Abstract

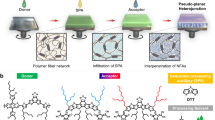

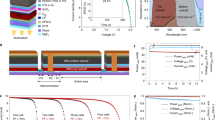

Despite the great success of organic photovoltaics in terms of device efficiency and stability at the laboratory scale, pressing demand for high-throughput and cost-effective solutions remains unresolved and rarely reported. Here we propose that a sequential-deposition, blade-coating approach using donor and acceptor materials can facilitate high-speed fabrication of photoactive layers while maintaining device performance. The sequential-deposition-processed blend and thickness of its designed PM6:T8 system can be optimized by the fine-tuning of the solution concentrations and coating speeds. We show that this strategy can be applied to a non-halogenated solvent and under high-humidity conditions. This high-speed approach is applicable to other non-fullerene photovoltaic systems and the slot-die coating technique. Techno-economic analysis suggests that this strategy can decrease the minimum sustainable price of module manufacturing. Overall, this work represents a step towards the scalable, cost-effective manufacturing of organic photovoltaics with both high performance and high throughput.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All of the data generated or analysed during this study are included in the published article and its Supplementary Information files. Source data are provided with this paper.

References

Brabec, C. J. et al. Material strategies to accelerate OPV technology toward a GW technology. Adv. Energy Mater. 10, 2001864 (2020).

Kini, G. P., Jeon, S. J. & Moon, D. K. Latest progress on photoabsorbent materials for multifunctional semitransparent organic solar cells. Adv. Funct. Mater. 31, 2007931 (2021).

Zhao, F. et al. Emerging approaches in enhancing the efficiency and stability in non‐fullerene organic solar cells. Adv. Energy Mater. 10, 2002746 (2020).

Burgués-Ceballos, I. et al. Transparent organic photovoltaics: a strategic niche to advance commercialization. Joule 5, 2261–2272 (2021).

Wang, G. et al. Synergistic optimization enables large-area flexible organic solar cells to maintain over 98% PCE of the small-area rigid devices. Adv. Mater. 32, 2005153 (2020).

Gertsen, A. S., Castro, M. F., Søndergaard, R. R. & Andreasen, J. W. Scalable fabrication of organic solar cells based on non-fullerene acceptors. Flex. Print. Electron. 5, 014004 (2020).

Carlé, J. E. et al. Overcoming the scaling lag for polymer solar cells. Joule 1, 274–289 (2017).

Lucera, L. et al. Highly efficient, large area, roll coated flexible and rigid OPV modules with geometric fill factors up to 98.5% processed with commercially available materials. Energy Environ. Sci. 9, 89–94 (2015).

Li, C. et al. Non-fullerene acceptors with branched side chains and improved molecular packing to exceed 18% efficiency in organic solar cells. Nat. Energy 6, 605–613 (2021).

Zhan, L. et al. Layer-by-layer processed ternary organic photovoltaics with efficiency over 18%. Adv. Mater. 33, 2007231 (2021).

Hong, L. et al. 18.5% efficiency organic solar cells with a hybrid planar/bulk heterojunction. Adv. Mater. 33, 2103091 (2021).

Sun, R. et al. PEDOT:PSS‐free polymer non‐fullerene polymer solar cells with efficiency up to 18.60% employing a binary‐solvent‐chlorinated ITO anode. Adv. Funct. Mater. 31, 2106846 (2021).

Lin, Y. et al. Self-assembled monolayer enables hole transport layer-free organic solar cells with 18% efficiency and improved operational stability. ACS Energy Lett. 5, 2935–2944 (2020).

Park, S. et al. Progress in materials, solution processes, and long-term stability for large-area organic photovoltaics. Adv. Mater. 32, 2002217 (2020).

Sun, R. et al. Achieving over 17% efficiency of ternary all-polymer solar cells with two well-compatible polymer acceptors. Joule 5, 1548–1565 (2021).

Ghasemi, M. et al. A molecular interaction–diffusion framework for predicting organic solar cell stability. Nat. Mater. 20, 525–532 (2021).

Xu, X. et al. Interface-enhanced organic solar cells with extrapolated T80 lifetimes of over 20 years. Sci. Bull. 65, 208–216 (2020).

Li, Y. et al. Non-fullerene acceptor organic photovoltaics with intrinsic operational lifetimes over 30 years. Nat. Commun. 12, 5419 (2021).

Du, X. et al. Efficient polymer solar cells based on non-fullerene acceptors with potential device lifetime approaching 10 years. Joule 3, 215–226 (2018).

Zhang, X. et al. Side-chain engineering for enhancing the molecular rigidity and photovoltaic performance of noncovalently fused-ring electron acceptors. Angew. Chem. Int. Ed. 60, 17720–17725 (2021).

Dudnik, A. S. et al. Tin-free direct C–H arylation polymerization for high photovoltaic efficiency conjugated copolymers. J. Am. Chem. Soc. 138, 15699–15709 (2016).

Sun, R. et al. High-performance all-small-molecule organic solar cells without interlayers. Energy Environ. Sci. 14, 3174–3183 (2021).

Guo, J. & Min, J. A cost analysis of organic solar modules. Adv. Energy Mater. 9, 1802521 (2018).

Wu, Q. et al. High‐performance all‐polymer solar cells with a pseudo‐bilayer configuration enabled by a stepwise optimization strategy. Adv. Funct. Mater. 31, 2010411 (2021).

Bernardo, G., Lopes, T., Lidzey, D. G. & Mendes, A. Progress in upscaling organic photovoltaic devices. Adv. Energy Mater. 11, 2100342 (2021).

Jeong, S. et al. Large-area nonfullerene organic solar cell modules fabricated by a temperature-independent printing method. ACS Appl. Mater. Interfaces 12, 41877–41885 (2020).

Krantz, J. et al. Spray-coated silver nanowires as top electrode layer in semitransparent P3HT:PCBM-based organic solar cell devices. Adv. Funct. Mater. 23, 1711–1717 (2012).

Ma, Z., Zhao, B., Gong, Y., Deng, J. & Tan, Z. Green-solvent-processable strategies for achieving large-scale manufacture of organic photovoltaics. J. Mater. Chem. A 7, 22826–22847 (2019).

Wu, Q. et al. Slot-die printed non-fullerene organic solar cells with the highest efficiency of 12.9% for low-cost PV-driven water splitting. Nano Energy 61, 559–566 (2019).

Ricciardulli, A. G., Yang, S., Feng, X. & Blom, P. W. M. Solution-processable high-quality graphene for organic solar cells. ACS Appl. Mater. Interfaces 9, 25412–25417 (2017).

Yuan, J. et al. Patterned blade coating strategy enables the enhanced device reproducibility and optimized morphology of organic solar cells. Adv. Energy Mater. 11, 2100098 (2021).

Kumari, T. et al. Over 13.8% efficiency of organic solar cells fabricated by air-processable spontaneously spreading process through water temperature control. Nano Energy 85, 105982 (2021).

Sun, R. et al. A layer-by-layer architecture for printable organic solar cells overcoming the scaling lag of module efficiency. Joule 4, 407–419 (2020).

Liu, K. et al. Roll-coating fabrication of flexible organic solar cells: comparison of fullerene and fullerene-free systems. J. Mater. Chem. A 4, 1044–1051 (2016).

Andersen, T. R. et al. Fully roll-to-roll prepared organic solar cells in normal geometry with a sputter-coated aluminium top-electrode. Sol. Energy Mater. Sol. Cells 149, 103–109 (2016).

Dong, S., Jia, T., Zhang, K., Jing, J. & Huang, F. Single-component non-halogen solvent-processed high-performance organic solar cell module with efficiency over 14%. Joule 4, 2004–2016 (2020).

Hosel, M. et al. High-volume processed, ITO-free superstrates and substrates for roll-to-roll development of organic electronics. Adv. Sci. 1, 1400002 (2014).

Jakubka, F. et al. Determining the coating speed limitations for organic photovoltaic inks. Sol. Energy Mater. Sol. Cells 109, 120–125 (2013).

Cui, C. et al. High-performance organic solar cells based on a small molecule with alkylthio-thienyl-conjugated side chains without extra treatments. Adv. Mater. 27, 7469–7475 (2015).

Zhang, T., Zeng, G., Ye, F., Zhao, X. & Yang, X. Efficient non-fullerene organic photovoltaic modules incorporating as-cast and thickness-insensitive photoactive layers. Adv. Energy Mater. 8, 1801387 (2018).

Chang, Y., Zhu, X., Lu, K. & Wei, Z. Progress and prospects of thick-film organic solar cells. J. Mater. Chem. A 9, 3125–3150 (2021).

Strohm, S. et al. P3HT: non-fullerene acceptor based large area, semi-transparent PV modules with power conversion efficiencies of 5%, processed by industrially scalable methods. Energy Environ. Sci. 11, 2225–2234 (2018).

Wu, Q. et al. Tailoring polymer acceptors by electron linkers for achieving efficient and stable all-polymer solar cells. Natl Sci. Rev. 9, nwab151 (2021).

Sun, R. et al. A universal layer-by-layer solution-processing approach for efficient non-fullerene organic solar cells. Energy Environ. Sci. 12, 384–395 (2019).

Zheng, Y. et al. Baseplate temperature-dependent vertical composition gradient in pseudo-bilayer films for printing non-fullerene organic solar cells. Adv. Energy Mater. 11, 102135 (2021).

Qin, Y. et al. The performance–stability conundrum of BTP-based organic solar cells. Joule 5, 2129–2147 (2021).

Ma, Y. et al. Efficient organic solar cells from molecular orientation control of M-series acceptors. Joule 5, 197–209 (2020).

Yuan, J. et al. Single-junction organic solar cell with over 15% efficiency using fused-ring acceptor with electron-deficient core. Joule 3, 1140–1151 (2019).

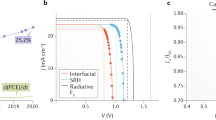

Cui, Y. et al. Single-junction organic photovoltaic cell with 19% efficiency. Adv. Mater. 33, 2102420 (2021).

Wang, Y. & Zhan, X. Layer-by-layer processed organic solar cells. Adv. Energy Mater. 6, 1600414 (2016).

Liu, S. et al. Printable and large‐area organic solar cells enabled by a ternary pseudo‐planar heterojunction strategy. Adv. Funct. Mater. 30, 2003223 (2020).

Huang, H. et al. Green solvent-processed organic solar cells based on low cost polymer donor and small molecule acceptor. J. Mater. Chem. C 8, 7718–7724 (2020).

Jiang, K. et al. Pseudo-bilayer architecture enables high-performance organic solar cells with enhanced exciton diffusion length. Nat. Commun. 12, 468 (2021).

Weng, K. et al. Optimized active layer morphology toward efficient and polymer batch insensitive organic solar cells. Nat. Commun. 11, 2855 (2020).

Bi, P. et al. Reduced non-radiative charge recombination enables organic photovoltaic cell approaching 19% efficiency. Joule 5, 2408–2419 (2021).

Zhu, C. et al. Tuning the electron-deficient core of a non-fullerene acceptor to achieve over 17% efficiency in a single-junction organic solar cell. Energy Environ. Sci. 13, 2459–2466 (2020).

Hong, L. et al. Eco-compatible solvent-processed organic photovoltaic cells with over 16% efficiency. Adv. Mater. 31, 1903441 (2019).

Wang, W. et al. Controlling molecular mass of low-band-gap polymer acceptors for high-performance all-polymer solar cells. Joule 4, 1070–1086 (2020).

Sun, R. et al. A multi-objective optimization-based layer-by-layer blade-coating approach for organic solar cells: rational control of vertical stratification for high performance. Energy Environ. Sci. 12, 3118–3132 (2019).

Lucera, L. et al. Guidelines for closing the efficiency gap between hero solar cells and roll-to-roll printed modules. Energy Technol. 3, 373–384 (2015).

Rolston, N. et al. Rapid open-air fabrication of perovskite solar modules. Joule 4, 2675–2692 (2020).

Cui, Y. et al. Over 16% efficiency organic photovoltaic cells enabled by a chlorinated acceptor with increased open-circuit voltages. Nat. Commun. 10, 2515 (2019).

Yang, W. et al. Balancing the efficiency, stability, and cost potential for organic solar cells via a new figure of merit. Joule 5, 1209–1230 (2021).

Sofia, S. E. et al. Economic viability of thin-film tandem solar modules in the United States. Nat. Energy 3, 387–394 (2018).

Song, Z. et al. A technoeconomic analysis of perovskite solar module manufacturing with low-cost materials and techniques. Energy Environ. Sci. 10, 1297–1305 (2017).

Powell, D. M. et al. The capital intensity of photovoltaics manufacturing: barrier to scale and opportunity for innovation. Energy Environ. Sci. 8, 3395–3408 (2015).

Powell, D. M. et al. Crystalline silicon photovoltaics: a cost analysis framework for determining technology pathways to reach baseload electricity costs. Energy Environ. Sci. 5, 5874–5883 (2012).

Ma, L. et al. Completely non-fused electron acceptor with 3D-interpenetrated crystalline structure enables efficient and stable organic solar cell. Nat. Commun. 12, 5093 (2021).

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China (grant numbers 52061135206 and 22279094 to J.M.) and Fundamental Research Funds for the Central Universities (to J.M.). We thank the Core Facility of Wuhan University for the optical microscope and AFM measurements.

Author information

Authors and Affiliations

Contributions

R.S. and J.M. conceived of the ideas. R.S. fabricated all of the solar cell samples, conducted the measurements and performed the data analysis. T.W. and X.Y. contributed to synthesizing the T8 and PM6-Ir1 materials. Y. Wu contributed to synthesizing the Y6 and N3 materials. Y. Wang, M.Z. and Y.L. contributed to conducting the TEM measurements. R.S. and Q.W. contributed to conducting the module fabrication. R.S. and Y. Wu studied the techno-economic analysis. C.J.B., R.S. and J.M. contributed to manuscript preparation. R.S. conceived of and directed the project while being supervised by J.M. All authors commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Seok-In Na, Leonard Ng and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Scheme 1, Figs. 1–46, Tables 1–40 and Notes 1–3.

Supplementary Data 1

Statistical source data for Supplementary Figs. 1–46.

Supplementary Data 2

Statistical source data for Tables 1 and 2.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Source Data Fig. 6

Statistical source data.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, R., Wang, T., Yang, X. et al. High-speed sequential deposition of photoactive layers for organic solar cell manufacturing. Nat Energy 7, 1087–1099 (2022). https://doi.org/10.1038/s41560-022-01140-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-022-01140-4

This article is cited by

-

High-efficiency flexible organic solar cells with a polymer-incorporated pseudo-planar heterojunction

Discover Nano (2024)

-

The role of interfacial donor–acceptor percolation in efficient and stable all-polymer solar cells

Nature Communications (2024)

-

Suppressing electron-phonon coupling in organic photovoltaics for high-efficiency power conversion

Nature Communications (2023)

-

Solid Additive-Assisted Layer-by-Layer Processing for 19% Efficiency Binary Organic Solar Cells

Nano-Micro Letters (2023)

-

Challenges, limitations, and applications of nanofluids in solar thermal collectors—a comprehensive review

Environmental Science and Pollution Research (2023)