Abstract

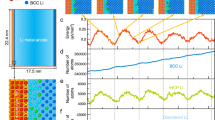

Electrodeposition of lithium (Li) metal is critical for high-energy batteries1. However, the simultaneous formation of a surface corrosion film termed the solid electrolyte interphase (SEI)2 complicates the deposition process, which underpins our poor understanding of Li metal electrodeposition. Here we decouple these two intertwined processes by outpacing SEI formation at ultrafast deposition current densities3 while also avoiding mass transport limitations. By using cryogenic electron microscopy4,5,6,7, we discover the intrinsic deposition morphology of metallic Li to be that of a rhombic dodecahedron, which is surprisingly independent of electrolyte chemistry or current collector substrate. In a coin cell architecture, these rhombic dodecahedra exhibit near point-contact connectivity with the current collector, which can accelerate inactive Li formation8. We propose a pulse-current protocol that overcomes this failure mode by leveraging Li rhombic dodecahedra as nucleation seeds, enabling the subsequent growth of dense Li that improves battery performance compared with a baseline. While Li deposition and SEI formation have always been tightly linked in past studies, our experimental approach enables new opportunities to fundamentally understand these processes decoupled from each other and bring about new insights to engineer better batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author on reasonable request.

References

Liu, B., Zhang, J.-G. & Xu, W. Advancing lithium metal batteries. Joule 2, 833–845 (2018).

Peled, E. The electrochemical behavior of alkali and alkaline earth metals in nonaqueous battery systems—the solid electrolyte interphase model. J. Electrochem. Soc. 126, 2047–2051 (1979).

Boyle, D. T. et al. Transient voltammetry with ultramicroelectrodes reveals the electron transfer kinetics of lithium metal anodes. ACS Energy Lett. 5, 701–709 (2020).

Li, Y. et al. Atomic structure of sensitive battery materials and interfaces revealed by cryo–electron microscopy. Science 358, 506–510 (2017).

Li, Y. et al. Correlating structure and function of battery interphases at atomic resolution using cryoelectron microscopy. Joule 2, 2167–2177 (2018).

Li, Y., Li, Y. & Cui, Y. Catalyst: how cryo-EM shapes the development of next-generation batteries. Chem 4, 2250–2252 (2018).

Zhang, E. et al. Expanding the cryogenic electron microscopy toolbox to reveal diverse classes of battery solid electrolyte interphase. iScience 25, 105689 (2022).

Fang, C. et al. Quantifying inactive lithium in lithium metal batteries. Nature 572, 511–515 (2019).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Liu, B. et al. Coupling a sponge metal fibers skeleton with in situ surface engineering to achieve advanced electrodes for flexible lithium-sulfur batteries. Adv. Mater. 32, e2003657 (2020).

Peled, E. & Menkin, S. Review—SEI: past, present and future. J. Electrochem. Soc. 164, A1703–A1719 (2017).

Bai, P., Li, J., Brushett, F. R. & Bazant, M. Z. Transition of lithium growth mechanisms in liquid electrolytes. Energy Environ. Sci. 9, 3221–3229 (2016).

Ren, X. et al. Guided lithium metal deposition and improved lithium Coulombic efficiency through synergistic effects of LiAsF6 and cyclic carbonate additives. ACS Energy Lett. 3, 14–19 (2017).

Zhang, Y. et al. Dendrite-free lithium deposition with self-aligned nanorod structure. Nano Lett. 14, 6889–6896 (2014).

Qian, J. et al. Dendrite-free Li deposition using trace-amounts of water as an electrolyte additive. Nano Energy 15, 135–144 (2015).

Weber, R. et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 4, 683–689 (2019).

Zhang, W. et al. Colossal granular lithium deposits enabled by the grain-coarsening effect for high-efficiency lithium metal full batteries. Adv. Mater. 32, e2001740 (2020).

Qian, J. et al. High rate and stable cycling of lithium metal anode. Nat. Commun. 6, 6362 (2015).

Zhou, S. et al. Incorporation of LiF into functionalized polymer fiber networks enabling high capacity and high rate cycling of lithium metal composite anodes. Chem. Eng. J. 404, 126508 (2021).

Zheng, J. et al. Regulating electrodeposition morphology of lithium: towards commercially relevant secondary Li metal batteries. Chem. Soc. Rev. 49, 2701–2750 (2020).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4418 (2004).

Odziemkowski, M. & Irish, D. E. An electrochemical study of the reactivity at the lithium electrolyte/bare lithium metal interface. I. Purified electrolytes. J. Electrochem. Soc. 139, 3063–3074 (1992).

Verbrugge, M. W. & Koch, B. J. Microelectrode investigation of ultrahigh-rate lithium deposition and stripping. J. Electroanal. Chem. 367, 123–129 (1994).

Boyle, D. T. et al. Resolving current-dependent regimes of electroplating mechanisms for fast charging lithium metal anodes. Nano Lett. 22, 8224–8232 (2022).

Boyle, D. T. et al. Correlating kinetics to cyclability reveals thermodynamic origin of lithium anode morphology in liquid electrolytes. J. Am. Chem. Soc. 144, 20717–20725 (2022).

Mao, H. et al. Current-density regulating lithium metal directional deposition for long cycle-life Li metal batteries. Angew. Chem. Int. Ed. 60, 19306–19313 (2021).

Jiang, F. & Peng, P. Elucidating the performance limitations of lithium-ion batteries due to species and charge transport through five characteristic parameters. Sci. Rep. 6, 32639 (2016).

Du, Z., Wood, D. L., Daniel, C., Kalnaus, S. & Li, J. Understanding limiting factors in thick electrode performance as applied to high energy density Li-ion batteries. J. Appl. Electrochem. 47, 405–415 (2017).

Jurng, S., Brown, Z. L., Kim, J. & Lucht, B. L. Effect of electrolyte on the nanostructure of the solid electrolyte interphase (SEI) and performance of lithium metal anodes. Energy Environ. Sci. 11, 2600–2608 (2018).

Cao, X. et al. Monolithic solid–electrolyte interphases formed in fluorinated orthoformate-based electrolytes minimize Li depletion and pulverization. Nat. Energy 4, 796–805 (2019).

Yu, Z. et al. Molecular design for electrolyte solvents enabling energy-dense and long-cycling lithium metal batteries. Nat. Energy 5, 526–533 (2020).

Pei, A., Zheng, G., Shi, F., Li, Y. & Cui, Y. Nanoscale nucleation and growth of electrodeposited lithium metal. Nano Lett. 17, 1132–1139 (2017).

Sekerka, R. F. Equilibrium and growth shapes of crystals: how do they differ and why should we care? Cryst. Res. Technol. 40, 291–306 (2005).

Liu, M. et al. Enhanced electrocatalytic CO2 reduction via field-induced reagent concentration. Nature 537, 382–386 (2016).

He, X. et al. The passivity of lithium electrodes in liquid electrolytes for secondary batteries. Nat. Rev. Mater. 6, 1036–1052 (2021).

Gunnarsdóttir, A. B., Vema, S., Menkin, S., Marbella, L. E. & Grey, C. P. Investigating the effect of a fluoroethylene carbonate additive on lithium deposition and the solid electrolyte interphase in lithium metal batteries using in situ NMR spectroscopy. J. Mater. Chem. A 8, 14975–14992 (2020).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Behling, C., Mayrhofer, K. J. J. & Berkes, B. B. Formation of lithiated gold and its use for the preparation of reference electrodes—an EQCM study. J. Solid State Electrochem. 25, 2849–2859 (2021).

Hu, X., Gao, Y., Zhang, B., Shi, L. & Li, Q. Superior cycle performance of Li metal electrode with {110} surface texturing. EcoMat 4, e12264 (2022).

Sur, U. K., Dhason, A. & Lakshminarayanan, V. A simple and low-cost ultramicroelectrode fabrication and characterization method for undergraduate students. J. Chem. Educ. 89, 168–172 (2011).

Guo, R. & Gallant, B. M. Li2O solid electrolyte interphase: probing transport properties at the chemical potential of lithium. Chem. Mater. 32, 5525–5533 (2020).

Peled, E., Golodnitsky, D. & Ardel, G. Advanced model for solid electrolyte interphase electrodes in liquid and polymer electrolytes. J. Electrochem. Soc. 144, L208 (1997).

Verbrugge, M. W. & Koch, B. J. Microelectrode study of the lithium/propylene carbonate interface: temperature and concentration dependence of physicochemical parameters. J. Electrochem. Soc. 141, 3053–3059 (1994).

Churikov, A. V., Gamayunova, I. M. & Shirokov, A. V. Ionic processes in solid-electrolyte passivating films on lithium. J. Solid State Electrochem. 4, 216–224 (2000).

Churikov, A. V., Nimon, E. S. & Lvov, A. L. Impedance of Li-Sn, Li-Cd and Li-Sn-Cd alloys in propylene carbonate solution. Electrochim. Acta 42, 179–189 (1997).

Acknowledgements

We acknowledge the support of the National Science Foundation (CBET-2143677) and the use of the University of California, Los Angeles California NanoSystems Institute EICN Facilities.

Author information

Authors and Affiliations

Contributions

X.Y. and Y.L. conceived the project and designed the experiments. X.Y. built the UME set-up and performed electrochemical experiments and SEM characterization. B.L. helped with COMSOL simulations and data analysis. X.Y. and Y.L. carried out cryo-EM experiments. M.M. advised on microscope and imaging analyses. X.Y. and Y.L. co-wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Shizhao Xiong and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

This file contains Supplementary Discussion, Figs. 1–19, Table 1 and references.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, X., Liu, B., Mecklenburg, M. et al. Ultrafast deposition of faceted lithium polyhedra by outpacing SEI formation. Nature 620, 86–91 (2023). https://doi.org/10.1038/s41586-023-06235-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06235-w

This article is cited by

-

Controlled large-area lithium deposition to reduce swelling of high-energy lithium metal pouch cells in liquid electrolytes

Nature Energy (2024)

-

High lithium oxide prevalence in the lithium solid–electrolyte interphase for high Coulombic efficiency

Nature Energy (2024)

-

Ultrahigh Li ion diffusivity in anodic SEI suppresses dendrite growth in lithium metal batteries

Science China Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.