Abstract

Ionogels are gaining popularity as a potential replacement for volatile organic solvents in various processes, such as catalysts, electrochemistry, spectroscopy, and medicinal chemistry, due to their low toxicity, high thermal stability, and good solubility. Magnet-responsive ion gels with high magnetic susceptibility are promising and can be used as catalysts, sensors, and MRI contrast agents. Herein, we fabricated simple and novel magnet choline carbomer ionogels using a precipitation-deposition method with carbomers and choline hydroxide. The morphology and structure of the resulting ionogels were analyzed using various characterization techniques, including FTIR, EDX, TGA, and SEM spectroscopy. These magnet ionogels were effective catalysts for a one-pot, three-component synthesis of benzopyran derivatives, providing mild reaction conditions, environmental friendliness, and good to excellent (78–96%) yields within a short reaction time (1–2 h). Additionally, the magnet ionogels were easily recyclable, and they could be reused up to five times without catalytic deactivation.

Similar content being viewed by others

Introduction

In recent years, due to their sustainability, there has been exceptional interest in using ionic liquids as an alternative to classic volatile solvents1,2. These media, composed of cationic and anionic components, can be designed to have specific properties owing to the reaction condition3,4. In this regard, the term “planner solvents” have been used to indicate the potential of this group of ecologically safe liquids for chemical reactions5,6. The molecular structure of ionic liquids consists of different cations and anions. Usually, the role of cation is played by a bulky organic compound (positively charged), but the anions are much smaller in volume than the cations (negatively charged), and their structure is inorganic7,8. Thanks to the size difference between anions and cations, the bond between the two components of ionic liquids is feeble. They do not have a crystal arrangement, so these compounds are liquid at temperatures below 100 °C9. Ionic liquids play a dual role as a reaction medium catalyst in electrochemistry, spectroscopy, Biology, and medicinal chemistry10. Ionic liquids with paramagnetic properties consist of a cation, anion, and a transition metal, mainly the Lanthanide complex systems11. Due to their unique physicochemical properties, magnetic ionic liquids gained innovative applications in catalysis, separation extraction, and material synthesis12. Since transition metals can be used in many different applications and are primarily significant catalysts, it seemed to be a good idea to turn the paramagnetic ionic liquids into magnetic ionic gels13. Due to the cost and recyclability limitation of pure ionic liquids, the industrial utilization of its need to be immobilized IL in a solid matrix without creating any change in the IL structure14,15. An ionogel combines the attributes of a solid and a liquid, displaying the properties of both IL and the solid phase except flowing16,17,18. Ionogels have recently received significant attention in transistors, batteries, supercapacitors, and fuel cells19,20,21. Ionogels can be formed in several ways and have different types of classifications. The most favorite one is their assortment, based on their solid construction. They can be organic (with a polymer), inorganic (silica-based), or organic–inorganic22,23,24.

Magnetic catalysts combined with ionic liquids represent an interesting and promising approach in the field of catalysis25. Applications of magnetic catalysts combined with ionic liquids can be found in various fields, including organic synthesis26,27, biomass conversion28,29, and energy-related processes30,31. Researchers continue to explore and develop new catalytic systems to harness the advantages offered by this combination, aiming to achieve more efficient and sustainable chemical transformations32,33,34,35.

Carbomers are white and fluffy powders crosslinked acrylic acid polymers employed as thickeners and rheology modifiers. They create transparent gels with a wide range of applications like personal care, home care, drugs, buffering agent, institutional care products, printing inks, adhesives, and coatings36. Due to their utility, reliability, biocompatibility, and rare ability to rescue doomed products, they were used for various purposes. Carbomers are acid-based polymers that are acidic in their unneutralized state and have to be neutralized with an appropriate base, such as triethanolamine, sodium hydroxide, potassium hydroxide, and EDTA, to achieve their thickening ability. We can take the benefits of the acid-based properties of such soft products to prepare the magnetic ionic liquid more straightforwardly in the presence of choline hydroxide as a gelling agent and ionic media. Choline hydroxide has been of thinking in terms of being an efficient catalyst in some chemical reactions since it is an affordable, un-contaminating, innocuous ionic liquid with basic properties which is also water-soluble37,38,39,40,41.

Recently, we reported the application of greener solvents such as water, deep eutectic solvent, and ionic liquids in various organic transformations42,43,44. Herein we report a novel and simple sol–gel method to confine the ionic liquid and magnetic nanoparticles simultaneously within a polymer matrix through a one-step process. The basic idea developed is straightforward, practical, and applicable in the industrial revolution due to its environmentally friendly nature and inexpensive starting materials.

Experimental

General information

All chemicals have been provided by Merck, and other available chemical suppliers and used without purification. The Buchi 53 melting point device has recorded the melting point. An illustration of FT-IR spectra was executed on a Bruker Vector-22 infrared spectrometer utilizing KBr cake and announced in cm−1. EDX was used for morphological studies.

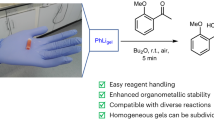

Preparation of magnetic ionogel

150 mL of double distilled water was poured into 500 mL of a three-neck round-bottom flask with mechanical stirring under a nitrogen atmosphere. Next, FeCl3·6H2O (8.1 g) and FeCl2·4H2O (4.97 g) were added to the flask and stirred thoroughly until the iron salts were wholly dissolved. Afterward, 2 g carbomer 940 was added to the solution under vigorous stirring at 80 °C, and the pH solution was adjusted to 10 using 40% choline hydroxide solution in water. After continuous stirring for 2 h, the magnetite precipitates were washed to pH = 7 using deionized water. The black gel was washed several times with deionized water until the pH of the eluent decreased to 7. The resulting magnetic ionogel was collected by an external magnet and washed with double distilled water until the solution was neutral. Then, it was washed with ethanol successively and dried under a vacuum (Fig. 1).

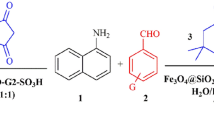

General procedure

In a 5 mL round-bottom flasks with a magnetic stirring bar, benzaldehyde (100 µL, 1.0 mmol), dimedone (140 mg, 1.0 mmol), and malononitrile (63 µL, 1.0 mmol) in the presence of magnetic ionogel (50 mg) in water (2 mL) were added respectively. The reaction mixture was stirred at 60 °C until the reaction mixture was completed. After the reaction, ethyl acetate (10 mL) was added, and magnetic ionogel in water was separated by external magnet. After the evaporation of solvents in a rotary evaporator, the residue was recrystallized from hot ethanol to yield the corresponding pure products. All the products listed in Table 2 were synthesized following this procedure. The product yield was determined by comparing the observed melting point of the isolated product with the reported melting point range of the desired compound in the literature. This approach was used to assess the success of the synthesis and ensure the obtained product aligned with the expected properties. Furthermore, in some cases, NMR analysis was performed to assess the purity of the compounds.

Selected data:

4a: White solid; 1H NMR (500 MHz, DMSO-d6) δ 0.92 (s, 3H, Me), 1.08 (s, 3H, Me), 2.08 (d, J = 8.4 Hz, CH2, 2H), 2.24 (d, J = 8.4 Hz, CH2, 2H), 4.17 (s, CH, 1H), 7.08 (brs, NH2), 7.08–7.18 (m, 2H, Ar–H), 7.29 (t, 2H, Ar–H); 13C NMR (125 MHz, DMSO-d6) δ 26.9, 29.2, 32.5, 35.9, 40.2, 51.0, 59.5, 113.2, 121.0, 128.1, 127.9, 129.1, 146.1, 159.1, 162.9, 195.8;

4b: White solid; 1H NMR (500 MHz, DMSO-d6) δ 1.31 (s, Me, 3H), 1.29 (s, Me, 3H), 2.16 (d, J = 8.2 Hz, CH2, 2H), 2.35 (s, Me, 3H), 2.35 (d, J = 8.2 Hz, CH2, 2H), 4.39 (s, CH, 1H), 7.23 (brs, NH2), 7.27 (d, J = 8.1 Hz, Ar–H, 2H), 7.33 (d, J = 8.1 Hz, Ar–H, 2H); 13C NMR (125 MHz, DMSO-d6) δ: 22.1, 28.1, 28.9, 33.0, 36.0, 41.1, 51.2, 59.1, 114.1, 121.2, 128.0, 130.3, 137.4, 143.6, 159.2, 163.1, 195.9;

4g: White solid, 1H NMR (500 MHz, DMSO-d6) δ: 0.96 (s, Me, 3H), 1.03 (s, Me, 3H), 2.11 (d, J = 8.1 Hz, CH2, 2H), 2.29 (d, J = 8.1 Hz, CH2, 2H), 4.19 (s, 1H, CH), 7.11 (d, J = 8.9 Hz, 2H, Ar–H), 7.35 (s, 2H, NH2), 7.91 (d, J = 8.9 Hz, 2H, Ar–H); 13C NMR (125 MHz, DMSO-d6) δ: 28.1, 29.2, 33.1, 36.9, 51.3, 59.3, 113.4, 120.2, 129.5, 131.2, 133.4, 145.3, 159.8, 195.9.

The possible reaction mechanism

From the possible Mechanism, we assume that the synthesized magnetic ionogel catalyst the Knoevenagel condensation reaction as well as the Micheal addition has followed. The nucleophilic addition of an activated compound to a carbonyl group (II–III intermediates) and following the reaction with the Micheal addition (Intermediate IV) of a nucleophile structure to an α, β-unsaturated carbonyl compound has led to the creation of the final product (Fig. 2).

The combination of Fe3O4 nanoparticles and choline hydroxide exhibits a synergistic catalytic effect, particularly in mild Lewis acid catalytic reactions. Fe3O4 nanoparticles possess inherent catalytic activity, acting as mild Lewis acid catalysts. On the other hand, choline hydroxide serves as a promoter or co-catalyst, further enhancing the catalytic performance of Fe3O4. The synergistic interaction between Fe3O4 and choline hydroxide facilitates surface interactions and creates an ionic medium, leading to improved reactant adsorption and promoting efficient catalytic transformations. This interaction enhances the accessibility of catalytic active sites, resulting in enhanced catalytic activity and selectivity. Moreover, the presence of Fe3O4 contributes to the stability and recyclability of the catalyst system.

Results & discussion

Preparation and characterization of the magnetic ionogel

The magnetic ionogel catalyst was prepared following the procedure shown in Fig. 1. The protocol design was straightforward. A reaction of choline chloride and potassium hydroxide prepared the precursor choline hydroxide. Magnetic ionogel is easily prepared via a one-pot reaction of carbomer, choline hydroxide, and iron salts in water. The morphology and distribution of the synthesized catalyst were characterized using SEM and the results were shown in Fig. 3. SEM images show the presence of some particles with different sizes formed on the carbomer surface during the process. These particles are attributed to iron oxide compositions generated under reaction conditions.

Energy Dispersive X-ray Spectroscopy-Mapping Analysis (EDX – MAP) was used to determine the elemental constitution of the synthesized magnetic ionogel (Fig. 4). The EDX spectrum of the catalyst shows the presence of elements C, N, O, and Fe in the catalyst, which revealed the grafting of the magnetic nanoparticles on the surface of the carbomer.

The MAP analysis demonstrated the frequency distribution of the elements of C, O, N, and Fe and their distribution in the magnetic ionogel, as shown in Fig. 5.

The detailed investigation of the functionalization of magnetic ionogel was performed by FT-IR spectroscopy (Fig. 6). In accordance with the result of FT-IR analysis of the carbomer based magnetic ionogel, a peak in 696 cm–1, can be associated to the stretching of Fe–O that is related to Fe3O4 particles which have been trapped in the gel structure. The strong band observed at around 1042 cm–1 can be demonstrated for the C–N stretching bond, while 1066 cm–1 is for the C–O bond. On the other hand, the band at 1408 cm–1 stands for the symmetrical stretching bond of C–O, and 1451.8 cm–1 can show CH2 bending bond. In addition, 1641 cm–1 illustrates C=O asymmetric bond in carbomer. The catalyst exhibit adsorptions at 2956 cm–1 C–H stretching vibration of carbomer followed by 3415 cm–1 and 2049 cm–1 due to the O–H groups water in the gel matrix.

Thermogravimetric analysis (TGA) is a powerful analytical technique used to investigate the thermal stability of materials by measuring their weight changes as a function of temperature or time under controlled conditions. TGA analysis is used to study the thermal properties of magnetic Fe3O4-supported ionogels, composite materials composed of Fe3O4 nanoparticles, and ionic liquids immobilized in a solid matrix (Fig. 7). The TGA analysis of magnetic ionogel typically reveals two main stages of weight loss. The first stage corresponds to the removal of adsorbed water and other volatile components, while the second stage involves the degradation of the ionic liquid and the organic matrix.

The structure of the magnetic ionogel was characterized by X-ray diffraction (XRD), and the corresponding patterns are shown in Fig. 8. The XRD analysis revealed characteristic diffraction peaks which can be attributed to the (220), (222), (400), (511), (440), and (533) crystal planes, respectively. These peaks are in good agreement with the standard Fe3O4 nanoparticles (PDF# 88-0315). However, the XRD patterns of the magnetic gel showed exhibit broader or less intense diffraction peaks, indicating a disruption or distortion in the crystalline structure. This can be attributed to the presence of gel matrix in the surface Fe3O4.

The catalytic activities of magnetic ionogel were investigated using the one-pot, three-component condensation reaction between benzaldehydes (1 mmol), dimedone (1mmol), and malononitrile (1 mmol) in deionized water (2.0 mL) as the model reaction (Table 1). According to the results provided in Table 1, the magnetic ionogel performed well to give the desired product within 4 h in 68% yield at room temperature (Table 1, entry 1). As we expected, the outcome of the desired products could be improved to 96% within 1 h by increasing the reaction temperature to 60 °C (Table 1, entry 3). The model reaction was carried out in various polar and nonpolar solvents (Table 1, entries 5–10) to investigate the solvent effect. The model reaction in organic solvents such as toluene, ethyl acetate, CH3CN dimethylformamide, and tetrahydrofuran was unsuccessful in the presence of magnetic ionogel. Next, the loaded amounts of magnetic ionogel were investigated. Increasing the catalyst to 100 mg, did not change the reaction conditions in terms of yields and times (Table 1, entry 15). On the other hand, the amount of catalyst is reduced to 10 mg, and increased reaction time was required to get the optimal results (Table 1, entries 11–14).

Temperature plays a crucial role in catalytic reactions, impacting reaction kinetics, thermodynamics, and the stability of intermediates and transition states. In the Fe3O4 and choline hydroxide ionogel catalytic system, the temperature dependence of the product yield can be attributed to factors such as reaction rate and equilibrium position. In the specific case of this system, it has been observed that after 24 h of reaction, only the reaction between aldehydes and malononitrile was observed, and the desired benzopyran products did not show improved yields. However, it is important to consider the influence of the equilibrium position on the overall product yield. The cyclization reaction leading to benzopyran products may be reversible, and the equilibrium position can be temperature-dependent. By increasing the temperature, it becomes possible to shift the equilibrium towards the desired benzopyran products, thereby increasing their yields.

To study the green protocol's scope and generality, a series of 4H-pyran derivatives were synthesized from various aldehydes with different electronic properties (Table 2) under optimal conditions. All the tested aldehydes afforded the corresponding 4H-pyran in good to excellent yields. The reaction worked well with aromatic aldehydes containing electron-withdrawing groups or electron-donating to give the desired products good to excellent yields with high purity. In addition, our environmentally friendly strategies are successful for more challenging acid-sensitive aldehydes such as 2-furfural that proceed with smooth condensation without forming any side products. (Table 2, entry 12). The one-pot, three-component cyclization reaction proceeded smoothly in water and was completed in 1 to 2 h.

In addition to high catalytic activity and inexpensive properties of magnetic ionogel, simple separation is another advantage in industrial processes. The magnetic ionogel could be recycled easily. The one-pot reaction of benzaldehyde, dimedone, and malononitrile was chosen as a model reaction. The yields corresponding to five consecutive runs are shown in Fig. 9. After each cycle, ethyl acetate was added to the reaction mixture, and products and unreacted starting materials were recovered. The aqueous solution containing magnetic ionogel was reused for the next run with good reusable stability under air without apparent deactivation. The TON (Turnover Number) and TOF (Turnover Frequency) values for the five-cycle run using a reused catalyst were determined to be 2802 and 56 h–1, respectively.

Analyzing the reused ionogel using FTIR (Fig. 10) and EDX spectrometry (Fig. 11) is a common approach to assess the stability and changes in catalysts. The fact that the results showed no change after the five cycle run indicates that the catalyst remained stable throughout the experimental process.

Table 3 showed the comparison of the activity of magnetic ionogels with various methods commonly used for the one-pot synthesis of benzopyran derivatives in the literature. Magnetic ionogels offer a promising approach for the one-pot synthesis of benzopyran derivatives45,46,47,48,49,50,51,52,53,54,55,56. They combine the advantages of magnetic nanoparticles and ionic liquids or ionogels, providing improved catalytic activity, easy separation, and recyclability (Table 3).

Conclusion

The study presents a methodology for synthesizing benzopyran derivatives using a magnetic ionogel catalyst in water, which offers several advantages over traditional methods. The development of the magnetic ionogel catalyst was achieved using a simple and novel approach, resulting in a highly efficient catalyst that led to the formation of a variety of benzopyran compounds with excellent yields in a short reaction time. Furthermore, the catalyst was easily recoverable, and the reaction system could be reused for up to five cycles with consistent yields. These results highlight the potential of magnetic ionogels as sustainable and versatile catalysts for various chemical transformations. This work contributes to the field by introducing a novel approach to fabricating magnet choline carbomer ionogels for the first time and showcasing their potential as multifunctional materials with applications in catalysis, sensing, and medical imaging.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Lei, Z. Introduction: Ionic liquids. Chem. Rev. 117, 6633–6635 (2017).

Chakraborti, A. K., Roy, S. R., Kumar, D. & Chopram, P. Catalytic application of room temperature ionic liquids: [bmim][MeSO4] as a recyclable catalyst for the synthesis of bis(indolyl)methanes. Ion-fishing by MALDI-TOF-TOF MS and MS/MS studies to probe the proposed mechanistic model of catalysis. Green Chem. 10, 1111–1118 (2008).

Yang, J., Tan, J. N. & Gu, Y. Lactic acid as an invaluable bio-based solvent for organic reactions. Green Chem. 14, 3304–3317 (2012).

Gao, F. et al. Replacement strategies for non-green dipolar aprotic solvents. Green Chem. 22, 6240–6257 (2020).

Gu, Y. & Jérôme, F. Glycerol as a sustainable solvent for green chemistry. Green Chem. 12, 1127–1138 (2010).

Chakraborti, A. K., Rudrawar, S., Jadhav, K. B., Kaur, G. & Chankeshwara, S. V. On water organic synthesis: A highly efficient and clean synthesis of 2-aryl/heteroaryl/styryl benzothiazoles and 2-alkyl/aryl alkyl benzothiazolines. Green Chem. 9, 1335–1340 (2007).

Liu, P., Hao, J. W., Mo, L. P. & Zhang, Z. H. Recent advances in the application of deep eutectic solvents as sustainable media as well as catalysts in organic reactions. RSC Adv. 5, 48675–48704 (2015).

Zhang, Z., Song, J. & Han, B. Catalytic transformation of lignocellulose into chemicals and fuel products in ionic liquids. Chem. Rev. 117, 6834–6880 (2017).

Yuan, J. S., Pavlovich, M. J., Ragauskas, A. J. & Han, B. Biotechnology for a sustainable future: biomass and beyond. Trends Biotechnol. 40, 1395–1398 (2022).

Yang, D., Zhu, Q. & Han, B. Electroreduction of CO2 in ionic liquid-based electrolytes. Innovation 1, 100016 (2020).

McNeice, P., Marr, P. C. & Andrew, C. Basic ionic liquids for catalysis: The road to greater stability. Catal. Sci. Technol. 11, 726–741 (2021).

Klingshirn, M. A., Spear, S. K., Holbreyc, J. D. & Rogers, R. D. Ionic liquids as solvent and solvent additives for the synthesis of sol–gel materials. J. Mater. Chem. 15, 5174–51802 (2005).

Bideau, J., Viau, L. & Vioux, A. Ionogels, ionic liquid-based hybrid materials. Chem. Soc. Rev. 40, 907–925 (2011).

Néouze, M. A., Bideau, J., Gaveau, P., Bellayer, S. & Vioux, A. Ionogels, new materials arising from the confinement of ionic liquids within silica-derived networks. Chem. Mater. 18, 3931–3936 (2006).

Kumar Gupta, A., Singh Manish, P., Kumar Singh, R., Chandra, S. & Trans, D. Low density ionogels obtained by rapid gellification of tetraethyl orthosilane assisted by ionic liquids. Dalton Trans. 41, 6263–6271 (2012).

Santos, E., Albo, J. & Irabien, A. Magnetic ionic liquids: Synthesis, properties and Applications. RSC Adv. 4, 40008–40018 (2014).

Gonçalves, W. B. et al. Ionogels based on a single ionic liquid for electronic nose application. Chemosensors 30, 201–212 (2021).

Bideau, J. L., Viaub, L. & Vioux, A. Ionogels, ionic liquid-based hybrid materials. Chem. Soc. Rev. 40, 907–925 (2011).

Ziółkowski, B. et al. Magnetic ionogels (MagIGs) based on iron oxide nanoparticles, poly (nisopropylacrylamide), and the ionic liquid trihexyl (tetradecyl)phosphonium dicyanamide. Eur. J. Inorg. Chem. 32, 5245–5251 (2012).

Pratap Singh, M., Kumar Singh, R. & Chandra, S. Ionic liquids confined in porous matrices: Physicochemical properties and applications. Prog. Mater. Sci. 64, 73–120 (2014).

Manasa, C., Basavanna, V. & Ningaiah, S. Ionic liquid-based hybrid materials: Ionogel review. Biointerface Res. Appl. Chem. 13, 391–403 (2023).

Li, T., Wang, Y., Li, S., Liu, X. & Sun, J. Mechanically robust, elastic, and healable ionogels for highly sensitive ultra-durable ionic skins. Adv. Mater. 32, 2002706 (2020).

Xie, Z. L., Jeliić, A., Wang, F. P., Beuermann, S. & Taubert, A. Transparent, flexible, and paramagnetic ionogels based on PMMA and the iron-based ionic liquid 1-butyl-3-methylimidazolium tetrachloroferrate(iii) [Bmim][FeCl4]. J. Mater. Chem. 20, 9543–9549 (2010).

Yan, J., Liu, J., Jing, P., Gao, D. & Fang, Y. Cholesterol-based low-molecular mass gelators towards smart ionogels. Soft Matter 8, 11697–11703 (2012).

Ying, A. et al. Fabrication of DABCO functionalized poly(ionic liquids): Vital role of ferric oxides in the formation of mesoporous structure and used as highly efficient and recyclable catalysts for multi-component reactions. J. Catal. 391, 312–326 (2020).

Lu, X. et al. Novel photic and magnetic double responsive Pickering interfacial solid catalysts for biodiesel production. Fuel 310, 122318 (2022).

Ying, A. et al. Sandwich like poly(ionic liquid)s functionalized microspheres: Efficient interfacial catalysts for preparation of biodiesel. Chem. Eng. J. 473, 145361 (2023).

Li, S. et al. Template-free fabrication of magnetic mesoporous poly(ionic liquid)s: Efficient interfacial catalysts for hydrogenation reaction and transesterification of soybean oil. J. Mater. Chem. A 10, 3531–3542 (2022).

Aziizi, N., Manochehri, Z., Nahayi, A. & Torkashvand, S. A facile one-pot synthesis of tetrasubstituted imidazoles catalyzed by eutectic mixture stabilized ferrofluid. J. Mol. Liq. 196, 153–158 (2014).

Maleki, B., Jamshidi, A., Peiman, S. & Housaindokht, M. R. Tri-vanadium substituted dawson-type heteropolytungstate nanocomposite (g-C3N4/Fe3O4@P2W15V3) as a novel, green, and recyclable nanomagnetic catalyst in the synthesis of tetrahydrobenzo[b]pyrans. Polycycl. Aromat. Compd. https://doi.org/10.1080/10406638.2023.2184398 (2023).

Naderi, S., Sandaroos, R., Peiman, S. & Maleki, B. Novel crowned cobalt (II) complex containing an ionic liquid: A green and efficient catalyst for the one-pot synthesis of chromene and xanthene derivatives starting from benzylic alcohols. J. Phys. Chem. Solids 180, 111459 (2023).

Valipour, Z., Hosseinzadeh, R., Sarrafi, S. & Maleki, S. Natural deep eutectic solvent as a green catalyst for the one-pot synthesis of chromene and 4H-pyran derivatives. Org. Prep. Proced. Int. https://doi.org/10.1080/00304948.2023.2232917 (2023).

Maleki, B., Reiser, O., Esmaeilnezhad, E. & Choi, H. J. SO3H-dendrimer functionalized magnetic nanoparticles (Fe3O4@Dsingle bondNHsingle bond(CH2)4single bondSO3H): Synthesis, characterization and its application as a novel and heterogeneous catalyst for the one-pot synthesis of polyfunctionalized pyrans and polyhydroquinolines. Polyhedron 162, 129–141 (2019).

Veisi, H. et al. Bio-inspired synthesis of palladium nanoparticles fabricated magnetic Fe3O4 nanocomposite over Fritillaria imperialis flower extract as an efficient recyclable catalyst for the reduction of nitroarenes. Sci. Rep. 11, 4515 (2021).

Ghani, M. et al. Synthesis of cellulose nanofibers-based ImSalophen@Fe3O4 as a green sorbent for magnetic solid-phase extraction of chlorophenols followed by quantification via high-performance liquid chromatography-ultraviolet detection. Microchem. J. 187, 108368 (2023).

Indah Safitri, F., Nawangsari, D. & Febrina, D. Overview: Application of carbopol 940 in gel. AHMS https://doi.org/10.2991/ahsr.k.210127.018 (2020).

Arora, S., Gupta, N. & Singh, V. Choline based basic ionic liquid (BIL)/acidic DES mediated cellulose rich fractionation of agricultural waste biomass and valorization to 5-HMF. Waste Biomass Valoriz. 11, 3345–3354 (2020).

Azizi, N. & Edrisi, M. Biodegradable choline hydroxide promoted environmentally benign thiolysis of epoxides. Tetrahedron Lett. 57, 525–528 (2016).

Zhu, A., Bai, S., Li, L., Wang, M. & Wang, J. Choline hydroxide: An efficient and biocompatible basic catalyst for the synthesis of biscoumarins under mild conditions. Catal. Lett. 145, 1089–1093 (2015).

Kumar Krishnammagari, S., Lim, K. T., Cho, B. G. & Jeong, Y. T. Choline hydroxide: An efficient and biodegradable catalyst for the synthesis of 2-amino-3-nitro-4H-chromene derivatives in an aqueous medium. Phosphorus Sulfur Silicon Relat. Elem. 193, 574–581 (2018).

Singh, B. S., Lobo, H. R. & Shankarling, G. S. Choline chloride based eutectic solvents: Magical catalytic system for carbon–carbon bond formation in the rapid synthesis of β-hydroxy functionalized derivatives. Catal. Commun. 24, 70–74 (2012).

Mirmashhori, B., Azizi, N. & Saidi, M. R. A simple, economical, and highly efficient synthesis of β-hydroxynitriles from epoxide under solvent free conditions. J. Mol. Catal. A Chem. 247, 159–161 (2006).

Saidi, M. R. & Azizi, N. Highly diastereoselective aminoalkylation of naphthols with chiral amines mediated by lithium perchlorate solution in diethyl ether. Tetrahedron Asymmetry 14, 389–392 (2003).

Saidi, M. R., Azizi, N. & Zali-Boinee, H. A simple one-pot three-component reaction for preparation of secondary amines and amino esters mediated by lithium perchlorate. Tetrahedron 57, 6829–6832 (2001).

Kaupp, G., Naimi-Jamal, M. R. & Schmeyers, J. Solvent-free Knoevenagel condensations and Michael additions in the solid state and in the melt with quantitative yield. Tetrahedron 59, 3753–3760 (2003).

Honarmand, M., Tzani, A. & Detsi, A. 2-Hydroxyethyl-1-ammonium 3-hydroxypropane-1-sulfonate: A biodegradable and recyclable ionic liquid for the one-pot synthesis of 2-amino-3-cyano-4H-pyrans. J. Iran. Chem. Soc. 16, 571–581 (2019).

Khalil, K. D. & Al-Matar, H. M. Chitosan based heterogeneous catalyses: Chitosan-grafted-poly(4-vinylpyridne) as an efficient catalyst for Michael additions and alkylpyridazinyl carbonitrile oxidation. Molecules 18, 5288–5305 (2013).

Saraswat, A. & Singh, R. K. P. Utilization of dissociation constant (pKa) value perspective of –CH acid in electrochemical synthesis of 4H-chromene and its derivatives. Asian J. Chem. 32, 1697–1702 (2020).

Diniz, L. F. et al. Synthesis and X-ray crystal structures of polyfunctionalized 4H-chromene derivatives via tricomponent reaction with Knoevenagel adducts as intermediates in aqueous medium. J. Mol. Struct. 1223, 129226 (2021).

Tu, S. J., Gao, Y., Guo, C., Shi, D. & Lu, Z. A convenient synthesis of 2-amino-5,6,7,8-tetrahydro-5-oxo-4-aryl-7,7-dimethyl-4H-benzo-[b]-pyran-3 -carbonitrile under microwave irradiation. Synth. Commun. 32, 2137–2141 (2002).

Tu, S. et al. A facile and efficient synthesis of new polysubstituted indeno[1,2-b]pyridines via one-pot, three-component microwave-assisted reaction. Synlett 3, 480–484 (2007).

Banerjee, S. & Saha, A. Free-ZnO nanoparticles: A mild, efficient and reusable catalyst for the one-pot multicomponent synthesis of tetrahydrobenzo[b]pyran and dihydropyrimidone derivatives. New J. Chem. 37, 4170–4175 (2013).

Anamika, Yadav, C. L., Drew, M. G. B., Kumar, K. & Singh, N. Ferrocene-functionalized dithiocarbamate zinc(II) complexes as efficient bifunctional catalysts for the one-pot synthesis of chromene and imidazopyrimidine derivatives via Knoevenagel condensation reaction. Inorg. Chem. 60, 6446–6462 (2021).

Gupta, P., Kumar, P. & Sharma, C. Surface modified novel magnetically tuned halloysite functionalized sulfonic acid: Synthesis, characterization and catalytic activity. Catal. Sci. Technol. 11, 3775–3786 (2021).

Beerappa, M. & Shivashankar, K. One pot synthesis of pyran-based heterocycles from benzyl halides as key reagents. RSC Adv. 5, 30364–30371 (2015).

Rajput, J. K. & Kaur, G. Synthesis and applications of CoFe2O4 nanoparticles for multicomponent reactions. Catal. Sci. Technol. 4, 142–151 (2014).

Guo, R. Y. et al. Meglumine: A novel and efficient catalyst for one-pot, three-component combinatorial synthesis of functionalized 2-amino-4 H-pyrans. ACS Comb. Sci. 11, 557–563 (2013).

Acknowledgements

Financial support for this work by Chemistry and Chemical Engineering Research Center of Iran is gratefully appreciated.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. S.S. performed material preparation, data collection and analysis. The first draft of the manuscript was written by N.A., Z.M. and H.S. was supervised and Writing- review & editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shojaee, S., Azizi, N., Mirjafary, Z. et al. Magnet-responsive choline carbomer ionogels as a versatile and recyclable catalyst for one-pot synthesis of benzopyran in water. Sci Rep 13, 21232 (2023). https://doi.org/10.1038/s41598-023-48625-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-48625-0

This article is cited by

-

Ultrafast and efficient continuous flow organic synthesis with a modified extruder-grinder system

Scientific Reports (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.