilities_potential/ (2023).

Environment Investigation Agency. Plastic waste power play: the offshoring and recycling displacement involved in trying to recycle EU plastic waste. https://eia-international.org/report/the-offshoring-and-recycling-displacement-involved-in-trying-to-recycle-eu-plastic-waste/ (2023).

Anderson, S. Plastic in Sweden—facts and practical advice: Data from 2020. Naturvårdsverket https://www.naturvardsverket.se/4ac845/globalassets/media/publikationer-pdf/8800/978-91-620-8888-0.pdf (2022).

World Economic Forum, Ellen MacArthur Foundation & McKinsey & Company. The new plastics economy: rethinking the future of plastics. https://www.ellenmacarthurfoundation.org/the-new-plastics-economy-rethinking-the-future-of-plastics (2016).

Acknowledgements

The authors acknowledge the financial support from the MBIE New Zealand under the Endeavour “Smart Ideas” grant (UOCX2206). The authors also thank Professor Shusheng Pang (University of Canterbury) for sharing insights into pyrolysis and gasification technologies and Professor Shauhrat Chopra (City University of Hong Kong) for the fruitful discussions on carbon footprint analyses. W.Y.T. acknowledges the Ministry of Higher Education Malaysia via the Fundamental Research Grant Scheme (FRGS/1/2022/TK08/UM/02/43), Australian Research Council (DP200102121), Southeast Asia-European Joint Funding Scheme (JFS21-123 HYPERMIS), and UM Matching Grants (IMG002-2022, MG001-2023).

Author information

Authors and Affiliations

Contributions

A.F.J.T.: conceptualization, methodology, discussion, writing-original draft, review & editing. S.Y.: discussion, writing-original draft. C.W.: discussion, review & editing. G.H.Y.: discussion, writing-original draft, review & editing. W.Y.T.: conceptualization, discussion, writing-original draft, review & editing. A.C.K.Y.: conceptualization, discussion, writing-original draft, review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tan, A.F.J., Yu, S., Wang, C. et al. Reimagining plastics waste as energy solutions: challenges and opportunities. npj Mater. Sustain. 2, 2 (2024). https://doi.org/10.1038/s44296-024-00007-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44296-024-00007-x