Abstract

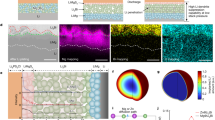

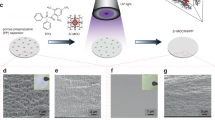

All-solid-state lithium-metal batteries (ASSLBs) have attracted intense interest due to their high energy density and high safety. However, Li dendrite growth and high interface resistance remain challenging due to insufficient understanding of the mechanism. Here we develop two types of porous lithiophobic interlayer (Li7N2I–carbon nanotube and Li7N2I–Mg) to enable Li to plate at the Li/interlayer interface and reversibly penetrate into the porous interlayer. The experimental and simulation results reveal that a balance of lithiophobicity, electronic and ionic conductivities and interlayer’s porosity are the key enablers for stable Li plating/stripping at a high capacity. A fine-tuned Li7N2I–carbon nanotube interlayer enables Li/LNI/Li symmetric cell to achieve a high critical current density of 4.0 mA cm−2 at 4.0 mAh cm−2 at 25 °C; the Li7N2I–Mg interlayer enables a Li4SiO4@LiNi0.8Mn0.1Co0.1O2/Li6PS5Cl/20 µm-Li full cell to achieve an areal capacity of 2.2 mAh cm−2, maintaining 82.4% capacity retention after 350 cycles at 60 °C at a rate of 0.5 C. The interlayer design principle opens opportunities to develop safe and high energy ASSLBs.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information files.

References

Larcher, D. & Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 7, 19–29 (2015).

Nunes, A., Woodley, L. & Rossetti, P. Re-thinking procurement incentives for electric vehicles to achieve net-zero emissions. Nat. Sustain. 5, 527–532 (2022).

Janek, J. & Zeier, W. G. A solid future for battery development. Nat. Energy 1, 16141 (2016).

Famprikis, T., Canepa, P., Dawson, J. A., Islam, M. S. & Masquelier, C. Fundamentals of inorganic solid-state electrolytes for batteries. Nat. Mater. 18, 1278–1291 (2019).

Bates, A. M. et al. Are solid-state batteries safer than lithium-ion batteries? Joule 6, 742–755 (2022).

He, X. et al. The passivity of lithium electrodes in liquid electrolytes for secondary batteries. Nat. Rev. Mater. 6, 1036–1052 (2021).

Monroe, C. & Newman, J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 152, A396 (2005).

Wang, Y., Dang, D., Wang, M., Xiao, X. & Cheng, Y. T. Mechanical behavior of electroplated mossy lithium at room temperature studied by flat punch indentation. Appl. Phys. Lett. 115, 043903 (2019).

Cao, D. et al. Lithium dendrite in all-solid-state batteries: growth mechanisms, suppression strategies, and characterizations. Matter 3, 57–94 (2020).

Swamy, T. et al. Lithium metal penetration induced by electrodeposition through solid electrolytes: example in single-crystal Li6La3ZrTaO12 garnet. J. Electrochem. Soc. 165, A3648–A3655 (2018).

Liu, H. et al. Controlling dendrite growth in solid-state electrolytes. ACS Energy Lett. 5, 833–843 (2020).

Han, F. D. et al. High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes. Nat. Energy 4, 187–196 (2019).

Liu, X. et al. Local electronic structure variation resulting in Li ‘filament’ formation within solid electrolytes. Nat. Mater. 20, 1485–1490 (2021).

Raj, V. et al. Direct correlation between void formation and lithium dendrite growth in solid-state electrolytes with interlayers. Nat. Mater. 21, 1050–1056 (2022).

Han, F. D., Zhu, Y., He, X., Mo, Y. & Wang, C. Electrochemical stability of Li10GeP2S12 and Li7La3Zr2O12 solid electrolytes. Adv. Energy Mater. 6, 1501590 (2016).

Wang, S. et al. Lithium chlorides and bromides as promising solid-state chemistries for fast ion conductors with good electrochemical stability. Angew. Chem. Int. Ed. 58, 8039–8043 (2019).

Shen, F., Dixit, M. B., Xiao, X. & Hatzell, K. B. Effect of pore connectivity on Li dendrite propagation within LLZO electrolytes observed with synchrotron X-ray tomography. ACS Energy Lett. 3, 1056–1061 (2018).

Venturi, V. & Viswanathan, V. Thermodynamic analysis of initial steps for void formation at lithium/solid electrolyte interphase interfaces. ACS Energy Lett. 7, 1953–1959 (2022).

Tsai, C.-L. et al. Li7La3Zr2O12 interface modification for li dendrite prevention. ACS Appl. Mater. Interfaces 8, 10617–10626 (2016).

Han, X. et al. Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat. Mater. 16, 572–579 (2017).

Wang, C. et al. Universal soldering of lithium and sodium alloys on various substrates for batteries. Adv. Energy Mater. 8, 1701963 (2018).

Tian, Y. et al. Li6.75La3Zr1.75Ta0.25O12@amorphous Li3OCl composite electrolyte for solid state lithium-metal batteries. Energy Storage Mater. 14, 49–57 (2018).

You, Y. et al. Effect of charge non-uniformity on the lithium dendrites and improvement by the LiF interfacial layer. ACS Appl. Energy Mater. 5, 15078–15085 (2022).

Ji, X. et al. Solid-state electrolyte design for lithium dendrite suppression. Adv. Mater. 32, 2002741 (2020).

Wang, T. et al. A self-regulated gradient interphase for dendrite-free solid-state Li batteries. Energy Environ. Sci. 15, 1325–1333 (2022).

Lee, Y.-G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Biswal, P., Stalin, S., Kludze, A., Choudhury, S. & Archer, L. A. Nucleation and early stage growth of Li electrodeposits. Nano Lett. 19, 8191–8200 (2019).

Jo, S. et al. The roles of nucleation and growth kinetics in determining Li metal morphology for Li metal batteries: columnar versus spherical growth. J. Mater. Chem. A 10, 5520–5529 (2022).

Dickinson, E. J. F. & Wain, A. J. The Butler–Volmer equation in electrochemical theory: origins, value, and practical application. J. Electroanal. Chem. 872, 114145 (2020).

Pei, A., Zheng, G., Shi, F., Li, Y. & Cui, Y. Nanoscale nucleation and growth of electrodeposited lithium metal. Nano Lett. 17, 1132–1139 (2017).

Suzuki, N. et al. Highly cyclable all-solid-state battery with deposition-type lithium metal anode based on thin carbon black layer. Adv. Sustain. Syst. 11, 2100066 (2021).

Kim, S. et al. High-power hybrid solid-state lithium–metal batteries enabled by preferred directional lithium growth mechanism. ACS Energy Lett. 8, 9–20 (2023).

Wang, C. et al. Identifying soft breakdown in all-solid-state lithium battery. Joule 6, 1770–1781 (2022).

Rebelo, S. L. H. et al. Progress in the Raman spectra analysis of covalently functionalized multiwalled carbon nanotubes: unraveling disorder in graphitic materials. Phys. Chem. Chem. Phys. 18, 12784–12796 (2016).

Guan, X. et al. Controlling nucleation in lithium metal anodes. Small 14, 1801423 (2018).

Huang, C. J. et al. Decoupling the origins of irreversible coulombic efficiency in anode-free lithium metal batteries. Nat. Commun. 12, 1452 (2021).

Krauskopf, T., Mogwitz, B., Rosenbach, C., Zeier, W. G. & Janek, J. Diffusion limitation of lithium metal and Li–Mg alloy anodes on LLZO-type solid electrolytes as a function of temperature and pressure. Adv. Energy Mater. 9, 1902568 (2019).

Obayashi, H., Gotoh, A. & Nagai, R. Composition dependence of lithium ionic conductivity in lithium nitride-lithium iodide system. Mat. Res. Bull. 16, 581–585 (1981).

Lu, X. et al. Liquid–metal electrode to enable ultra-low temperature sodium–beta alumina batteries for renewable energy storage. Nat. Commun. 5, 4578 (2014).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 54, 11169 (1996).

Perdew, J. P., Ernzerhof, M. & Burke, K. Rationale for mixing exact exchange with density functional approximations. J. Chem. Phys. 105, 9982–9985 (1996).

Jain, A. et al. Commentary: the materials project: a materials genome approach to accelerating materials innovation. APL Mater. 1, 011002 (2013).

Nose, S. Constant temperature molecular dynamics methods. Prog. Theor. Phys. Suppl. 103, 1–46 (1991).

Blatov, V. A., Shevchenko, A. P. & Proserpio, D. M. Applied topological analysis of crystal structures with the program package ToposPro. Cryst. Growth Des. 14, 3576–3586 (2014).

Meng, D., Zheng, B., Lin, G. & Sushko, M. L. Numerical solution of 3D Poisson–Nernst–Planck equations coupled with classical density functional theory for modeling ion and electron transport in a confined environment. Commun. Comput. Phys. 16, 1298–1322 (2014).

Wang, H., Thiele, A. & Pilon, L. Simulations of cyclic voltammetry for electric double layers in asymmetric electrolytes: a generalized modified Poisson–Nernst–Planck model. J. Phys. Chem. C. 117, 18286–18297 (2013).

Sommer, J. L. & Mortensen, A. Forced unidirectional infiltration of deformable porous media. J. Fluid Mech. 31, 193–217 (1996).

Brinkman, H. C. A calculation of the viscous force exerted by a flowing fluid on a dense swarm of particles. Flow Turbul. Combust. 1, 27–34 (1949).

Chen, L. et al. Modulation of dendritic patterns during electrodeposition: a nonlinear phase-field model. J. Power Sources 300, 376–385 (2015).

Acknowledgements

This work was supported by the US Department of Energy (DOE) under award number DEEE0008856 (received by C.W.) and award number DE-AC05-76RL01830.

Author information

Authors and Affiliations

Contributions

Z.W. designed and conducted the experiments, performed the calculations and analysed the data. J.X, X.J. and H.W. conducted the electrochemical experiments. J.X., J.Z. X.H. and W.Z. performed XRD, Raman, SEM and ToF-SIMS characterizations. Y.L. synthesized the LLZO. Z.W. wrote the draft manuscript. All authors revised the manuscript. C.W. conceived and supervised the project. All authors contributed to the interpretation of the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Nagaphani Aetukuri, Nicolas Delaporte and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–40, Tables 1–6 and Notes 1–13.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Xia, J., Ji, X. et al. Lithium anode interlayer design for all-solid-state lithium-metal batteries. Nat Energy 9, 251–262 (2024). https://doi.org/10.1038/s41560-023-01426-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-023-01426-1