Abstract

Inhibition of copper corrosion by some pyrimidinone derivatives, namely; (E)-N-(3-((1,3-dimethyl-2,4,6-trioxohexahydropyrimidin-5-yl)diazenyl)-2,5-diethoxyphenyl)benzamide (MA-975) and(E)-6-(4-((4-chlorophenyl)diazenyl)-3-methyl-5-oxo-4,5-dihydro-1H-pyrazol-1-yl)-1,3 dimethylpyrimidine-2,4(1H,3H)-dione (MA-978C) in 1.0 M nitric acid (HNO3) was studied using weight loss (WL), electrochemical impedance spectroscopy (EIS), and potentiodynamic polarization (PP) measurements. The efficiency of inhibition increases as the concentration of inhibitor increases, and it also increases as the temperature increases. With the addition of the examined inhibitors, significant corrosion protection was obtained, and (MA-975) showed a very promising % IE (89.59%) at 21 × 10−6 M using the (WL) method. The polarization data revealed that these compounds act as mixed-type compounds and are adsorbed on the copper surface following Langmuir adsorption isotherm forming a protective thin film protecting the metal in the corrosive media. Scanning electron microscopy (SEM) and Energy Dispersive X-ray were used to examine the surface morphology of copper samples. Quantum calculations and Monte Carlo simulation techniques were applied with informative yields and the results matched the experimental findings.

Similar content being viewed by others

Introduction

Corrosion is an essential process to consider in terms of safety and economics, especially for metals. Copper is a moderately noble metal1,2,3, and it has great electrical and thermal conductivities, as well as good corrosion resistance and workability. It is used in a lot of heating and cooling systems also it is utilized broadly as a part of industry, because of its warm conductivity. Copper’s major problem is its strong response to the acidic solutions. Several acid solutions (HCl, H2SO4, and HNO3) are it is utilized to remove harmful rust in various industrial operations. Among the commercially available acids, the most frequently used one is HNO3. The utilized corrosion protective of Cu in acid medium is mainly to less the corrosion of Cu at the time of acid descaling and cleaning. Copper corrosion depends on the way of nature as well as the state of utilization of materials. The most used method for copper corrosion protection is the utilization of organic inhibitors. Numerous organic inhibitors utilized are either created from low-cost raw materials or selected from compounds having hetero atoms in their long-chain carbon or aromatic system4. Most organic inhibitors are costly, toxic, and have a negative effect on the corrosion of metal. As a result, it is important and necessary to improve environmentally safe and low-cost corrosion protection5. The majority of the understood acid inhibitors are organic heterocyclic compounds containing O, S, P and/or N atoms6,7,8,9, these atoms enhance the activity of corrosion inhibitor. Adsorption of an inhibitor facilitates the protection of the metal surface10. As a result, covalent bonding (chemisorption) and/or electrostatic interaction (physisorption) can be used to create an adsorption coating on metal, protecting it against corrosive species attack11. It has been thought that it would be more desired and significant to produce novel low- or non-toxic corrosion inhibitors because the majority of conventional organic inhibitors are dangerous to the environment and people12. The presence of these functional groups and hetero-atoms in organic compound molecules promotes their action as copper corrosion inhibitors because these functional groups and hetero-atoms induce chemisorption. Organic derivatives also have a unique aptitude for inhibiting metal corrosion in acidic media13 and other solutions. The protection efficiency of organic inhibitors is primarily due to the presence of a polar group acting as an active center for adsorption on the metallic surface14. The presence of unoccupied d-orbitals in copper atoms that form coordinative bonds with atoms that can give electrons confirms this. There is also interaction with rings having conjugated bonds π-electrons. Heterocycle-containing pyrimidines have been reported to be safe inhibitors with excellent corrosion inhibition actions on copper metal in acidic media15. The corrosion inhibition properties of two pyrimidinone compounds were investigated in this study, coded MA-975 and MA-978C which clearly indicates that these derivatives work well as corrosion inhibitors, and that further research is recommended. Furthermore, considering recent environmental issues, these compounds are of significant concern due to their non-toxic appearances and high solubility in the test solution, which promotes protection efficiency. Some pyrimidine derivatives were utilized as corrosion inhibitors for steel and other metals in HCl and H2SO4 solutions with their percent IE predicted in Table 1. The most popular method of examining inhibitors today is still dazzle filtration. Researchers have coupled molecular dynamics simulation with thickness utility hypothesis calculation to urge deep insights into the barrier component of natural substances in an effort to understand this problem16.

Our objective is to study more about the inhibitory action of these pyrimidinone compounds because these derivatives have high molecular size, low toxicity (safe) and contain O, N, CH3 groups and benzene rings. Some advanced techniques are used, SEM and EDX were employed to examine the surface, in addition to the application of quantum chemical calculations and Monte Carlo simulation was applied also.

Materials and techniques

Composition of copper samples

The chemical composition of the copper alloy used in this paper is as follows: (weight %) 0.0050 Zn, 0.0023 Pb, 0.0023 P, 0.0018 Co, 0.019 Fe, 0.0015 Si, 0.004 Ni, 0.0011 S.

Solutions

The aggressive solution 0.5 M HNO3 was made by diluting analytical grade HNO3 (69%) with bi-distilled water, and all WL tests were performed in 100 ml unstirred solutions. Every studied compound's 100 ml stock solutions (10–3 M) were prepared by dissolving an accurately weighed quantity of each compound in an appropriate volume of dimethyl formamide (DMF) and absolute ethanol, then diluting with bi-distilled water to the needed concentrations (5 × 10–6–21 × 10–6 M).The solutions of these compounds are completely soluble in HNO3 due to it can be protonated in acid medium.

Inhibitors

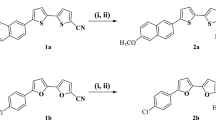

The synthesis of two pyrimidinone inhibitors was depicted in Fig. 1 as reported previously31 and their chemical structures and molecular formulas were listed in Table 2. The investigations of the two pyrimidinone compounds were done at different concentrations (5 × 10−6, 9 × 10−6, 13 × 10−6, 17 × 10−6 and 21 × 10−6 M) in the attendance and non-existence of the investigated compounds. In thermostatic conditions, all experiments were conducted.

Corrosion methods

WL method

In corrosion investigations, WL measurements were utilized to select the best corrosion inhibitor32. The ASTM standard G 31–7231 was used to take this measurement. Mechanical polishing was done on the Cu alloy samples using various grades of emery sheets (1/0, 2/0, 3/0, 4/0, 5/0, and 6/0). The specimens are carefully cleaned with bi-distilled water and then degreased with acetone, dried at room temperature and then weighed. The test pieces were suspended by appropriate glass hooks at the beaker's edge and about 1 cm below the surface of the test fluid. The pieces were removed after a set amount of time, washed with bi-distilled water, dried, and weighed again. For three hours, different concentrations of inhibitors were tested for corrosion. 100 ml of blank without inhibitor and 1 M HNO3 with inhibitor were used to create these concentrations. The average value was calculated after the experiment was repeated three times. The percent Ew of the different solutions is calculated using the WL values acquired after a specified period in the mathematical Eq. (1):

where ΔW and ΔW° are weight losses per unit area (mg.cm−2) in the presence and the absence of the tested inhibitors, respectively.

Potentiodynamic polarization (PP) tests

A three electrode cell assembly with copper as the working electrode, a saturated calomel electrode (SCE) as the reference electrode, and platinum foil as the counter electrode was employed for these electrochemical research. The test sample was given 30 min to attain the steady state value of OCP before beginning the electrochemical studies. The potential range was (-200 to + 200 mV vs. SCE) at OCP with a scan rate of 0.1 mVs-1. The icorr calculation was used to calculate the Ep and the θ from the following Eq. (2):

where icorr and iocorr are the corrosion current densities with and without inhibitors, respectively.

Electrochemical impedance spectroscopy (EIS) tests

EIS measurements were carried out by using AC signal of 10 mV amplitude for the frequency spectrum from 100 kHz to 0.01 Hz. A Gamry Potentiostat / Galvanostat / ZRA" was utilized in electrochemical (PP & EIS) investigations (PCI4-G750). The DC105 DC Corrosion Program, the EIS300 EIS Program, and a data collection computer are all part of Gamry. Echem Analyst version 5.5 was used to plot and calculate data.

Surface morphology investigation by (SEM and EDX) analysis

The applied technique to study metal surface morphology are SEM and EDX it is used to give data about the surface morphology of Cu coins with and without highest degree of concentration of the three pyrimidine inhibitors utilizing (SEM model JOEL, JSM-T20, Japan). An energy dispersive X-ray (EDX) spectroscopy device was also used to evaluate the copper samples (Zeiss Evo 10 instrument model). The beam accelerating voltage was 25 kV.

Quantum chemical calculations

All the quantum chemical tests occurred with finishing geometry similarity utilized Accelrys Material Studio.

Quantum Monte Carlo simulation

MC is a molecular dynamics method based on classical mechanics and is one of the most broadly used theoretical techniques to describe the interaction between metal and inhibitor because it provides some essential parameters such as total energy, adsorption energy, and rigid adsorption energy. In our present study, the Monte Carlo simulation calculation was used to find the lowest energy for the tested system. The outputs and descriptors achieved by the Monte Carlo simulations, such as the whole adsorption, adsorption energy, firm adsorption, and deformation energies represent the most stable low energy configuration for the adsorption of the studied pyrimidine inhibitors on Cu (111) surface obtained through the Monte Carlo simulations 33.

Results and discussion

WL measurements

Effect of concentrations and temperature

The corrosion rate of copper alloy in nonexistence and existence of various concentrations of pyrimidine derivatives (5 × 10–6 M to 21 × 10–6 M) in 1.0 M HNO3 at 25–45 °C was studied. WL-time curves are graphically represented in Fig. 2 of pyrimidine derivatives. Corrosion parameters derived from WL method at different temperatures are given in Table 3, illustrate the calculated values of corrosion rate kcorr (mg.cm-2.min-1), (%Ew) and the (θ) for copper alloy dissolution from which a reduction in kcorr is noticed when copper alloy the concentration of pyrimidine derivatives increases. This behavior can be explained based on the strong interaction among pyrimidine derivatives and copper alloy surface34. In general, when the concentration of these pyrimidine derivatives rises, the value of (percent Ew) rises as well. These findings offer evidence that pyrimidines are effective inhibitors for Cu alloy against dissolution35. By increasing temperature, this lead to increase adsorption of inhibitor molecules on the alloy surface and some chemical changes in the inhibitor molecules may occur, resulting in an increase in electron densities at the adsorption centers of the molecules. There is a slight decrease in the corrosion rate kcorr of pyrimidine derivatives13 and hence the %Ew reaches (89.59%) at the optimum concentration (21 × 10–6 M). The trend of %Ew follows the order MA-975 > MA-978C.

Thermodynamic activation parameters

Corrosion reactions obey Arrhenius processes and the apparent activation energy, E*a, for corrosion of copper alloy in 1 M HNO3 solution in the existence, and absence at different concentrations of pyrimidine derivatives at 25–45 °C was calculated from Arrhenius Eq.3:

where \({{\varvec{E}}}_{{\varvec{a}}}^{\boldsymbol{*}}\) is the apparent activation energy of copper alloy dissolution and A is the pre-exponential factor, R is the molar gas constant, T is the absolute temperature. Plots of log kcorr vs. 1/T are displayed as straight lines for the tested inhibitors and the E*a was calculated from the slope of these lines Fig. 3. It can be seen from Table 4 the data that \({{\varvec{E}}}_{{\varvec{a}}}^{\boldsymbol{*}}\) values for the inhibitors attains lower values for inhibitor-containing solutions. Similar results have been obtained in the corrosion inhibition of copper alloy and the decrease in \({{\varvec{E}}}_{{\varvec{a}}}^{\boldsymbol{*}}\) signifies chemisorption36. The transition state equation (4) was used to calculate other important thermodynamic activation parameters36:

where, kcorr denotes to the corrosion rate, R is the molar gas constant, ΔH* and ΔS* is the enthalpy and entropy of activation, respectively. Plots of log kcorr/T vs 1000/T in Fig. 4 for the two derivatives, from which the values of ΔH* and ΔS*were calculated and are recorded in Table 4 for the investigated inhibitors Fig. 4 shows \({{\varvec{E}}}_{{\varvec{a}}}^{*}\) for blank solution is 68 0.71 kJ mol−1 and it decreased with increasing the concentrations of pyrimidine inhibitors. The decreased value of \({{\varvec{E}}}_{{\varvec{a}}}^{\boldsymbol{*}}\) when inhibitors are present is owing to their adsorption on the Cu surface. The chemisorption process37 has this tendency. When ΔH* reaches a positive value, the corrosion process is endothermic, and it is classified as chemical adsorption. The activation entropy ∆S* is large and negative, showing that the creation of an activated complex in the transition state involves association rather than dissociation, and that there is a decrease in disorder as reactants transform into the activated complex 38.

Adsorption study

Isotherms provide significant information for understanding the nature of the corrosion inhibition process. The best fit was found using the Langmuir isotherm, which created a linear relationship between θ values and inhibitor concentration C. The Langmuir model asserts that the metal surface has a definite proportion of adsorption sites with one adsorbate, and the Gibbs free energy of adsorption for the sites is the same, regardless of the value of ϴ. This adsorption isotherm is described by the following equation Eq. (5) 39

where Kads is the equilibrium constant of adsorption process and C is the concentration of inhibitor and θ is the fraction of surface coverage. The ∆Gºads of adsorption process was calculated from the following Eq. (6):

Table 4 displays that the ∆Gºads attained slightly more negative values than -40 kJ mol-1 and increases slightly by raising the temperature. This indicates that pyrimidine inhibitors may adsorbed physically or chemically on Cu surface, but the chemical adsorption is acceptable than the physical one 40. Also, other important adsorption parameters were calculated such as the enthalpy (ΔHoads) and the entropy (ΔSoads) of adsorption by applying Vanʼt Hoff (7) and thermodynamic general Eq. (8) 34:

Table 5 reveals that positive values of ΔH°ads indicate that pyrimidine derivative adsorption is an endothermic process41, implying that the inhibition efficiency increases as the temperature rises. This behavior can be explained by the fact that as the temperature rose, inhibitor molecules adhered to the metal surface42. In the presence of pyrimidine derivatives, the value of ΔS°ads is positive because the endothermic adsorption process is always accompanied by a rise in entropy. The adsorption of inhibitor onto the Cu surface was propelled by an increase in entropy.44. Figure 5shows Langmuir isotherm plots for the corrosion of Cu in the 1 M HNO3 with optimum concentrations of the investigated inhibitors.

Electrochemical impedance spectroscopy (EIS) measurements

The corrosion manners of copper alloy in 1 M HNO3 solution absence and presence of various doses of investigated pyrimidine was studied at 25 ± 1 °C. The impedance plots including the Nyquist (a) and Bode (b) are presented in Figs. 6 and 7. In the presence of inhibitor, the Nyquist diagram shows two-time constants: the capacitive loop at high frequencies and a straight line perceived as Warburg impedance at low frequencies. The charge transfer process can be related to higher frequency capacitive loops. Surface layer resistance, surface layer capacity, and the Warburg element, which signals a diffusion process across the surface layer, make up the second time constant in the low frequency range. With the addition of MA-978C and MA-975 to the Bode plots recorded in the presence of inhibitor, the Bode amplitude values over the entire frequency range increase. As further inspection in Fig. 7 in most cases of copper alloy corrosion in acid solution, the obtained Nyquist impedance diagrams in most cases does not show perfect semicircle, and this is arising from the frequency dispersion due to the roughness and heterogeneity of the electrode surface42,43. From EIS measurements, the impedance diagram is presented as a large capacitive loop with low frequencies dispersion44. The EIS spectra were analyzed by assuming CPE circuit and modeling the impedance data with the simplest equivalent electrical circuit (Fig. 8). In this equivalent circuit, the solution resistance Rs and the double layer capacitance Cdl are considered in parallel to the charge transfer resistance Rct45. The standard criteria for evaluation of pyrimidine derivatives best-fit were followed: The chi-square error was low (< 10−3) and the acceptable errors of elements in fitting (5%). In inhibited solution of 1.0 M HNO3 with various concentrations of inhibitors, the impedance diagrams follow the same pattern (one capacitive loop), however, the diameter of this capacitive loop increases with increasing concentration46. “n” is the CPE parameter which characterizes the deviation of the system from ideal capacitive behavior. The values n is between -1 and 1. For a perfect resistor, n = 0 and for an inductor n =-1 for solutions contain pyrimidine are higher than those obtained for pyrimidine free solution which reflects their inhibitive action for copper alloy dissolution process. The (n) value is a measure of a surface's roughness, and its rise in this study could indicate a drop in the heterogeneity of the working electrode surface due to inhibitor molecule adsorption and increases with inhibitor concentration, while the reverse is the case with Yo. The EIS parameters such as Rct, Rs, Cdl, and θ and % EEIS were listed in Table 6, from which we can conclude that47, Rct increases and Yο decreases when the concentration of pyrimidine inhibitors increased and hence, the %EEIS increases. This is due to the increased thickness of the double layer or a reduced dielectric constant. The decreased Yο values recommended the decreased thickness of the oxide layer in the presence of inhibitors. The lowering in Cdl, might be caused by a decrease in local dielectric constant and/or an increase in the thickness of the electrical double layer, indicates that the inhibitor molecules have adsorb at the metal/solution interface48. The increase of Rs with inhibitor concentration proofs the increase of the thickness of double layer. Also, single charge transfer process occurred during dissolution of copper alloy in 1.0 M HNO3 which does not change in the presence of investigated pyrimidine. This is indicated from the presence of single semicircle loop 49. The impedance of the CPE represented by the next Eq. (9):

Yo is referred to CPE constant, j is referring to the imaginary root, ɷ is refer to the angular frequency, n (-1 < n < 1) stands for the deviation index.

The Cdl value was obtained from this eq. (10)50.

The corrosion %η was calculated by using the Eq. (11):

where Roct, and Rct are the resistance of the charge transfer in the absence and presence of the tested compounds respectively.

Open circuit potential (EOC)

Figure 9 shows the EOC fluctuation with time for copper in an acid corrosive media with no dose of organic component (21 × 10–6) present. Figure 9 shows that after 100 s, the blank solution stabilizes at a value of -7 mV/SCE. Cu oxidizes, resulting in the formation of corrosive products on its surface. As a result, when an organic compound is present at a dose of 21 × 10–6 M, the potential changes quickly and remains stable over time. The resistance of Cu dissolving in the acid corrosive media is indicated by the initial shifts in EOC while adding concentrations of organic substance. The disintegration of the oxide coating and the formation of a protective film on the Cu surface can explain this phenomenon.

Potentiodynamic polarization (PP) measurements

Tafel polarization curves of copper alloy in uninhibited and inhibited 1 M HNO3 solution with different concentrations of pyrimidine derivatives at 25°Care illustrated in Fig. 10. Cu exposed to an uncontrolled system corroded severely; this is due to the aggressive NO-3 ions, which drive strong Cu dissolution. Fortunately, the addition of pyrimidine analogues to a solution minimized Cu oxidation due to considerable reductions in icorr. The variation of PP parameters with the concentration of pyrimidine compounds are given in Table 7. The PP indicates that, the behavior of pyrimidine derivatives is of Tafel-type because the addition of pyrimidine compounds increases the cathodic and anodic potential with a displacement to more negative and positive values, respectively. The corrosion current density (icorr) drops as the concentration of pyrimidine increases, indicating that the presence of these compounds slows Cu dissolution and that the degree of inhibition is proportional to the concentration. The order of additives is \(\mathrm{MA}-975>\mathrm{MA}-978\mathrm{C}\). The maximum difference in Ecorr values between the inhibited and uninhibited systems was less than 39 mV, indicating that the investigated pyrimidine derivatives are mixed type inhibitors that affect both the cathodic and anodic polarization curves51. Moreover, the cathodic and anodic polarization Tafel lines keep a similar pattern and slightly changed by adding the pyrimidine derivatives. In other words, the nature of the polarization curves remains approximately the same irrespective of different concentration of these derivatives addition to acid solution which suggests that the mechanism of Cu in nitric acid does not change by adding these derivatives to the acid solution. The inhibitive action of pyrimidine compounds is initiated by adsorption on the reactive sites on the electrode surface and blocking corrosion cells and reducing the exposed surface area available for attack from corrosion environment52. The Ep% was calculated next Eq. (12):

where i‵corr and icorr refer to the corrosion current of the copper metal presence and absence pyrimidine derivatives, respectively. The results showed that icorr reduces with increasing concentration up to 21 × 10–6 M and then significantly decreases when the concentration of pyrimidine derivatives reaches 25 × 10–6 M. As a result, when the concentration of pyrimidine compounds was raised to 21 × 10–6 M, the inhibitory performance improved. The addition of more pyrimidine derivatives than 21 × 10–6 M may lead to a slower kinetic at the adsorption sites, allowing the desorption of the adsorbed layer and hence lower inhibition efficiency.

Surface analysis

Scanning electron microscope (SEM) and energy dispersive X-ray (EDX) analysis.

The morphology of the copper metal surface was investigated using a scanning electron microscope, when copper samples were immersed in 1 M HNO3 solution for 24 h with and without the tested pyrimidine derivatives53. The effect of these derivatives on the corroding copper metal surface is also analyzed by EDX with SEM images to investigate the pyrimidine derivatives adsorption by comparing the elements identified and detected on the copper metal surface with the elements in the pyrimidine derivatives molecular structure. Figures 11 and 12 show SEM and EDX images, respectively. According to EDX analysis, the copper surface is heavily damaged without the inhibited solution, where the images of inhibited copper surface indicated less corrosion in the presence of examined pyrimidine derivatives. Also, the percentage of iron in the copper surface immersed in inhibited solution is decreasing, while the percentage of the carbon and heteroatoms (S, O and N) is increasing54. From the SEM–EDX tests, we can conclude that the examined derivatives adsorbed on the copper metal surface show an excellent image for preventing severe corrosion of the metal surface55.

Quantum calculations

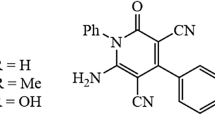

To determine whether there is a correlation between the molecular structures of investigated inhibitors and their inhibitory actions, quantum chemical simulations were conducted46. The synthesized MA-978C and MA-975 inhibitors' computed quantum chemical characteristics (EHOMO, ELUMO, and ΔE) were determined and are displayed in Table 8.The EHOMO, ELUMO represented a molecule's capacity for electron donation and acceptance. These values may be seen in Fig. 13 as well. The ability of the inhibitor to give electrons was stronger the higher the EHOMO value, whereas the ability of the inhibitor to receive electrons was stronger the lower the ELUMO value56. A molecule's ability to deliver electrons to a suitable acceptor with unoccupied molecular orbitals is indicated by high values of EHOMO. The ELUMO, on the other hand, demonstrates a molecule's capacity to accept electrons; lower values correspond to a higher electron-accepting capacity.

The energy to eliminate an electron from the last orbital occupied is called the gap in the energy band (ΔE = ELUMO − EHOMO)57. Low ΔE facilitates adsorption of the molecule and thus will cause higher inhibition efficiency, as ΔE decreases, the reactivity of the molecule increases leading to increase the inhibition efficiency of the molecule. The dipolar moment (μ) is a measurement of the polarity of the covalent bond between the compounds under examination Eq. (13). The high μ values are thought to improve the adsorption tendency of the compounds examined on metal surfaces. According to theoretical calculations, the band gap energy values ΔE for MA-975 is less than MA-978C, so the inhibition efficiency is supposed to be in the order MA-975 > MA-978C. This reflects a greater correlation between corrosion IE and this result58. The inhibitor (MA-975) has the lowest total energy, which suggests that its adsorption is higher with the highest softness, as shown in all the data in Fig. 13 and Table 8. In addition, the dipole moment is the parameter most used to describe the polarity of a molecule. It is clearly proved in the literature that molecules with high dipole moments are more reactive and hence, MA-975 > MA-978C59. Chemical properties that are important for determining molecular stability and reactivity include chemical hardness (\(\eta\)) (Eq. 15), which evaluates an atom's resistance to charge transfer, and softness (\(\sigma\)) (Eq. 16), which defines an atom or group of atoms' ability to accept electrons. From the results, as the chemical reactivity increases, the percent IE of adsorption increases, and the molecule with the lowest hardness value should have the highest inhibitory efficiency60. Because of the increase in softness (σ = 0.253, 0.224 eV-1 for MA-975, MA-978C, respectively) and reduction in hardness ((η) = 4.095, 3.955 eV, for MA-975C, MA-978, respectively), the CBIPM inhibitor has high chemical reactivity with the metallic surface. The following equations were used to calculate the global hardness (η), softness (σ), and chemical potential (µ) in terms of IP and EA 61:

The results show that the hetero atoms (N, S, and O) in the structure of compounds have a significant impact on quantum chemical parameters. This theoretically illustrates that the hetero atom (S) influences the adsorption of inhibitor chemicals on metal. We performed a molecular dynamics simulation on the inhibitors' adsorption on the copper surface.

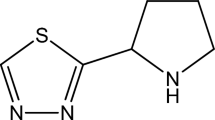

Monte Carlo (MC) simulation

MC is an excellent technique for determining the most stable adsorption conformations of substituted pyrimidine derivatives in 1 M HNO3. Figure 14 shows the equilibrium adsorption configurations of the inhibitors molecules on the Cu (111) surface: inhibitors side view and top view. Different parameters derived from the Monte Carlo simulation shown in Table 9. The parameters contain total energy of the substrate–adsorbate outline. The sum of the rigid energy and the deformation energy is called to be the adsorption energy. In this study, the substrate energy is considered as zero. In addition, the energy of the adsorption in reports energy liberated when the relaxed adsorbate component is adsorbed on the substrate. The energy of the rigid adsorption reports the energy, liberated when the unrelaxed adsorbate components are adsorbed on the substrate, meaning that before the geometry optimization step. The deformation energy reports the energy, liberated when the adsorbed adsorbate constituents are relaxed on the substrate surface62. Table 9 shows also (dEads/dNi), which reports the energy, of substrate–adsorbate configurations where one of the adsorbate components has been eliminated. As shown in Table 9, MA-975 and MA-978C Inhibitors gave high adsorption energy in negative value found during the simulation process. Furthermore, the protonated form of C23H25N5O6H+ and C16H15ClN6O3H+ molecules in corrosive solution have a higher negative adsorption energy than the neutral form, indicating that the protonated form of C23H25N5O6H+ and C16H15ClN6O3H+ molecules in corrosive solution has a positive impact on the corrosion protection process. Superior inhibition efficiency is typically correlated with high binding energy (Ebinding) between the inhibitor and alloy63. Inhibitor molecule equilibrium adsorption configurations on the Cu (111) surface for neutral and protonated side views and top views are shown in Fig. 14. (MA-975 > MA-978C) is the order of the manufactured inhibitors based on IE percent. It is obvious that both inhibitor molecules, in their various forms, adhere to the surface of Cu (111) in a nearly parallel pattern, covering the Cu alloy's maximum surface area. This behavior is primarily attributed to two inhibitor compounds' strong propensity to donate electrons to the vacant Cu orbitals and to accept electrons from copper's d-orbitals via a back-bonding64.

Mechanism of corrosion inhibition

Physicochemical characteristics and the Cu charge may be utilized to illustrate adsorption based on the experimental study and theoretical calculations. Figure 15 depicts the inhibitory action of these pyrimidine derivatives on the surface of copper. Several studies have been revealed that the Cu surface in HNO3 solution is positively charged65. The presence of function groups capable of securely attaching the inhibitor molecules on the metal surface explains the inhibitor's propensity for being adsorbed on the metal surface. When the inhibitor concentration is raised, the formation of a protective coating of inhibitor molecules at the metal/solution interface improves inhibition effectiveness. The charge that is positive Cu surfaces encourage NO3- adsorption, resulting in a negative charge surface that makes it simpler to adsorb cations in solution. These organic pyrimidine derivatives can be protonated in solution due to the unshared electron pairs of the N, O, and S electrons. Because of electrostatic interaction the protonated molecules were physisorbed on the metal surface. Meanwhile, as shown in Fig. 15, further adsorption of these inhibitors can be accomplished by forming covalent interactions (chemisorption). Based on quantum chemical measurements of both WL and electrochemical values, the percent IE of the two investigated pyrimidine derivatives is as follows: MA-975 > MA-978C. This is due to the following factors: MA-975 has a larger molecular size than MA-978C, allowing it to cover a larger area from the surface; MA-975 has 5 N and 6O atoms, but MA-978C contains 6 N, 3O, and one Cl, which is a withdrawing group, reducing the electron density on the molecule.

Conclusion

-

(1)

The study revealed that the investigated pyrimidine derivatives were utilized as highly, safe efficient inhibitors for copper in 1 M HNO3.

-

(2)

The adsorption of the investigated inhibitors on copper surface follows the Langmuir adsorption isotherm. The development of a protective layer on the copper surface was confirmed using SEM and EDX analyses.

-

(3)

Tafel curves indicated that pyrimidine derivatives acted as a mixed-type corrosion inhibitor and provided superior inhibition performance for Cu corrosion in HNO3 medium at different temperatures, which was further confirmed by EIS method. The obtained IE values from EIS increased with increasing pyrimidine derivatives concentration which agreed well with those obtained from Tafel method.

-

(4)

The charge transfer resistance increases while the capacitance double layer drops by raising the inhibitor dosage which may be attributed to the adsorption of inhibitor molecules on the copper surface.

-

(5)

The high and low Ebinding values indicated substantial pyrimidine derivative adsorption on copper surface. The pyrimidine derivatives' excellent capacity to donate and absorb electrons to/from copper was validated by the flat adsorption orientation of the compounds, creating an anchoring barrier to stop copper from corroding.

-

(6)

The obtained results of chemical, electrochemical and theoretical studies are in good agreement.

Data availability

Authors can confirm that all relevant data are included in the article.

References

Atia, A. A. & Saleh, M. M. Inhibition of acid corrosion of steel using cetylpyridinium chloride. J. Appl. Electrochem. 33, 171–177 (2003).

Tamilselvi, S. & Rajeswari, S. The effect of triazoles and surfactants on the corrosion inhibition of carbon steel in acid solution. Anti-Corrosion Methods Mater. 50, 223 (2003).

Keera, S. T. The beneficial influence of halide ions on the inhibition characteristics of nitrogen-containing organic inhibitors to reduce the corrosion rate of carbon steel in HCl. Anti-Corrosion Methods Mater. 50, 280 (2003).

Loto, C. A., Loto, R. T. & Popoola, A. P. I. Corrosion inhibition of thiourea and thiadiazole derivatives: A review. J. Mater. Environ. Sci. 3, 885–894 (2012).

Ladha, D. G., Naik, U. J. & Shah, N. K. Investigation of Cumin (Cuminum Cyminum) extract as an eco-friendly green corrosion inhibitor for pure Aluminium in Acid medium. J. Mater. Environ. Sci 4, 701–708 (2013).

Chetouani, A., Hammouti, B., Aouniti, A., Benchat, N. & Benhadda, T. New synthesised pyridazine derivatives as effective inhibitors for the corrosion of pure iron in HCl medium. Prog. Org. Coatings 45, 373–378 (2002).

Bekkouch, K., Aouniti, A., Hammouti, B. & Kertit, S. Corrosion inhibition of a carbon steel in 2M H3PO4 medium by" triazine" compounds. J. Chim. Phys. Phys.-Chimie Biol. 96, 838–850 (1999).

Bouklah, M. et al. Effect of the substitution of an oxygen atom by sulphur in a pyridazinic molecule towards inhibition of corrosion of steel in 0.5 M H2SO4 medium. Prog. Org. coatings 51, 118–124 (2004).

Branzoi, V., Golgovici, F. & Branzoi, F. Aluminium corrosion in hydrochloric acid solutions and the effect of some organic inhibitors. Mater. Chem. Phys. 78, 122–131 (2003).

Kaminski, M. & Szklarska-Smialowska, Z. Adsorption of thiophene derivatives on steel in sulphuric acid solutions. Corros. Sci. 13, 557–565 (1973).

Dutta, A., Saha, S. K., Adhikari, U., Banerjee, P. & Sukul, D. Effect of substitution on corrosion inhibition properties of 2-(substituted phenyl) benzimidazole derivatives on mild steel in 1 M HCl solution: A combined experimental and theoretical approach. Corros. Sci. 123, 256–266 (2017).

Qiang, Y., Zhang, S., Zhao, H., Tan, B. & Wang, L. Enhanced anticorrosion performance of copper by novel N-doped carbon dots. Corros. Sci. 161, 108193 (2019).

Gomma, G. K. & Wahdan, M. H. Temperature coefficient of corrosion inhibition of steel by adenine. Bull. Chem. Soc. Jpn. 67, 2621–2626 (1994).

Rasheeda, K., Vijaya, D. P., Krishnaprasad, P. A. & Samshuddin, S. Pyrimidine derivatives as potential corrosion inhibitors for steel in acid medium-an overview. Int. J. Corros. Scale Inhib. 7, 48–61 (2018).

Elewady, G. Y. Pyrimidine derivatives as corrosion inhibitors for carbon-steel in 2M hydrochloric acid solution. Int. J. Electrochem. Sci 3, 1149 (2008).

Bedair, M. A., El-Sabbah, M. M. B., Fouda, A. S. & Elaryian, H. M. Synthesis, electrochemical and quantum chemical studies of some prepared surfactants based on azodye and Schiff base as corrosion inhibitors for steel in acid medium. Corros. Sci. 128, 54–72 (2017).

Fouda, A. S., El-Mekabaty, A., Shaaban, I. E. I. & El-Hossiany, A. Synthesis and biological evaluation of novel thiophene derivatives as green inhibitors for aluminum corrosion in acidic media. Prot. Met. Phys. Chem. Surfaces 57, 1060–1075 (2021).

Gurudatt, D. M. & Mohana, K. N. S. Influence of some synthesized pyrimidine derivatives on corrosion inhibition of mild steel in hydrochloric acid medium. Eur. J. Chem. 5, 53–64 (2014).

Ansari, K. R., Sudheer Singh, A. & Quraishi, M. A. Some pyrimidine derivatives as corrosion inhibitor for mild steel in hydrochloric acid. J. Dispers. Sci. Technol. 36, 908–917 (2015).

Soltani, N., Behpour, M., Oguzie, E. E., Mahluji, M. & Ghasemzadeh, M. A. Pyrimidine-2-thione derivatives as corrosion inhibitors for mild steel in acidic environments. RSC Adv. 5, 11145–11162 (2015).

Caliskan, N. & Akbas, E. Corrosion inhibition of austenitic stainless steel by some pyrimidine compounds in hydrochloric acid. Mater. Corros. 63, 231–237 (2012).

Mohajernia, S. et al. Inhibitive assessment of 1-(7-Methyl-5-Morpholin-4-Yl-Thiazolo [4, 5-D] Pyrimidin-2-Yl)-Hydrazine as a corrosion inhibitor for mild steel in sulfuric acid solution. J. Iran. Chem. Soc. 10, 831–839 (2013).

Aswin, K., Mansoor, S. S., Logaiya, K. & Sudhan, S. P. N. Triphenylphosphine: An efficient catalyst for the synthesis of 4, 6-diphenyl-3, 4-dihydropyrimidine-2 (1H)-thione under thermal conditions. J. King Saud Univ. 26, 141–148 (2014).

Behpour, M., Ghoreishi, S. M., Vatani, F., Mohammadi, N. & Ghasemzadeh, M. A. The inhibiting effect of some new derivatives of pyrimidine-2-thione on the corrosion of stainless steel 304 in sulfuric acid media. J. Mech. Eng. Tech 2, 1–11 (2014).

Khaled, M. A., Ismail, M. A., El-Hossiany, A. & Fouda, A. S. Novel pyrimidine-bichalcophene derivatives as corrosion inhibitors for copper in 1 M nitric acid solution. RSC Adv.,11, 25104–25121 (2021).

Lahmidi, S. et al. Corrosion inhibition of mild steel by two new 1, 2, 4-triazolo [1, 5-a] pyrimidine derivatives in 1 M HCl: Experimental and computational study. J. Mater. Environ. Sci 8, 225–237 (2017).

Verma, C. et al. Corrosion inhibition of mild steel in 1M HCl by D-glucose derivatives of dihydropyrido [2, 3-d: 6, 5-d′] dipyrimidine-2, 4, 6, 8 (1H, 3H, 5H, 7H)-tetraone. Sci. Rep. 7, 1–17 (2017).

Shetty, P. B., Suresha Kumara, T. H., Mamatha, D. M., Rao, V. R. & Chitharanjan Hegde, A. Inhibition effect of a new pyrimidine derivative on the corrosion of mild steel in hydrochloric acid solution. Surf. Eng. Appl. Electrochem. 53, 42–51 (2017).

Qiang, Y., Guo, L., Li, H. & Lan, X. Fabrication of environmentally friendly Losartan potassium film for corrosion inhibition of mild steel in HCl medium. Chem. Eng. J. 406, 126863 (2021).

Qiang, Y. et al. Experimental and molecular modeling studies of multi-active tetrazole derivative bearing sulfur linker for protecting steel from corrosion. J. Mol. Liq. 351, 118638 (2022).

Zoorob, H. H., Abou Elzahab, M., Abdel-Mogib, M., Ismail, M. A. & Abdel-Hamid, M. 1, 3-Dimethylpyrimidoheterocycles as antibacterial agents. Arzneimittelforschung. 47, 958–962 (1997).

Qian, B., Wang, J., Zheng, M. & Hou, B. Synergistic effect of polyaspartic acid and iodide ion on corrosion inhibition of mild steel in H2SO4. Corros. Sci. 75, 184–192 (2013).

Haldhar, R., Prasad, D. & Bhardwaj, N. Surface adsorption and corrosion resistance performance of Acacia concinna pod extract: An efficient inhibitor for mild steel in acidic environment. Arab. J. Sci. Eng. 45, 131–141 (2020).

Gonçalves, R. S., Azambuja, D. S. & Lucho, A. M. S. Electrochemical studies of propargyl alcohol as corrosion inhibitor for nickel, copper, and copper/nickel (55/45) alloy. Corros. Sci. 44, 467–479 (2002).

Fouda, A. S., Shalabi, K. & E-Hossiany, A. Moxifloxacin antibiotic as green corrosion inhibitor for carbon steel in 1 M HCl. J. Bio- Tribo-Corrosion 2, 1–13 (2016).

Lavanya, D. K., Frank, V. P. & Vijaya, D. P. Corrosion inhibitive effect of novel eco friendly corrosion inhibitors for mild steel in 0.5 M HCl—A comparative study. Surf. Eng. Appl. Electrochem. 56, 524–532 (2020).

Yadav, M., Sinha, R. R., Sarkar, T. K., Bahadur, I. & Ebenso, E. E. Application of new isonicotinamides as a corrosion inhibitor on mild steel in acidic medium: Electrochemical, SEM, EDX, AFM and DFT investigations. J. Mol. Liq. 212, 686–698 (2015).

Fouda, A., El-Gharkawy, E.-S., Ramadan, H. & El-Hossiany, A. Corrosion resistance of mild steel in hydrochloric acid solutions by clinopodium actions as a green inhibitor. Biointerface Res. Appl. Chem. 11, 9786–9803 (2021).

Kumar, P., Kalia, V., Kumar, H. & Dahiya, H. Corrosion inhibition for mild steel in acidic medium by using hexadecylamine as corrosion inhibitor. Chem. Sci. Trans. 6, 497–512 (2017).

Fouda, A. S., Ibrahim, H., Rashwaan, S., El-Hossiany, A. & Ahmed, R. M. Expired drug (pantoprazole sodium) as a corrosion inhibitor for high carbon steel in hydrochloric acid solution. Int. J. Electrochem. Sci. 13, 6327–6346 (2018).

Bahrami, M. J., Hosseini, S. M. A. & Pilvar, P. Experimental and theoretical investigation of organic compounds as inhibitors for mild steel corrosion in sulfuric acid medium. Corros. Sci. 52, 2793–2803 (2010).

Fouda, A. S., Al-Hazmi, N. E., El-Zehry, H. H. & El-Hossainy, A. Electrochemical and surface characterization of chondria macrocarpa extract (CME) as save corrosion inhibitor for aluminum in 1M HCl medium. J. Appl. Chem. 9, 362–381 (2020).

Ouici, H. B. et al. Inhibition of mild steel corrosion in 5% HCl solution by 5-(2-hydroxyphenyl)-1, 2, 4-triazole-3-thione. Res. Chem. Intermed. 39, 2777–2793 (2013).

Quraishi, M. A. Thermodynamic and Electrochemical Investigation of Pantoprazole:{(RS)-6-(difluoromethoxy)-2-[(3, 4-dimethoxypyridin-2-yl) methylsulfinyl]-1 H-benzo [d]-imidazole} as Corrosion Inhibitor for Mild Steel in Hydrochloric Acid Solution. Arab. J. Sci. Eng. 38, 99–109 (2013).

Elgyar, O. A., Ouf, A. M., El-Hossiany, A. & Fouda, A. E. A. S. The inhibition action of viscum album extract on the corrosion of carbon steel in hydrochloric acid solution. Biointerface Res. Appl. Chem. 11, 14344–14358 (2021).

Gece, G. & Bilgiç, S. Quantum chemical study of some cyclic nitrogen compounds as corrosion inhibitors of steel in NaCl media. Corros. Sci. 51, 1876–1878 (2009).

Motawea, M. M., El-Hossiany, A. & Fouda, A. S. Corrosion control of copper in nitric acid solution using chenopodium extract. Int. J. Electrochem. Sci. 14, 1372–1387 (2019).

ElBelghiti, M. et al. Experimental, quantum chemical and Monte Carlo simulation studies of 3, 5-disubstituted-4-amino-1, 2, 4-triazoles as corrosion inhibitors on mild steel in acidic medium. J. Mol. Liq. 218, 281–293 (2016).

El Hamdani, N., Fdil, R., Tourabi, M., Jama, C. & Bentiss, F. Alkaloids extract of Retama monosperma (L.) Boiss. seeds used as novel eco-friendly inhibitor for carbon steel corrosion in 1 M HCl solution: Electrochemical and surface studies. Appl. Surf. Sci. 357, 1294–1305 (2015).

Alibakhshi, E. et al. Glycyrrhiza glabra leaves extract as a green corrosion inhibitor for mild steel in 1 M hydrochloric acid solution: Experimental, molecular dynamics, Monte Carlo and quantum mechanics study. J. Mol. Liq. 255, 185–198 (2018).

Muthukrishnan, P., Jeyaprabha, B. & Prakash, P. Mild steel corrosion inhibition by aqueous extract of Hyptis suaveolens leaves. Int. J. Ind. Chem. 5, 1–11 (2014).

Fouda, A., Azeem, M. A., Mohamed, S., El-Hossiany, A. & El-Desouky, A. Corrosion inhibition and adsorption behavior of nerium oleander extract on carbon steel in hydrochloric acid solution. Int. J. Electrochem. Sci. 14, 3932–3948 (2019).

Migahed, M. A., Azzam, E. M. S. & Morsy, S. M. I. Electrochemical behaviour of carbon steel in acid chloride solution in the presence of dodecyl cysteine hydrochloride self-assembled on gold nanoparticles. Corros. Sci. 51, 1636–1644 (2009).

Fouda, A. S., Abd El-Maksoud, S. A., Belal, A. A. M., El-Hossiany, A. & Ibrahium, A. Effectiveness of some organic compounds as corrosion inhibitors for stainless steel 201 in 1M HCl: Experimental and theoretical studies. Int. J. Electrochem. Sci. 13, 9826–9846 (2018).

Gong, Y., Wang, Z., Gao, F., Zhang, S. & Li, H. Synthesis of new benzotriazole derivatives containing carbon chains as the corrosion inhibitors for copper in sodium chloride solution. Ind. Eng. Chem. Res. 54, 12242–12253 (2015).

Guo, L. et al. Theoretical insight into an empirical rule about organic corrosion inhibitors containing nitrogen, oxygen, and sulfur atoms. Appl. Surf. Sci. 406, 301–306 (2017).

Hamani, H. et al. Electrochemical and quantum chemical studies of some azomethine compounds as corrosion inhibitors for mild steel in 1 M hydrochloric acid. Corros. Sci. 88, 234–245 (2014).

Abdallah, M., Alfakeer, M., Alonazi, A. M. & Al-Juaid, S. S. Ketamine drug as an inhibitor for the corrosion of 316 stainless steel in 2M HCl solution. Int. J. Electrochem. Sci 14, 10227–10247 (2019).

Obot, I. B. & Obi-Egbedi, N. O. Theoretical study of benzimidazole and its derivatives and their potential activity as corrosion inhibitors. Corros. Sci. 52, 657–660 (2010).

Ramya, K., Mohan, R. & Joseph, A. Adsorption and electrochemical studies on the synergistic interaction of alkyl benzimadazoles and ethylene thiourea pair on mild steel in hydrochloric acid. J. Taiwan Inst. Chem. Eng. 45, 3021–3032 (2014).

Osman, U. M. et al. Correlation data of (Z)-1-[4-(trifluoromethyl) benzylidene] thiosemicarbazide via spectroscopic methods and Density Functional Theory studies. Data Br. 27, 104673 (2019).

Kosari, A. et al. Electrochemical and quantum chemical assessment of two organic compounds from pyridine derivatives as corrosion inhibitors for mild steel in HCl solution under stagnant condition and hydrodynamic flow. Corros. Sci. 78, 138–150 (2014).

Li, H., Zhang, S. & Qiang, Y. Corrosion retardation effect of a green cauliflower extract on copper in H2SO4 solution: Electrochemical and theoretical explorations. J. Mol. Liq. 321, 114450 (2021).

Qiang, Y., Li, H. & Lan, X. Self-assembling anchored film basing on two tetrazole derivatives for application to protect copper in sulfuric acid environment. J. Mater. Sci. Technol. 52, 63–71 (2020).

Niamien, P. M. et al. Copper corrosion inhibition in 1 M HNO3 by two benzimidazole derivatives. Int. Sch. Res. Not. 2012, 1–15 (2012).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

A.El-A.S.F., M.A.I., M.A.K., A.A.El-H., wrote the main manuscript text. M.A.K. prepared figures, A.A.El-H. calculate the quantum part, A.El-A.S.F., M.A.I. reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fouda, A.S., Ismail, M.A., Khaled, M.A. et al. Experimental and computational chemical studies on the corrosion inhibition of new pyrimidinone derivatives for copper in nitric acid. Sci Rep 12, 16089 (2022). https://doi.org/10.1038/s41598-022-20306-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-20306-4

This article is cited by

-

Experimental and theoretical studies of the efficiency of metal–organic frameworks (MOFs) in preventing aluminum corrosion in hydrochloric acid solution

BMC Chemistry (2024)

-

Comparative studies of tetrazole derivatives on the corrosion inhibition of copper and commercial brass in simulated seawater

Discover Applied Sciences (2024)

-

Protective Coatings Containing ZnMOF-BTA Metal–Organic Framework for Active Protection of AA2024-T3

Acta Metallurgica Sinica (English Letters) (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.