Abstract

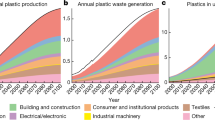

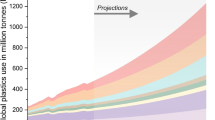

Over the past four decades, global plastics production has quadrupled1. If this trend were to continue, the GHG emissions from plastics would reach 15% of the global carbon budget by 20502. Strategies to mitigate the life-cycle GHG emissions of plastics, however, have not been evaluated on a global scale. Here, we compile a dataset covering ten conventional and five bio-based plastics and their life-cycle GHG emissions under various mitigation strategies. Our results show that the global life-cycle GHG emissions of conventional plastics were 1.7 Gt of CO2-equivalent (CO2e) in 2015, which would grow to 6.5 GtCO2e by 2050 under the current trajectory. However, aggressive application of renewable energy, recycling and demand-management strategies, in concert, has the potential to keep 2050 emissions comparable to 2015 levels. In addition, replacing fossil fuel feedstock with biomass can further reduce emissions and achieve an absolute reduction from the current level. Our study demonstrates the need for integrating energy, materials, recycling and demand-management strategies to curb growing life-cycle GHG emissions from plastics.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the main data supporting the findings of this study are available within the Letter and Supplementary Information. Additional data are available from the corresponding author on reasonable request.

Change history

10 May 2019

In the version of this Letter originally published, in Fig. 1 the label ‘PPA 159 Mt’ should have been ‘PP&A 159 Mt’. This has now been amended.

References

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

World Economic Forum The New Plastics Economy—Rethinking the Future of Plastics (Ellen MacArthur Foundation, McKinsey & Company, 2016).

Jambeck, J. R. et al. Plastic waste inputs from land into the ocean. Science 347, 768–771 (2015).

Law, K. L. Plastics in the marine environment. Annu. Rev. Mar. Sci. 9, 205–229 (2017).

Law, K. L. & Thompson, R. C. Microplastics in the seas. Science 345, 144–145 (2014).

Rochman, C. M. et al. Classify plastic waste as hazardous. Nature 494, 169–171 (2013).

Lithner, D., Larsson, Å. & Dave, G. Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci. Total Environ. 409, 3309–3324 (2011).

Fischedick, M. et al. in Climate Change 2014: Mitigation of Climate Change (eds Edenhofer, O. et al.) Ch. 10 (IPCC, Cambridge Univ. Press, 2014).

Hillmyer, M. A. The promise of plastics from plants. Science 358, 868–870 (2017).

Weiss, M. et al. A review of the environmental impacts of biobased materials. J. Ind. Ecol. 16, S169–S181 (2012).

Yates, M. R. & Barlow, C. Y. Life cycle assessments of biodegradable, commercial biopolymers—a critical review. Resour. Conserv. Recycl. 78, 54–66 (2013).

Chen, G.-Q. & Patel, M. K. Plastics derived from biological sources: present and future: a technical and environmental review. Chem. Rev. 112, 2082–2099 (2012).

Spierling, S. et al. Bio-based plastics—a review of environmental, social and economic impact assessments. J. Clean. Prod. 185, 476–491 (2018).

Albertsson, A.-C. & Hakkarainen, M. Designed to degrade. Science 358, 872–873 (2017).

Policies for Bioplastics in the Context of a Bioeconomy (OECD, 2013).

A European Strategy for Plastics in a Circular Economy (European Commission, 2018).

Bioplastics Market Data 2017 (European Bioplastics, 2017).

Posen, I. D., Jaramillo, P., Landis, A. E. & Griffin, W. M. Greenhouse gas mitigation for U.S. plastics production: energy first, feedstocks later. Environ. Res. Lett. 12, 034024 (2017).

Hopewell, J., Dvorak, R. & Kosior, E. Plastics recycling: challenges and opportunities. Philos. Trans. R. Soc. B 364, 2115–2126 (2009).

Lazarevic, D., Aoustin, E., Buclet, N. & Brandt, N. Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resour. Conserv. Recycl. 55, 246–259 (2010).

Hottle, T. A., Bilec, M. M. & Landis, A. E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 98, 1898–1907 (2013).

Olivier, J. G. J., Schure, K. M. & Peters, J. A. H. W. Trends in Global CO 2 and Total Greenhouse Gas Emissions: Summary of the 2017 Report (PBL Netherlands Environmental Assessment Agency, 2017).

Zhu, J.-B., Watson, E. M., Tang, J. & Chen, E. Y.-X. A synthetic polymer system with repeatable chemical recyclability. Science 360, 398–403 (2018).

Bing, X., Bloemhof-Ruwaard, J., Chaabane, A. & van der Vorst, J. Global reverse supply chain redesign for household plastic waste under the emission trading scheme. J. Clean. Prod. 103, 28–39 (2015).

Soroudi, A. & Jakubowicz, I. Recycling of bioplastics, their blends and biocomposites: a review. Eur. Polym. J. 49, 2839–2858 (2013).

Reddy, R. L., Reddy, V. S. & Gupta, G. A. Study of bio-plastics as green & sustainable alternative to plastics. Int. J. Emerg. Technol. Adv. Eng. 3, 82–89 (2013).

Wernet, G. et al. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230 (2016).

European Reference Life Cycle Database (European Commission & JRC, 2018); https://eplca.jrc.ec.europa.eu/ELCD3/

B. Bilitewski et al. (eds) Global Risk-Based Management of Chemical Additives II:Risk-Based Assessment and Management Strategies (Springer, 2013).

Eco-profiles and Environmental Product Declarations of the European Plastics Manufacturers: Di-isononyl phthalate (DINP) (European Council for Plasticisers and Intermediates, 2015).

Keoleian, G., Miller, S., De Kleine, R., Fang, A. & Mosley, J. Life Cycle Material Data Update for GREET Model (Center for Sustainable Systems, 2012).

Life Cycle Inventory of Plastic Fabrication Processes: Injection Molding and Thermoforming (Franklin Associates, 2011).

Madival, S., Auras, R., Singh, S. P. & Narayan, R. Assessment of the environmental profile of PLA, PET and PS clamshell containers using LCA methodology. J. Clean. Prod. 17, 1183–1194 (2009).

Thomas, B., Fishwick, M., Joyce. J., & Santen A.V. A Carbon Footprint for UK Clothing and Opportunities for Savings (The Waste and Resources Action Programme, 2012).

Life Cycle Inventory of 100% Postconsumer HDPE and PET Recycled Resin from Postconsumer Containers and Packaging (Franklin Associates, 2010).

Lovett, J. Sustainable Sourcing of Feedstocks for Bioplastics (Corbion Group Netherlands B.V., 2016).

Posen, I. D., Jaramillo, P. & Griffin, W. M. Uncertainty in the life cycle greenhouse gas emissions from U.S. production of three biobased polymer families. Environ. Sci. Technol. 50, 2846–2858 (2016).

Rossi, V. et al. Life cycle assessment of end-of-life options for two biodegradable packaging materials: sound application of the European waste hierarchy. J. Clean. Prod. 86, 132–145 (2015).

Liptow, C. & Tillman, A.-M. A Comparative life cycle assessment study of polyethylene based on sugarcane and crude oil. J. Ind. Ecol 16, 420–435 (2012).

Tsiropoulos, I. et al. Life cycle impact assessment of bio-based plastics from sugarcane ethanol. J. Clean. Prod. 90, 114–127 (2015).

Shen, L. & Patel, M. K. Life cycle assessment of polysaccharide materials: a review. J. Polym. Environ. 16, 154 (2008).

Groot, W. J. & Borén, T. Life cycle assessment of the manufacture of lactide and PLA biopolymers from sugarcane in Thailand. Int. J. Life Cycle Assess. 15, 970–984 (2010).

Harding, K. G., Dennis, J. S., von Blottnitz, H. & Harrison, S. T. L. Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 130, 57–66 (2007).

Tsiropoulos, I. et al. Life cycle assessment of sugarcane ethanol production in India in comparison to Brazil. Int. J. Life Cycle Assess. 19, 1049–1067 (2014).

Castro-Aguirre, E., Iñiguez-Franco, F., Samsudin, H., Fang, X. & Auras, R. Poly(lactic acid)—mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 107, 333–366 (2016).

Lim, L.-T., Auras, R. & Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 33, 820–852 (2008).

Hermann, B. G., Debeer, L., De Wilde, B., Blok, K. & Patel, M. K. To compost or not to compost: Carbon and energy footprints of biodegradable materials’ waste treatment. Polym. Degrad. Stab 96, 1159–1171 (2011).

Shen, L., Haufe, J. & Patel, M. K. Product Overview and Market Projection of Emerging Bio-based Plastics (Utrecht Univ., 2009).

Ashter, S. A. in Introduction to Bioplastics Engineering (ed. Ashter, S. A.) 227–249 (William Andrew Publishing, 2016).

Luckachan, G. E. & Pillai, C. K. S. Biodegradable polymers- a review on recent trends and emerging perspectives. J. Polym. Environ. 19, 637–676 (2011).

Babu, R. P., O’Connor, K. & Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater 2, 8 (2013).

Chanprateep, S. Current trends in biodegradable polyhydroxyalkanoates. J. Biosci. Bioeng. 110, 621–632 (2010).

Wang, X.-L., Yang, K.-K. & Wang, Y.-Z. Properties of starch blends with biodegradable. Polymers. J. Macromol. Sci. Part C 43, 385–409 (2003).

Broeren, M. L. M., Kuling, L., Worrell, E. & Shen, L. Environmental impact assessment of six starch plastics focusing on wastewater-derived starch and additives. Resour. Conserv. Recycl. 127, 246–255 (2017).

Acknowledgements

We acknowledge the financial support of the US Environmental Protection Agency's Science to Achieve Results Program under Grant No. 83557907. We also acknowledge UCSB Mellichamp Sustainability Fellowship and the Technology Management Program Young Innovator Scholarship for financial aid. We thank Y. Qin, E. Wall and Y. Ren (at University of California Santa Barbara) for their helpful comments.

Author information

Authors and Affiliations

Contributions

J.Z. performed the research and analysed the data. S.S. conceived the idea and designed the study. Both authors wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Journal peer review information Nature Climate Change thanks Hans Josef Endres, Ola Eriksson and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–12 and Supplementary references

Rights and permissions

About this article

Cite this article

Zheng, J., Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 9, 374–378 (2019). https://doi.org/10.1038/s41558-019-0459-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41558-019-0459-z

This article is cited by

-

Designing a circular carbon and plastics economy for a sustainable future

Nature (2024)

-

Optimizing bioplastics translation

Nature Reviews Bioengineering (2024)

-

Light-driven polymer recycling to monomers and small molecules

Nature Communications (2024)

-

A Comparative Study of Effects of Biodegradable and Non-biodegradable Microplastics on the Growth and Development of Black Soldier Fly Larvae (Hermetia illucens)

Waste and Biomass Valorization (2024)

-

Towards a Low-Carbon Plastic Waste Recycling in Finland: Evaluating the Impacts of Improvement Measures on GHG Emissions

Circular Economy and Sustainability (2024)