Abstract

Irregularly shaped wood created as waste from construction is considered challenging to reuse because of its complicated geometry and a lack of well-defined design methods. Here, we propose a sustainable building design and construction framework as a systematic methodology for upcycling irregular off-cut wood into new components. This framework consists of repeatable steps, as follows: a. material reclamation system: 3D scanning is employed as the main technical method to record a material’s 3D information and material-specific parameters and create a database; b. structural generation and assessment system: material screening, voxel-based filling, and structure generation based on finite element analysis to employed to assess the generated results prior to construction to optimize the final structure. Using furniture, building components, and installations/buildings, we verify the use of this framework for material recycling and generative design and construction.

Similar content being viewed by others

Introduction

Three sustenance clusters exist in ecosystems: producers (plants), consumers (animals) and decomposers (bacteria). Manufactured systems and social production systems tend to focus on producers and consumers without considering the role of decomposers, ignoring waste processing or relying on natural absorption. Thus, neglected decomposer (end-of-life) processes emulate sustainable natural cycles, treat them as a new cycle of renewable resources, reinput and carry out sustainable design and composition instead of understanding waste as a final and definitive social output to be eliminated1,2,3. In the urban development process, many resources/materials that are difficult to recycle and reuse are directly discarded and left idle due to technological and process limitations. As urbanization rates increase and natural resources shrink, the UN Sustainable Development Goals 11 and 12 proposed adopting the method of preventing, reducing, recycling and reusing—as well as properly collecting and discharging—urban solid waste to reduce its total by half globally by 2030. The public perception of discarded items and materials has also shifted from social output to reusable sustainable resources4.

Wood, a critical biobased material, is considered a renewable but limited resource because of its long growth cycle and the actual supply and demand of the market, which are limited by the boundary of the growth environment5,6. In 2030, wood production is expected to be insufficient to meet societal demand7,8. The sustainable use of wood resources and the effective collection, disposal, and reclamation system of waste wood is of great importance to alleviate supply and demand conflicts and overexploitation pressure on the natural environment9,10,11,12. Building and industrial waste streams are vast reservoirs of materials and components, of which wood is a significant proportion. However, until now, wood upcycling only occupied approximately 2.5% of the total, and wood downcycling occupied approximately 89.6%, including chipping, downcycling, and repurposing for material use (mulch, composting, medium density fiberboard, chipboard, animal bedding) and biomass energy13. Downcycling or destroying these valuable recyclable materials is a waste of resources we cannot afford.

Linear to circular construction is a design principle for mediators to reduce or even eliminate disputes over human needs for natural, long-lasting cycles. Traditional approaches do not successfully reintegrate wood into production but delay its disposal, which ends up as waste14,15,16,17,18,19. A sustainable opportunity lies in resetting the lifecycle of waste wood through a viable reclamation, design, and fabrication framework tailored to the materials and the reuse market to reduce its placement into landfills and improve the recycling rate20,21. The industry aims to accomplish a sustainable design transformation by reintegrating recycled materials, workflows, and technologies22,23,24,25.

Reclaimed wood is a sustainable material with a renewable and unique customized nature, and the reclaimed wood esthetics and urban wood esthetics that represent nature make recycled wood products stand out from the competition in recycled products26,27. More specifically, potential upcycling work denotes the reuse and repurposing of used woods or building components as new building components (constructional elements) for sustainable design and construction. By summarizing reconfiguring design practices, the existing research case for sustainable circular system design can be described as follows: (a) embracing a circular economy and recycling waste; (b) mitigating a series of ecological problems caused by overexploitation of material resources, such as member exhaustion and climate change; (c) managing the urban environment; (d) easing urban development processes and sustainable development and mitigating the negative effects of divergent goals28,29,30,31,32,33,34,35,36,37,38. Thus, enhancing recycling performance and eco-environmental benefits through the adaptive modification of waste as input materials to produce renewable outputs is considered a promising approach.

In summary, we reviewed a vast group of upcycled wood products as alternate construction resources and highlighted 9 typical cases (Table 1, Supplementary Table 7), comparing the material recycling and reuse information and reuse methods12,39,40. Architects have demonstrated the potential for reuse and architectural design and construction by recycling recycled wood, timber originals, and timber building discrete components into new architectural practices. At the same time, in terms of material recycling, material information recording, material-based design, and the construction process, since there is no design guidebook, all cases are designed based on the experience of architects, and no method that can be replicated has formed the principal and technical route (Table 2). When analysing and summarizing reclaimed-wood-based building design and construction projects, it was found that fewer than 20% of these construction projects had established databases for recycled materials, and those with databases had the following deficiencies: (1) for materials, only regularly shaped waste architectural resources that could be easily recycled were considered, such as in the Tysons Living Learning Center project41; (2) for recycling processes, the deconstructed building components were disassembled and sorted; and (3) for recording, materials were collected and sorted using an alphabetical approach, which is a 2D method of on-site recording, sorting, and documenting. Due to limitations in comprehensiveness and information accuracy, this approach presents challenges for subsequent design and technical accuracy; and (4) projects with databases are not open sourced, which means their methods for material selection, quality control, and classification are not transparent, leading to limited replicability that can be universally applied to the industry.

This article proposes a rethinking of how different scales of waste wood, from edge scrap to building components, can be reused in building design and fabrication. The experimental hypothesis of our proposed sustainable building design and construction (SBDC) framework is that it can reclaim off-cut wood and can be reconfigured for new buildings. It involves the transition from digital to physical, which entails creating material databases, topology simulations, and physical constructions of various scales, from furniture to buildings to architecture, engineering and construction (AEC). Our technical route to achieving reproducibility is establishing a system framework using previously used off-cut wood and wooden components from renewable and salvaged sources. It also details how to verify the possibility of the method from the scale of furniture to the scale of architecture.

Results

Sustainable building design and construction (SBDC) framework

The SBDC framework integrates green technologies with a multidisciplinary approach to sustainability, computer science, design and manufacturing, and materials science. It involves a comprehensive material reclamation system (MRS), which records and summarizes complex geometric details and material properties, and the MRS platform consists of two modules: material recovery and a material database. It is designed to collect and process recycled material information prior to the design phase. To complete the technical method of material data collection, its characteristics include the following: (1) it can provide 3D information collection methods for different scales of wood; (2) it can realize the visualization of data collection information, classify the data model information, and provide convenience for architects to screen materials; and (3) it can collect information accurately, quickly and flexibly, whether in the lab or on-site in different scenarios, and is not limited to the working local area network and the basic equipment environment. The structural generation and assessment system (SGAS) is a technical method for generating structural systems prior to actual construction. Prior to the fabrication phase, the SGAS utilizes two modules—structural generation and structural evaluation—by analysing new components to ensure their proper infill, design and evaluation of their construction possibilities (Fig. 1).

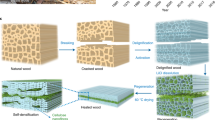

Material reclamation system (MRS) and material database

We investigated five wood manufacturing sawmills in the suburbs of London. Problems were found with the improper disposal of irregular wood, such as a lack of data recording and classified storage. Large amounts of wood were exposed and uncovered in the outdoor environment, which resulted in varying degrees of damage from insect infestation and its eventual waste. Therefore, following the “upcycling” vision of the material reclamation module, this study proposes a digital recording method instead of the traditional single-letter recording method, which is limited to regular wood only. It allows a more comprehensive 3D data capture process for irregular reclaimed wood. Multiple 3D scanning technologies (Supplementary Video 1), including 3D laser scanning, LiDAR, and photogrammetry, were employed. Additionally, comprehensive wood information was measured and recorded, including wood type, length, width, weight, approximate growing age, recycling grade, approximate moisture content, tree species, density, and material proportion. A wood database was then constructed after summarizing the information to provide data support for SBDC (Fig. 2, Supplementary Fig. 1).

The database demonstrates the information on wood type, length, width, weight, approximate age, recycled grade, and material proportions were measured and recorded (Details: Supplementary Table 3). Type A contains complete and broken pallets.

Structure generation and assessment system (SGAS): reclaimed off-cut wood-based sustainable furniture design

Off-cut wood arises from cutting timber into marketable sizes during preliminary wood processing. Off-cut wood is recycled primarily following a standardized process and a specified length. To reclaim regular off-cut wood, easily reclaimed sections of 25 mm, 75 mm, and 100 mm are circulated in the second-hand market (Supplementary Table 1). The rest of the off-cut wood, which has an irregular cross-sectional size or has not entered the preliminary recycling process, is considered waste wood. Many materials are regarded as firewood sold on eBay and other platforms or downgraded and made into plywood, or the waste wood is disposed of by burning, causing resource waste and environmental pollution.

Off-cut wood is typically used in manufacturing and designing projects with simple geometric characteristics and categories. Those with the same section are considered regular easy-to-reconfigure off-cut wood that can be built into furniture and installed through simple reconfiguration (Supplementary Figs. 4–6). In the design phase, a maximum of five types of wood are normally used in the same topology for the same assembled structure (Supplementary Table 2). With the help of the Wave Function Collapse (WFC) algorithm, it is possible to generate a simulation of the assembled structure for wood species with the same section size, approximate weight density, and approximate moisture content (Supplementary Figs. 7–12). This offers more possibilities for assembly solutions of reclaimed off-cut wood. Meanwhile, it also enables statistical analysis of the generated structures, which contributes to easily comparing the overall quantity and types of materials used in different developed solutions (Supplementary Table 2).

Another portion of off-cut wood from sawmills has a variety of geometric characteristics, and it is therefore difficult to collect and summarize the data. Although more than the vast majority of off-cut wood is not suitable for standardized processing, there is no other applicable recycling method for irregular wood and limited utilization of waste off-cut wood38,42,43. For this reason, irregular hard-to-reconfigure off-cut wood is generally considered waste. The difficulty in integrating this into large-scale complicated structures lies in the material selection, utilization, packing method adapted to the digital aggregation, and realities encountered during assembly. Specifically, this includes the following:

-

Controlling the relationship between a single wood component into a new block and the whole structure: How can reclaimed off-cut wood of different sizes be packed to complete the unitization process?

-

Design and structure generation: how can the structure generation performance of the same topology be quantitatively analysed? How can the rationalization of material utilization in the wood database be maximized?

There are several steps in the SGAS workflow of furniture scale (Fig. 3a). Voxel size definition (Supplementary Fig. 2a): The first step of the structure generation is to pack 4–6 pieces of off-cut wood from the database and place them in 60 mm, 80 mm, 100 mm and 120 mm voxels and then summarize them by comparing their packing methods with their internal filling rate (IFR) and external overflow rate. Ideally, the external overflow rate should tend to be 0, with a higher IFR being more favorable for later applications. A voxel size of 100*100*100 mm could achieve an average filling rate of approximately 42.45% and an average overflow rate of 0%. This voxel size is therefore chosen as the unit of utilization for the experiment. Input voxel matrix (Supplementary Fig. 2b): The matrix is the basis of the computational methods for the design and representation of irregular structural materials. The generation of blocks and components provides opportunities for off-cut wood-based design and construction in the generation of irregular structures. The voxel-based packing material is used to define the input matrix, to construct the adjacency rules between blocks and to determine the availability of blocks. The XYZ axes are set with respect to the corners and internal positions to obtain four different types of matrices, corresponding to the internal and external voxels in the horizontal or vertical areas.

SGAS Workflow in furniture and architectural components scales (Details: Supplementary Table 4). a Stool generation. b Column generation.

Voxel rotation mechanism (Supplementary Fig. 2c): The simulated structures are completed with the aid of calculations by means of a modular material packing method. Adjacency rules define whether and how blocks match each other by enforcing geometric compatibility at the interfaces and avoiding unnecessary geometric features. More precisely, in the horizontal and vertical areas, the adjacency rule defines whether the voxels of the basic structure match each other to complete the construction of the structure (Supplementary Fig. 2c) by means of the connection surfaces of the voxels and the interfaces of the blocks after wood utilization. Within the input matrix, some green voxels satisfy the characteristics of the re-entrant structure: they can re-enter the generating topology without considering the direction. Additionally, the “consecutive repetition of the same voxel” as a case of re-entrant structures is prohibited to avoid building incomplete structures. Finally, part of the blue voxel is considered a chiral structure to ensure that it generates a more continuous top-down block, limiting its rotation direction and rules44,45. Material rationalization replacement (Supplementary Fig. 2d): In the simulations of the generating structure components, blocks of the same section size often appear due to their rotation mechanism and the adjacency rules between neighboring voxels, so when this occurs, the block is replaced directly in the database with a whole piece of wood of the same shape according to the dimensions of the block. This minimizes the need for secondary wood processing and rationalizes the use of the material in the database.

Voxelized stool typology (Supplementary Fig. 2e–g): The structure generation is based on a geometry of 300*300*400 mm and then voxelized to the voxel size determined in the first step. Four types of stool prototypes were set up manually by comparing them with common stool shapes. The difference between the prototypes lies in the number of voxels and may change the degree of continuity of the off-cut wood within the voxels, which in turn affects the overall structural strength. Then, the structural growth of the irregular material is simulated to achieve digital aggregation to reality. With the WFC algorithm, 3D blocks are defined to follow the principle of adjacent structure generation, with different colored blocks corresponding to real materials within a real connected voxel. This allows the virtual simulation process to generate 3D structured materials, completing the digital aggregation of the design attempt. Finite element analysis (FEA) of the structure (Supplementary Fig. 2h, i): To observe and compare the different paradigms generated for the same structure, FEA is used to visualize and compare the stress behavior of the structure, the maximum load-bearing areas, etc. (Supplementary Table 4, Supplementary Method 1).

The project illustrates a replicable design system and construction process for reused wood under the SBDC framework (Fig. 4). It provides a basis for the application of these reclaimed materials in sustainable buildings from design to assembly. The final commercialization process is accomplished by digitally documenting and analysing the recycled off-cut wood for sustainable furniture design and construction (Supplementary Video 2).

Verification and case studies: SBDC in architectural components

This research expands the design scale to the building scale after finishing the off-cut wood-based generation and topology optimization at the furniture scale. A major architectural component, a column, is used as an example (Figs. 3b, 5). To ensure that the project is actually implemented, that is, the actual wood can support the actual construction, we first complete the calculation and statistics of the total volume and quantity of the required wood and complete the data classification (specific classification, total amount, data situation in Supplementary Table 6, Supplementary Fig. 13). Verification and case studies of the column carried the previous off-cut wood voxel filling logic, proportions, and species and thus unfolded directly from column typology voxelization (Supplementary Fig. 3a). The column generation is based on a geometry of 300*300*1600 mm—approximately two-thirds of the actual column heigh—and is esthetically optimized after voxelization by removing the voxel that is outside the structural and decorative part. The voxel classification step (Supplementary Fig. 3b, c) adds a parent classification, the structural and decorative, to the previous horizontal and vertical classifications and produces four classifications: the structural horizontal voxel, the structural vertical voxel, the decorative horizontal voxel, and the decorative vertical voxel. The research uses three types of voxels other than structural horizontal voxels in the design of architectural components such as columns. In this step, it is necessary to ensure the presence of structural vertical voxels in each horizontal plane of the vertical section, which can increase the number of off-cut wood replaced in the voxels and thus improve their continuity, as well as better load-bearing performance. Then, the off-cut wood is replaced with the filled voxel in the Supplementary Fig. 2b matrix to obtain multiple column typologies. After analysing and comparing the stress behavior and the maximum load-bearing areas of different column paradigms in the same design language, the construction was carried out by recycling and using discarded off-cut wood from Hong Kong and complying with the desired height and section width at the beginning of the design (Supplementary Fig. 3d, e). A real column was built. The architectural components were realized and validated from digital aggregation, and the actual building process based on the reclaimed off-cut wood database as material resources laid the foundation for the subsequent spatial design with all the basic architectural components.

Primitive Hut: purposed sustainable building design and construction

In the architectural scale design and fabrication proposal, this research takes a pavilion as an example, named the Primitive Hut. Notably, unlike the previous column design, a voxel-volumetric structural system, panel system, and surface system are added to the pavilion. The voxel-volumetric structural system, panel system, and surface system were added to the Primitive Hut. The pavilion typology voxelization (Fig. 6a) indicates a process from pavilion shape and boundary optimization. Systematic voxel classification (Fig. 6b) demonstrates different boundaries of architectural components in a pavilion, which is divided into several parts, including two floors, one stair, five columns, and a roof. Meanwhile, these parts contain the four voxels mentioned in Supplementary Fig. 3b and fill in the off-cut wood according to the three systems mentioned above to form the digital aggregation in Fig. 6c. Two possible environments for this pavilion, the Primitive Hut, are shown in Fig. 6d.

Discussion

Upcycling and reuse have become the focal points for reducing resource waste and realizing reuse. The vital difficulty lies in systematically summarizing complex wood parameters and data and finding a nonexperience-oriented design practice method. This paper has considered all types of off-cut wood, a regular easy-to-reconfigure topology, and an irregular hard-to-reconfigure typology. We proposed the SBDC framework to carry out design research on reclaimed wood, taking furniture scale experiments as examples and practising the specific process from reclaimed materials and design to construction. The framework mainly highlights the following: (a). The SBDC framework processes used and waste off-cut and irregular wood upcycling for AEC. (b). The MRS records and categorizes sophisticated geometric details and material properties based on multiple 3D scanning technologies. (c). The SGAS is a programmable approach to designing and generating structural systems. (d). FEA is an effective quantitative method for research by design as data support prior to AEC. (e). The definition, design, assessment and fabrication of regular easy-to-reconfigure wood and irregular hard-to-reconfigure wood provides theoretical guidance and technical assistance in the AEC industry’s long-term development process.

The method proposed in this paper is reproducible. It provides a technical workflow to support the design generation and construction of furniture, installations, and buildings at different scales and helps to preserve wood resources that are becoming scarce. It also offers a solid case study and database for the design and construction of irregular materials in applications (Supplementary Video 3).

In a circular economy, attempts are made to reset the life cycle of materials and products through the recycling of items. However, the material cannot be recycled infinitely. Therefore, the durability and reliability of recyclable materials, low energy consumption, and refurbishment capabilities should also be considered to reduce waste, maintenance, and upgrades in the production process46. Based on the principle of nondegradable recycling, the study responded to the assembly of components and the way they can be reassembled.

Regarding wood storage, it was discovered during the investigation that the wood was randomly placed in the environment, which can cause problems such as insect infestation. To realize the commercialization process of existing wood, there should be a complete set of wood evaluation systems, surface treatment, potential damage degree, etc., as well as an evaluation of the strengths and weaknesses of the former uses of wood through a SWOT47,48 analysis to determine the strength and structural properties aged wood has and how to determine the possibility of using reclaimed wood in furniture production49.

FEA should be applied as a consideration for structural selection. Different from the design and construction of furniture, the study used FEA combined with a genetic algorithm (GA) to complete the selection and optimization for building and structure construction. In the future, the SBDC framework will screen materials, design structure generation methods, and directly use FEA as a consideration to complete iterations of the generation optimization process in real time (developed with the help of the GA) to show a relatively optimal solution and improve the entire system. Additionally, a novel module integrates FEA simulation, scientific visualization, and load measurement into an AR-based environment50.

A building design fabrication platform was proposed. After the assembly practice, we tried to reconstruct the model through the 3D model retrieval technology of photogrammetry (Fig. 7). By comparing the initially generated model, we found that there were deviations in details in the manual-guided construction case, and it was not easy to distinguish materials of different sizes, which increased the construction time. Regarding the problems mentioned above that can be improved and fabrication errors, construction techniques must be developed to address accuracy and time cost.

For more complex furniture, installations, and architecture design, we are developing autonomous construction technologies, i.e., robotic assembly (autonomous assembly processes in lights-out manufacturing, such as Tesla), and AR-aided assembly methods, including picking and sorting guide methods, to avoid wasting time searching for materials and to avoid errors caused by manual construction during the construction process.

Additionally, the design phase should also consider the use of environmentally friendly materials and processes to minimize the environmental impact during production. The design for disassembly maximizes the reuse potential of the components and avoids the fabrication of new materials for future applications51,52,53,54,55. The current building process with nails and glue as the connections between materials should consider whether it is possible to choose a connection that is easy to configure, such as wood soldering, folding metal, adaptable plastic joinery, and Chinese mortises, to achieve the proper configuration of reused wood. The design principle of the combination of discrete architecture and SBDC, combined with the above flexible and adaptable joinery methods, can develop three or more connections through multiple assemblies, deconstructions, and reconfigurations of the original as follows: (a) adaptable plastic joinery as a new perspective on design for irregular and multiple-typology connection methods56,57; (b) Chinese mortise joinery to reclaim material-based blocks and components and reconfigure them easily to new installations; and (c) folding metal as a reconfigurable joint method between structural units and surface/minor surface units. These approaches can be adapted to multiple aggregation and assembly directions. The design for the disassembly process can be evaluated. The evaluation of carbon emissions, life cycle assessment, economy, time, transportation, and other parameters optimizes the framework and tries to put it in the early stages of research as a new condition and consideration.

MRS: Toxicity detection is added when collecting database information, and those materials that are toxic and unstable in chemical composition are directly deleted from the database (physical material database and digital database), and the related toxicity of the wood data is referenced (Supplementary Table 5)58.

Methods

SGAS workflow

This workflow shows the structure generation at the furniture and architectural scales, taking a stool with a boundary size of 300*300*400 mm and a column with a boundary size of 300*300*1600 mm as examples. After voxelization, the boundary is divided into two parts: the horizontal areas above and the vertical areas below (horizontal areas are present at both the top and bottom of a column), and the voxels in these two areas are manually combined into different and more accurate boundaries according to some common stool shapes and column structures. Then, with the help of the WFC algorithm, all off-cut wood in the specified color outer frame is filled with voxels of the corresponding color. Finally, FEA and topology optimization are performed on the overall structure.

Data preparation: 3D scanning

A variety of 3D scanning techniques and physical information recording techniques for materials are used. In-depth records are kept on the geometric topology, materials, and numerous properties of diverse materials. The creation of the database for irregular wood is finalized to more fully comprehend the topological paradigm of irregular wood in the generation of structures. This research digitally packs irregular wood based on the induction of voxel units and uses algorithms to finish the structural simulation creation under specific circumstances. A FEA of the structure was performed before construction as part of the discussion process. There have been multiple attempts at wood recycling, design, and building.

3D scanning equipment and technical route (Supplementary Video 1). The database is built based on 3D scanning technologies. The process uses 3D laser scanning, LiDAR, and photogrammetry to record the geometric information of the wood and record the wood type, part, length and width, weight, approximate growth years, and recycling by measuring grade, water content, material proportion, etc. For different scales of wood, the study used different equipment to carry out scanning work. The small scale is limited by the boundary of the EinScan-SE 3D Scanner rotary table, less than 200*200*200 mm, for recording. The 700*700*700 mm medium-scale wood is recorded by means of photogrammetry, that is, photos taken from different angles are taken with a SONY A6400 digital camera, and the digital model is reconstructed and texture colorized using reality capture. For wood larger than 700*700*700 mm, one recording process uses the same method of photogrammetry with drones (DJI Mavic Pro) to scan wood in large sizes. Another recording process uses VX Element, an EinScan Pro 2X Handheld Scanner or its adapted portable workstation for model recording, and healthy reclaimed wood is logged in the database library. At the same time, a BENETCH-GM630 wood moisture meter was used to assess the wood moisture content and density range, wood species and so on.

To ensure that the locally collected wood has sufficient materials for building assembly, experiments were accurately realized through calculations in the early research and design stages (Supplementary Table 6, Supplementary Fig. 13). Take the column in the architectural proposal (Fig. 5) as an example of innovation, statistical analysis, and fabrication (Supplementary Fig. 3). In the off-cut wood database, according to the off-cut wood belonging to hardwood, softwood, density, fire resistance, easy maintenance, strength, and durability-material screening stage, it is divided into structural parts and decorative parts.

The experiment assumes that the reclaimed wood is divided into two grades: Grade A and Grade B. The different grades are defined by the ratio of the volume of the wood itself to the total volume of the minimum number of voxels formed on the periphery of the wood. When this ratio is greater than 80%, the wood is classified as Grade A, which means that it can be considered as a structural part of the building. When this ratio is between 60% and 80%, the wood is classified as Grade B, which means it can be considered as a decorative part of the building. The fabrication will select a specific number of woods from Grade A and B to achieve the previously defined construction target, with a 5% redundancy compared to the digital model of that target to accommodate errors in the fabrication process, such as material wastage or overlapping connections. The IFR of voxels and the redundancy of the amount of wood are calculated using the following method. This paper employs wood data in the reclaimed wood database which can be defined using both Eq. (1) and Eq. (2).

Here, IFR denotes the IFR of all voxels on the periphery of the wood, R represents the redundancy of the amount of wood actually used. The subscript w and v stand for the wood and voxels, and a, b, i, d represent Grade A, Grade B, ith wood, and the digital model.

From reclaimed material to geometry: from geometry to structural form

Off-cut wood material can be seen as statistical, and there is a rate of repetition among the same typologies. By analysing and summarizing it, geometry variants are built as the input matrix. The input logic can be readily translated by computer languages. Thus, this research used programmable-based digital aggregation methods, and the WFC algorithm applied to microstructure typology and geometry generation44 also provided more convenience to rapid 3D building model aggregation through build rules and variants59. The experiments take a voxel as a basic unit through digital packing work and automatic generation of the structure of off-cut wood. Depending on the desired structure to set the limits of the growth, more details, such as voxel rotation mechanism, connection logic, and adjacency relation, defined the adjacency relation in the existing matrix of the WFC algorithm as a positive adjacency relation and introduced the prohibited adjacency relation60,61, outputting a random showcase (furniture, column, building) of the rules built by the matrix/voxel definition.

Static simulation: FEA

This research uses mathematical models to understand and quantify the effects of real-world conditions on assembly. FEA has been extensively applied to the structural assessment of furniture, installation, and buildings, identifying critical components, evaluating structural reliability, estimating the structural behavior under a given load and determining new typologies43,62. More precisely, FEA allows us to locate potential problems in a design, including areas of tension and weak spots shown on a computer-generated color scale. The resulting topology is thus improved. In the chapter of furniture scale tests, the support surface and load surface are distinguished, and real-word parameters are set according to the usage of the structure to observe its static analysis. The columns and beams in the chapter of architectural components adopt the volumetric load static simulation method, and the volume load is 1.08 kN/m3 for the output program logic (Supplementary Table 4).

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Awasthi, A. K. et al. Zero waste approach towards a sustainable waste management. Resour. Environ. Sustain. 3, 100014 (2021).

Campbell-Johnston, K., ten Cate, J., Elfering-Petrovic, M. & Gupta, J. City level circular transitions: barriers and limits in Amsterdam, Utrecht and the Hague. J. Clean. Prod. 235, 1232–1239 (2019).

Mark, G. Resource salvation: the architecture of reuse (ed. Mark, G.) 48–50 (Wiley, Hoboken, 2018).

Cibrario, D. “SDG 11: to ensure sustainable waste services, we must value waste workers and make sure they are in decent jobs.” Spotlight Sustain. Dev. https://www.2030spotlight.org/en/book/1730/chapter/sdg-11-ensure-sustainable-waste-services-we-must-value-waste-workers-and-make (2018).

Börjesson, M. & Ahlgren, E. Biomass CHP energy systems: a critical assessment. in comprehensive renewable energy (ed. Sayigh, A.) 87–97 (Elsevier, 2012).

Ali, N. S., Khairuddin, N. F. & Zainal Abidin, S. Upcycling: re-use and recreate functional interior space using waste materials. In Proc. 15th International Conference on Engineering and Product Design Education (eds Erik, B. et al.) 798-803 (The Design Society, 2013).

Höglmeier, K., Weber-Blaschke, G. & Richter, K. Utilization of recovered wood in cascades versus utilization of primary wood—a comparison with life cycle assessment using system expansion. Int. J. Life Cycle Assess. 19, 1755–1766 (2014).

Bernstein, A. et al. Renewables need a grand-challenge strategy. Nature 538, 30 (2016).

Russell, J. D., Huff, K. & Haviarova, E. Evaluating the cascading-use of wood furniture: how value-retention processes can contribute to material efficiency and circularity. J. Ind. Ecol. 27, 856–867 (2022).

Kutnar, A. Environmental Use of Wood Resources. In Environmental Impacts of Traditional and Innovative Forest-based Bioproducts (eds. Kutnar, A. & Muthu, S. S.) 1–18 (Springer International Publishing, New York, 2016).

Bergman, R. D., Gu, H., Falk, R. H. & Napier, T. R. Using reclaimed lumber and wood flooring in construction: measuring environmental impact using life-cycle inventory analysis. In Proc. The International Convention of Society of Wood Science and Technology and United Nations Economic Commission for Europe (eds Winandy J. E. & Herian V. L.) 1–11 (Timber Committee, Geneva, 2010).

Addis, B. Building with reclaimed components and materials: a design handbook for reuse and recycling (ed. Addis, B.) (Routledge, London, 2006).

Cramer, M. Insights in timber recycling and demolition. Centre for Wood Science & Technology. https://blogs.napier.ac.uk/cwst/timber-recycling-and-demolition/ (2020).

Robertson, A. B., Lam, F. C. F. & Cole, R. J. A comparative Cradle-to-Gate life cycle assessment of mid-rise office building construction alternatives: laminated timber or reinforced concrete. Buildings 2, 245–270 (2012).

Van Dijk, S., Tenpierik, M. & van den Dobbelsteen, A. Continuing the building’s cycles: a literature review and analysis of current systems theories in comparison with the theory of Cradle to Cradle. Resour. Conserv. Recycl. 82, 21–34 (2014).

Bjørn, A. & Hauschild, M. Z. Life cycle assessment: theory and practice (eds. Hauschild, M. Z., Rosenbaum, R. K. & Olsen, S. I.) 605–631 (Springer International Publishing, 2018).

Brommet, O. & Post, J. Cradle to cradle in residential building: the feasibility to implement the cradle concept in residential building. J. Archit. Environ. 18, 135 (2019).

Albatici, R., Serpelloni, A. & Gialanella, S. Cradle to cradle: architecture beyond LCA. TEMA. 2, 1–10 (2016).

McDonough, W. & Braungart, M. Towards a sustaining architecture for the 21st century: the promise of cradle-to-cradle design. Ind. Environ. http://www.uneptie.org/media/review/vol26no2-3/voL26_no2-3.htm. (2003).

Dong, X. et al. Low-value wood for sustainable high-performance structural materials. Nat. Sustain. 5, 628–635 (2022).

Zink, T. & Geyer, R. Material recycling and the myth of landfill diversion. J. Ind. Ecol. 23, 541–548 (2019).

Bruno, A. W., Scott, B., D’Offay-Mancienne, Y. & Perlot, C. Recyclability, durability and water vapour adsorption of unstabilised and stabilised compressed earth bricks. Mater. Struct. 53, 149 (2020).

Wang, S. Application of Product Life Cycle Management Method in Furniture Modular Design. Math. Probl. Eng. 2022, 1–10 (2022).

Daian, G. & Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 17, 1594–1602 (2009).

Badiu, A., Badiu, I. & Dradomir, M. Studies Regarding the Use of Reclaimed Wood in the Manufacture of Modern Furniture – Part I. Acta Tech. Napocensis 58, 225–230 (2015).

Pitti, A. R., Espinoza, O. & Smith, R. The case for urban and reclaimed wood in the circular economy. BioResources 15, 5226–5245 (2020).

Baik, E. & Suh, M. W. A study of the modern furniture’s material and sustainable. J. Korea Furnit. Soc. 27, 80–90 (2016).

Doyle, M. W. & Stiglitz, J. E. Eliminating extreme inequality: a sustainable development goal, 2015–2030 https://www.ethicsandinternationalaffairs.org/journal/eliminating-extreme-inequality-a-sustainable-development-goal-2015-2030 (2014).

van Ewijk, S., Stegemann, J. A. & Ekins, P. Limited climate benefits of global recycling of pulp and paper. Nat. Sustain. 4, 180–187 (2021).

Kollikkathara, N., Feng, H. & Stern, E. A purview of waste management evolution: special emphasis on USA. J. Waste Manag. 29, 974–985 (2009).

Yu, B. & Fingrut, A. Sustainable building design (SBD) with reclaimed wood library constructed in collaboration with 3D scanning technology in the UK. Resour. Conserv. Recycl. 186, 106566 (2022).

Luminita, I. Leveraging green finance for low-carbon energy, sustainable economic development, and climate change mitigation during the COVID-19 pandemic. Rev. Contemp. Philos. 20, 175–186 (2021).

Singh, R. et al. Cloud manufacturing, internet of things-assisted manufacturing and 3D printing technology: reliable tools for sustainable construction. Sustainability 13, 7327 (2021).

Ogbonna, D. N., Amangabara, G. T. & Ekere, T. O. Urban solid waste generation in Port Harcourt metropolis and its implications for waste management. Manag. Environ. Qual. 18, 71–88 (2007).

Walsh, E. et al. Quantitative guidelines for urban sustainability. Technol. Soc. 28, 45–61 (2006).

Barrow, C. J. Environmental management: principles and practice (ed. Barrow, C. J.) 17–29 (Routledge, London, 1999).

Matthews, E., Amann, C. & Bringezu, S. The weight of nations: material outflows from industrial economies (ed. Matthews. E.) 4–13 (World Resources Institute, Washington, 2000).

Narayana, T. Municipal solid waste management in India: from waste disposal to recovery of resources? Waste Manage. 29, 1163–1166 (2009).

Hebel, D. E., Wisniewska, M. H. & Heisel, F. Building from Waste: Recovered Materials in Architecture and Construction (ed. Andreas, M.) 63–83 (Birkhäuser, Basel, 2014).

Bahamón, A. & Sanjinés, M. C. Rematerial: from waste to architecture (ed. Bahamón, A.) (W. W. Norton & Company, New York, 2010).

Hellmuth + Bicknese Architects. Living Learning Center. Tyson Research Center https://tyson.wustl.edu/living-learning-center (2009).

Sseremba, O. E. et al. Timber management practices and timber species used by small scale furniture workshops in Uganda. Maderas. Ciencia y Tecnología. 13, 347–358 (2011).

Maropoulos, P. G. & Ceglarek, D. Design verification and validation in product lifecycle. CIRP Annals 59, 740–759 (2010).

Liu, K., Sun, R. & Daraio, C. Growth rules for irregular architected materials with programmable properties. Science 377, 975–981 (2022).

Chen, D., Skouras, M., Zhu, B. & Matusik, W. Computational discovery of extremal microstructure families. Sci. Adv. 4, eaao7005 (2018).

Milios, L. Advancing to a circular economy: three essential ingredients for a comprehensive policy mix. Sustain. Sci. 13, 861–878 (2018).

Will, K. SWOT Analysis: How To With Table and Example. Investopedia https://www.investopedia.com/terms/s/swot.asp (2023).

Puspita, A. A. & Sriwarno, A. B. Design process & product development challenges in furniture based on reclaimed wood in central java. BCM. 3, 132–138 (2016).

Kristiin, B. Study of the properties of reclaimed wood in furniture manufacturing. Master’s Thesis. (Tallinn University of Technology, Tallinn, 2015).

Huang, J. M., Ong, S. K. & Nee, A. Y. C. Real-time finite element structural analysis in augmented reality. Adv. Eng. Softw. 87, 43–56 (2015).

Arslan, H. Re-design, re-use and recycle of temporary houses. Build. Environ. 42, 400–406 (2007).

Grosso, M. & Thiebat, F. Life cycle environmental assessment of temporary building constructions. Energy Procedia 78, 3180–3185 (2015).

Arslan, H. & Cosgun, N. Reuse and recycle potentials of the temporary houses after occupancy: example of Duzce, Turkey. Build. Environ. 43, 702–709 (2008).

Rios, F. C., Chong, W. K. & Grau, D. Design for disassembly and deconstruction - challenges and opportunities. Procedia Eng. 118, 1296–1304 (2015).

Arrigoni, A., Zucchinelli, M., Collatina, D. & Dotelli, G. Life cycle environmental benefits of a forward-thinking design phase for buildings: the case study of a temporary pavilion built for an international exhibition. J. Clean. Prod. 187, 974–983 (2018).

Bates, E. Types of Wood Joints. MT Copeland https://mtcopeland.com/blog/types-of-wood-joints/ (2021).

Micaella, P. Design & Making Studio. Micaella Pedros https://www.micaellapedros.com (2023).

Eric, M. Wood Working Toxic Woods. rebornpipes https://rebornpipes.com/2013/04/17/wood-working-toxic-woods/ (2013).

Gao, T. & Yu, T. Building model generation framework based on wave function collapse. J. Phys. Conf. Ser. 2356, 012043 (2022).

Kim, H., Lee, S., Lee, H., Hahn, T. & Kang, S. automatic generation of game content using a graph-based wave function collapse algorithm. In IEEE Conference on Games (CoG) 1-4 (IEEE, 2019).

Karth, I. & Smith, A. M. Addressing the Fundamental Tension of PCGML with Discriminative Learning. In Proc. 14th International Conference on the Foundations of Digital Games (eds Deterding, S. et al.) 1–9 (Association for Computing Machinery, 2019).

Ong, S. K. & Huang, J. M. Structure design and analysis with integrated AR-FEA. CIRP Annals 66, 149–152 (2017).

Grozdanic, L. Spanish architects reuse railway sleepers to build a sculptural library extension. Inhabitat https://inhabitat.com/spanish-architects-reuse-railway-sleepers-to-build-a-sculptural-library-extension/ (2015).

Sheward, R. Pinohuacho Observation Deck. ArchDaily https://www.archdaily.com/4160/pinohuacho-observation-deck-rodrigo-sheward (2006).

Dorado, E. Willoughby Design Barn. ArchDaily https://www.archdaily.com/106333/willoughby-design-barn-el-dorado (2011).

I-Beam Design. The pallet house. I-BEAM https://www.i-beamdesign.com/new-york-humanitarian-projects-design (2008).

Riddel Architecture. Hill End Ecohouse. ArchDaily https://www.archdaily.com/57708/hill-end-ecohouse-riddel-architecture?ad_medium=gallery (2010).

Next Phase. Old Oak Dojo https://oldoakdojo.com/ (2013).

Frearson, A. Kaap Skil Maritime and Beachcombers Museum by Mecanoo. dezeen https://www.dezeen.com/2013/09/18/kaap-skil-maritime-and-beachcombers-museum-by-mecanoo/ (2013)..

Author information

Authors and Affiliations

Contributions

B.Y., J.L. and Y.S. made the same contribution. B.Y., J.L. and M.Z. wrote the main manuscript text, revision. B.Y., J.L. and Y.S. prepared all figures and revisions. A.F. and L.Z. revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yu, B., Luo, J., Shi, Y. et al. Framework for sustainable building design and construction using off-cut wood. npj Mater. Sustain. 1, 2 (2023). https://doi.org/10.1038/s44296-023-00002-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44296-023-00002-8