Abstract

To satisfy global energy demands and decrease the level of atmospheric greenhouse gases, alternative clean energy sources are required. Hydrogen is one of the most promising clean energy sources due to its high chemical energy density and near-zero greenhouse gas emissions. A single alloyed phase of Pd/Pt nanoclusters as quantum dots (QDs) was prepared and loaded over Co3O4 nanoparticles with a low loading percentage (1 wt.%) for hydrogen generation from the hydrolysis of NaBH4 at room temperature. L-glutathione (SG) was used as a capping ligand. It was found that the single alloy catalyst (Pd0.5–Pt0.5)n(SG)m/Co3O4 caused a significant enhancement in hydrogen generation in comparison to the monometallic clusters (Pdn(SG)m and Ptn(SG)m). Moreover, the Pd/Pt alloy showed a positive synergistic effect compared to the physical mixture of Pd and Pt clusters (1:1) over Co3O4. The QDs alloy and monometallic Pd and Pt clusters exhibited well-dispersed particle size in ~ 1 nm. The (Pd0.5–Pt0.5)n(SG)m)/Co3O4 catalyst offers a high hydrogen generation rate (HGR) of 8333 mL min− 1 g− 1 at room temperature. The synergistic effect of Pd and Pt atoms in the nanoclusters alloy is the key point beyond this high activity, plus the prepared clusters' unique atomic packing structure and electronic properties. The effect of the NaBH4 concentration, catalyst amount, and reaction temperature (25–60 °C) were investigated, where HGR reaches 50 L min− 1 g− 1 at 60 °C under the same reaction conditions. The prepared catalysts were analyzed by UV–Vis, TGA, HR-TEM, XRD, and N2 adsorption/desorption techniques. The charge state of the Pd and Pt in monometallic and alloy nanoclusters is zero, as confirmed by X-ray photoelectron spectroscopy analysis. The catalysts showed high recyclability efficiency for at least five cycles due to the high leaching resistance of the alloy nanoclusters within the Co3O4 host. The prepared catalysts are highly efficient for energy-based applications.

Similar content being viewed by others

Introduction

Bimetallic systems as heterogeneous catalysts have received tremendous scientific and industrial attention due to their excellent catalytic performance compared to monometallic systems1,2,3. The synergistic effect and cooperative interactions between the two metals are the main reason beyond their activity, where the electrons transfer or exchange between the two metals in the bimetallic lattice enhances the catalytic activity of the bimetallic systems1,2,4.

Recently, hydrogen as clean energy has been considered a key factor in the increasing depletion of fossil fuels and exacerbating the environmental pollution crisis5,6. Hydrogen is universally accepted as a clean energy source due to its relatively high energy density (142 MJ kg− 1) in comparison to diesel and gasoline (46 MJ kg− 1) and can reduce the amount of greenhouse gas and acid rain when used as fuel7. Hydrolysis of sodium borohydride (NaBH4) has been reported to be a promising way to generate hydrogen due to its high hydrogen content (10.65 wt.%), low price, and nontoxicity (NaBH4 + 2H2O → NaBO2 + 4H2, ΔH = − 300 kJ mol− 1)6,7,8,9,10,11,12. Metal alloys such as NiB and CoB showed good activity in the hydrolysis of NaBH49,10,13, where 5 wt. % CoB/CeO2 showed hydrogen generation rate (HGR) of 533 mL g− 1 min− 110. Patel et al.14 reported the effect of electron transfer between metallic Co and B.

Noble metals such as Au, Pd, Ru, and Pt-based catalysts were reported as ideal candidates for hydrogen generation due to their excellent catalytic activity and high stability11,12,15. 20 wt.% of Ru (19.9 nm), Pd (12.2 nm), and Pt (3.2 nm) over Co3O4 showed high catalytic activity in hydrolysis of NaBH4 with HGR of 6514, 4713, and 2109 mL g− 1 min− 1, respectively11. Pt/Al2O3, Rh/Al2O3, and Pd/Al2O3 exhibited some catalytic activity in hydrolysis of 15–23 wt.% NaBH4 solutions16. The bimetallic catalysts showed higher performance in the hydrolysis of NaBH4 than the corresponding monometallic17,18,19,20,21,22,23. Pt-Ru bimetallic system over LiCoO2 support exhibited catalytic activity in the hydrolysis of NaBH4 more than the monometallic Ru or Pt20. The Ru-Co alloys over γ-Al2O3 showed higher HGR in NaBH4 hydrolysis than single monometallic samples21. Ni − Pt/CeO2 over granular activated carbon catalyst achieved complete and rapid decomposition of hydrazine hydrate to generate H2 with a 100% selectivity at moderate temperature in the presence of 1 M NaOH22. Moreover, the salisylaldimine-Ni complex has shown 190% increment in NaBH4 hydrolysis than pure Ni catalyst with a maximum hydrogen production rate of 2240 ml min−1 g−124.

To prepare size-selected metal nanoclusters (quantum dots, QDs), a great deal of work should be done; for example, deposition of Pt clusters over single-crystal supports such as MoO3 and TiO2 under ultrahigh vacuum (UHV) conditions 10− 9 mbar25. This model of catalysis is very complicated and largely deviated from the real world of catalytic conditions. Monolayer-protected nanoclusters of noble metals have recently gained much attention in the catalysis field due to their unique atomic packing structure and electronic properties26,27,28,29,30,31,32,33,34,35,36,37,38. In our previous work, platinum nanoclusters protected with l-cysteine and N-acetyl-l-cysteine over TiO2 showed high catalytic activity in the oxidation of styrene26 and solar degradation of methylene blue38, respectively. Pd nanoclusters protected with N-acetyl-l-cysteine exhibited superior catalytic activity in hydrogenation of α, β-unsaturated aldehydes such as cinnamaldehyde33. Moreover, size-selected gold clusters (Au25(SCH2CH2Ph)18, Au38(SCH2CH2Ph)24, and Au144(SCH2CH2Ph)60) over ceria showed high catalytic activity in the oxidation of carbon monoxide at a low temperature35,36,37.

To the best of our knowledge, this is the first time to prepare a single alloyed Pd/Pt quantum dots (QDs) in regime of 1 nm by simple way in a large yield. A very low loading percentage (1 wt.%) from the prepared alloy over Co3O4 achieved a high hydrogen yield with a hydrogen generation rate (HGR) 8333 mL g−1 min−1. Additionally, a comparison between the activity of the single alloy and the physical mixing of Pd and Pt nanoclusters was studied, where the alloy exhibited a positive synergistic effect and the physical mixing showed a negative synergistic effect. Where, the physical mixture of palladium and platinum nanoclusters (1:1) was loaded over the Co3O4 nanoparticles for comparison. 1 wt.% (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst showed the best catalytic activity in NaBH4 hydrolysis reaction to generate hydrogen gas. However, the physical mixing of Pd and Pt nanoclusters over Co3O4 showed lower activity than monometallic platinum clusters. The synergistic effect between Pd and Pt atoms in the nanoclusters alloy plays the main role in this activity. As confirmed by HR-TEM, the particle size of palladium, platinum, and single alloy nanoclusters is around 1 nm. The stoichiometric ratio between the metallic and organic parts in the three prepared nanoclusters was determined by TG analysis. The crystallinity and surface area of the loaded nanoclusters over Co3O4 were measured by X-ray diffraction (XRD) and N2 adsorption/desorption isotherms at − 196 °C. X-ray photoelectron spectroscopy (XPS) confirmed that the charge of Pd and Pt in the monometallic and bimetallic nanoclusters is zero.

Experimental

Chemicals

Potassium hexachloropalladate (IV) (K2PdCl6, 98%, Sigma–Aldrich), chloroplatinic acid (H2PtCl6.6H2O, ≥ 37.5% Pt basis, Sigma–Aldrich), sodium borohydride (NaBH4, ≥ 96%, Aldrich), l-glutathione (99%, Sigma–Aldrich) and ethanol were used for preparing the protected Pd and Pt nanoclusters and the Pd–Pt alloy nanoclusters. Cobalt (II, III) oxide (Co3O4) nanopowder, < 50 nm particle size (99.5%, Sigma–Aldrich), was used as active support. All chemicals were used as received. All glassware was thoroughly cleaned with aqua regia (HCl:HNO3 = 3:1 v/v), rinsed with double distilled water and ethanol, and dried in an oven before use.

Preparation of Pdn(SG)m nanoclusters

79.466 mg potassium hexachloropalladate (IV) (K2PdCl6, 0.2 mmol) was dissolved in 10 mL double-distilled water, 43.02 mg l-glutathione (0.14 mmol) was dissolved in 3 mL double-distilled water, and added to the palladium solution, under vigorously stirring (~ 1100 rpm) at room temperature. During the addition of the l-glutathione solution, the orange color of the palladium salt solution became light orange, and then the color changed to red. After 30 min. of stirring, a freshly prepared aqueous solution of NaBH4 (75.66 mg, 2 mmol, dissolved in 3 mL double-distilled water) was added dropwise over the resulting solution while stirring vigorously (~ 1100 rpm). The red solution converted quickly to black, indicating the reduction of the palladium salt and the formation of palladium nanoclusters. The reaction was allowed to proceed under constant stirring for 1 h. The mixture was evaporated under a vacuum to near dryness, and then the particles were precipitated by adding ethanol. The black-brown precipitate was re-dissolved in double-distilled water and re-precipitated by ethanol. This step should be repeated three times to remove excess NaBH4. The resulting precipitate was then collected through centrifugal precipitation and washed with ethanol to remove the unreacted material. The black-brown solid consisting of Pdn(SG)m nanoclusters was finally dried overnight at 100 °C26,27,28,29,30,31,32,33,34,35,36,37,38.

Preparation of Ptn(SG)m nanoclusters

81.96 mg chloroplatinic acid (H2PtCl6.6H2O, 0.2 mmol) was dissolved in 10 mL double-distilled water, and 43.02 mg l-glutathione (0.14 mmol) was dissolved in 3 mL double distilled water and added to the platinum solution, under vigorously stirring (~ 1100 rpm) at room temperature. During the addition of the l-glutathione solution, the yellow solution of platinum salt showed some turbidity after adding the ligand, then the color changed to orange and finally to canary yellow. After 30 min stirring, a freshly prepared aqueous solution of NaBH4 (75.66 mg, 2 mmol, dissolved in 3 mL double-distilled water) was added dropwise over the resulting solution while stirring vigorously (~ 1100 rpm). The canaries yellow color solution converted gradually to black, indicating the reduction of the platinum salt and formation of platinum nanoclusters. The reaction was allowed to proceed under constant stirring for 1 h. Then, the Ptn(SG)m nanoclusters were separated, purified, and dried as described in the case of Pdn(SG)m nanoclusters26.

Preparation of (Pd0.5–Pt0.5)n(SG)m nanoclusters

40.98 mg chloroplatinic acid (H2PtCl6.6H2O, 0.1 mmol) was dissolved in 5 mL double-distilled water (solution A). 32.73 mg potassium tetrachloropalladate (II) (K2PdCl4, 0.1 mmol) was dissolved in 5 mL double-distilled water (solution B). Solution A was mixed with solution B for 30 min., and then 43.02 mg l-glutathione (0.14 mmol) was dissolved in 3 mL double-distilled water and added to the solution vigorously stirring (~ 1100 rpm) at room temperature. The l-glutathione solution reacted with the mixed solutions of the two salts simultaneously. After adding the ligand, the yellow solution showed some turbidity; then the color changed to orange and finally to canary yellow. After 30 min. stirring, a freshly prepared aqueous solution of NaBH4 (75.66 mg, 2 mmol, dissolved in 3 mL double-distilled water) was added dropwise over the resulting solution while stirring vigorously (~ 1100 rpm). The canaries yellow color solution converted gradually to black, indicating the platinum and palladium salts reduced simultaneously to form Pd–Pt single alloy nanoclusters. The reaction was allowed to proceed under constant stirring for 1 h. Then, the (Pd0.5–Pt0.5)n(SG)m alloy was separated, purified, and dried as described in the case of Pdn(SG)m nanoclusters26,38.

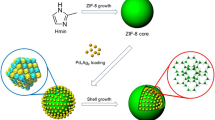

Loading of the prepared nanoclusters over Co3O4

The 1 wt.% of catalysts (Pdn(SG)m/Co3O4, Ptn(SG)m/Co3O4, Pdn(SG)m + Ptn(SG)m/Co3O4 and (Pd0.5–Pt0.5)n(SG)m/Co3O4) were prepared by a well-known impregnation method. 0.5 g of Co3O4 nanoparticles were suspended in 50 mL double-distilled water in an ultrasonic bath for 30 min., 5 mg of the clusters were dissolved in 10 mL double-distilled water, and then added to the Co3O4 slurry. The slurry was stirred 24 h at room temperature, and then the loaded catalyst was collected by centrifuge at 6000 rpm, for 10 min. The brown color of the clusters solution becomes colorless, confirming the transfer of all clusters amount to the Co3O4 surface. The loaded catalysts were dried in an oven at 100 °C overnight26,38.

The catalytic reaction for the hydrolysis of NaBH4

The hydrolysis of NaBH4 has been performed at room temperature (25 °C), over 5 mg of the prepared catalysts (Pdn(SG)m/Co3O4, Ptn(SG)m/Co3O4, Pdn(SG)m + Ptn(SG)m/Co3O4, and (Pd0.5–Pt0.5)n(SG)m/Co3O4). 1 g of NaBH4 was added to 100 mL of water (corresponding to 1 wt.%), and the catalyst was added. The reaction solution was stirred at 1000 rpm. The hydrogen-generated volume was measured using the water displacement method9,10,11,12. (Pd0.5–Pt0.5)n(SG)m/Co3O4 was used as a model catalyst to study the effect of catalyst weight (5, 15, 30, and 50 mg) in the hydrolysis of 1 wt.% NaBH4 solution at 25 °C.

5 mg of the (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst was chosen to employ different NaBH4 solutions such as 0.189, 0.5, 1, and 2 wt.%. The same amount of the catalyst was used to follow up the reaction at different temperatures 25, 45, and 60 °C, of the 1 wt.% NaBH4 solution.

In the recyclability study, 5 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst was repeatedly used five times to generate H2 using 1 wt.% NaBH4 solution at 25 °C. Once the hydrolysis reaction of NaBH4 was completed, a new NaBH4 solution was added for a second cycle, and so on.

Results and discussion

Optical properties and chemical composition of the prepared nanoclusters

Metal nanoclusters exhibit some absorption in a visible region, and these absorptions come from the excitation of plasmon resonance electrons or interband transitions26,30,31,33,38. These absorption peaks' positions and width depend on the metal type, particle size, protecting ligand, and chemical charge26,29,31,33,38. Pt nanoparticles in regime 4–10 nm show an absorption peak at 215 nm39,40. The intensity of this peak decreases by decreasing particle size and is essentially undetectable for smaller clusters less than 2 nm41. S-containing Pd(II) complexes exhibited surface plasmon peak at 350–500 nm, corresponding to the charge transfer between the metal and ligand42.

The prepared Pd and Pt nanoclusters and Pd/Pt alloy nanoclusters in water show featureless absorption curves in the UV–vis region, where their color is dark brown (Fig. 1-I). These absorption curves agree with the theoretical calculations by Creighton and Eadon39. As shown in Fig. 1-I, there are no peaks or noise in the 350–500 nm region, indicating the prepared nanoclusters are pure from the intermediated complex (Pd(II)-SG), and all the palladium ions are reduced to Pd(0)33. Moreover, the prepared nanoclusters are pure from the unreacted l-glutathione ligand, which shows one absorption peak at 224 nm38.

(I) UV–Vis absorption spectra of the prepared nanoclusters (Pd0.5–Pt0.5)n(SG)m (a), Pdn(SG)m (b), and Ptn(SG)m (c). The prepared clusters show featureless absorption curves in the visible region of 350–900 nm. (II) The thermogravimetric analysis (TGA) of the prepared clusters ((Pd0.5–Pt0.5)n(SG)m (a), Pdn(SG)m (b), and Ptn(SG)m (c)) and the protecting ligand l-glutathione (d).

Thermogravimetric analysis (TGA) is used to obtain the ratio between the organic and metallic parts in the protected nanoclusters26,29,31,33,38. Therefore, the metal-to-ligand ratio (M/L) and the average chemical formula of the MPCs can be estimated. Figure 1-II shows the TGA curves of the prepared nanoclusters and the pure ligand. According to the TGA curves, the protecting ligand in Pdn(SG)m, Ptn(SG)m, and (Pd0.5–Pt0.5)n(SG)m nanoclusters decompose in two decomposition steps. The ligand decomposition is completed at 900 °C; the residual is the metallic part. The weight percentage of the metallic part of the prepared nanoclusters Pdn(SG)m, Ptn(SG)m, and (Pd0.5–Pt0.5)n(SG)m are 50.18, 62.1, and 56 wt. % (Table 1). The average metal/ligand ratio (M/L) and the average molecular formula of the prepared nanoclusters are calculated and summarized in Table 126,38.

The particles size and charge of the prepared nanoclusters

High resolution-transmission electron microscopy (HR-TEM) was used to measure the particle size of the prepared nanoclusters. Figure 2 (I, II, and III) shows the HR-TEM images of the Pdn(SG)m, Ptn(SG)m, and (Pd0.5–Pt0.5)n(SG)m, respectively. The particle size of the prepared clusters is ~ 1 nm, which appears as QDs. The single alloy QDs (Pd0.5–Pt0.5)n(SG)m) shows a particle size that is uniformly distributed similar to the monometallic nanoclusters (Pdn(SG)m and Ptn(SG)m). This indicates that the method can be used for bimetallic and monometallic QDs preparation.

The particle charge of the prepared nanoclusters is characterized by X-ray photoelectron spectroscopy (XPS). The Pd 3d XPS spectrum of the Pdn(SG)m clusters is shown in Fig. 3-I. The binding energies of the Pd 3d5/2 and 3d3/2 electrons are at 335.42 and 340.66 eV16 respectively, corresponding to Pd(0). These findings are in agreement with those obtained for Pd nanoparticles loaded on Co3O4 nanoparticles43,44. Figure 3-II shows the XPS spectrum of platinum atoms in Ptn(SG)m clusters, the binding energies of the Pt 4F5/2 and 4F7/2 electrons are 74.58 and 71.19 eV, respectively, that are corresponding to Pt(0)45. The charge of Pd and Pt atoms in the single alloy nanoclusters (Pd0.5–Pt0.5)n(SG)m are also zero, as confirmed by XPS analysis (Fig. 3-III,IV), where the binding energies of the Pd 3d5/2 and 3d3/2 electrons are 335.44 and 340.70 eV, and for Pt 4F5/2 and 4F7/2 electrons are 74.36 and 71.02 eV, respectively. The absence of the two peaks of Pd4+ at 339.2 and 342.9 eV indicates the presence of Pd in metallic form (neither as PdO2 nor Pd(OH)4)43.

Texture properties and crystallinity of the prepared catalysts

Liquid nitrogen at − 196 °C is used to determine the surface texture properties of the pure support (Co3O4) and the doped Co3O4 with the prepared nanoclusters (Pdn(SG)m/Co3O4, Ptn(SG)m/Co3O4, Pdn(SG)m + Ptn(SG)m/Co3O4 and (Pd0.5–Pt0.5)n(SG)m/Co3O4) by measuring the adsorption/desorption isotherms (Fig. 4). According to the IUPAC classification of hysteresis loops, the sorption isotherms of the prepared catalysts and the pure support are type H3 hysteresis loops46,47,48. The surface areas of the prepared catalysts and support are summarized in Table 2. The values of surface area that are measured by BET equation (SBET) and T-method (St) for all the investigated catalysts are close to each other, which confirms the correct choice of standard t-curves for pore analysis and indicates the absence of ultra-micropores in these catalysts26,33.

X-ray diffraction is used to measure the crystallinity of the prepared catalysts. Figure 5 illustrates the XRD diffractograms of the prepared catalysts and Co3O4. The characteristic diffraction planes of the Co3O4 are (111), (220), (311), (222), (400), (422), (511) and (440) appear at 2θ equal to 19.0°, 31.2°, 36.7°, 38.5°, 44.8°, 55.5°, 59.3° and 65.4°, respectively (Fig. 5a)49,50. The prepared catalysts show the same XRD pattern as pure Co3O4, and no new peaks related to the presence of Pd or Pt clusters are detected, where the doping percentage is very low (1 wt.%) (Fig. 5b–e). This means the crystallinity of pure Co3O4 does not affect loading with the prepared clusters. Also, there is no significant difference in either diffraction angle or peak width between the Co3O4 and prepared catalysts, indicating that the crystal structure of Co3O4 is not affected by doping. The crystalline size (dCo3O4) of bare Co3O4 is calculated using Debye–Scherrer Equations51 as 20 nm for the broadening of (311) peak reflection (Fig. 5). The dCo3O4 value for 1 wt.% (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst is less than bare Co3O4 18.6 nm (Fig. 5)26,33.

The catalytic activity of the prepared catalysts

The hydrolysis reaction of NaBH4 for hydrogen generation is chosen as a model reaction to estimate the catalytic activities of Pdn, Ptn, physical mixture (Pdn + Ptn) clusters and the single alloy clusters (Pd0.5–Pt0.5)n over Co3O4 nanoparticles as support. Figure 6 shows the volume of generated hydrogen at room temperature (25 °C) against reaction time over the prepared catalysts. 5 mg of 1 wt.% Pdn(SG)m/Co3O4 catalyst produces the maximum hydrogen volume i.e. 500 mL from the hydrolysis of NaBH4 solution (1 g NaBH4 in 100 mL H2O) within 26 min. stirring. Ptn(SG)m nanoclusters over Co3O4 show more activity than Pd clusters in the hydrolysis of NaBH4 solution, where the Ptn(SG)m/Co3O4 catalyst produces the maximum hydrogen volume within 18 min. stirring at room temperature (Fig. 6). However, the physical mixing of Pd and Pt clusters over Co3O4 with the same doping percentage (~ 1 wt.%) shows lower catalytic activity than 1 wt. % Ptn(SG)m/Co3O4 catalyst. Surprisingly, the single alloy of Pd and Pt QDs (Pd0.5–Pt0.5)n(SG)m/Co3O4) shows amazing catalytic activity, where it reaches the maximum hydrogen volume i.e. 500 mL, within only 12 min. stirring (Fig. 6) with HGR of 8333 mL min− 1 g− 1. The HGRs for the NaBH4 hydrolysis reaction over the prepared catalysts are summarized in Table 3.

The excellent synergetic interaction between Pd and Pt atoms in the single alloy (Pd0.5–Pt0.5)n(SG)m QDs plays a crucial role in the observed high catalytic activity. This positive synergistic effect does not appear in the physical mixing of nanoclusters over the support (Pdn(SG)m + Ptn(SG)m/Co3O4) by the same doping percentage. Since there are two types of synergetic effect (positive and negative)52, if the qualitative effect of electronic interaction between the components of the bimetallic system and the geometric effects due to changes in lattice constants are in the same direction as the bimetallic system will enhance the reaction effectively in comparison to the monometallic systems. However, if the electronic and geometric effect direction is opposite, the lower activity will be received52.

Figure 7 shows the effect of catalyst weight on the hydrolysis of NaBH4. (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst was chosen to study this factor. 5, 15, 30, and 50 mg of the catalyst were added to the NaBH4 solution (1 g NaBH4 in 100 mL H2O) at room temperature (25 °C). As shown in Fig. 7, the time to reach the maximum hydrogen volume (500 mL) decreases with the increase in the weight of the catalyst. Where the time to reach the maximum hydrogen volume decreases from 12.0 to 1.5 min. over 5 and 50 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4, respectively (Fig. 7).

Different concentrations of NaBH4 solution (0.189, 0.5, 1 and 2 wt.%) were tested over 5 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst at 25 °C (Fig. 8-I). The reaction time decreases with the increase of the NaBH4 concentration. The maximum hydrogen volume was reached within 19, 15, 12, and 9 min. of the 0.189, 0.5, 1, and 2 wt.% NaBH4 solution over (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst, respectively (Fig. 8-I). The effect of reaction temperature was also tested for hydrogen generation from the 1 wt.% NaBH4 solution over 5 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst (Fig. 8-II). The reaction was measured at different temperatures at 25, 45, and 60 °C; the reaction time decreased with the temperature increasing (Fig. 8-II). The maximum hydrogen volume was reached within only 2 min stirring over 5 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst at 60 °C with HGR 50,000 mL min− 1 g− 1 (Fig. 8-II).

(I) Effect of NaBH4 amount for hydrogen generation over 1 wt.% (Pd0.5–Pt0.5)n(SG)m/Co3O4. Reaction conditions: 0.189, 0.5, 1 and 2 g NaBH4 amount in 100 H2O; Catalyst, 5 mg; at 25 °C. (II) Effect of reaction temperature for hydrogen generation from the hydrolysis of NaBH4 over 1 wt.% (Pd0.5–Pt0.5)n(SG)m/Co3O4. Reaction conditions: 1 g of NaBH4 in 100 H2O; catalyst, 5 mg; at 25–60 °C.

The best property of heterogeneous catalysis is easily separating the catalyst from the reaction mixture and reusing it until its activity decreases26,27,28,32,33,38. Thus, the ability of the (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst to recycle is tested for the hydrolysis of 1 wt. % NaBH4 solution at room temperature using 5 mg from the catalyst. After each run, the catalyst was collected and reused without any treatment. The HGRs values were nearly identical for the 5 cycles (Fig. 9). These results reveal that the (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst can be reused, and their catalytic activity is quite consistent without significant change.

The NaBH4 hydrolysis reaction mechanism can be further illustrated in view of Langmuir–Hinshelwood model. Where, Kojima et al.53 reported the hydrolysis mechanism of NaBH4 over Pt/LiCoO2 catalyst, according to the Langmuir–Hinshelwood model. It was found that BH4− ions are adsorbed on Pt, while H2O molecules are adsorbed on the oxide support to give H2 and B(OH)4−53. These findings were confirmed by Liu et al.54 using X-ray absorption. Co3O4 played the same role as LiCoO2 for Pt/Co3O4 catalyst as claimed by Hung et al.55. The suggested mechanism of NaBH4 hydrolysis over the (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst is demonstrated in Fig. 10, according to the Langmuir–Hinshelwood model. The catalytic process involves two different adsorption sites. The first site is suggested to be electron-rich Pt0 and Pd0 nanoclusters, whereas the second site is electron-deficient (Coδ+). The hydrolysis of the four hydrides of BH4− occurs one after the other by reaction with one adsorbed H2O for each hydride (Fig. 10)56.

A comparison with different catalysts used for hydrogen generation via NaBH4 hydrolysis is listed in Table 4. As shown in Table 4, the prepared catalysts in this work showed superior catalytic activity in hydrogen generation from the hydrolysis of NaBH4 using a relatively low noble metal loading (1 wt.%). Where (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst showed the highest hydrogen yield in the Table 4 with HGR equal to 8333 mL g−1 min−1. Moreover, 1 wt.% loading percentage of monometallic Pt and Pd clusters over Co3O4 exhibited HGR 5555 and 3846 mL g−1 min−1, however, the 20 wt.% Pt and Pd nanoparticles over the same support exhibited only 4713 and 2109 mL g−1 min−111. This high catalytic activity is due to the unique atomic packing structure and electronic properties of the nanoclusters.

Conclusions

In conclusion, a single alloy of Pd/Pt quantum dots over Co3O4 (Pd0.5–Pt0.5)n(SG)m/Co3O4) exhibited promising catalytic activity in hydrogen generation from the hydrolysis of NaBH4. The maximum hydrogen volume i.e. 500 mL was reached within only 12 min. of stirring at room temperature with HGR 8333 mL min− 1 g− 1. However, the physical mixing of the prepared two clusters (Pdn(SG)m and Ptn(SG)m) over Co3O4 exhibited a lower hydrogen yield in comparison to the single alloy clusters. The time to reach the maximum hydrogen volume decreases with the increase of the (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst weight (5, 15, 30, and 50 mg). Moreover, the effect of NaBH4 concentration (0.189, 0.5, 1 and 2 wt.%) over 5 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst at 25 °C was studied. The hydrolysis of the NaBH4 reaction was measured at different temperatures of 25, 45, and 60 °C, where 5 mg of (Pd0.5–Pt0.5)n(SG)m/Co3O4 catalyst produced the maximum hydrogen volume within only 2 min stirring at 60 °C, with HGR 50,000 mL min− 1 g− 1. The extremely catalytic activity of this catalyst attributes to the ultra-small particle size and the synergistic effect between Pd and Pt atoms in the alloy quantum dots.

Data availability

All data generated or analyzed during this study are included in this published article (and its Supplementary Information files).

References

Rai, R. K. et al. Access to highly active Ni–Pd bimetallic nanoparticle catalysts for C–C coupling reactions. Catal. Sci. Technol. 6, 5567–5579. https://doi.org/10.1039/c6cy00037a (2016).

Wang, D., Villa, A., Porta, F., Su, D. & Prati, L. Single-phase bimetallic system for the selective oxidation of glycerol to glycerate. Chem. Commun. https://doi.org/10.1039/b518069d (2006).

Şahin, Ö., Kılınç, D. & Saka, C. Bimetallic Co–Ni based complex catalyst for hydrogen production by catalytic hydrolysis of sodium borohydride with an alternative approach. J. Energy Inst. 89, 617–626. https://doi.org/10.1016/j.joei.2015.05.007 (2016).

Farrag, M. Ultrasmall bimetallic Ru-Co alloy nanoclusters immobilized in amino-functionalized UiO-66 and N-doped carbonaceous zirconium oxide nanocomposite for hydrogen generation. J. Alloy. Compd. 920, 165893. https://doi.org/10.1016/j.jallcom.2022.165893 (2022).

Şahin, Ö., Kılınç, D. & Saka, C. Hydrogen generation from hydrolysis of sodium borohydride with a novel palladium metal complex catalyst. J. Energy Inst. 89, 182–189. https://doi.org/10.1016/j.joei.2015.02.005 (2016).

Kılınç, D., Saka, C. & Şahin, Ö. Hydrogen generation from catalytic hydrolysis of sodium borohydride by a novel Co(II)–Cu(II) based complex catalyst. J. Power Sour. 217, 256–261. https://doi.org/10.1016/j.jpowsour.2012.06.018 (2012).

Brack, P., Dann, S. E. & Wijayantha, K. G. U. Heterogeneous and homogenous catalysts for hydrogen generation by hydrolysis of aqueous sodium borohydride (NaBH4) solutions. Energy Sci. Eng. 3, 174–188. https://doi.org/10.1002/ese3.67 (2015).

Amendola, S. C. et al. An ultrasafe hydrogen generator: Aqueous, alkaline borohydride solutions and Ru catalyst. J. Power Sour. 85, 186–189. https://doi.org/10.1016/s0378-7753(99)00301-8 (2000).

Schlesinger, H. I. et al. Sodium borohydride, its hydrolysis and its use as a reducing agent and in the generation of hydrogen. J. Am. Chem. Soc. 75, 215–219. https://doi.org/10.1021/ja01097a057 (1953).

Lu, Y.-C., Chen, M.-S. & Chen, Y.-W. Hydrogen generation by sodium borohydride hydrolysis on nanosized CoB catalysts supported on TiO2, Al2O3 and CeO2. Int. J. Hydrog. Energy 37, 4254–4258. https://doi.org/10.1016/j.ijhydene.2011.11.105 (2012).

Bozkurt, G., Özer, A. & Yurtcan, A. B. Development of effective catalysts for hydrogen generation from sodium borohydride: Ru, Pt, Pd nanoparticles supported on Co3O4. Energy 180, 702–713. https://doi.org/10.1016/j.energy.2019.04.196 (2019).

Abdelhamid, H. N. UiO-66 as a catalyst for hydrogen production via the hydrolysis of sodium borohydride. Dalton Trans. 49, 10851–10857. https://doi.org/10.1039/d0dt01688h (2020).

Liu, B. H., Li, Z. P. & Suda, S. Solid sodium borohydride as a hydrogen source for fuel cells. J. Alloy. Compd. 468, 493–498. https://doi.org/10.1016/j.jallcom.2008.01.023 (2009).

Patel, N. et al. Thin films of Co–B prepared by pulsed laser deposition as efficient catalysts in hydrogen producing reactions. Appl. Catal. A 323, 18–24. https://doi.org/10.1016/j.apcata.2007.01.053 (2007).

Shu, H. et al. Ultra small cobalt nanoparticles supported on MCM41: One-pot synthesis and catalytic hydrogen production from alkaline borohydride. Catal. Commun. 118, 30–34. https://doi.org/10.1016/j.catcom.2018.09.012 (2019).

Minkina, V. G., Shabunya, S. I., Kalinin, V. I. & Smirnova, A. Hydrogen generation from sodium borohydride solutions for stationary applications. Int. J. Hydrog. Energy 41, 9227–9233. https://doi.org/10.1016/j.ijhydene.2016.03.063 (2016).

Fiorenza, R., Crisafulli, C. & Scirè, S. H2 purification through preferential oxidation of CO over ceria supported bimetallic Au-based catalysts. Int. J. Hydrog. Energy 41, 19390–19398. https://doi.org/10.1016/j.ijhydene.2016.05.114 (2016).

Fiorenza, R., Scirè, S. & Venezia, A. M. Carbon supported bimetallic Ru-Co catalysts for H2 production through NaBH4 and NH3BH3 hydrolysis. Int. J. Energy Res. 42, 1183–1195. https://doi.org/10.1002/er.3918 (2018).

Crisafulli, C., Galvagno, S., Maggiore, R., Scire, S. & Saeli, A. Performance of supported Ru-Cu bimetallic catalysts prepared from nitrate precursors. Catal. Lett. 6, 77–83. https://doi.org/10.1007/bf00764055 (1990).

Krishnan, P., Yang, T.-H., Lee, W.-Y. & Kim, C.-S. PtRu-LiCoO2 an efficient catalyst for hydrogen generation from sodium borohydride solutions. J. Power Sour. 143, 17–23. https://doi.org/10.1016/j.jpowsour.2004.12.007 (2005).

Rachiero, G. P., Demirci, U. B. & Miele, P. Bimetallic RuCo and RuCu catalysts supported on γ-Al2O3. A comparative study of their activity in hydrolysis of ammonia-borane. Int. J. Hydrog. Energy 36, 7051–7065. https://doi.org/10.1016/j.ijhydene.2011.03.009 (2011).

Dai, H., Qiu, Y.-P., Dai, H.-B. & Wang, P. Ni–Pt/CeO2 Loaded on granular activated carbon: An efficient monolithic catalyst for controlled hydrogen generation from hydrous hydrazine. ACS Sustain. Chem. Eng. 6, 9876–9882. https://doi.org/10.1021/acssuschemeng.8b01098 (2018).

Şahin, Ö., Kilinç, D. & Saka, C. Hydrogen production by catalytic hydrolysis of sodium borohydride with a bimetallic solid-state Co-Fe complex catalyst. Sep. Sci. Technol. 50, 2051–2059. https://doi.org/10.1080/01496395.2015.1016040 (2015).

Kılınç, D., Şahin, Ö. & Saka, C. Investigation on salisylaldimine-Ni complex catalyst as an alternative to increasing the performance of catalytic hydrolysis of sodium borohydride. Int. J. Hydrog. Energy 42, 20625–20637. https://doi.org/10.1016/j.ijhydene.2017.06.230 (2017).

Kunz, S. et al. Size-selected clusters as heterogeneous model catalysts under applied reaction conditions. Phys. Chem. Chem. Phys. 12, 10288. https://doi.org/10.1039/c0cp00288g (2010).

Farrag, M. Monodisperse and polydisperse platinum nanoclusters supported over TiO2 anatase as catalysts for catalytic oxidation of styrene. J. Mol. Catal. A: Chem. 413, 67–76. https://doi.org/10.1016/j.molcata.2015.12.011 (2016).

Farrag, M. Enantioselective silver nanoclusters: Preparation, characterization and photoluminescence spectroscopy. Mater. Chem. Phys. 180, 349–356. https://doi.org/10.1016/j.matchemphys.2016.06.017 (2016).

Farrag, M., Das, M. K., Moody, M. & Samy El-Shall, M. Ligand-protected ultrasmall Pd nanoclusters supported on metal oxide surfaces for CO oxidation: Does the ligand activate or passivate the Pd nanocatalyst?. ChemPhysChem 22, 312–322. https://doi.org/10.1002/cphc.202000656 (2020).

Farrag, M., Thämer, M., Tschurl, M., Bürgi, T. & Heiz, U. Preparation and spectroscopic properties of monolayer-protected silver nanoclusters. J. Phys. Chem. C 116, 8034–8043. https://doi.org/10.1021/jp210453v (2012).

Farrag, M., Tschurl, M., Dass, A. & Heiz, U. Infra-red spectroscopy of size selected Au25, Au38 and Au144 ligand protected gold clusters. Phys. Chem. Chem. Phys. 15, 12539. https://doi.org/10.1039/c3cp51406d (2013).

Farrag, M., Tschurl, M. & Heiz, U. Chiral gold and silver nanoclusters: Preparation, size selection, and chiroptical properties. Chem. Mater. 25, 862–870. https://doi.org/10.1021/cm3033725 (2013).

Farrag, M. Microwave-assisted synthesis of ultra small bare gold clusters supported over Al2O3 and TiO2 as catalysts in reduction of 4-nitrophenol to 4-aminophenol. Microporous Mesoporous Mater. 232, 248–255. https://doi.org/10.1016/j.micromeso.2016.06.032 (2016).

Farrag, M. Preparation of mesoporous palladium nanoclusters supported over hematite (α-Fe2O3) for selective catalytic hydrogenation of α, β-unsaturated aldehydes. Microporous Mesoporous Mater. 257, 110–117. https://doi.org/10.1016/j.micromeso.2017.08.022 (2018).

Good, J. et al. On the functional role of the cerium oxide support in the Au38(SR)24/CeO2 catalyst for CO oxidation. Catal. Today 280, 239–245. https://doi.org/10.1016/j.cattod.2016.04.016 (2017).

Nie, X., Qian, H., Ge, Q., Xu, H. & Jin, R. CO oxidation catalyzed by oxide-supported Au25/(SR)18 nanoclusters and identification of perimeter sites as active centers. ACS Nano. 6, 6014–6022. https://doi.org/10.1021/nn301019f (2012).

Nie, X. et al. CeO2-supported Au38(SR)24 nanocluster catalysts for CO oxidation: A comparison of ligand-on and -off catalysts. Nanoscale 5, 5912. https://doi.org/10.1039/c3nr00970j (2013).

Li, W. et al. Mild activation of CeO2-supported gold nanoclusters and insight into the catalytic behavior in CO oxidation. Nanoscale 8, 2378–2385. https://doi.org/10.1039/c5nr07498c (2016).

Farrag, M. & Mohamed, R. A. Ecotoxicity of ∼1 nm silver and palladium nanoclusters protected by L-glutathione on the microbial growth under light and dark conditions. J. Photochem. Photobiol. A 330, 117–125. https://doi.org/10.1016/j.jphotochem.2016.07.027 (2016).

Creighton, J. A. & Eadon, D. G. Ultraviolet–visible absorption spectra of the colloidal metallic elements. J. Chem. Soc Faraday Trans. 87, 3881–3891. https://doi.org/10.1039/ft9918703881 (1991).

Chen, S. & Kimura, K. Synthesis of thiolate-stabilized platinum nanoparticles in protolytic solvents as isolable colloids. J. Phys. Chem. B 105, 5397–5403. https://doi.org/10.1021/jp0037798 (2001).

Hostetler, M. J. et al. Alkanethiolate gold cluster molecules with core diameters from 1.5 to 5.2 nm: Core and monolayer properties as a function of core size. Langmuir 14, 17–30. https://doi.org/10.1021/la970588w (1998).

Burcham, L. J. & Wachs, I. E. The origin of the support effect in supported metal oxide catalysts: In situ infrared and kinetic studies during methanol oxidation. Catal. Today 49, 467–484. https://doi.org/10.1016/s0920-5861(98)00442-8 (1999).

Huang, R., Kim, K., Kim, H. J., Jang, M. G. & Han, J. W. Size-controlled Pd nanoparticles loaded on Co3O4 nanoparticles by calcination for enhanced CO oxidation. ACS Appl. Nano Mater. 3, 486–495. https://doi.org/10.1021/acsanm.9b02056 (2020).

Yang, N., Ni, S., Sun, Y. & Zhu, Y. A facial strategy to synthesize Pd/Co3O4 nanosheets with enhanced performance for methane catalytic oxidation. Mol. Catal. 452, 28–35. https://doi.org/10.1016/j.mcat.2018.03.016 (2018).

Matin, M. A., Lee, E., Kim, H., Yoon, W.-S. & Kwon, Y.-U. Rational syntheses of core–shell Fe@(PtRu) nanoparticle electrocatalysts for the methanol oxidation reaction with complete suppression of CO-poisoning and highly enhanced activity. J. Mater. Chem. A 3, 17154–17164. https://doi.org/10.1039/c5ta03809j (2015).

Buck, R. P. & Lindner, E. Recommendations for nomenclature of ionselective electrodes (IUPAC Recommendations 1994). Pure Appl. Chem. 66, 2527–2536. https://doi.org/10.1351/pac199466122527 (1994).

Fouad, O. A., Ali, G. A. M., El-Erian, M. A. I. & Makhlouf, S. A. Humidity sensing properties of cobalt oxide/silica nanocomposites prepared via sol-gel and related routes. Nano https://doi.org/10.1142/S1793292012500385 (2012).

Abdel Ghafar, H. H., Ali, G. A. M., Fouad, O. A. & Makhlouf, S. A. Enhancement of adsorption efficiency of methylene blue on Co3O4/SiO2 nanocomposite. Desalin. Water Treat. 53, 2980–2989 (2015).

Ali, G. A. M., Fouad, O. A. & Makhlouf, S. A. Structural, optical and electrical properties of sol–gel prepared mesoporous Co3O4/SiO2 nanocomposites. J. Alloy. Compd. 579, 606–611. https://doi.org/10.1016/j.jallcom.2013.07.095 (2013).

Fouad, O. A., Makhlouf, S. A., Ali, G. A. M. & El-Sayed, A. Y. Cobalt/silica nanocomposite via thermal calcination-reduction of gel precursors. Mater. Chem. Phys. 128, 70–76. https://doi.org/10.1016/j.matchemphys.2011.02.072 (2011).

Patterson, A. The Scherrer formula for X-ray particle size determination. Phys. Rev. 56, 978 (1939).

Dimitratos, N. et al. Pd and Pt catalysts modified by alloying with Au in the selective oxidation of alcohols. J. Catal. 244, 113–121. https://doi.org/10.1016/j.jcat.2006.08.019 (2006).

Kojima, Y. et al. Hydrogen generation using sodium borohydride solution and metal catalyst coated on metal oxide. Int. J. Hydrog. Energy 27, 1029–1034. https://doi.org/10.1016/s0360-3199(02)00014-9 (2002).

Liu, R. S. et al. Investigation on mechanism of catalysis by Pt−LiCoO2 for hydrolysis of sodium borohydride using X-ray absorption. J. Phys. Chem. B 112, 4870–4875. https://doi.org/10.1021/jp075592n (2008).

Hung, T.-F. et al. An alternative cobalt oxide-supported platinum catalyst for efficient hydrolysis of sodium borohydride. J. Mater. Chem. 21, 11754–11759. https://doi.org/10.1039/C1JM11720C (2011).

Andrieux, J., Demirci, U. B. & Miele, P. Langmuir-Hinshelwood kinetic model to capture the cobalt nanoparticles-catalyzed hydrolysis of sodium borohydride over a wide temperature range. Catal. Today 170, 13–19. https://doi.org/10.1016/j.cattod.2011.01.019 (2011).

Su, C.-C., Lu, M.-C., Wang, S.-L. & Huang, Y.-H. Ruthenium immobilized on Al2O3 pellets as a catalyst for hydrogen generation from hydrolysis and methanolysis of sodium borohydride. RSC Adv. 2, 2073–2079 (2012).

Peña-Alonso, R., Sicurelli, A., Callone, E., Carturan, G. & Raj, R. A picoscale catalyst for hydrogen generation from NaBH4 for fuel cells. J. Power Sour. 165, 315–323. https://doi.org/10.1016/j.jpowsour.2006.12.043 (2007).

Peng, S., Fan, X., Zhang, J. & Wang, F. A highly efficient heterogeneous catalyst of Ru/MMT: Preparation, characterization, and evaluation of catalytic effect. Appl. Catal. B 140–141, 115–124. https://doi.org/10.1016/j.apcatb.2013.03.029 (2013).

Liang, Y., Dai, H.-B., Ma, L.-P., Wang, P. & Cheng, H.-M. Hydrogen generation from sodium borohydride solution using a ruthenium supported on graphite catalyst. Int. J. Hydrogen Energy 35, 3023–3028. https://doi.org/10.1016/j.ijhydene.2009.07.008 (2010).

Acknowledgements

This work was financially supported by Assiut University, Egypt.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Farrag, M., Ali, G.A.M. Hydrogen generation of single alloy Pd/Pt quantum dots over Co3O4 nanoparticles via the hydrolysis of sodium borohydride at room temperature. Sci Rep 12, 17040 (2022). https://doi.org/10.1038/s41598-022-21064-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-21064-z

This article is cited by

-

In-situ preparation of sulfonated carbonaceous copper oxide-zirconia nanocomposite as a novel and recyclable solid acid catalyst for reduction of 4-nitrophenol

Scientific Reports (2023)

-

Heterogeneous kinetics of NaBH4 hydrolysis catalyzed by Co/TiO2

Reaction Kinetics, Mechanisms and Catalysis (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.