Abstract

Potentiodynamic study was carried out on nickel in Na2SO4 solution in the presence of ClO4–, WO42–, MoO42–, NO2– and NO3– ions. The anodic excursion spans of the metal nickel in a solution of Na2SO4 are marked by the appearance of clearly defined anodic peak, passive region, and transpassive shoulder. According to the data, the anodic peak current density (IPAI) rise from 1.82 to 8.12 mA cm–2 as the concentration of the Na2SO4 solution rises from 0.2 to 1.0 M. It is clear that as scan rate increases, the IPAI rises reaching to 11.8 mA cm–2. The apparent activation energy of nickel corrosion in Na2SO4 is 33.25 kJ mol–1. ClO4– anion addition speeds up nickel’s active dissolution, as well tends to break down the passive layer, and causes pitting penetration. It was found that, the pitting potential (Epit) of nickel in solutions containing the two anions ClO4– and SO42– shifts to the positive direction by addition of WO42–, MoO42–, NO2– anions and shifts to the negative direction by addition NO3- anion. Epit increased by 0.67, 0.37 and 0.15 V in the presence of WO42–, MoO42– and NO2–, respectively. WO42– > MoO42– > NO2– was the order in which the inhibitors were most effective.

Similar content being viewed by others

Introduction

Nickel has attracted many investigations of its electrochemical and other properties in different electrolytes1,2,3,4, due to its wide speared industrial applications. Nickel is a metal with strong resistance to corrosion according to many circumstances; however, it may still corrode under some conditions. Nickel corrosion behavior is affected by environmental variables, including the existence of corrosive chemicals, and the specific type of nickel (for instance, native nickel, nickel alloys).

Nickel may corrode in corrosive conditions, especially those including halides e.g. chlorides. The incorporation of halides can hasten the corrosion process by breakdown the passivity of the nickel surface5,6,7. The proposed mechanisms in which chlorides ions are adsorbed on the nickel surface in competition with water molecules as the following:

In the presence of other different species, including perchlorate, sulphate, and nitrate ions, localized corrosion of nickel can also happen8. Several corrosion preventative methods can be used to reduce nickel corrosion that includes:

Coatings: Using protection coatings like nickel plating, electroless metal coatings, as well as organic coatings might give an extra shield towards corrosion9.

Alloying: To improve corrosion resistance in certain settings, the alloy of nickel with additional elements can be used. Because of their superior resistance to different corrosive chemicals, nickel-based alloys such as Inconel or Hastelloy alloy are frequently used in corrosive settings10.

Cathodic protection: Using cathodic protection methods including sacrificial electrodes system or impressed current structures, nickel may be protected from corrosion11.

Nickel corrosion resistance may be significantly improved by chromate ions12,13. Chromate is first adsorbed on the cathodic sites of the metal surface, followed by electrochemical cathodic reduction to give some kinds of Cr oxides. This oxide layer acts as a barrier from further corrosion by blocking corrosive substances such as oxygen and moisture from accessing the underlying metal. By encouraging the creation of a stable and protective chromium oxide layer, the chromate ion passivation technique can improve the corrosion resistance of nickel. In alkaline or somewhat acidic situations, chromate passivation is especially effective. But as a result to their toxicity, hexavalent chromium material, such as chromate ions have recently caused environmental issues. As a consequence, studies regarding new, environmentally conscious corrosion inhibitors and passivation approaches have changed.

In the current work, alternative inorganic materials, WO42–, MoO42–, NO2–, NO3– ions are being explored for their anti-corrosion properties on nickel in Na2SO4 solution in the presence of perchlorate ions. These ions are considered as a less toxic alternative to hexavalent chromium compounds. Ongoing research aims to optimize the use of these inorganic materials and develop effective passivation materials for nickel and its alloys.

Experimental

Polarization measurements were performed on cylindrical electrodes machined nickel rod (99.98%, surface area 0.463 cm–2). Every time, the nickel surface was cleaned up by using emery paper for polishing from no. 400 to no. 2500. Finally, the working electrode was washed with double distilled water and degreased with acetone. Studies on potentiodynamic polarization were conducted using a computer and a potentiostat instrument (Gamry-3000). The tests have been carried out in a standard three-compartment cell employing a saturated calomel electrode to be the reference electrode, a platinum foil to be the auxiliary electrode, and nickel to be the working electrode. The polarization curves were swept from − 2.0 to 2.0 V. Potential scan rate range from 20 to 100 mV s–1.

Chemicals of analytical grade and three-time distilled pure water were used to create solutions. For all studies, various concentrations of Na2SO4 solutions were prepared using laboratory-grade Na2SO4 (Merck) and triple distilled water. Sigma-Aldrich Company supplied the inorganic compounds (NaClO4, Na2WO4, NaNO2, NaNO3), which were utilized without any extra purification. By submerging the cell in a water thermostat, the temperature of the experiment’s solution was regulated with a temperature range of 30–70 °C. All experiments were conducted in aerated solutions.

The surface morphology of some samples after immersion for 120 h at 30 °C was performed using Scanning Electron Microscope (SEM) ZEISS Gemini-SEM Microscopy.

Results and discussion

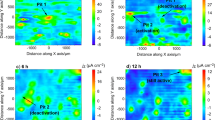

Electrochemical polarization of nickel in Na2SO4 solution

Typical polarization curves of nickel in various concentrations of Na2SO4 solution (0.2 to 1.0 M) are given in Fig. 1. The curves were swept from -2.0 V to 2.0 V at scan rate υ = 20 mVs–1 and at 30 °C. On positive going scan, the cathodic current density decreases continually reaching corrosion potential (Ecorr) at zero current density. Prior to the oxygen evolution reaction, each anodic curve shows one dissolution peak (I), a definitive passive state, and a transpassive state (II). The dissolution peak (I) of nickel is related to electroformation of hydrous Ni(OH)214,15,16 layer, which is transformed chemically and electrochemically to produce the passive NiO layer in the end17,18,19. When the concentration of nickel oxide exceeds the solubility product of NiO, precipitation of a porous oxide film occurs on the electrode surface. The current decreases to an extremely low value, signalling the beginning of primary passivation, when the surface is completely covered with a nonporous passive film. The passivation current start to increase markedly, forming transpassive state prior to oxygen evaluation. Sato and Kamoto20,21,22,23 attributed this behaviour to the dissolution of Nickel yielding Ni2+ ions, through active spots in the passive film.

The anodic peak current density (IPA1) rise from 1.82 to 8.12 mA cm–2 as the concentration of the Na2SO4 solution rises from 0.2 to 1.0 M, as shown in Fig. 1. Furthermore, as the concentration of the Na2SO4 solution increases, the anodic peak potential relatively shifts in a less positive direction.

Figure 2 depicts the findings of this study on the effect of potential scan rate (υ) on the potentiodynamic polarization of a nickel electrode in 0.4 M Na2SO4 solution at 30 °C. It is clear that as υ increases, the peak current density (IPA1) rises reaching to 11.8 mA cm–2 and its peak potential (EPA1) moves towards more negative values. Good linearity of the (IPA1) verses υ1/2 plot was observed (Fig. 3), but do not pass through the origin. It illustrates that a combined operation including direct film formation and diffusion-controlled dissolve may be used to explain the oxide layer formation process in the potential area of peak A1.

Figure 4 shows the effect of solution temperature on the potentiodynamic polarization response of nickel in 0.4 M Na2SO4 solution at scan rate of 20 mVs–1. The data clearly show that, the rise of temperature increases the value of IPA1 and slightly shifts its peak potential towords more negative values. This is results can be interpreted on the bases of the fact that, at high temperature, porous oxide film is then, soft, and non-protective. This is because, the solubility of the oxide film by the electrolyte increase with increasing temperature, thus enhancing the anodic dissolution processes24. Rise in temperature in temperature also accelerates the transport of reagent and reaction products to and from electrode surface25.

In Fig. 5, the values of log IPA1 are displayed as variables of (1/T)(K) (Arrhenius graph) for several temperatures. Based on the slope of that Arrhenius plotting, the apparent activation energy Ea for anodic reaction was determined. The data provide a value for the apparent activation energy, Ea = 33.25 kJ mol–1.

Effect ClO4 – ions on the electrochmeical behavior of nickel

It was investigated how different NaClO4 addition concentrations (0.1–0.5 M) affected the potentiodynamic, E/I, polarization of nickel in 0.4 M Na2SO4 at 30 °C and 20 mVs–1 scan rate (see Fig. 6). The data shows that, the progressive additions of NaClO4 cause an increase in the peak current density (IPA) of the anodic peaks and shifts its potential to more negative. These findings imply that perchlorate ions disrupt the oxidation operations of nickel electrodes. Competing with SO42– ions for adsorption on the bare metal surface, ClO4– ions can take part in electrode dissolution processes directly26. However, the ClO4- in the sulphate liquid increases Ipass and has a tendency to dissolve the passive layer. The passive current goes up abruptly and strongly at a specific critical potential (Epit), signifying the breakdown of the passive barrier and the beginning and progression of the pitting. As the amount of ClO4- gets higher, the pitting potential (Epit) moves to an increasingly negative (active) location. Figure 7 data demonstrates that, in accordance with Eq. (5), Epit is in a linear manner linked to log [ClO4–].

where x and y are constants and depends on the condations and nature of the electrode.

The adsorption of ClO4– on the oxide wrapped layer, specifically at its weakness points and flaws, can be attributed to the breakdown of the definitive passive barrier and the beginning of the pitting corrosion. Pit growth begins earlier when ClO4- concentration increases due to its mobility and acidity increases as a result of metal cation hydrolysis within pits27.

In Fig. 8, the significance of the scan rate (υ) regarding the E/I relation of a nickel electrode in a 0.4 M solution of Na2SO4 containing 0.3 M NaClO4 are shown. The anodic peak current is enhanced and has a more negative peak potential as υ increases. Furthermore, the increase in υ shifts Epit towards a more positive value. Incubation time is used to clarify this attitudes28. Once the scan has become high, pitting beginning takes place at higher positive potentials, which relate to a short enough incubation period—that is, the period of time required to penetrate the passive layering system.

Plotting IPA vs. υ1/2 yielded a linear trend depicted in Fig. 9.The resulting straightaway fails to pass through the origin. In theory, the plotting IPA vs. υ1/2 shows that diffusion is partially controlling the anodic dissolution operations on nickel in the existence of ClO4– anion29.

Effect of added inorganic anions on pitting corrosion

The impact of WO42–, MoO42–, NO2– and NO3– ions as corrosion-inhibiting agents has been investigated with the goal to learn more concerning the particular function that certain inorganic inhibitors serve on the preventing corrosion mechanisms taking place between the interface between the pure nickel electrode and the electrolyte. E/I curves for nickel in a solution of (0.4 M NaSO4 + 0.3 M NaClO4) at 30 °C are shown in Figs. 10 and 11, which show the effects when adding different amounts of WO42– and NO3– anions in turn. Figure 12 depicts the dependent relationship of Epit on logarithmic inorganic salts concentration.

Analyses of data in Figs. 10, 11, 12 show that, based on the kind and amount of the inhibitor, the existence of all of these anions (except NO3-), hinders the overall corrosion of nickel to a particular extent. The decline in IPA and the positive departure of the Epit demonstrate this clearly (see Tables 1 and 2). It is evident that these agents have a decreasing effect on nickel’s active dissolution in the following order: WO42– > MoO42– > NO2–. The adsorption competition of the inhibitor SO42– and ClO4– ions on the the outermost layer of the electrode is thought to hinder corrosion. Adsorption and founding of SO42– and ClO4– are hindered by the adsorption inhibitor ions. As a result, the SO42– and ClO4– anions’surface coverage diminished by the adsorbed inhibitor ions, and the total number of areas of defect at the film’s surface that the anions could enter was also decreased. The difference of the molar polarisation of these ions, which is in the order WO42– > MoO42– > NO2–, may be responsible for the different anions' inhibitory properties30. Because anion molar polarisation is believed to be entirely correlated to ions adsorption31, the inhibitory impact should improve with enhancing ions adsorption over the electrode. Surface active ions with higher defarmability are likely to adsorb onto the nickel surface, reducing the actual area that can be used by redox ions for reaction. Figure 11 data show that the NO3– anion promotes the IPAI and moves the Epit. in a negative way. These impacts may be clarified by the NO3– anion’s lower polarizability value with respect to the severe SO42– and ClO4– ions32.

The amount of inorganic salts needed to produce a significant positive shift in Epit (as indicated inhibition) improves in the following sequence: NO2– > MoO42– > WO42– (see Fig. 12). Because of their particular adsorbility, these inhibitors are able to remove ClO4– ion from the locations where it more readily enters the passive coating, which improves pitting resistance against corrosion33,34.

Furthermore, the reduced modes of these inhibitors (WO2 and MoO2), for example, transform into component of the passivating oxide and have a tendency to block its pores and weaknesses getting more effectively shielding capabilities. on the additional one, nitrite ions had been found to be reduced to ammonia in which oxygen that remained on the surface triggered the oxide reaction35. Figure 12 data demonstrate that the incorporation of NO3- ions moves Epit to a more negative direction, demonstrating that NO3- ions encourage pitting corrosion. The finding could be explained by the relatively low polarizability of NO3– ions36 in comparison to other ions.

The inhibition corrosion efficiency (IE%) of various inorganic ions was estimated as follows37:

where IPA(0) is the anodic current density in the absence inorganic ions. The inhibitory efficiency improves as the concentration of inorganic ions increases (see Table 3). The sequence of increase in the inhibitors' inhibitory effectiveness is WO42– > MoO42– > NO2–.

Surface studies

The surface morphology caused by immersion in the corrosive solution (0.4 M Na2SO4 + 0.3 M NaClO4) in the presence and absence of the compounds under consideration (ClO4–, WO42–, MoO42–, NO2– and NO3– ions, 0.03 M) were compared using the SEM methodology on nickel specimens.

The nickel specimens were subjected to (0.4 M Na2SO4 + 0.3 M NaClO4) for 120 h around 30 degrees Celsius, and then they were taken from the solution and allowed to sit for an additional hour to dry before examination. According to Fig. 13a depicts the image of the untreated sample in the corrosive solution (0.4 M Na2SO4 + 0.3 M NaClO4). In the absence of inhibitors, the large damaged regions, evident deteriorations, and pitting holes are visible.

In contrast, the microscope images of the tested nickel samples in the presence of the inhibitors, WO42–, MoO42–, NO2– and NO3–, in Fig. 13b–d, and e, respectively, showed highly effective corrosion inhibition efficiency as evidenced by the disappearance of deterioration areas, the disappearance of localized corrosion areas, and the fit (except NO3–).

The nickel surface was found to be very corrosive in the presence of NO3-ions (Fig. 13e). The present SEM results and the prior electrochemical technique results both show that the examined inhibitors (with the exception of NO3–) have effective corrosion control.

Conclusion

The current study investigates the anti-corrosion capabilities of various inorganic materials, such as WO42–, MoO42–, NO2– and NO3–, on nickel in Na2SO4 solution in the presence of perchlorate ions. Potentiodynamic curves show one dissolution peak (I), definitive passive, and transpassive state (II) regions. The data reveal that the anodic current density increase with increase in Na2SO4 solution concentration, potential scan rate (υ) and solution temperature. The progressive additions of NaClO4 cause an increase in corrosion of nickel electrode and tend to breakdown the passive layer. The presence of the inorganic anions studied (Except NO3–) inhibits both anodic dissolution and pitting corrosion of nickel. The sequence of increase in the inhibitors' inhibitory effectiveness is WO42– > MoO42– > NO2–.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Muñoza, A. G. & Schultze, J. W. Effects of NO2− on the corrosion of Ni in phosphate solutions. Electrochim. Acta 49, 293 (2004).

Shi, X., Niu, L., Yang, G., Wang, H. & Jin, Z. Surface modification of nickel-based superalloy by electrochemical selective dissolution. J. Alloys Compd. 947, 169628 (2023).

Petrauskas, A. V. et al. Potentiodynamic studies of the anodic behavior of Zn–Ni alloys electroplated from acetate-chloride baths. Prot. Metals 39, 454–458 (2003).

Hummel, R. E., Smith, R. J. & Verink, E. D. The passivation of nickel in aqueous solutions—I. The identification of insoluble corrosion products on nickel electrodes using optical and ESCA techniques. Corros. Sci. 27, 803–813 (1987).

Pan, Z., Luo, H., Zhao, Q., Cheng, H. & Li, X. Effect of Hf addition on microstructural evolution and corrosion behavior of nickel-based alloys in hydrochloric acid. Corros. Sci. 224, 111507 (2023).

Bell, S., de Bruyn, M., Steinberg, T. & Will, G. Corrosion resistance of 625 nickel superalloy exposed to isothermal and thermal cycling conditions in a chloride/carbonate salt. Solar Energy 249, 278–287 (2023).

Liu, H. et al. Metastable pitting corrosion behavior of laser powder bed fusion produced Ti6Al4V-Cu in 3.5% NaCl solution. Corros. Sci. 223, 111452 (2023).

Li, W. & Luo, J. Pitting corrosion induced by the interaction between microstructures of iron-based alloy in chloride-containing solution. J. Mater. Sci. Lett. 21, 1195–1198 (2002).

Hao, J.-Z. & Shi-Ai, Xu. Enhancement of the corrosion resistance of nickel-plated copper used for lithium-ion battery tabs with multilayer electroless coatings. Mater. Today Commun. 35, 105924 (2023).

Ouarga, A. et al. Corrosion of iron and nickel based alloys in sulphuric acid: Challenges and prevention strategies. J. Mater. Res. Technol. 26, 5105–5125 (2023).

Mobin, M. & Zehra, S. Chapter 13—Corrosion control by cathodic protection. In Electrochemical and Analytical Techniques for Sustainable Corrosion Monitoring (eds Aslam, J. et al.) 265–279 (Elsevier, 2023).

Zucchi, F., Fonsati, M. & Trabanelli, G. Corrosion and corrosion inhibition of nickel in HClO4 solutions using the EQCM technique. J. Appl. Electrochem. 29, 347–353 (1999).

Cheng, Y. F., Rairdan, B. R. & Luo, J. L. Features of electrochemical noise generated during pitting of inhibited A516–70 carbon steel in chloride solutions. J. Appl. Electrochem. 28, 1371–1375 (1998).

Stoychev, D., Stefanov, P., Nicolova, D., Valov, I. & Marinova, T. S. Chemical composition and corrosion resistance of passive chromate films formed on stainless steels 316 L and 1.4301. Mater. Chem. Phys. 73(2–3), 252–258 (2002).

Gassa, L. M., Vilche, J. R. & Arvía, A. J. A potentiodynamic study of anodic film formation on nickel in borate solutions. J. Appl. Electrochem. 13, 135–145 (1983).

Smith, R. J., Hummel, R. E. & Ambrose, J. R. The passivation of nickel in aqueous solutions—II. An in situ investigation of the passivation of nickel using optical and electrochemical techniques. Corros. Sci. 27(8), 815–826 (1987).

Pol, A., Sapakal, S., Khan, A. & Kadam, A. V. Synthesis of NiO thin film on 304-grade stainless steel substrate for oxygen evolution reaction. Surf. Interfaces 37, 102706 (2023).

Mac Dougall, B., Mitchell, D. F. & Graham, M. J. The use of electrochemical and surface-analytical techniques to characterize passive oxide films on nickel. Corrosion 38, 85–91 (1982).

MacDougall, B. & Graham, M. J. Effect of surface pretreatment on the galvanostatic oxidation of nickel. Electrochim. Acta 26(6), 705–710 (1981).

Mac Dougall, B. & Cohen, M. Mechanism of the anodic oxidation of nickel. J. Electrochem. Soc. 123, 1783 (1976).

Sato, N. & Okamoto, G. Electrochemical passivation of metals. In Electrochemical Materials Science. Comprehensive Treatise of Electrochemistry Vol. 4 (eds Bockris, J. O. et al.) (Springer, 1981).

Osterwald, J. & Uhlig, H. H. Anodic polarization and passivity of Ni and Ni-Cu alloys in sulfuric acid. J. Electrochem. Soc. 108, 515 (1961).

Misra, R. D. K. & Burstein, G. T. The repassivation of nickel-copper alloys in sulphuric acid. Corros. Sci. 24(4), 305–323 (1984).

Sun, H., Xinqiang, Wu. & Han, E.-H. Effects of temperature on the oxide film properties of 304 stainless steel in high temperature lithium borate buffer solution. Corros. Sci. 51, 2840–2847 (2009).

Sato, N. & Okamoto, G. Anodic passivation of nickel in sulfuric acid solutions. J. Electrochem. Soc 110, 605 (1963).

Láng, G., Ujvári, M. & Horányi, G. On the reduction of ClO4− ions in the course of metal dissolution in HClO4 solutions. Corros. Sci. 45(1), 1–5 (2003).

Bourkane, S., Gabrielli, C. & Keddam, M. Investigation of gold oxidation in sulphuric medium—II. Electrogravimetric transfer function technique. Electrochim. Acta 38(14), 1827–1835 (1993).

Zucchi, F., Fonsati, M. & Trabanelli, G. Corrosion and corrosion inhibition of nickel in HClO4 solutions using the EQCM technique. J. Appl. Electrochem. 28, 441 (1998).

Abd El-Rehim, S. S., Abd El-Wahab, S. M., Fouad, E. E. & Hassan, H. H. Passivity and passivity breakdown of zinc anode in alkaline medium. Mater. Corros. 46, 633 (1995).

Barbosa, M. R., Real, S. G., Vilche, J. R. & Arvia, A. J. Comparative potentiodynamic study of nickel in still and stirred sulfuric acid-potassium sulfate solutions in the 0.4–5.7 pH range. J. Electrochem. Soc. 135, 1077 (1988).

Foad El-Sherbini, E. E., Abd-El-Wahab, S. M., Amin, M. A. & Deyab, M. A. Electrochemical behavior of tin in sodium borate solutions and the effect of halide ions and some inorganic inhibitors. Corros. Sci. 48(8), 1885–1898 (2006).

Bockris, J. O. & Reddy, A. K. N. Modern Electrochemistry (McDonald, 1970).

Refaey, S. A. M. Inhibition of steel pitting corrosion in HCl by some inorganic anions. Appl. Surf. Sci. 240, 396–404 (2005).

Refaey, S. S. & Abd El Rehim, S. S. Inhibition of chloride pitting corrosion of tin in alkaline and near neutral medium by some inorganic anions. Electrochim. Acta 42, 667 (1996).

Hoar, T. P. The production and breakdown of the passivity of metals. Corros. Sci. 7(6), 341–355 (1967).

Leckie, H. P. & Uhlig, H. H. Environmental factors affecting the critical potential for pitting in 18–8 stainless steel. J. Electrochem. Soc. 113, 1262 (1966).

Foad El-Sherbini, E. et al. Effect of some polymeric materials on the corrosion behaviour of tin in succinic acid solution. J. Appl. Electrochem. 37, 533–541 (2007).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through small group Research Project under grant number (RGP. 1/336/44).

Author information

Authors and Affiliations

Contributions

M.A.D., M.M.A., A.A.El-Z. reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Deyab, M.A., Alghamdi, M.M. & El-Zahhar, A.A. Impact of some inorganic anions on the corrosion of nickel in a solution containing Na2SO4 and NaClO4. Sci Rep 14, 1853 (2024). https://doi.org/10.1038/s41598-024-52281-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-52281-3

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.